Research progress in high-performance power device packaging and power cycle reliability

-

摘要:

半导体技术的进步使得功率器件面临更高的电压、功率密度和结温,这对功率器件的封装的可靠性提出了更高的要求. 如何提高和检测功率器件的可靠性已经成为功率器件发展的重要任务. 提升器件封装可靠性主要围绕优化封装结构、改进芯片贴装技术和引线键合技术3个方向研究. 功率循环作为最贴近功率器件实际工况的可靠性测试方法,其测试技术、参数监测方法和失效机理得到广泛的研究. 对功率器件封装结构、封装技术以及功率循环机理的相关研究进行了综述,总结了近年国内外的提升封装可靠性的方法,并介绍功率循环测试的原理和钎料层、键合线的失效机理,最后对于功率器件封装的未来发展趋势进行了展望.

Abstract:The progress of semiconductor technology has made power devices face higher voltage, power density and junction temperature, which puts forward higher requirements for the reliability of power device packaging. How to improve and detect the reliability of power devices has become an important task in the development of power devices. Improving packaging reliability mainly focuses on optimizing packaging structure, improving die attach technology and wire bonding technology. Power cycling, as a reliability testing method closest to the actual operating conditions of power devices, has been widely studied in terms of testing techniques, monitoring methods, and failure mechanisms. This paper provides a review of research on the packaging structure, packaging technology, power cycling mechanism of power devices and attempts to summarize the methods for improving packaging reliability at home and abroad in recent years. This review also discusses the principles of power cycling test and the failure mechanisms of solder layers and bonding wires . Finally, the future development trend of power device packaging was prospected.

-

Keywords:

- power device /

- packaging structure /

- power cycling test /

- die attach /

- wire bonding

-

-

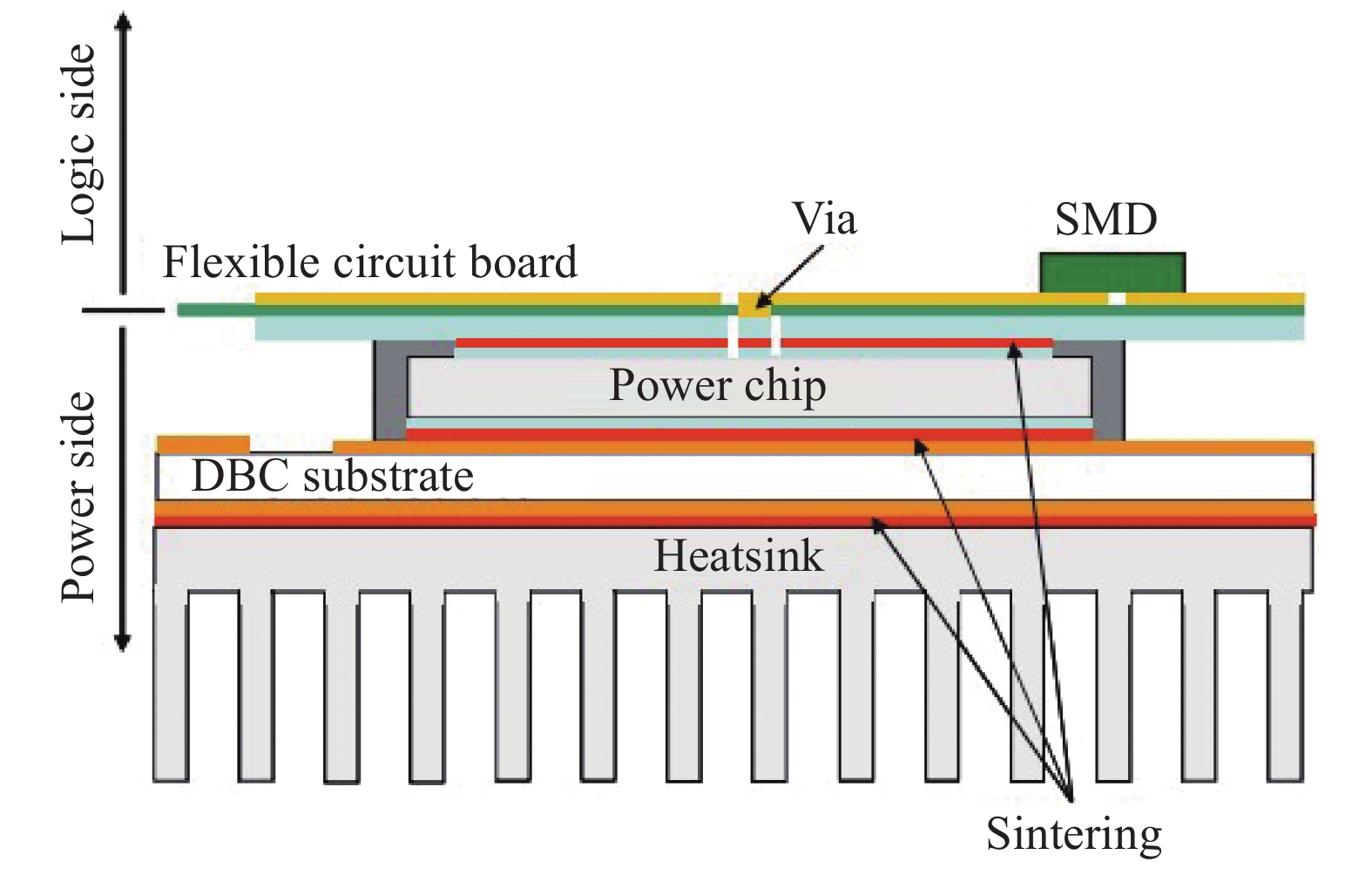

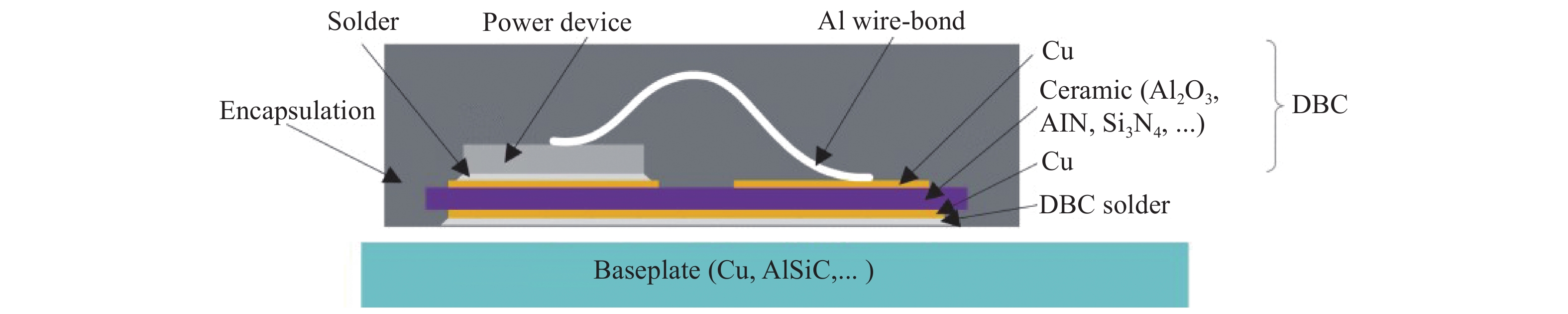

图 1 典型功率模块结构示意图[3]

Figure 1. Sectional view of typical power module structure

图 2 采用PCB板取代键合线的封装结构示意图[5]

Figure 2. Sectional view of packaging structure using PCB instead of bonding wire

图 3 SKiN封装横截面示意图[7]

Figure 3. Sectional view of SKiN packaging

图 4 Press -pack封装示意图[8]

Figure 4. Sectional view of press-pack packaging

图 5 双冷板模块剖面示意图[9]

Figure 5. Sectional view of the module with dual cold plates

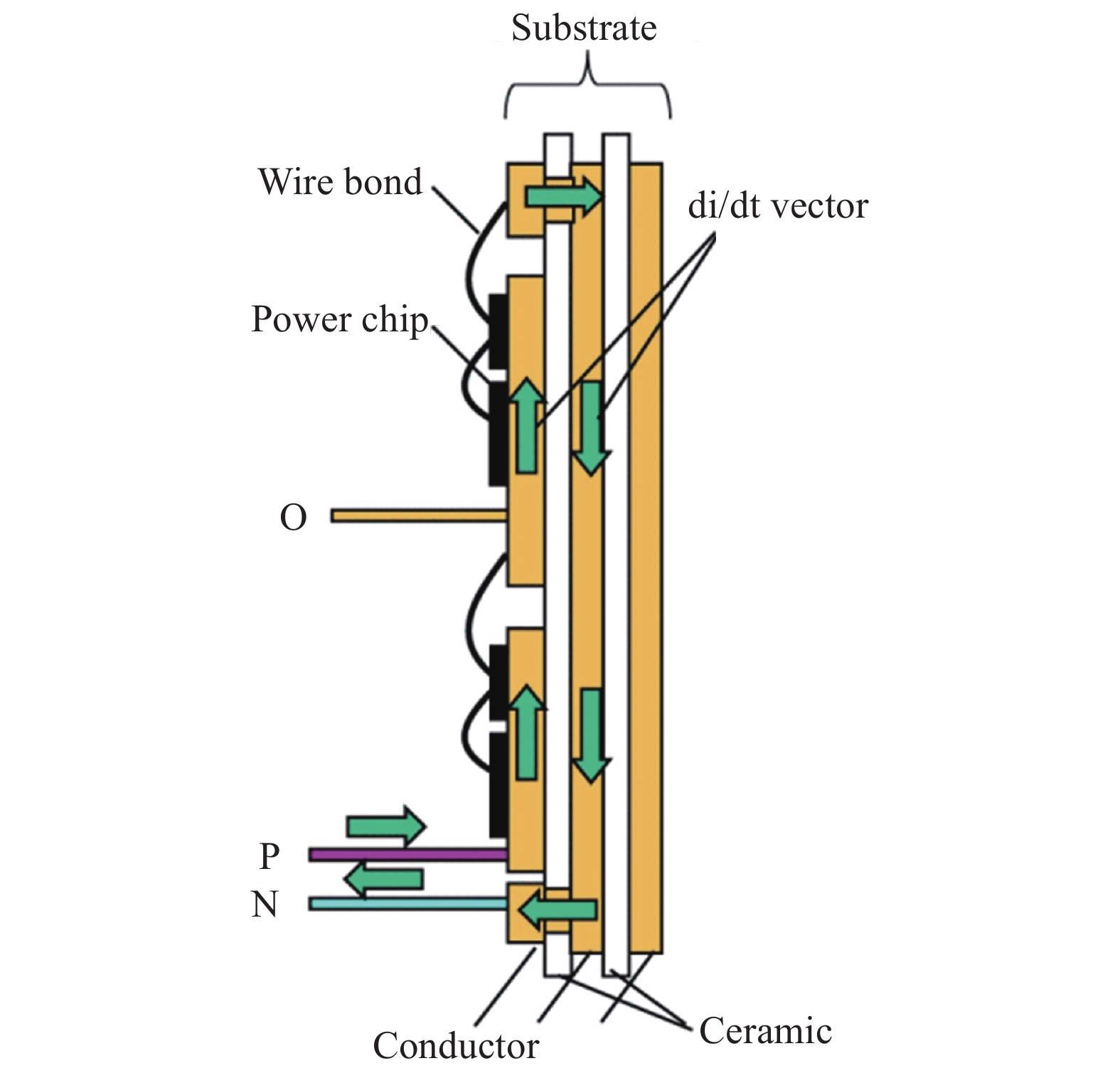

图 6 三导体双陶瓷基板结构示意图[12]

Figure 6. Sectional view of triple-conductor double-ceramic layered substrate

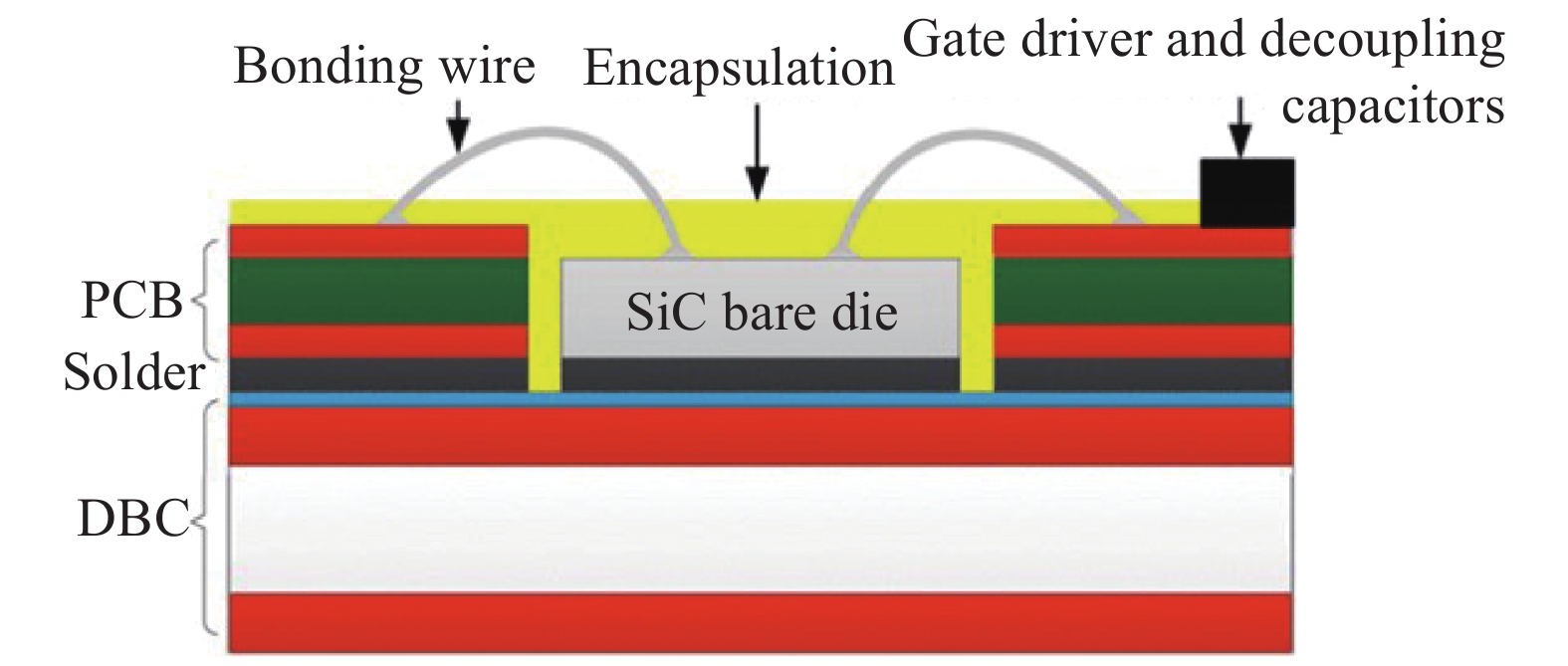

图 7 混合封装结构示意图[13]

Figure 7. Sectional view of hybrid package

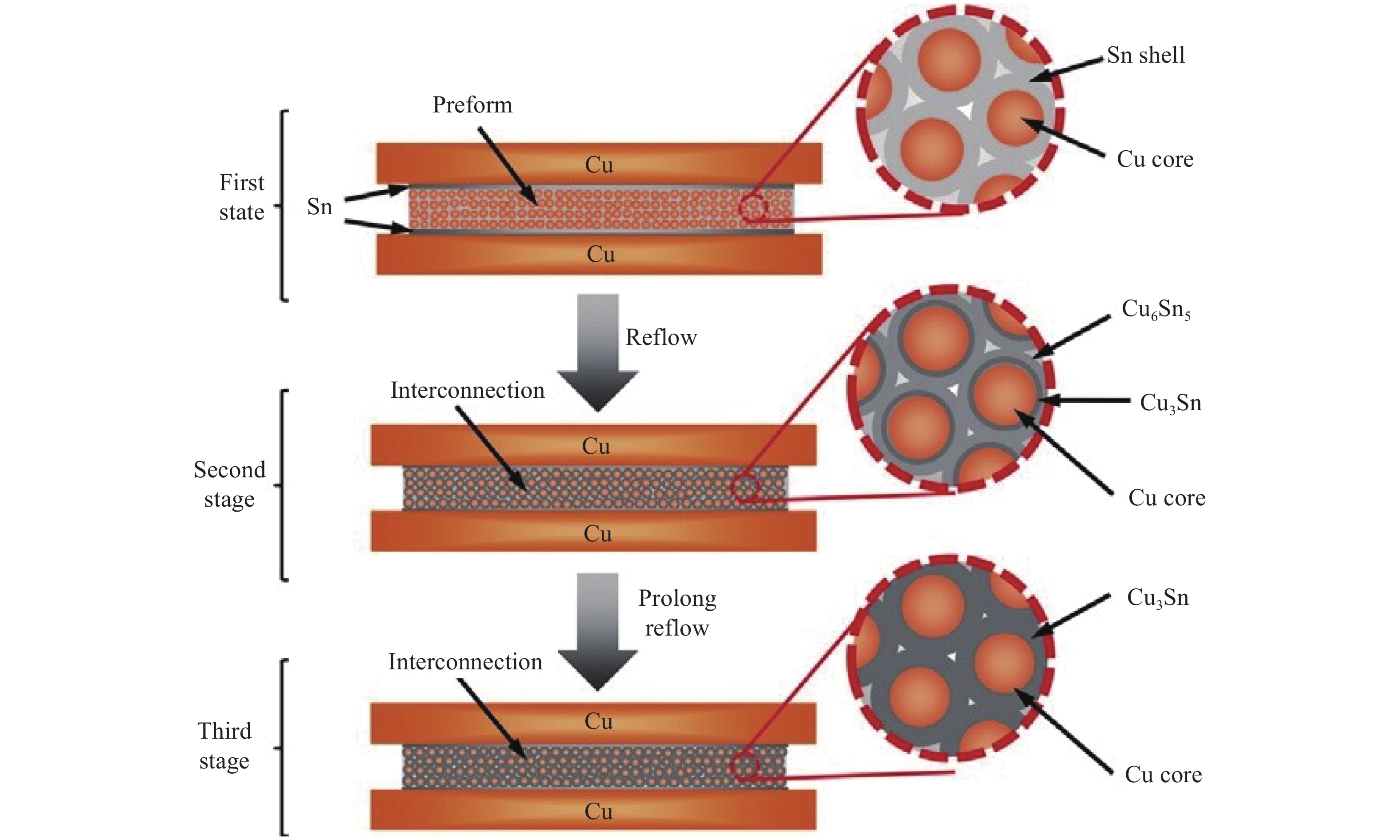

图 8 基于Cu@Sn粒子制备的高温剪切样品的结合工艺示意图[21]

Figure 8. Schematic diagram of the bonding process for the high-temperature shearing sample based on a preform fabricated with Cu@Sn particles

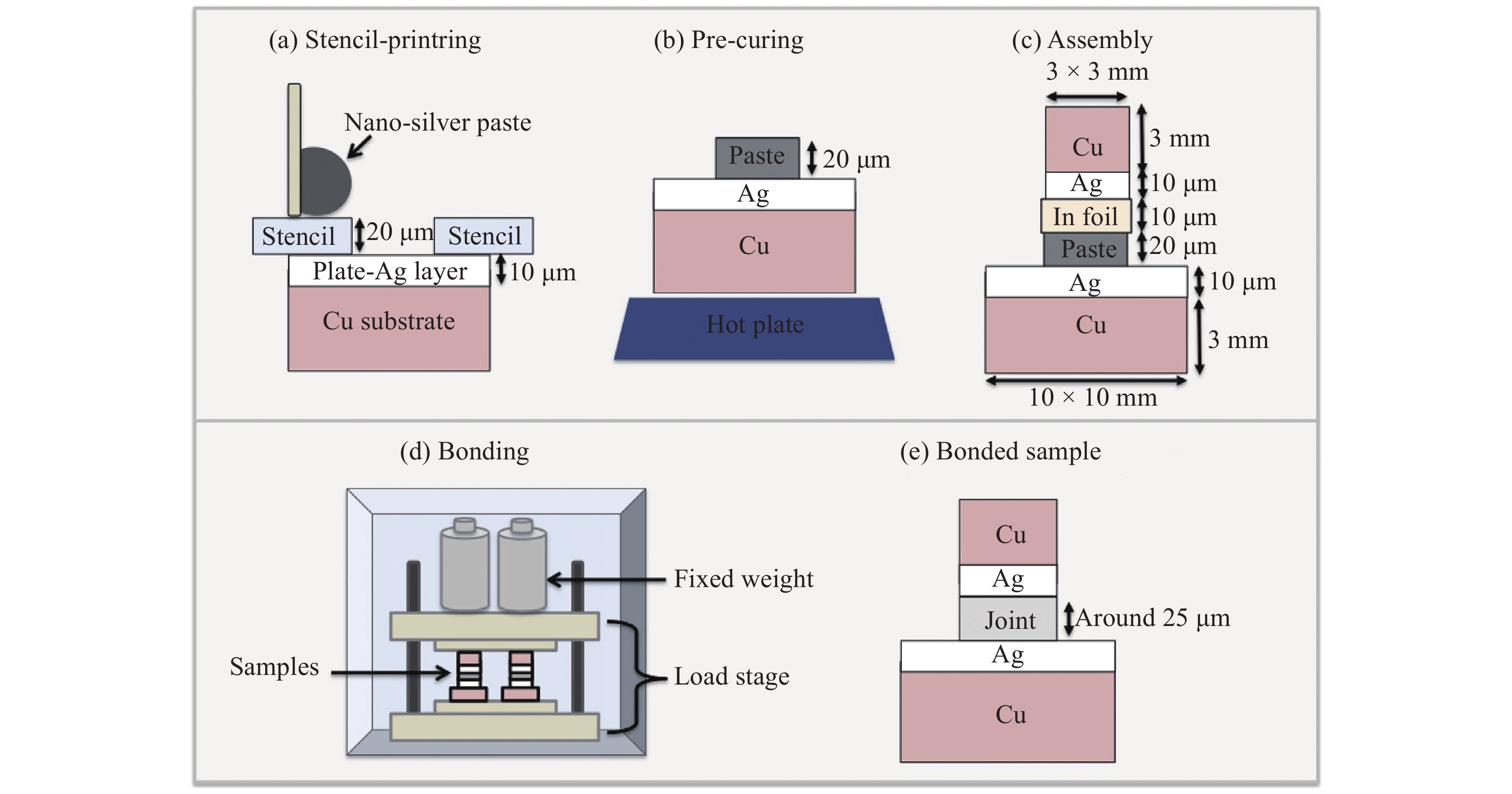

图 9 Ag-In接头制备过程示意图[24]

Figure 9. Assembly process of the Ag-In joints

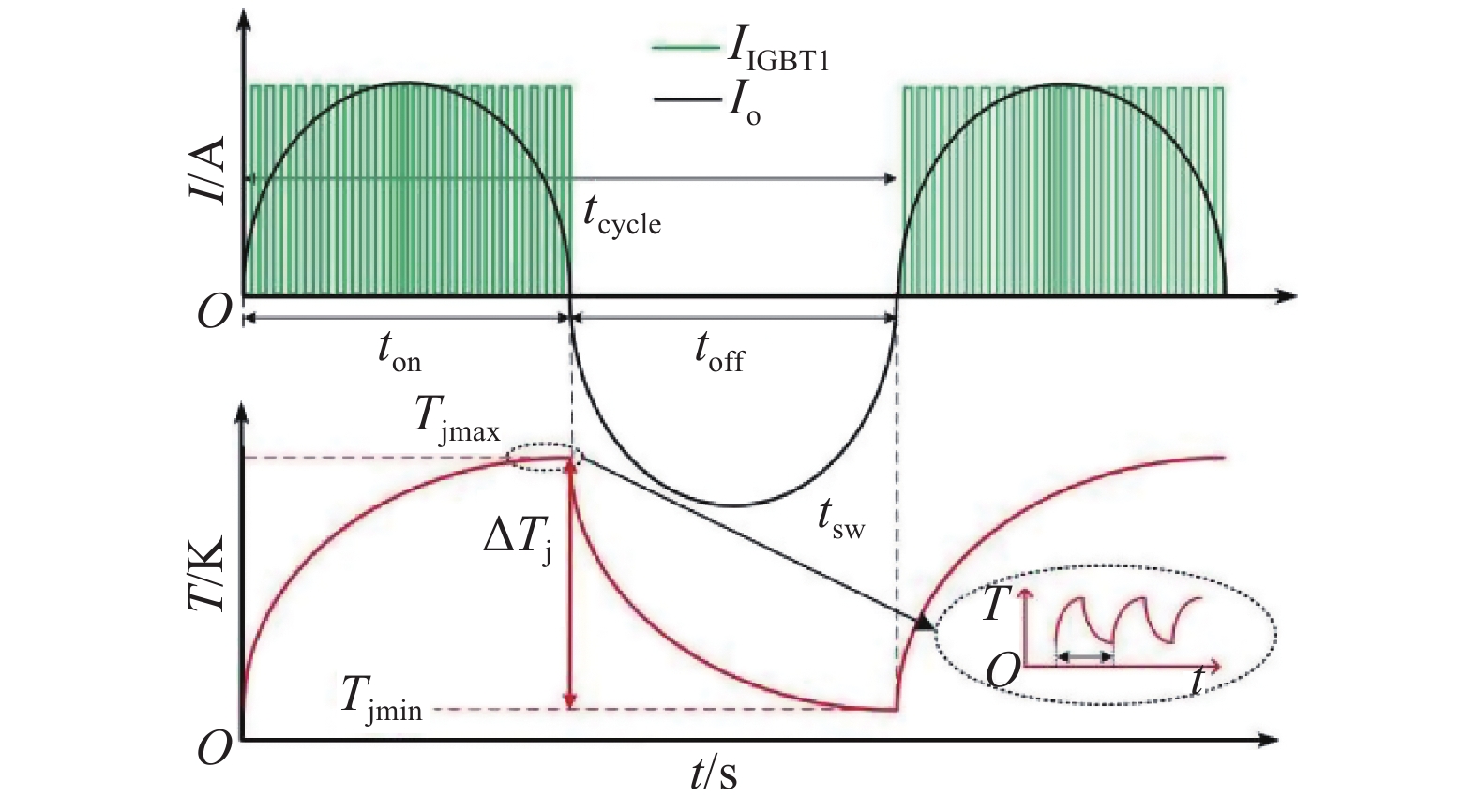

图 10 PWM电路下的电流及温度变化[36]

Figure 10. Current and temperature changes in PWM circuits

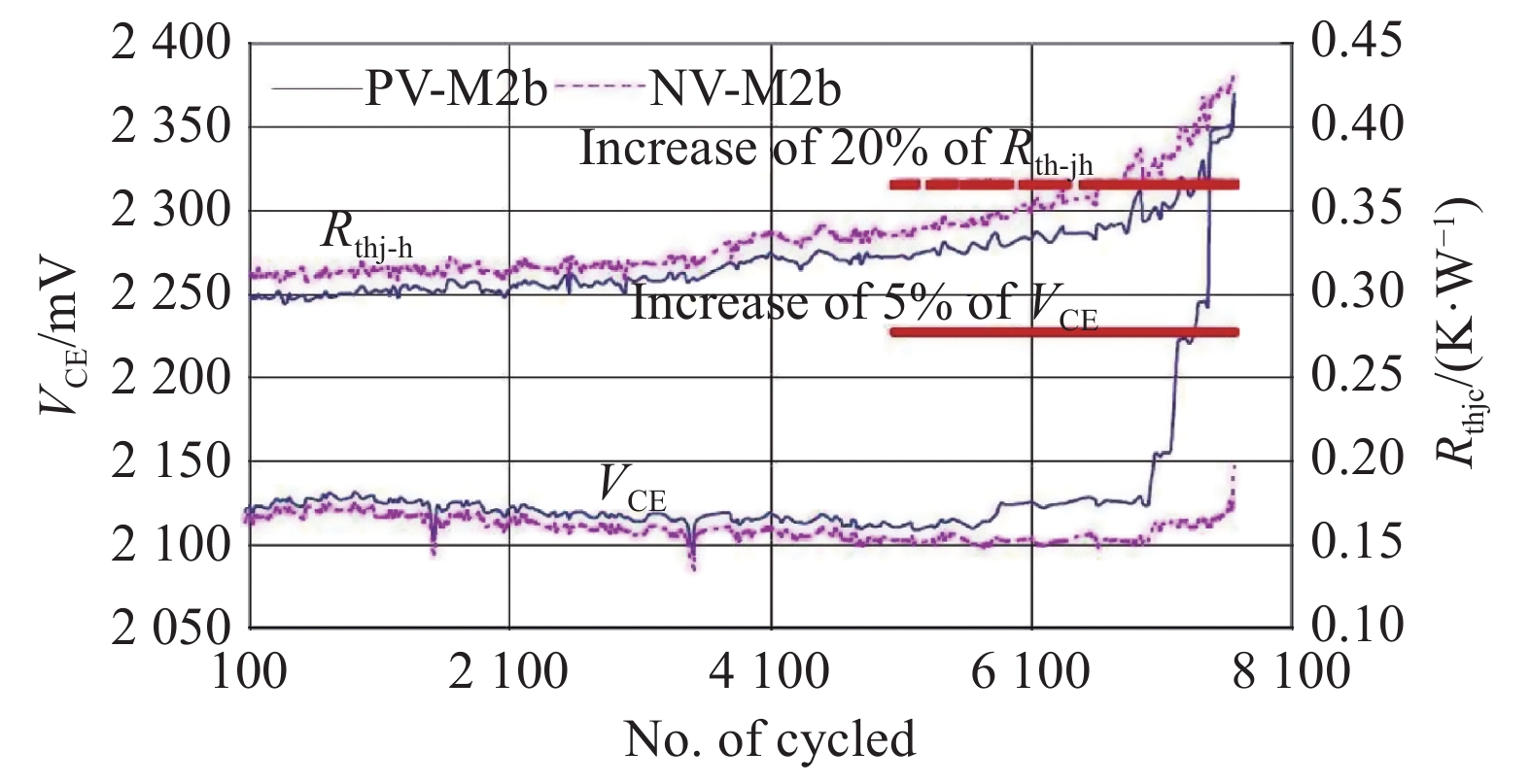

图 11 ECONOPACK电源模块APC测试期间VCE和Rthjc的演变[41]

Figure 11. Evolution of VCE and Rthjc during APC testing of ECONOPACK power module

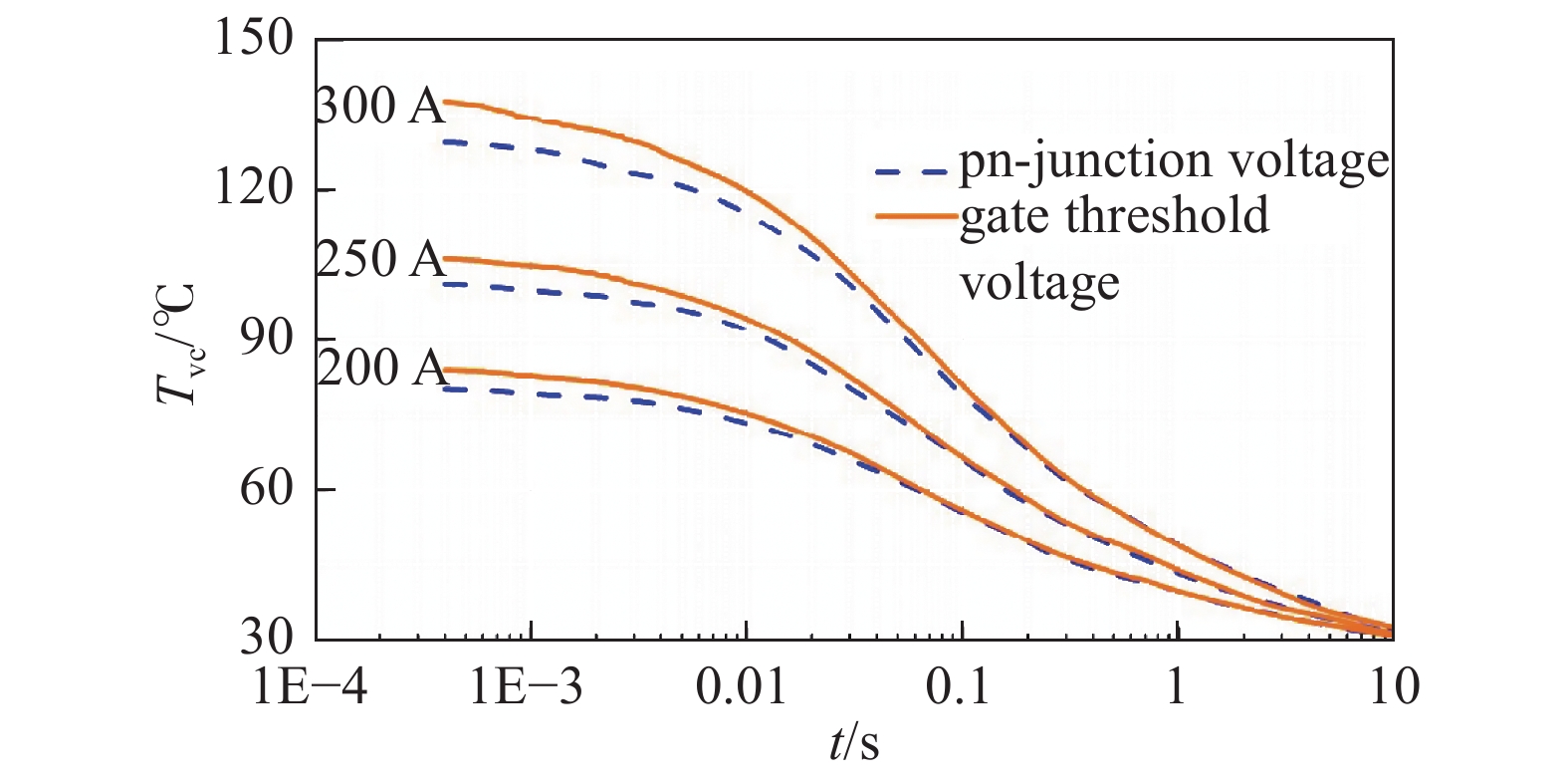

图 12 650 V IGBT器件两种方法测量结温过程的对比[45]

Figure 12. Comparison of two methods for measuring junction temperature in 650 V IGBT devices

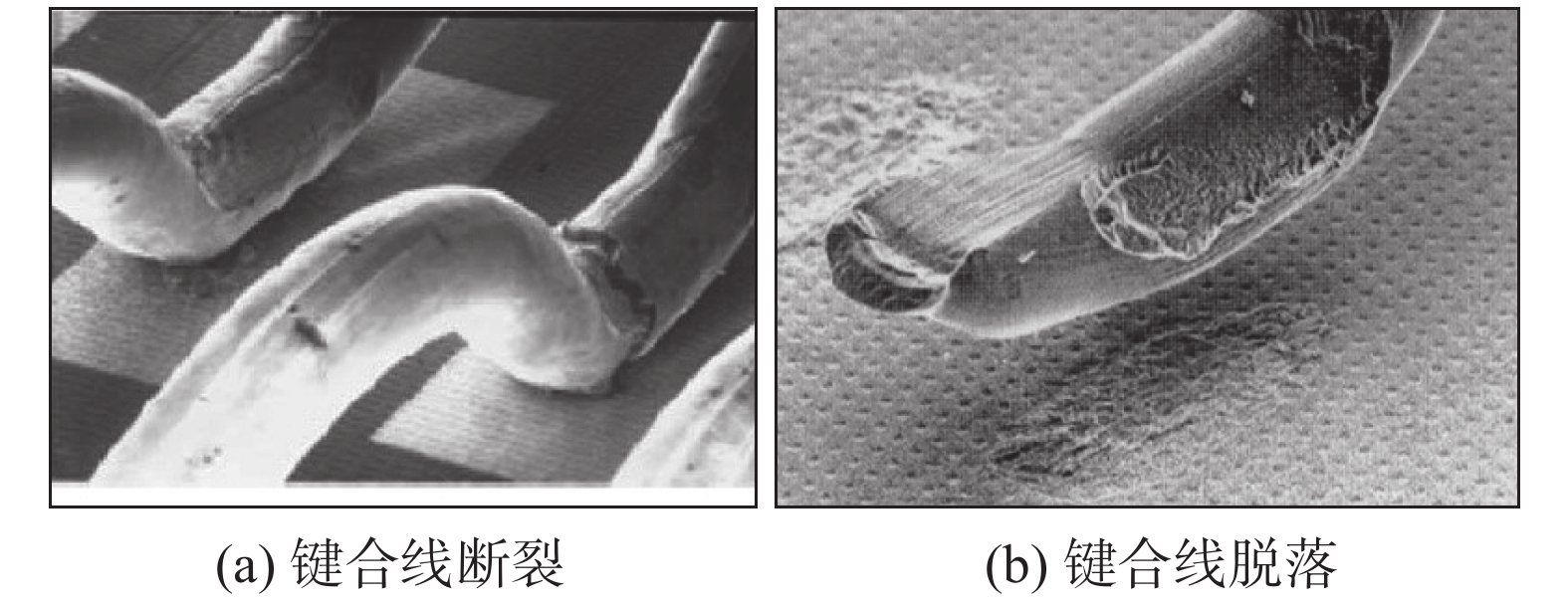

图 13 键合线根部断裂和脱落的微观形貌[55]

Figure 13. Microscopic morphology of fracture and detachment at the root of the bonding line. (a) fracture; (b) detachment

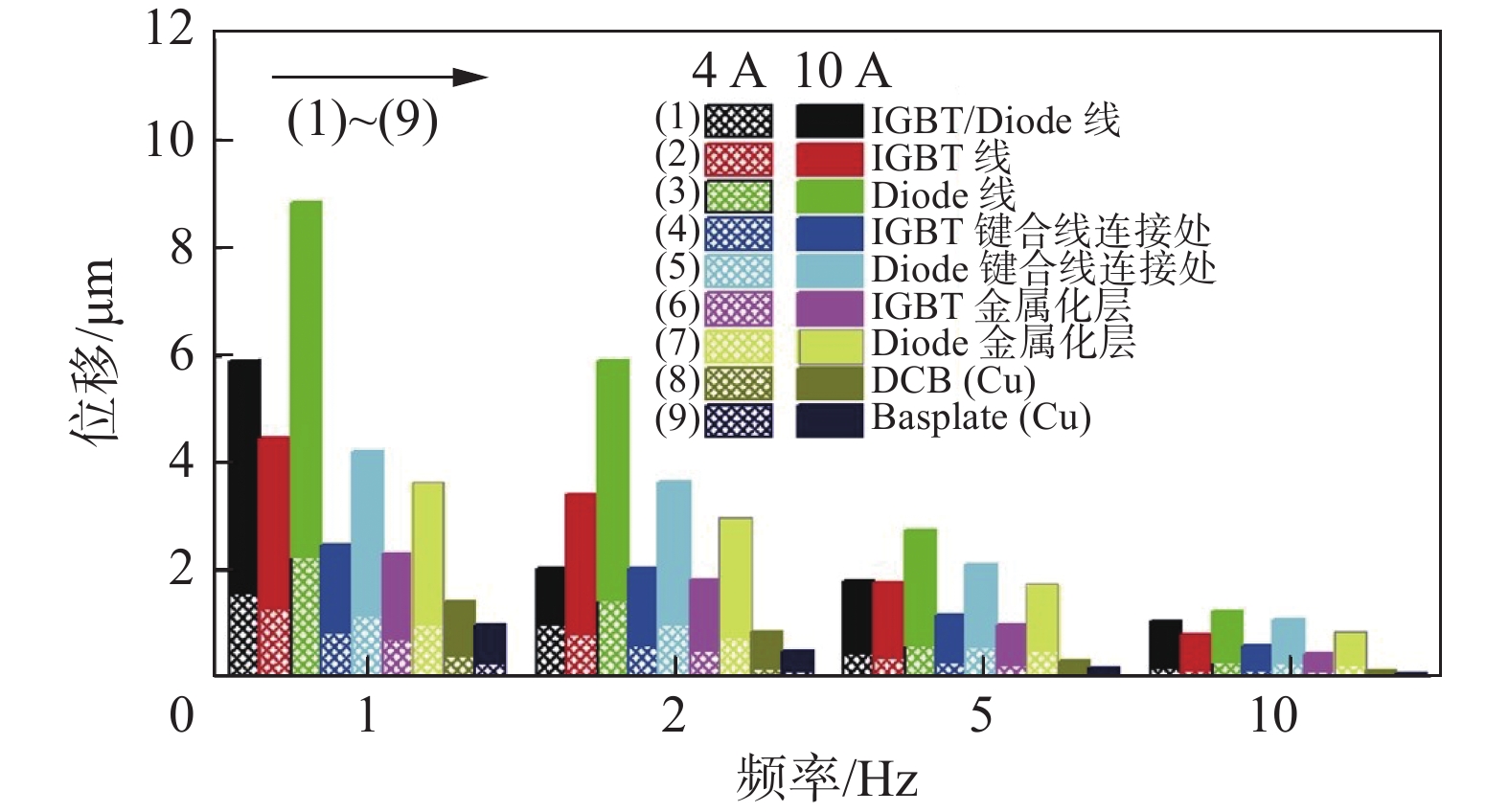

图 14 IGBT功率器件内部不同部位的垂直位移情况[56]

Figure 14. Vertical displacement of different parts inside IGBT power devices

-

[1] Yoder M N. Wide bandgap semiconductor materials and devices[J]. IEEE Transactions on Electron Devices, 1996, 43(10): 1633 − 1636. doi: 10.1109/16.536807

[2] 蔡蔚, 杨茂通, 刘洋, 等. SiC 功率模块封装技术及展望[J]. 汽车工程, 2022, 44(4): 638 − 648. Cai Wei, Yang Maotong, Liu Yang, et al. SiC power module packaging technologies and prospects[J]. Automotive Engineering, 2022, 44(4): 638 − 648.

[3] Hou F, Wang W, Cao L, et al. Review of packaging schemes for power module[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2019, 8(1): 223 − 238.

[4] Dimarino C, Boroyevich D, Burgos R, et al. Design and development of a high-density, high-speed 10 kV SiC mosfets module[C]//2017 19th European Conference on Power Electronics and Applications (EPE'17 ECCE Europe). IEEE, 2017.

[5] Ikeda Y, Iizuka Y, Hinata Y, et al. Investigation on wirebond-less power module structure with high-density packaging and high reliability [C]//IEEE, 2011.

[6] Stabach J, Cole Z, O'neal C, et al. A high performance power package for wide bandgap semiconductors using novel wire bondless power interconnections[J]. International Symposium on Microelectronics, 2015(1): 000353 − 000358. doi: 10.4071/isom-2015-WP16

[7] Stockmeier T, Beckedahl P, Göbl C, et al. SKiN: double side sintering technology for new packages [C]//2011 IEEE 23rd International Symposium on Power Semiconductor Devices and ICs. IEEE, 2011.

[8] Zhu N, Mantooth H A, Xu D, et al. A solution to press-pack packaging of SiC mosfets[J]. IEEE Transactions on Industrial Electronics, 2017, 64(10): 8224 − 8234. doi: 10.1109/TIE.2017.2686365

[9] Liang Z. Integrated double sided cooling packaging of planar SiC power modules [C]//2015 IEEE Energy Conversion Congress and Exposition (ECCE). IEEE, 2015: 4907 − 4912.

[10] Boteler L M, Miner S M, Hinojosa M. Co-designed high voltage module [C]//2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm). IEEE, 2018: 824 − 830.

[11] Fabian J, Hartmann S, Hamidi A. Partial discharge failure analysis of AlN substrates[J]. Microelectronics Reliability, 2004, 44: 1425 − 1430. doi: 10.1016/j.microrel.2004.07.111

[12] Tanimoto S, Matsui K. High junction temperature and low parasitic inductance power module technology for compact power conversion systems[J]. IEEE Transactions on Electron Devices, 2015, 62(2): 258 − 269. doi: 10.1109/TED.2014.2359978

[13] Chen C, Chen Y, Li Y, et al. An SiC-based half-bridge module with an improved hybrid packaging method for high power density applications[J]. IEEE Transactions on Industrial Electronics, 2017, 64(11): 8980 − 8991. doi: 10.1109/TIE.2017.2723873

[14] 杨东升, 张贺, 冯佳运, 等. 电子封装微纳连接技术及失效行为研究进展[J]. 焊接学报, 2022, 43(11): 126 − 136. doi: 10.12073/j.hjxb.20220702003 Yang Dongsheng, Zhang He, Feng Jiayun, et al. Research progress of low-temperature Cu-Cu bonding technology for advanced packaging[J]. Transactions of the China Welding Institution, 2022, 43(11): 126 − 136. doi: 10.12073/j.hjxb.20220702003

[15] 冯洪亮. Ni-Sn TLPS连接特性与动力学研究 [D]. 北京: 北京科技大学, 2018. Feng Hongliang. Study on the characteristics and kinetics of Ni-Sn TLPS bonding process[D]. Beijing: University of Science and Technology Beijing, 2018.

[16] Yamada Y, Takaku Y, Yagi Y, et al. Pb-free high temperature solder joints for power semiconductor devices[J]. Transactions of the Japan Institute of Electronics Packaging, 2009, 2(1): 79 − 84. doi: 10.5104/jiepeng.2.79

[17] Tanimoto S, Matsui K, Zushi Y, et al. Eutectic Zn-Al die attachment for higher Tj SiC power applications: Fabrication method and die shear strength reliability[J]. Journal of Microelectronics and Electronic Packaging, 2013, 10(2): 59 − 66. doi: 10.4071/imaps.373

[18] Liu H, Xue S, Tao Y, et al. Design and solderability characterization of novel Au–30Ga solder for high-temperature packaging[J]. Journal of Materials Science:Materials in Electronics, 2020, 31: 2514 − 2522. doi: 10.1007/s10854-019-02787-8

[19] 刘晗, 薛松柏, 王刘珏, 等. 金基中低温钎料的研究现状与展望[J]. 材料导报, 2019, 33(19): 3189 − 3195. doi: 10.11896/cldb.18090164 Liu Han, Xue Songbai, Wang Liuyu, et al. Research status and prospect of Au-based medium-low temperature filler metals[J]. Materials Reports, 2019, 33(19): 3189 − 3195. doi: 10.11896/cldb.18090164

[20] Li Z, Li M, Xiao Y, et al. Ultrarapid formation of homogeneous Cu6Sn5 and Cu3Sn intermetallic compound joints at room temperature using ultrasonic waves[J]. Ultrasonics Sonochemistry, 2014, 21(3): 924 − 929. doi: 10.1016/j.ultsonch.2013.09.020

[21] Hu T, Chen H, Li M. Die attach materials with high remelting temperatures created by bonding Cu@ Sn microparticles at lower temperatures[J]. Materials & Design, 2016, 108: 383 − 390.

[22] 邹贵生, 闫剑锋, 刘磊, 等. 纳米金属颗粒膏合成及其低温烧结连接的电子封装应用研究进展[J]. 机械制造文摘(焊接分册), 2013(1): 12 − 16. Zou Guisheng, Yan Jianfeng, Liu Lei, et al. Development of the synthesis of metal nanoparticle paste[J]. Welding Digest of Machinery Manufacturing, 2013(1): 12 − 16.

[23] 贾强, 邹贵生, 张宏强, 等. 纳米颗粒材料作中间层的烧结连接及其封装应用研究进展[J]. 机械工程学报, 2022, 58(2): 2 − 16. Jia Qiang, Zou Guisheng, Zhang Hongqiang, et al. Research progress in sintering-bonding with nanoparticle materials as interlayer and its packaging application[J]. Journal of Mechanical Engineering, 2022, 58(2): 2 − 16.

[24] Yang C, Yang S, Liu X, et al. Enhancement of nano-silver chip attachment by using transient liquid phase reaction with indium[J]. Journal of Alloys and Compounds, 2018, 762: 586 − 597. doi: 10.1016/j.jallcom.2018.05.254

[25] Alayli N, Schoenstein F, Girard A, et al. Spark plasma sintering constrained process parameters of sintered silver paste for connection in power electronic modules: Microstructure, mechanical and thermal properties[J]. Materials Chemistry and Physics, 2014, 148(1-2): 125 − 133. doi: 10.1016/j.matchemphys.2014.07.021

[26] 迟聪聪, 夏亮, 王曌, 等. 丙三醇-水二元溶剂法抗氧化纳米铜的制备[J]. 包装工程, 2020, 41(13): 131 − 138. doi: 10.19554/j.cnki.1001-3563.2020.13.018 Chi Congcong, Xia Liang, Wang Zhao, et al. Preparation of antioxidant copper nanoparticles in glycerol-water binary solvent system[J]. Packaging Engineering, 2020, 41(13): 131 − 138. doi: 10.19554/j.cnki.1001-3563.2020.13.018

[27] Ji H, Zhou J, Liang M, et al. Ultra-low temperature sintering of Cu@ Ag core-shell nanoparticle paste by ultrasonic in air for high-temperature power device packaging[J]. Ultrasonics Sonochemistry, 2018, 41: 375 − 381. doi: 10.1016/j.ultsonch.2017.10.003

[28] 徐瑜, 戴东方, 杨仁彬, 等. 甲酸处理的纳米铜无压烧结性能及. 高温老化研究[J]. 重庆大学学报, 2023(10): 1 − 10. Xu Yu, Dai Dongfang, Yang Renbin, et al. Research on pressureless sintering performance and high temperature aging of formic acid-treated nano-copper[J]. Journal of Chongqing University, 2023(10): 1 − 10.

[29] Zhou H, Zhang Y, Cao J, et al. Research progress on bonding wire for microelectronic packaging[J]. Micromachines, 2023, 14(2): 432. doi: 10.3390/mi14020432

[30] Ling J M, Xu T, Chen R, et al. Cu and Al-Cu composite-material interconnects for power devices [C]//62nd IEEE Electronic Components and Technology Conference (ECTC). San Diego, CA, 2012: 1905 − 1911.

[31] Zhao J, Qin F, An T, et al. Electro-thermal and thermal-mechanical FE analysis of IGBT module with different bonding wire shape [C]//2017 18th International Conference on Electronic Packaging Technology (ICEPT). IEEE, 2017: 548 − 551.

[32] Celnikier Y, Dupont L, Herve E, et al. Optimization of wire connections design for power electronics[J]. Microelectronics Reliability, 2011, 51(9-11): 1892 − 1897. doi: 10.1016/j.microrel.2011.06.058

[33] European Center for Power Electronics. Qualification of power modules for use in power electronics converter units (PCUs) in motor vehicles: AQG 324 [S]. Nuremberg, Germany: ECPE Working Group, 2018.

[34] 陈杰, 邓二平, 张一鸣, 等. 功率循环试验中开通时间对高压大功率IGBT模块失效模式的影响及机理分析[J]. 中国电机工程学报, 2020, 40(23): 7710 − 7721. doi: 10.13334/J.0258-8013.PCSEE.200667 Chen Jie, Deng Erping, Zhang Yiming, et al. Influence and mechanism analysis of load pulse duration on failure mode of high power IGBT module under power cycling condition[J]. Proceedings of the CSEE, 2020, 40(23): 7710 − 7721. doi: 10.13334/J.0258-8013.PCSEE.200667

[35] Tounsi M, Oukaour A, Tala-Ighil B, et al. Characterization of high-voltage IGBT module degradations under PWM power cycling test at high ambient temperature[J]. Microelectronics Reliability, 2010, 50(9-11): 1810 − 1814. doi: 10.1016/j.microrel.2010.07.059

[36] 谢露红, 赵雨山, 常桂钦, 等. DC功率循环与PWM功率循环的差异对比分析[J]. 半导体技术, 2021, 46(10): 808 − 818. doi: 10.13290/j.cnki.bdtjs.2021.10.012 Xie Luhong, Zhao Yushan, Chang Guiqin, et al. Comparison and analysis of the difference between dc power cycling and PWM power cycling[J]. Semiconductor Technology, 2021, 46(10): 808 − 818. doi: 10.13290/j.cnki.bdtjs.2021.10.012

[37] 邓二平, 严雨行, 陈杰, 等. 功率器件功率循环测试技术的挑战与分析[J]. 中国电机工程学报, 2023, 43(13): 5132 − 5151. Deng Erping, Yan Yuxing, Chen Jie, et al. Power cycling test technologies for power semiconductor devices-challenges and analysis[J]. Proceedings of the CSEE, 2023, 43(13): 5132 − 5151.

[38] Herold C, Franke J, Bhojani R, et al. Requirements in power cycling for precise lifetime estimation[J]. Microelectronics Reliability, 2016, 58: 82 − 89. doi: 10.1016/j.microrel.2015.12.035

[39] Herold C, Beier M, Lutz J, et al. Improving the accuracy of junction temperature measurement with the square-root-t method [C]//19th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC). IEEE. 2013: 92-94.

[40] 邓二平, 陈杰, 赵雨山, 等. IGBT封装形式对结温测量精度的影响[J]. 半导体技术, 2018, 43(12): 956 − 963. doi: 10.13290/j.cnki.bdtjs.2018.12.013 Deng Erping, Chen Jie, Zhao Yushan, et al. Influence of IGBT package types on the accuracy of junction temperature measurement[J]. Semiconductor Technology, 2018, 43(12): 956 − 963. doi: 10.13290/j.cnki.bdtjs.2018.12.013

[41] Amro D-I R. Power cycling capability of advanced packaging and interconnection technologies at high temperature swings [D]. Chemnitz: Technische Universitat Chemnitz, 2006.

[42] 陈杰, 邓二平, 赵雨山, 等. 高压大功率器件结温在线测量方法综述[J]. 中国电机工程学报, 2019, 39(22): 6677 − 6688. Chen Jie, Deng Erping, Zhao Yushan, et al. Review of on-line junction temperature measurement methods of high voltage power electronics[J]. Proceedings of the CSEE, 2019, 39(22): 6677 − 6688.

[43] Wei H, Zhiwen C. Review on failure analysis of interconnections in power devices[J]. China Welding, 2022, 31(1): 6 − 14.

[44] Schmidt R, Scheuermann U. Using the chip as a temperature sensor-The influence of steep lateral temperature gradients on the Vce (T)-measurement[J]. Epe Journal, 2011, 21(2): 5 − 11. doi: 10.1080/09398368.2011.11463790

[45] Zeng G, Cao H, Chen W, et al. Difference in device temperature determination using pn-junction forward voltage and gate threshold voltage[J]. IEEE Transactions on Power Electronics, 2018, 34(3): 2781 − 2793.

[46] 陈杰. 功率循环试验中芯片温度分布特性的测量方法研究 [D]. 北京: 华北电力大学(北京) , 2022. Chen Jie, Research on measurement method of temperature distribution characteristics on the chip in power cycling test[D]. Beijing: North China Electric Power University, 2022.

[47] 石巍. 大功率IGBT模块健康状态信息提取方法研究及加速老化试验平台研制 [D]. 杭州: 浙江大学, 2018. Shi Wei. Research on state-of-health exteacton method of high power IGBT modules and design of the accelarated aging testpPlatform system[D]. Hangzhou: Zhejiang University, 2018.

[48] 孙鹏菊, 王海波, 龚灿, 等. 短路电流作为绝缘栅双极型晶体管模块键合线老化特征量的机理研究[J]. 中国电机工程学报, 2019, 39(16): 4876 − 4883. doi: 10.13334/j.0258-8013.pcsee.181566 Sun Pengju, Wang Haibo, Gong Can, et al. Mechanism research of short-circuit current as bond wire ageing indicator of insulated gate bipolar transistor module[J]. Proceedings of the CSEE, 2019, 39(16): 4876 − 4883. doi: 10.13334/j.0258-8013.pcsee.181566

[49] Wang K, Zhou L, Sun P, et al. Monitoring bond wire defects of IGBT module using module transconductance[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2021, 9(2): 2201 − 2211. doi: 10.1109/JESTPE.2020.2973348

[50] 曾杰, 檀浩浩, 杨方, 等. IGBT模块焊层的被动热循环可靠性分析[J]. 焊接学报, 2023, 44(7): 123 − 128. doi: 10.12073/j.hjxb.20220517002 Zeng Jie, Tan Haohao, Yang Fang, et al. Reliability analysis of solder layer of IGBT module under passive thermal cycling[J]. Transactions of the China Welding Institution, 2023, 44(7): 123 − 128. doi: 10.12073/j.hjxb.20220517002

[51] Li H, An R, Wang C, et al. Effect of Cu grain size on the voiding propensity at the interface of SnAgCu/Cu solder joints[J]. Materials Letters, 2015, 144: 97 − 99. doi: 10.1016/j.matlet.2015.01.013

[52] 孙海峰, 杨舒曼. 焊料层空洞对绝缘栅双极型晶体管(IGBT)模块温度分布的影响[J]. 科学技术与工程, 2018, 18(32): 189 − 194. doi: 10.3969/j.issn.1671-1815.2018.32.029 Sun Haifeng, Yang Shuman. Influence of solder void on temperature distribution of insulated gate bipolar transistor ( IGBT) module[J]. Science Technology and Engineering, 2018, 18(32): 189 − 194. doi: 10.3969/j.issn.1671-1815.2018.32.029

[53] 江南, 陈民铀, 徐盛友, 等. 计及裂纹损伤的IGBT模块热疲劳失效分析[J]. 浙江大学学报(工学版), 2017, 51(4): 825 − 833. doi: 10.3785/j.issn.1008-973X.2017.04.025 Jiang Nan, Chen Minyou, Xu Shengyou, et al. Thermal fatigue of IGBT module considering crack damage[J]. Journal of Zhejiang University(Engineering Science), 2017, 51(4): 825 − 833. doi: 10.3785/j.issn.1008-973X.2017.04.025

[54] 郭秋亚. IGBT模块的焊料层疲劳失效机理研究 [D]. 天津: 天津理工大学 , 2020. Guo Qiuya. Study on fatigue failure mechanism of IGBT module's solder layer[D]. Tianjin: Tianjin University of Technology, 2020.

[55] 王学梅, 张波, 吴海平. 基于失效物理的功率器件疲劳失效机理[J]. 电工技术学报, 2019, 34(4): 717 − 727. doi: 10.19595/j.cnki.1000-6753.tces.171414 Wang Xuemei, Zhang Bo, Wu Haiping. A review of fatigue mechanism of power devices based on physics-of-failure[J]. Transactions of the China Electrotechnical Society, 2019, 34(4): 717 − 727. doi: 10.19595/j.cnki.1000-6753.tces.171414

[56] Czerny B, Lederer M, Nagl B, et al. Thermo-mechanical analysis of bonding wires in IGBT modules under operating conditions[J]. Microelectronics Reliability, 2012, 52(9-10): 2353 − 2357. doi: 10.1016/j.microrel.2012.06.081

[57] Dornic N, Ibrahim A, Khatir Z, et al. Analysis of the aging mechanism occurring at the bond-wire contact of IGBT power devices during power cycling[J]. Microelectronics Reliability, 2020, 114: 113873. doi: 10.1016/j.microrel.2020.113873

下载:

下载: