Research status and application progress of narrow gap welding technology for thick plates

-

摘要:

窄间隙焊接技术已经成为现代工业生产中厚板结构的首选技术,其技术和经济优势决定了它是今后厚板焊接技术发展的主要方向之一,近年来随着科技工作者的不断探索和研发,相继涌现了多种窄间隙焊接方法,文中对电弧焊、激光焊和激光−电弧复合焊等窄间隙焊接制造技术进行了系统阐述,概述了不同热源窄间隙焊接制造过程中的焊接质量、焊接效率的影响因素,归纳了不同热源窄间隙焊的工艺特点及应用领域,结合国内外相关技术的发展现状,总结了窄间隙焊技术面临的问题,提出了后续的发展建议,为相关领域的科研工作者提供参考.

Abstract:Narrow gap welding technology has become the first choice for welding thick plate structures in modern industrial production. Its technical and economic advantages determine it to become one of the main directions of the future development of thick plate welding technology. In recent years, with the continuous exploration and research and the development of scientific and technological workers, a variety of narrow gap welding methods have emerged. In this paper, narrow gap welding manufacturing technology is systematically described, introducing the narrow gap welding manufacturing technology such as electric arc welding, laser welding, and laser-arc hybrid welding. Meanwhile, this paper outlines the factors influencing the quality and efficiency of the manufacturing process of narrow gap welding with different heat sources, and summarizes the process characteristics and application areas of narrow gap welding with different heat sources. Subsequently, combined with the development status of related technologies at home and abroad, this paper summarizes the problems faced by narrow gap welding manufacturing technology and puts forward subsequent development proposals, with a view to providing references for researchers in related fields.

-

Keywords:

- narrow gap welding /

- electric arc welding /

- laser welding /

- laser-arc hybrid welding

-

-

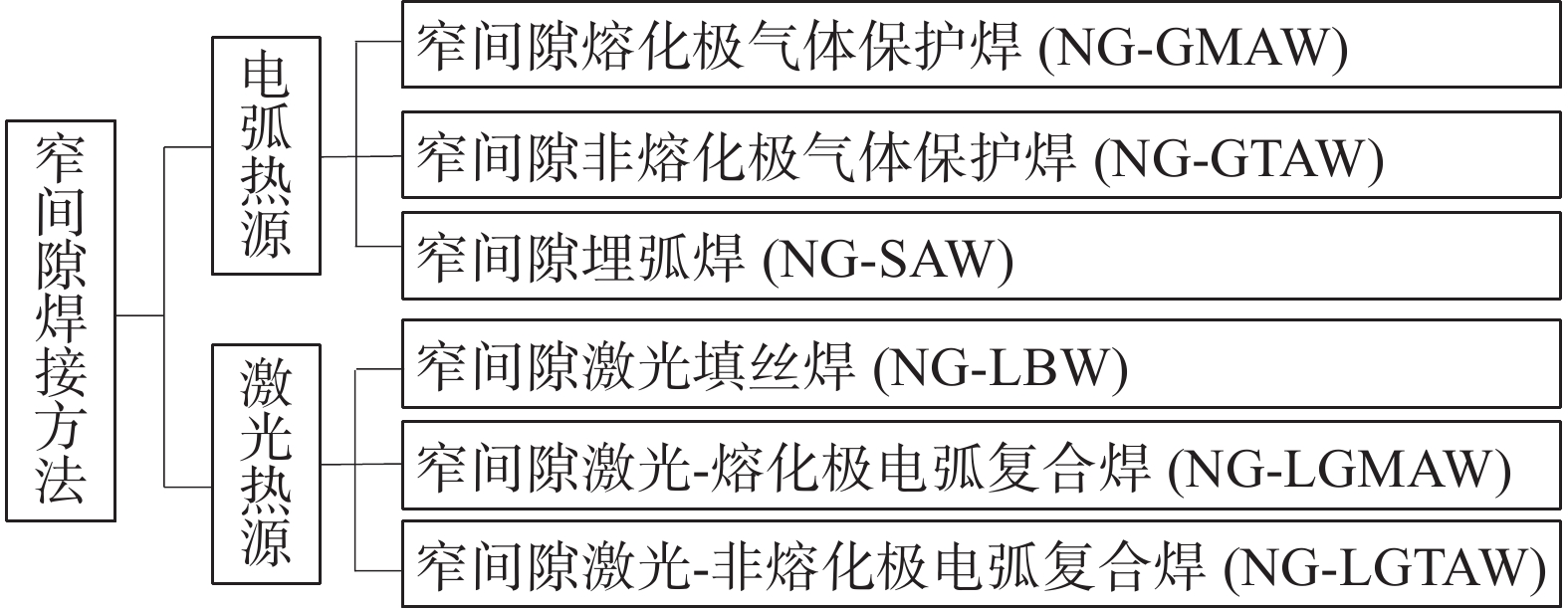

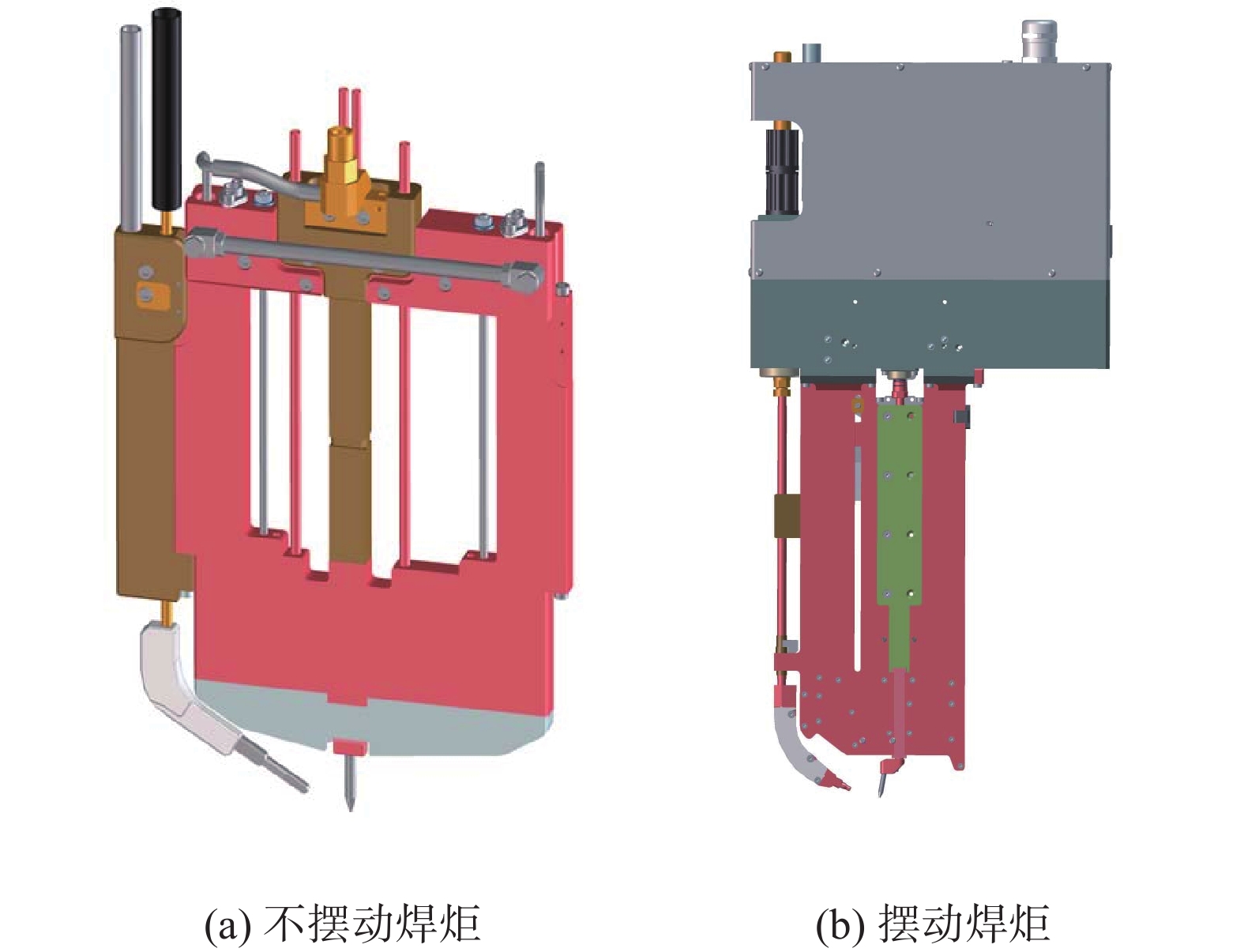

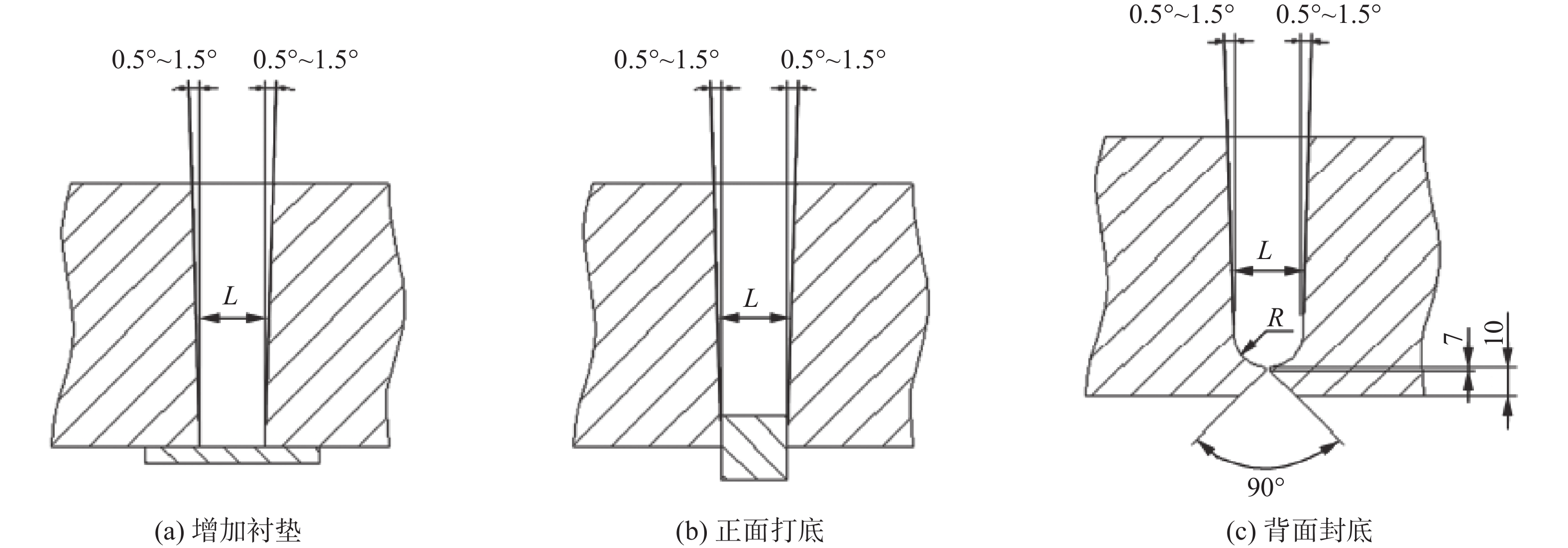

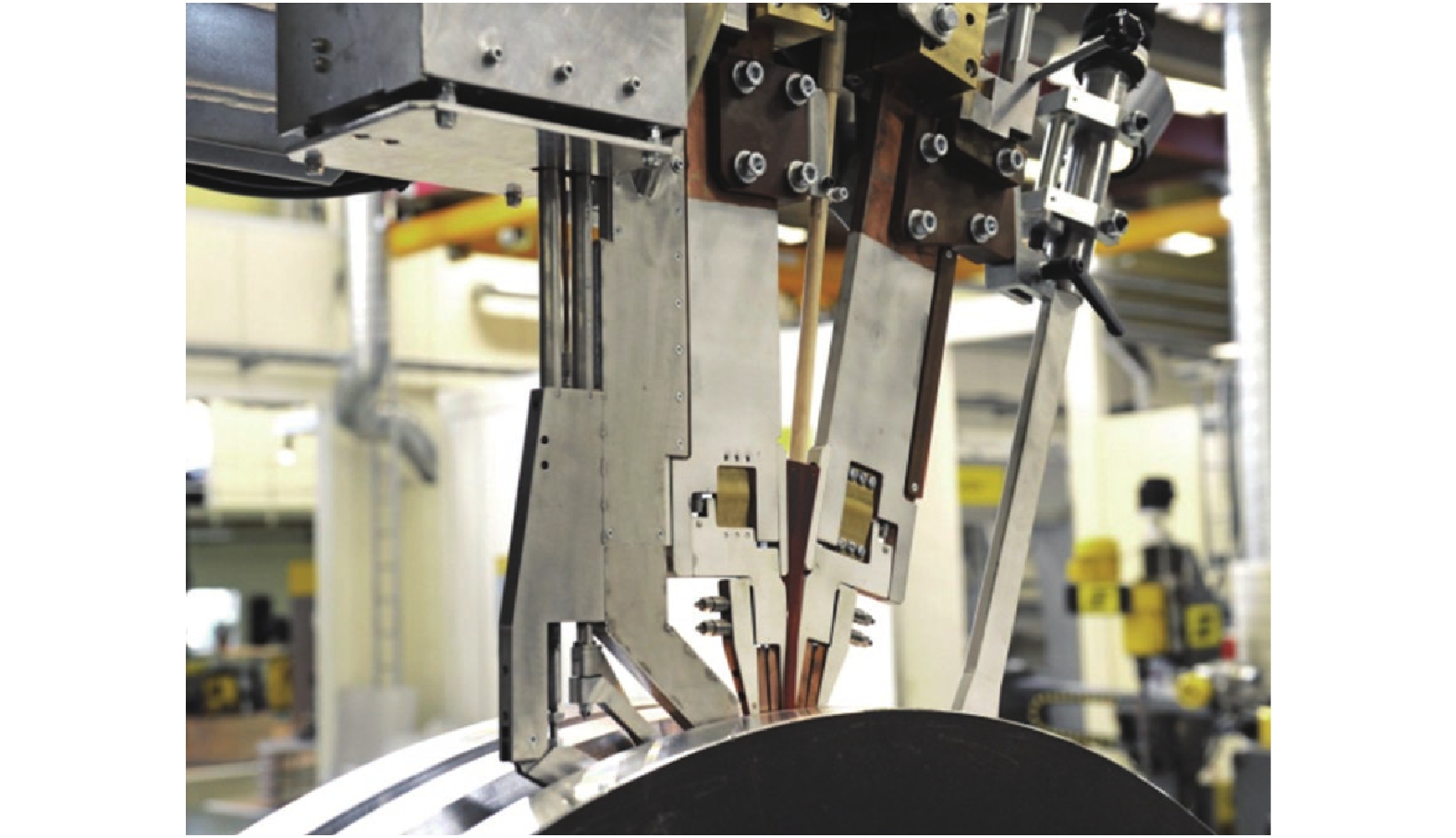

图 3 窄间隙双丝GMAW焊用焊炬[15]

Figure 3. Welding torch for narrow gap double wire GMAW. (a) structural front; (b) structural side

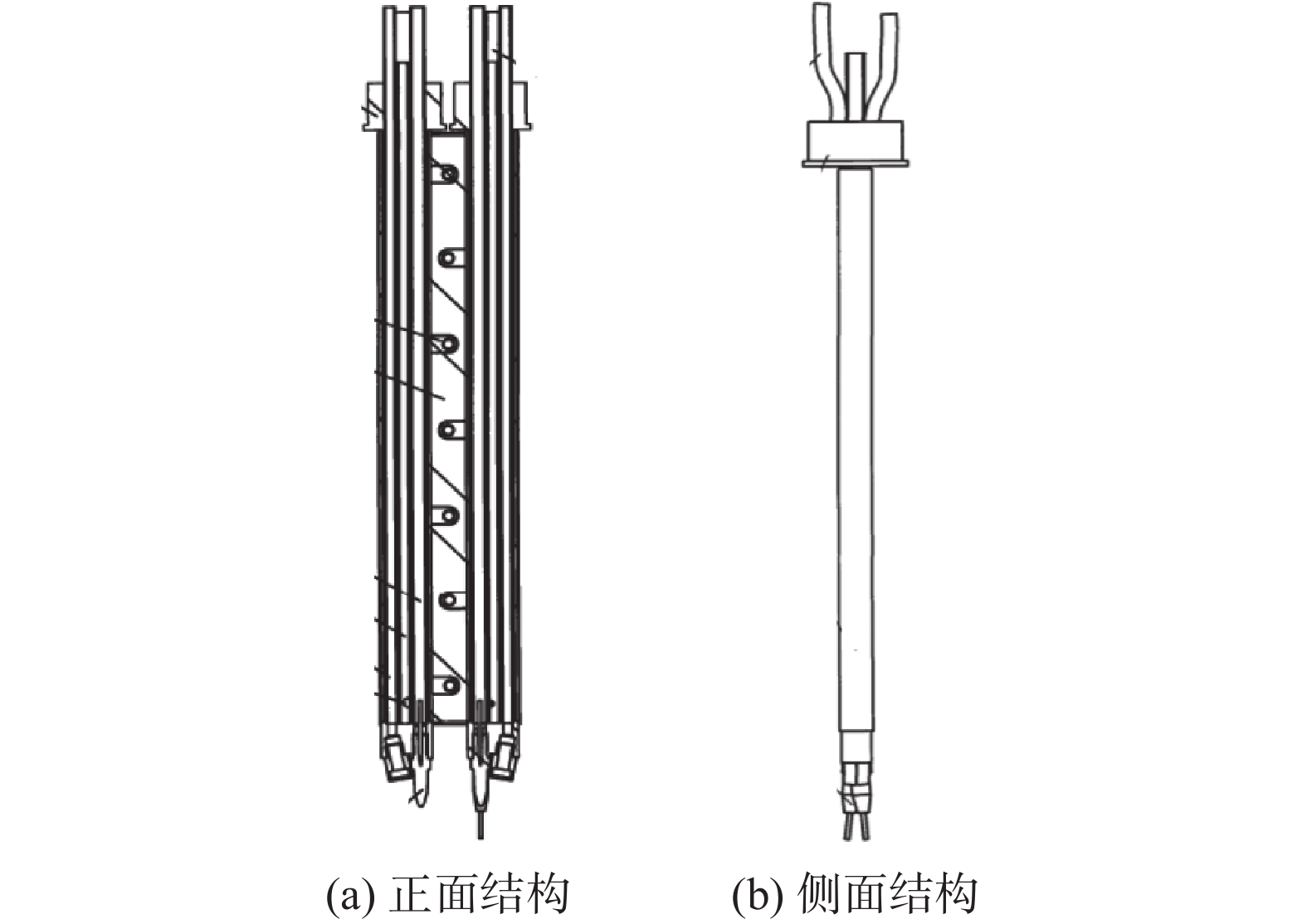

图 5 弯丝法焊接原理及焊后焊缝形貌[22]

Figure 5. Welding principle of the wire bending method and the shape of the weld after welding. (a) schematic;(b) Welded cross-section morphology

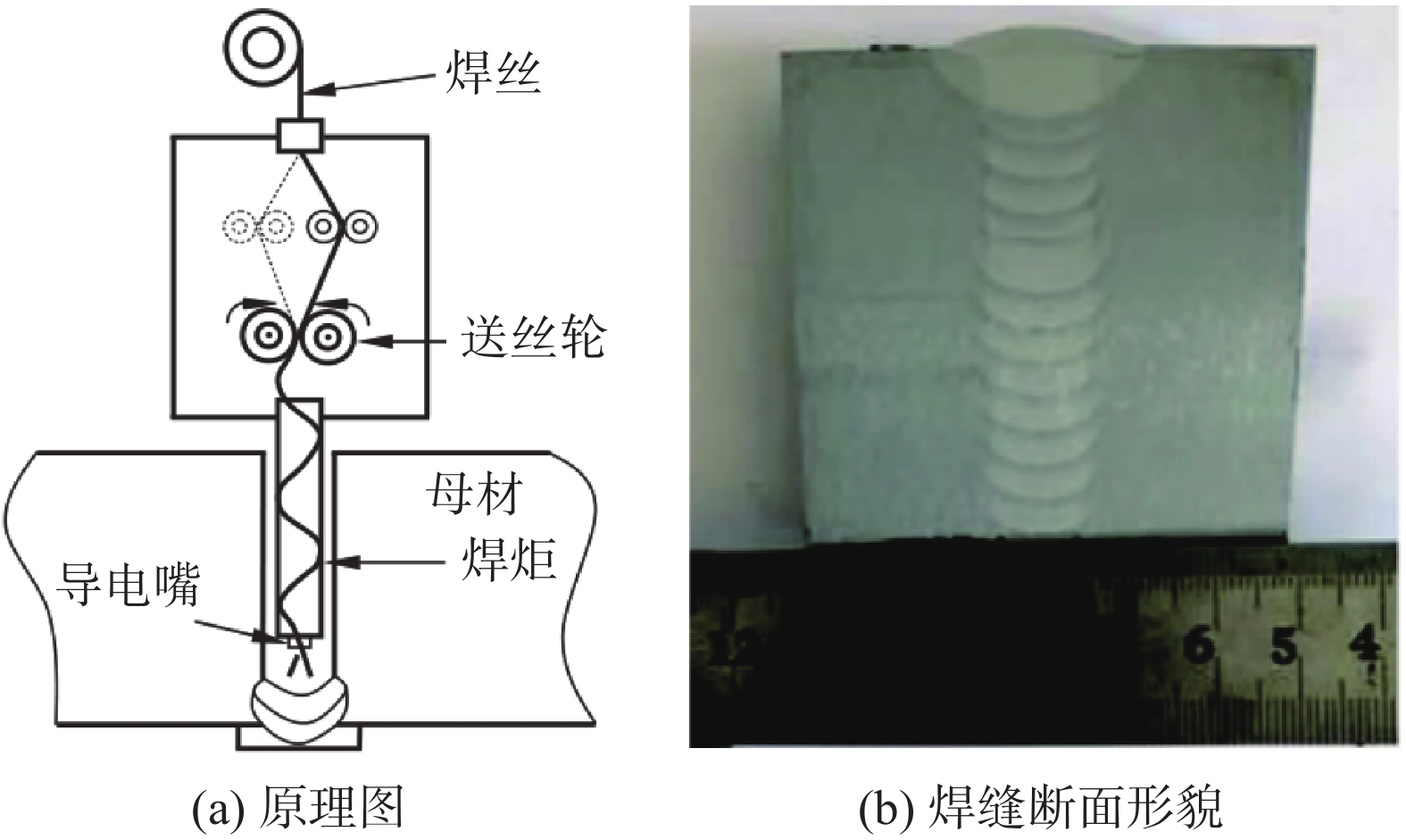

图 6 不同喷嘴角度下的气体流动特性[10]

Figure 6. Gas flow characteristics at different nozzle angles. (a) 0°; (b) 60°

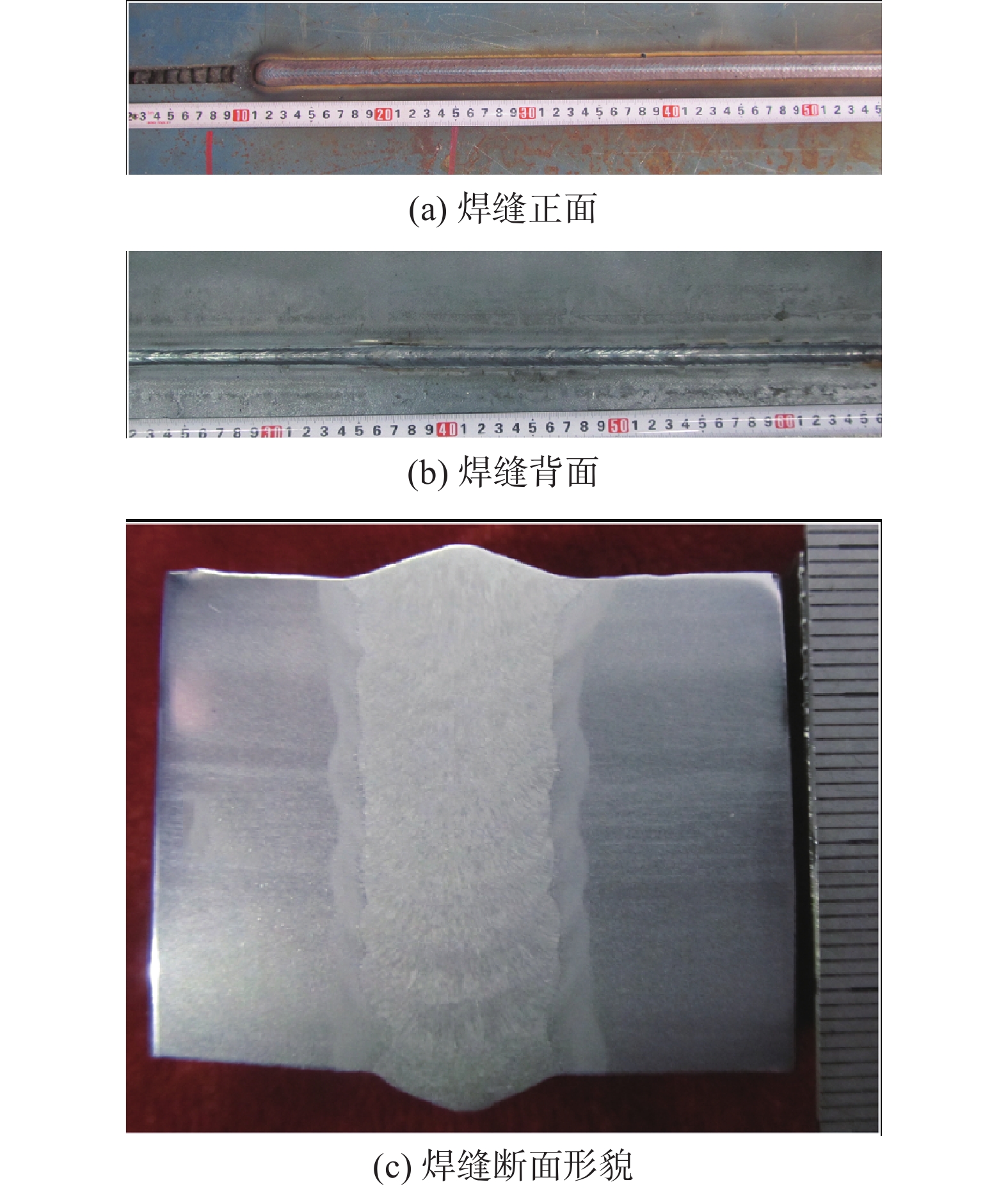

图 7 35 mm厚高强钢窄间隙焊缝形貌[23]

Figure 7. Narrow gap weld shape of 35mm thick high-strength steel. (a) welded front;(b) welded back;(c) Welded cross-section.

图 8 焊缝横截面上的气孔分布[24]

Figure 8. Hole distribution in the weld cross section. (a) NG-GMAW welds; (b) overlay welds; (c) butt welds

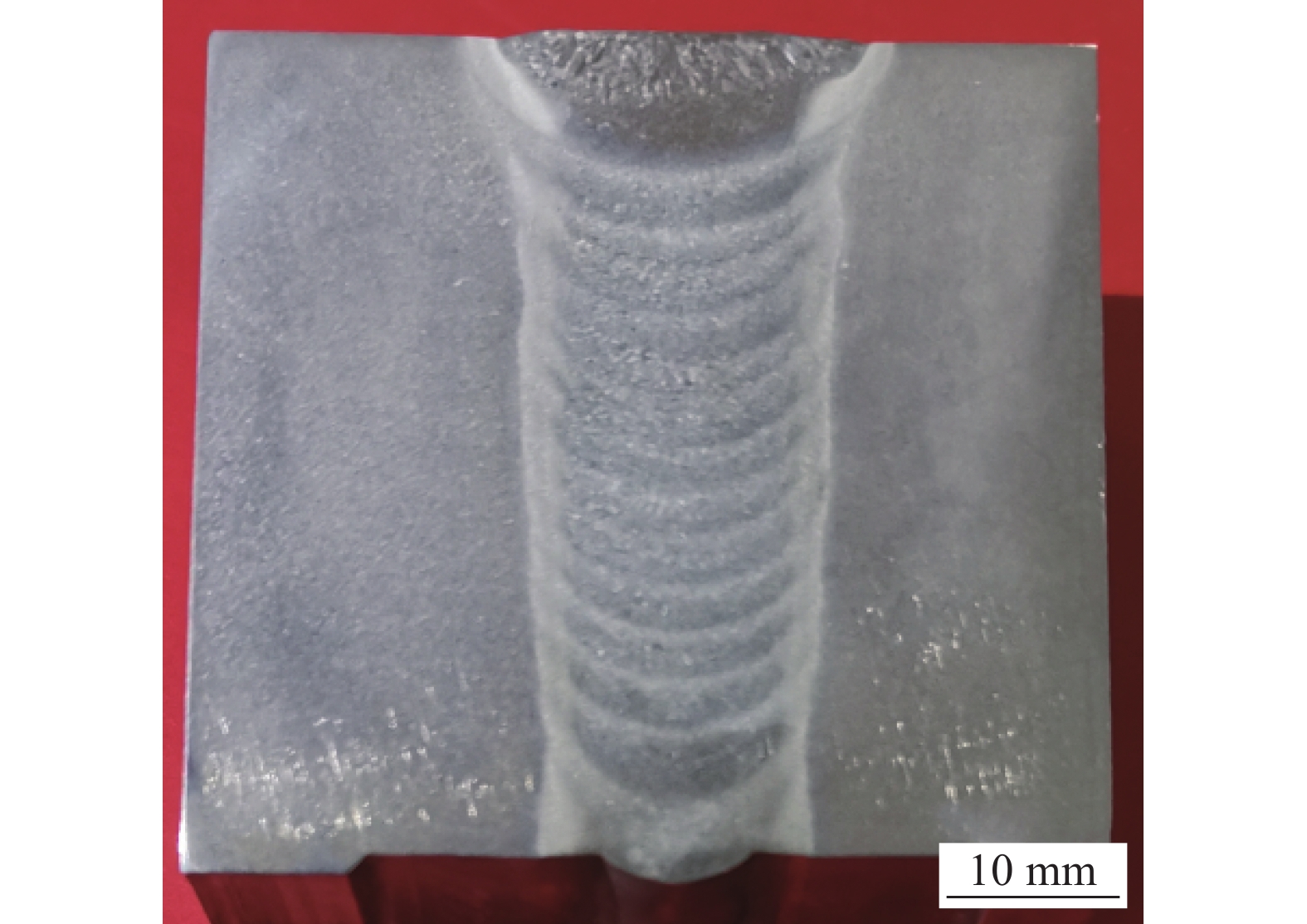

图 11 焊接接头断面宏观形貌[26]

Figure 11. Macroscopic morphology of the welded joint section

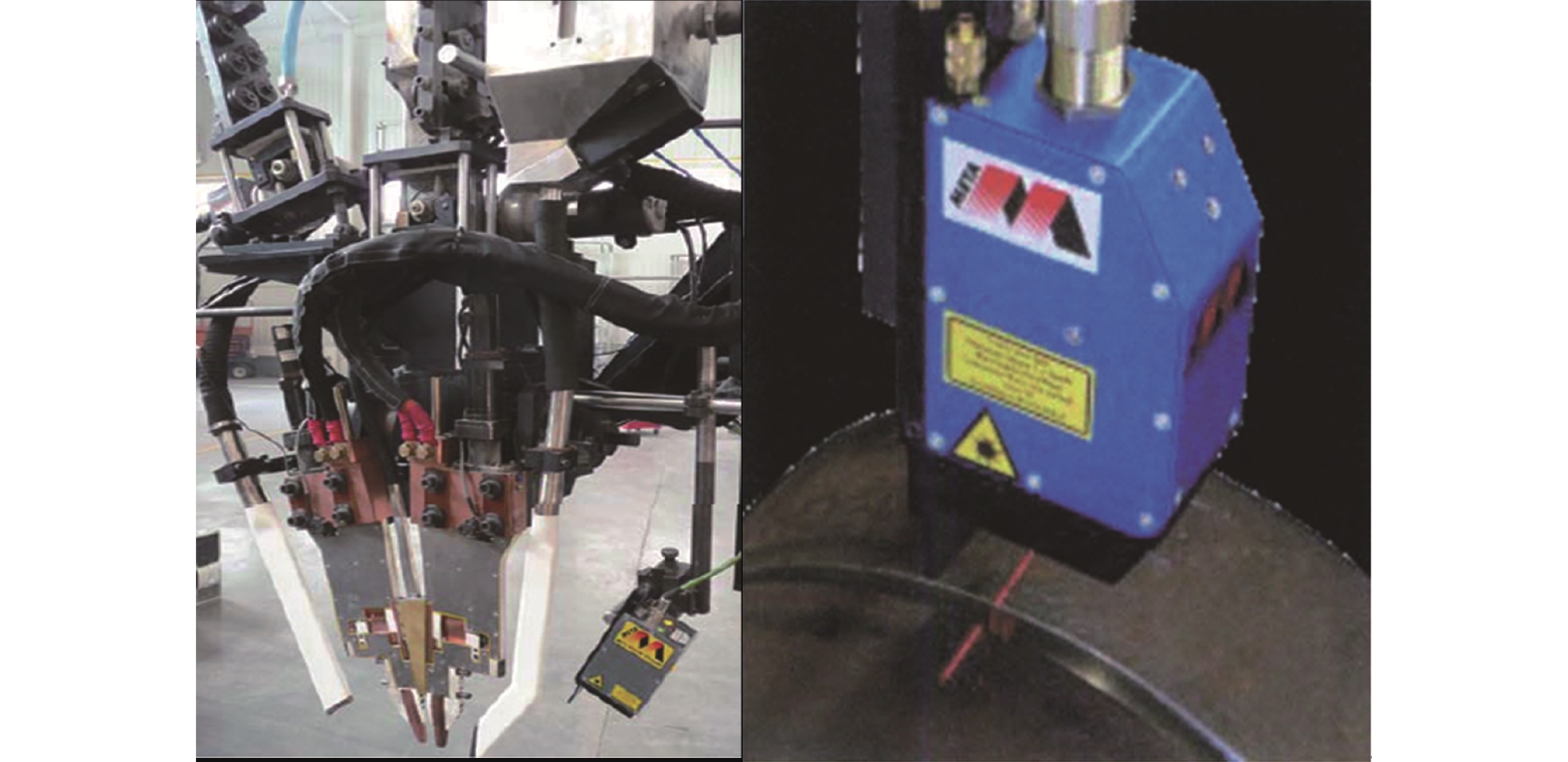

图 12 磁控窄间隙TIG焊接原理及过程图[31]

Figure 12. The principle and process diagram of magnetically controlled narrow gap TIG welding. (a) welding process schematic; (b) physical drawing; (c) magnetically controlled narrow gap welding process

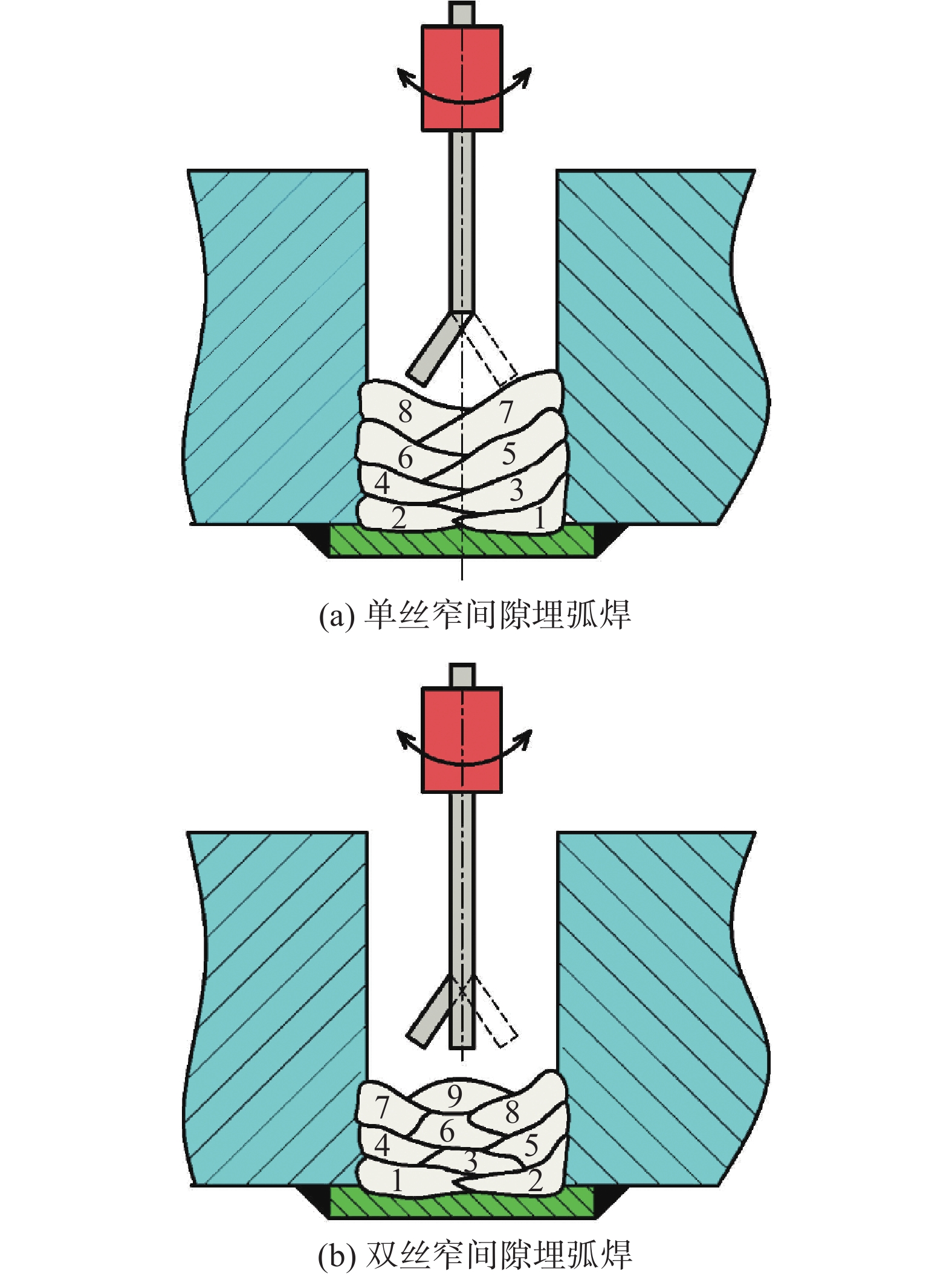

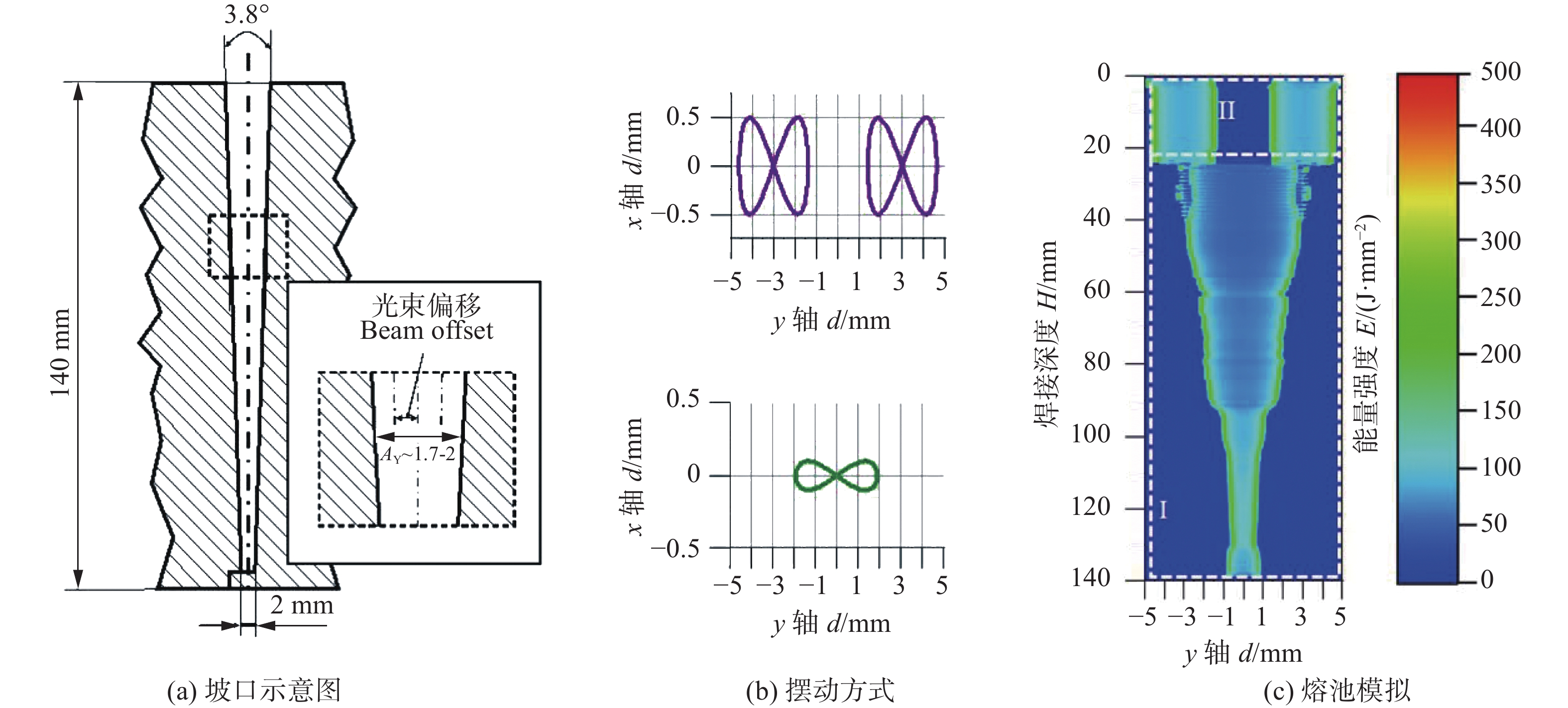

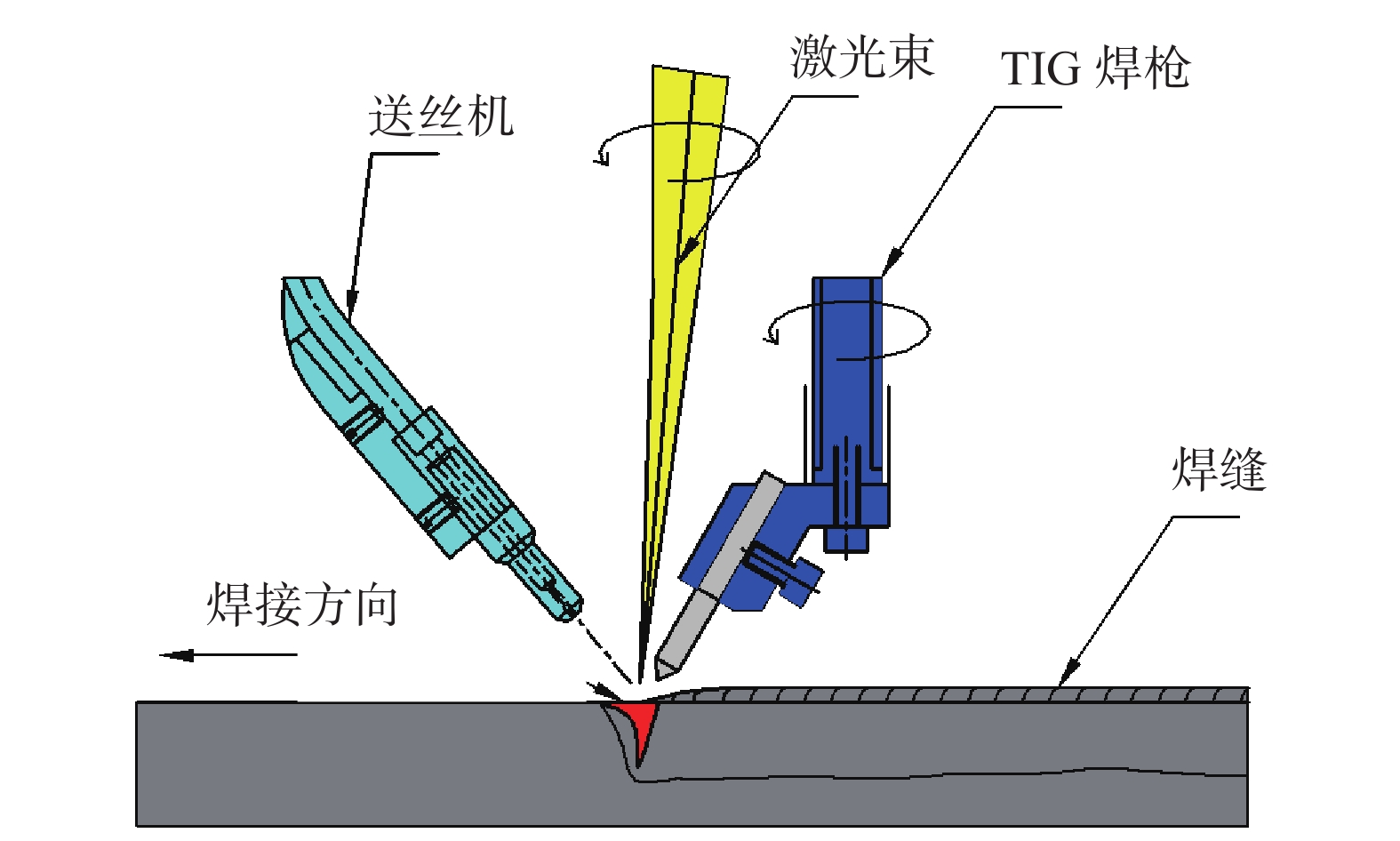

图 19 坡口形式及激光摆动方式[38]

Figure 19. Groove form and laser swing mode. (a) groove Schematic; (b) laser swing mode; (c) welt pool simulation

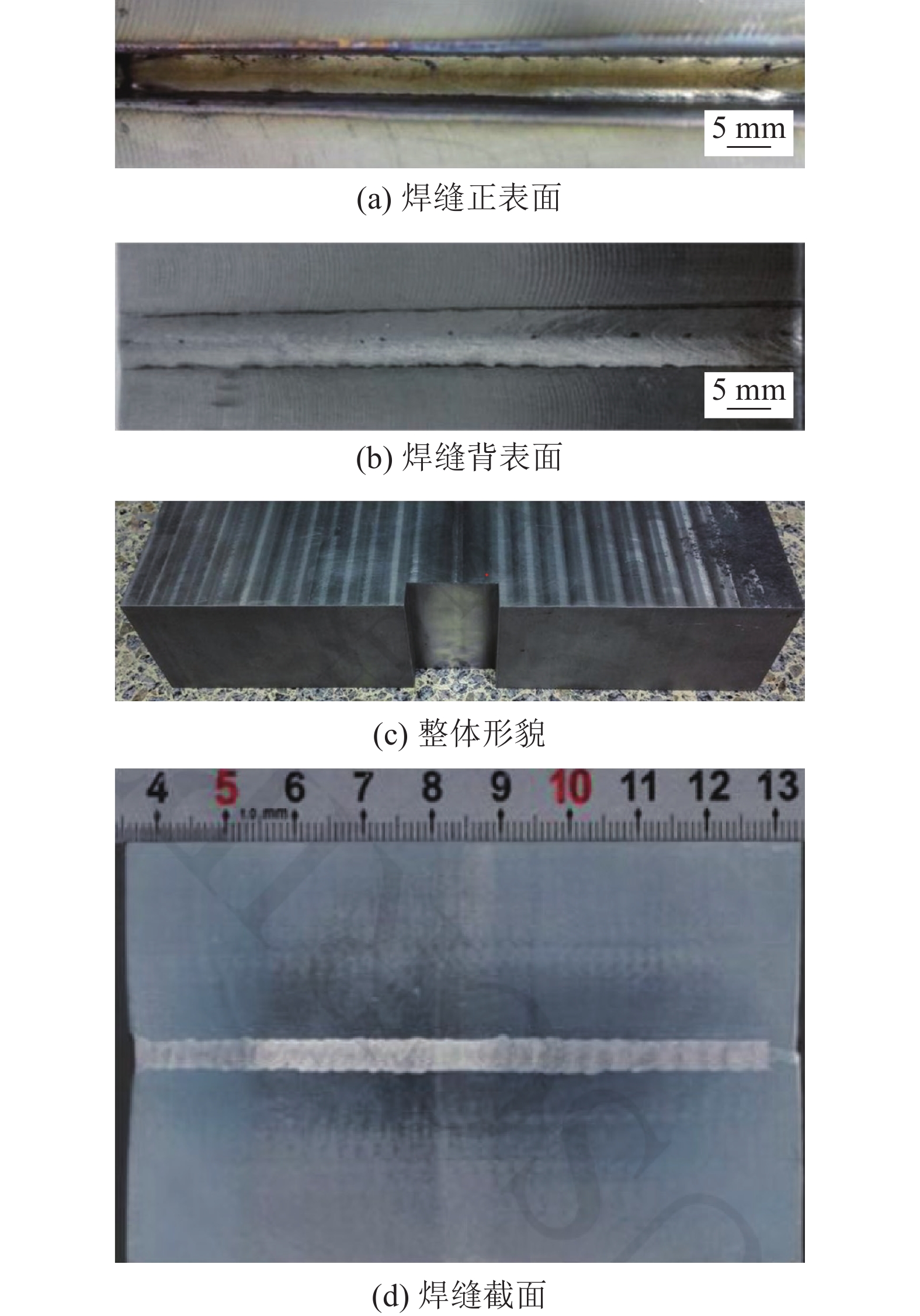

图 20 100 mm厚304不锈钢窄间隙激光填丝焊接接头[39]

Figure 20. Narrow gap laser welding joint of 304 stainless steel with 100 mm thickness and filler wire. (a) positive surface of welded; (b) welded back surface (c) overall shape; (d) welded cross-section

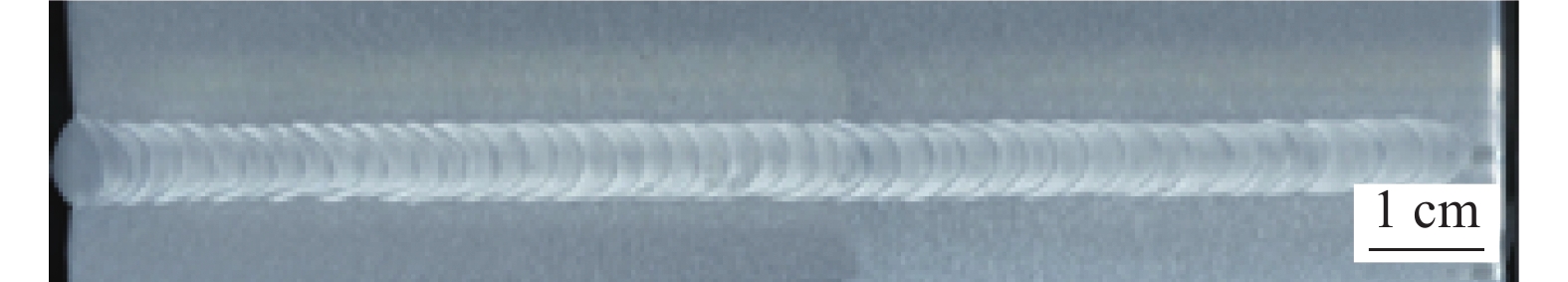

图 21 130 mm厚焊缝截面[40]

Figure 21. 130 mm Weld cross section

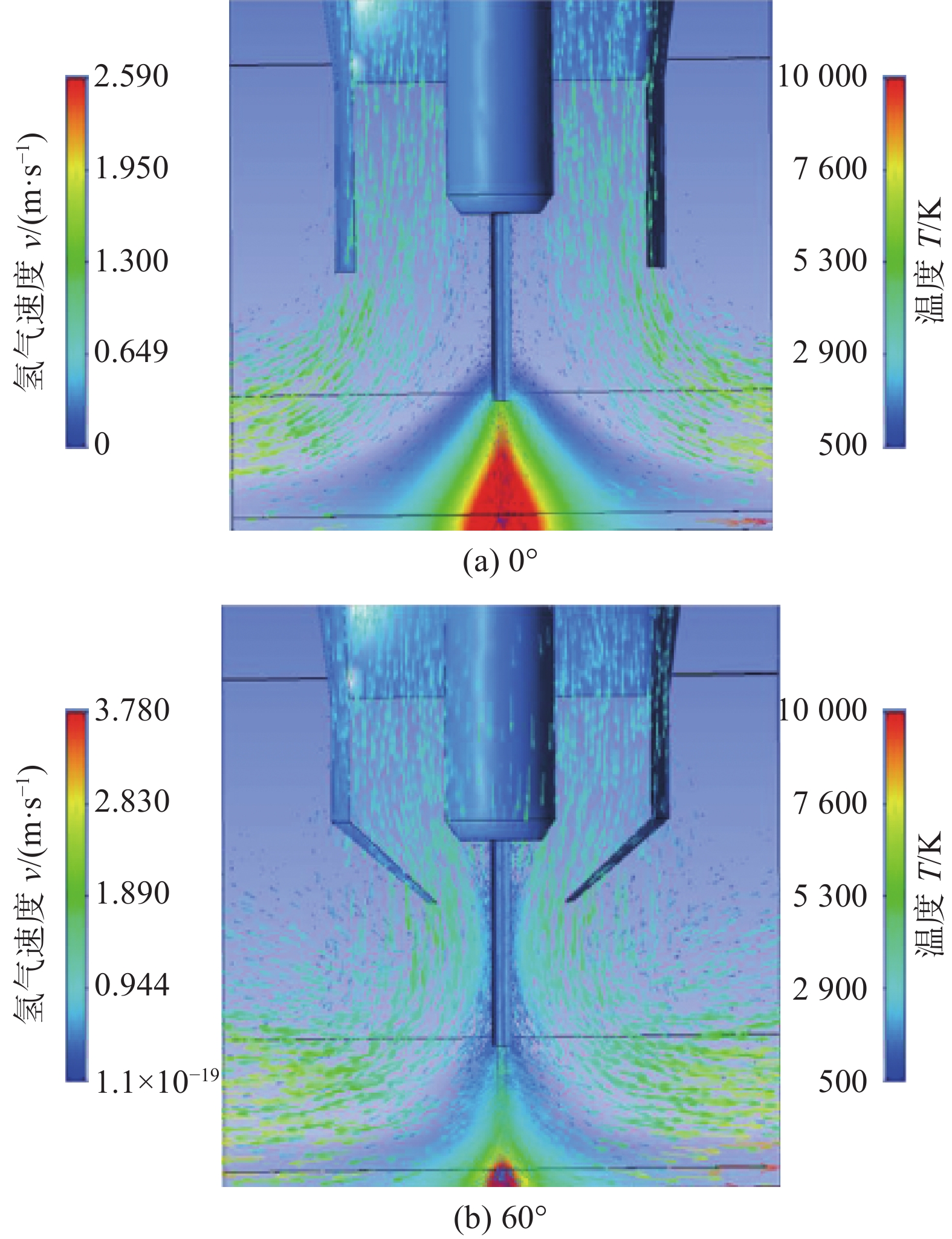

表 1 窄间隙焊接方法综合评价

Table 1 Comprehensive evaluation of narrow gap welding methods

方法 生产效率 焊接质量 技术成熟度 NG-GMAW ○ ○ ○ NG-GTAW ◇ ● ● NG-SAW ● ● ● NG-LBW ○ ○ ◇ NG-LGMAW ● ○ ◇ NG-LGTAW ○ ● ◇ 备注:◇低;○中;●高. -

[1] Meister R P, Martin D C. Narrow-gap welding process[J]. British Welding Journal, 1966, 13(5): 252 − 257.

[2] 张富巨, 郭嘉琳, 张国栋. 窄间隙/超窄间隙焊接技术(三) 窄间隙气体保护焊相关关键技术[J]. 电焊机, 2017, 47(7): 30 − 33. Zhang Fuju, Guo Jialin, Zhang Guodong. Key technologies of narrow gap gas shielded arc welding[J]. Electric Welding Machine, 2017, 47(7): 30 − 33.

[3] 周方明, 王江超, 周涌明, 等. 窄间隙焊接的应用现状及发展趋势[J]. 焊接技术, 2007, 36(4): 4 − 7. doi: 10.3969/j.issn.1002-025X.2007.04.002 Zhou Fangming, Wang Jiangchao, Zhou Yongming, et al. Application status and development trend of narrow gap welding[J]. Welding Technology, 2007, 36(4): 4 − 7. doi: 10.3969/j.issn.1002-025X.2007.04.002

[4] 谭环. 日本窄间隙焊的现状及其发展趋势[J]. 现代兵器, 1983, 12: 31 − 39. Tan Huan. Current situation and development trend of narrow gap welding in Japan[J]. Modern Weapons, 1983, 12: 31 − 39.

[5] Malin V Y. The state of the art of narrow gap welding[J]. Welding Joumal, 1983, 62(14): 22 − 30.

[6] 草野和喜, 渡边浩. 最近の高能率ティグの開発動向—大溶着ティグ溶接ぉよび超狭開先ティグ溶接[J]. 溶接技術, 2002, 4: 132 − 136. Kazuno kusano, Ikuo Watari. Recent trends in the development of highly efficient tigs - large weld/ultra-narrow tip tig welding[J]. Japanese Welding Technology, 2002, 4: 132 − 136.

[7] 尹士科, 王振家译. 窄间隙焊接[M]. 北京: 机械工业出版社, 1988. Yin Shike, Wang Zhenjia. Narrow gap welding [M]. Beijing: China Machine Press, 1988.

[8] 林三宝, 蔡笑宇, 季相儒. 厚板窄间隙焊接技术研究进展[J]. 机械制造文摘(焊接分册), 2017(5): 33 − 38. Lin Sanbao, Cai Xiaoyu, Ji Xiangru. Research status of narrow gap welding for thick plates[J]. Machine Manufacturing Abstract (Welding Branch), 2017(5): 33 − 38.

[9] 张富巨, 罗传红. 窄间隙焊及其新进展[J]. 焊接技术, 2000, 6: 33 − 36. doi: 10.3969/j.issn.1002-025X.2000.06.017 Zhang Fuju, Luo Chuanhong. Narrow gap welding and its new progress[J]. Welding Technology, 2000, 6: 33 − 36. doi: 10.3969/j.issn.1002-025X.2000.06.017

[10] Anant R, Ghosh P K. Ultra-narrow gap welding of thick section of austenitic stainless steel to HSLA steel[J]. Journal of Materials Processing Technology, 2017, 239: 210 − 221. doi: 10.1016/j.jmatprotec.2016.08.016

[11] 徐祥久, 李宜男. 窄间隙热丝TIG焊接工艺研究及缺陷分析[J]. 电焊机, 2010, 40(2): 27 − 29. doi: 10.3969/j.issn.1001-2303.2010.02.006 Xu Xiangjiu, Li Yinan. Study on welding procedure and defects of narrow gap hot wire TIG[J]. Electric Welding Machine, 2010, 40(2): 27 − 29. doi: 10.3969/j.issn.1001-2303.2010.02.006

[12] 张磊, 王博健, 付傲, 等. 跟踪系统在窄间隙埋弧焊中的应用现状[J]. 电焊机, 2022, 52(7): 52 − 61. doi: 10.7512/j.issn.1001-2303.2022.07.08 Zhang Lei, Wang Bojian, Fu Ao, et al. Application status of tracking system in narrow gap submerge darc welding[J]. Electric Welding Machine, 2022, 52(7): 52 − 61. doi: 10.7512/j.issn.1001-2303.2022.07.08

[13] Keßler B, Brenner B, Dittrich D, et al. Laser-multi-pass-narrow-gap-welding of nickel superalloy-alloy 617OCC[J]. Journal of Laser Applications, 2019, 31(2): 3725 − 3735.

[14] Wu Y, Shan J, Li Z, et al. Narrow groove laser-arc hybrid welding of thick-sectioned HSLA steel using laser beam oscillation[J]. Welding Journal, 2022, 101(7): 181s − 196s. doi: 10.29391/2022.101.014

[15] 罗登峰, 顾迎新, 王荣, 等. 一种窄间隙双丝MIG/MAG 焊用焊枪: 中国, CN201010556051.4[P]. 2013-08-21. Luo Dengfeng, Gu Yingxin, Wang Rong, et al. A narrow gap double wire MIG/MAG welding torch: China, CN201010556051.4[P]. 2013-08-21.

[16] 张溢洋, 王桂鹏, 薛嘉峰, 等. 窄间隙MIG焊枪的发展状况[C]//全国地方机械工程学会、河南省机械工程学会. 第九届全国地方机械工程学会学术年会论文集. 河南, 2019: 251-254. Zhang Yiyang, Wang Guipeng, Xue Jiafeng, et al. Development status of narrow gap MIG welding gun [C]// National Local Mechanical Engineering Society, Henan Mechanical Engineering Society. Proceedings of the 9th National Local Mechanical Engineering Society Annual Conference. Henan, 2019: 251-254.

[17] Wang J, Zhu J, Ping F U, et al. A swing arc system for narrow gap GMA welding[J]. ISIJ International, 2012, 52(1): 110 − 114. doi: 10.2355/isijinternational.52.110

[18] Xu Guoxiang, Li Lin, Wang Jiayou, et al. Study of weld formation in swing arc narrow gap vertical GMA welding by numerical modeling and experiment[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96: 1905 − 1917. doi: 10.1007/s00170-018-1729-z

[19] 徐望辉, 林三宝, 杨春利, 等. 摆动电弧窄间隙立向上GMAW焊缝成形[J]. 焊接学报, 2015, 36(4): 56 − 60. Xu Wanghui, Lin Sanbao, Yang Chunli, et al. Weld bead formation in oscillating arc narrow gap vertical-up GMAW process[J]. Transactions of the China Welding Institution, 2015, 36(4): 56 − 60.

[20] 徐望辉, 林三宝, 杨春利, 等. 摆动电弧窄间隙GMAW熔滴过渡规律[J]. 焊接学报, 2017, 38(2): 109 − 114. Xu Wanghui, Lin Sanbao, Yang Chunli, et al. Study on droplet transfer of swing arc narrow gap GMAW[J]. Transactions of the China Welding Institution, 2017, 38(2): 109 − 114.

[21] 林三宝, 杨春利, 徐望辉, 等. 一种弯曲导电嘴式双丝窄间隙MIG/MAG 焊炬: 中国, CN201110337924.7[P]. 2013-05-15. Lin Sanbao, Yang Chunli, Xu Wanghui, et al. A curved conductive nozzle type double wire narrow gap MIG/MAG welding torch: China, CN201110337924.7[P]. 2013-05-15.

[22] 胡奉雅, 韩严法, 傅博, 等. EH40船板钢的弯曲焊丝窄间隙MAG焊工艺研究[J]. 上海金属, 2018, 40(4): 25 − 28. doi: 10.3969/j.issn.1001-7208.2018.04.005 Hu Fengya, Han Yanfa, Fu Bo, et al. Research on narrow gap metal active gas arc welding with curved wire for EH40 ship steel plate[J]. Shanghai Metal, 2018, 40(4): 25 − 28. doi: 10.3969/j.issn.1001-7208.2018.04.005

[23] Xu W H, Lin S B, Fan C L, et al. Evaluation on microstructure and mechanical properties of high-strength low-alloy steel joints with oscillating arc narrow gap GMA welding[J]. The International Journal of Advanced Manufacturing Technology, 2014, 75: 1439 − 1446. doi: 10.1007/s00170-014-6225-5

[24] Zhu C, Tang X, He Y, et al. Characteristics and formation mechanism of sidewall pores in NG-GMAW of 5083 Al-alloy[J]. Journal of Materials Processing Technology, 2016, 238: 274 − 283. doi: 10.1016/j.jmatprotec.2016.07.032

[25] 刘自刚, 张建峰, 钱雪娇, 等. 大熔覆速率TIG焊研究现状与展望[J]. 热加工工艺, 2024, 53(1): 12 − 16. doi: 10.14158/j.cnki.1001-3814.20212521 Liu Zigang, Zhang Jianfeng, Qian Xuejiao, et al. Research status and prospect of high cladding rate TIG welding[J]. Hot Working Technology, 2024, 53(1): 12 − 16. doi: 10.14158/j.cnki.1001-3814.20212521

[26] 徐祥久, 张宇, 黄超, 等. SA-335 P91钢全位置窄间隙热丝TIG焊接工艺及接头性能研究[J]. 压力容器, 2019, 36(8): 12 − 15. Xu Xiangjiu, Zhang Yu, Huang Chao, et al. Study on welding procedure and joint properties of SA-335 P91 steel with all-position narrow gap hot wire TIG[J]. Pressure Vessel Technology, 2019, 36(8): 12 − 15.

[27] 胡金亮, 曾才有, 余陈, 等. 厚板钛合金磁控窄间隙TIG焊接技术发展现状[J]. 精密成形工程, 2020, 12(4): 10-20. Hu Jinliang, Zeng Caiyou, Yu Chen, et al. Progress in magnetically-controlled narrow-gap TIG welding of thick-plate titanium alloys[J]. Precision Forming Engineering, 2020, 12(4): 10-20.

[28] 孙清洁, 李文杰, 胡海峰, 等. 厚板Ti-6Al-4V磁控窄间隙TIG焊接头性能[J]. 焊接学报, 2013, 34(2): 9 − 12. Sun Qingqing, Li Wenjie, Hu Haifeng, et al. Analysis on welded joint of thick Ti-6Al-4V plate by magnetically controlled narrow-gap TIG welding[J]. Transactions of the China Welding Institution, 2013, 34(2): 9 − 12.

[29] 胡金亮, 胡永俊, 曾才有, 等. 大厚度TA17钛合金磁控窄间隙TIG焊接头组织和力学性能[J]. 热加工工艺, 2023, 52(9): 42 − 46. doi: 10.14158/j.cnki.1001-3814.20210612 Hu Jinliang, Hu Yongjun, Zeng Caiyou, et al. Microstructure and mechanical properties of welded joints of TA17 Ti alloy by magnetically controlled narrow-gap TIG welding[J]. Hot Working Technology, 2023, 52(9): 42 − 46. doi: 10.14158/j.cnki.1001-3814.20210612

[30] 江淑园, 陈焕明, 刘志凌. 磁控技术在焊接中的应用及进展[J]. 中国机械工程, 2002, 21: 82 − 85. doi: 10.3321/j.issn:1004-132X.2002.21.023 Jiang Shuyuan, Chen Huanming, Liu Zhiling. Application and progress of magnetic control technology in welding[J]. China Mechanical Engineering, 2002, 21: 82 − 85. doi: 10.3321/j.issn:1004-132X.2002.21.023

[31] Wang J, Sun Q, Feng J, et al. Characteristics of welding and arc pressure in TIG narrow gap welding using novel magnetic arc oscillation[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1-4): 1 − 8. doi: 10.1007/s00170-016-9235-7

[32] 张建晓, 雷万庆, 牛庆伟, 等. 窄间隙埋弧焊在厚壁加氢反应器中的应用[J]. 电焊机, 2006, 10: 63 − 66. doi: 10.3969/j.issn.1001-2303.2006.10.020 Zhang Jianxiao, Lei Wanqing, Niu Qingwei, et al. Application of narrow gap welding technique in thick-wall hydrogenation r eactor[J]. Electric Welding Machine, 2006, 10: 63 − 66. doi: 10.3969/j.issn.1001-2303.2006.10.020

[33] 林尚扬, 于丹, 于静伟. 压力容器焊接新技术及其应用[J]. 压力容器, 2009, 26(11): 1 − 6. Lin Shangyang, Yu Dan, Yu Jingwei. New welding technologies for pressure vessel manufacturing[J]. Pressure Vessel, 2009, 26(11): 1 − 6.

[34] 王春伟. 双丝窄间隙埋弧焊的应用现状[J]. 内燃机与配件, 2018, 19: 119 − 120. doi: 10.3969/j.issn.1674-957X.2018.19.056 Wang Chunwei. Application status of double-wire narrow-gap submerged arc welding[J]. Internal Combustion Engine and Accessories, 2018, 19: 119 − 120. doi: 10.3969/j.issn.1674-957X.2018.19.056

[35] 方荣超, 张军, 曾军河, 等. 35钢/Q355B钢窄间隙摆动激光填丝焊研究[J]. 中国激光, 2019, 49(16): 135 − 142. Fang Rongchao, Zhang Jun, Zeng Junhe, et al. Narrow gap wobble laser with filling wire for welding of 35 steel and Q355B steel[J]. Chinese Journal of Lasers, 2019, 49(16): 135 − 142.

[36] Phaoniam R, Shinozaki K, Yamamoto M, et al. Development of a highly efficient hot-wire laser hybrid process for narrow-gap welding - welding phenomena and their adequate conditions[J]. Welding in the World, 2013, 57(5): 607 − 613. doi: 10.1007/s40194-013-0055-1

[37] Ramakrishna R V S M, Amrutha P H S L R, Rashid R A R, et al. Narrow gap laser welding (NGLW) of structural steels—a technological review and future research recommendations[J]. The International Journal of Advanced Manufacturing Technology, 2020, 111(7-8): 1 − 24. doi: 10.1007/s00170-020-06269-8

[38] Kessler B , Dittrich D , Brenner B , et al. Extension of the process limits in laser beam welding of thick-walled components using the laser multi-pass narrow-gap welding (Laser-MPNG) on the example of the nickel-based material Alloy 617 occ[J]. Welding in the World, 2021, 65: 1359–1371

[39] Yang W, Xin J, Fang C, et al. Microstructure and mechanical properties of ultra-narrow gap laser weld joint of 100mm-thick SUS304 steel plates[J]. Journal of Materials Processing Technology, 2019, 265: 130 − 137. doi: 10.1016/j.jmatprotec.2018.10.017

[40] 邹吉鹏, 李连胜, 宫建锋, 等. 铝合金厚板激光扫描填丝焊接气孔抑制[J]. 焊接学报, 2019, 40(10): 43 − 47. Zou Jipeng, Li Shenglian, Gong Jianfeng, et al. Aluminum alloy thick plate laser scanning wire filling welding porosity suppression[J]. Transactions of the China Welding Institution, 2019, 40(10): 43 − 47.

[41] Steen W M. Arc augmented laser processing of materials[J]. Journal of Application Physics, 1980, 51(11): 5636 − 5641. doi: 10.1063/1.327560

[42] Diebold T P, Albright C E. Laser-GTA welding of aluminum alloy 5050[J]. welding Journal, 1984, 64(1): 18 − 24.

[43] Matsuda J, Utsumi A. TIG or MIG arc augmented laser welding of thick mild steel plate[J]. Journal of Materials Processing Technology, 2014, 214(11): 2417−2422.

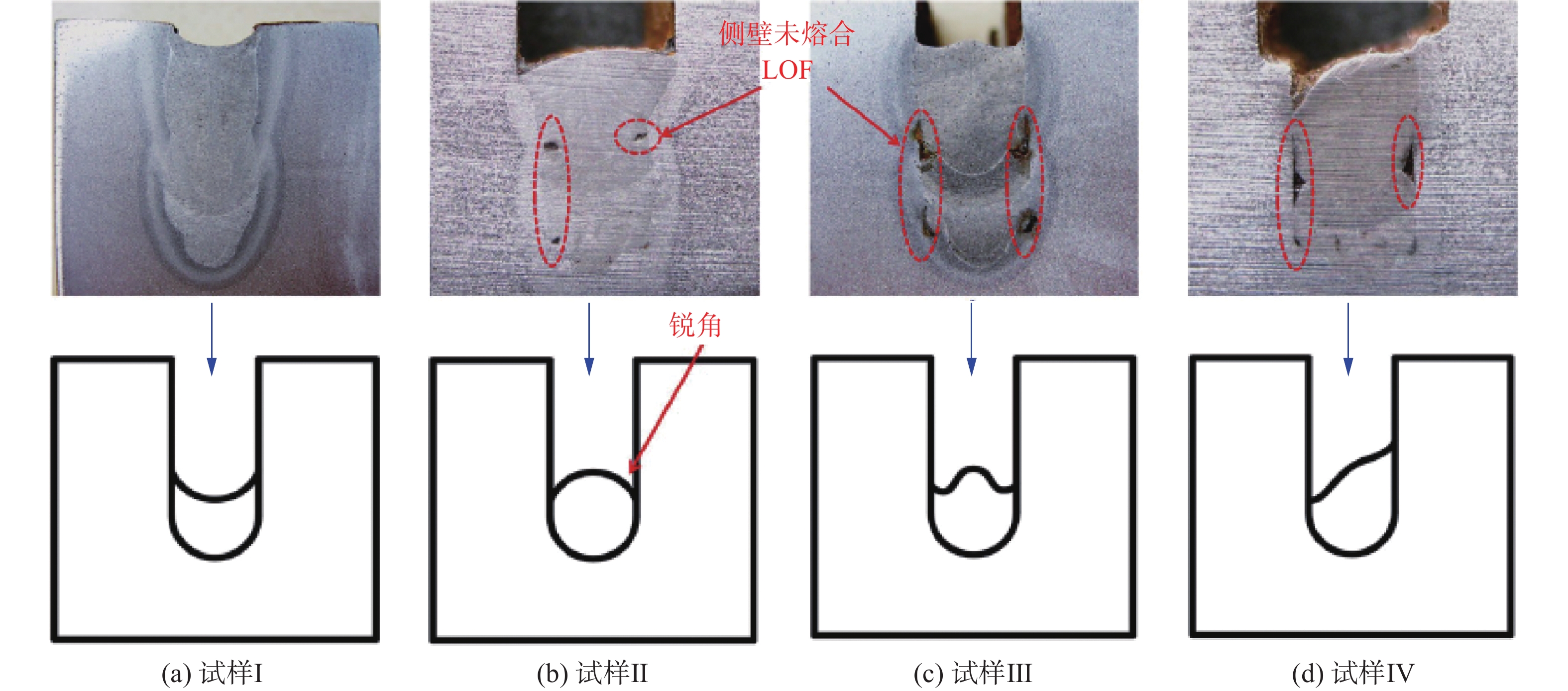

[44] Meng Yunfei, Li Geng, Gao Ming, et al. Formation and suppression mechanism of lack of fusion in narrow gap laser-arc hybrid welding[J]. The International Journal of Advanced Manufacturing Technology, 2019, 100: 2299 − 2309. doi: 10.1007/s00170-018-2851-7

[45] 滕彬, 张焱, 黄瑞生, 等. 一种窄间隙激光-TIG电弧复合焊接装置及焊接方法: 中国. CN202110664751.3[P]. 2021-09-14. Teng Bin, Zhang Yan, Huang Ruisheng, et al. A narrow gap laser-TIG arc composite welding device and welding method thereof: China. CN202110664751.3[P]. 2021-09-14.

[46] Shaga Chiaki, Ohta Akihiko, Hiraoka Kazuo, et al. Welding in research project on frontier structural materials[J]. Journal of the Japan Welding Society, 1997, 66(8): 43 − 48.

下载:

下载: