Effect of Ni interlayer on microstructure of aluminum/magnesium dissimilar metal friction stir welding joint

-

摘要: 采用搅拌摩擦焊(friction stir welding, FSW),引入厚度为0.05 mm镍箔作为中间层,在焊接速度不变条件下,采用不同转速对厚度为4 mm的6061铝合金和AZ31镁合金进行平板对接,对接头进行系列微观组织表征及力学性能测试,探讨转速对接头中镍颗粒分布状态,金属间化合物(intermetallic compounds, IMCs)种类与分布及接头强度的影响规律. 研究结果表明:与未引入中间层接头相比,引入镍改变了铝/镁异种金属FSW接头焊核区(weld nugget zone, WNZ)中IMCs种类及分布,WNZ存在明显的镁合金与铝合金相间的带状组织,其上分布着絮状Al12Mg17、颗粒状Mg2Ni、层状Al3Mg2及大小不一的镍箔颗粒;随着转速增加,镍箔颗粒分布愈加均匀,Al3Mg2数量相对减少,且脆性Al3Mg2由连续分布逐渐演变为断续分布;当转速为750 r/min时,接头抗拉强度达到最大值,与未引入中间层接头相比,引入镍中间层接头抗拉强度提高了56 MPa,达到镁合金的56.9%.Abstract: The flat butt welding tests were carried out on 6061 aluminum alloy and AZ31 magnesium alloy with the thickness of 4 mm by introducing 0.05 mm Ni foil interlayer under the condition of constant travel speed and different rotation speeds using the friction stir welding (FSW) technology. The effects of rotation speeds on the distribution of Ni foil particles, the types and distribution of the intermetallic compounds (IMCs) and the strength of the joints were investigated by series of microstructure characterization and mechanical property tests. The results showed that compared to the joint without Ni, the introduction of Ni foil interlayer changed the types and distribution of IMCs in the weld nugget zone (WNZ). In WNZ, there was an obvious banded structure between magnesium alloy and aluminum alloy on which the flocculent Al12Mg17, granular Mg2Ni, lamellar Al3Mg2, and Ni foil particles of varying sizes were distributed. With the increasing of rotation speed, the distribution of Ni became more uniform, while the Al3Mg2 decreased relatively, and the distribution of the brittle Al3Mg2 gradually changed from continuous to intermittent. The tensile strength of the joint reached the maximum value when the rotation speed was 750 r/min. Compared to the joint without Ni, the tensile strength of the joint with the introduction of Ni foil interlayer was increased by 56 MPa, which was 56.9% of the strength of magnesium alloy.

-

0. 序言

铝/镁复合结构具有密度低、比强度高以及电磁屏蔽效应等优点,广泛应用于航空航天、轨道交通等装备制造业领域[1-3]. 铝/镁异种金属焊接时,接头易形成脆性IMCs,严重降低接头力学性能,是铝/镁异种金属连接亟待解决的难题[4-5]. FSW属于固相连接技术,可有效避免铝/镁异种金属熔化焊时出现气孔、热裂纹及热影响区(heat affected zone, HAZ)软化等问题[6-8],同时可抑制接头中脆性IMCs的形成,在铝/镁异种金属连接方面最具发展潜力[9-10].

近年来,国内外众多学者对铝/镁异种金属FSW开展大量研究,主要集中在:一是优化焊接工艺,控制转速和焊接速度改善母材塑性流动行为进而改善接头微观组织;二是引入中间层元素,对接头中IMCs种类、数量及分布进行调控,进一步提高接头强度. 研究结果表明[11-13],优化工艺参数仍无法有效避免脆性Al-Mg系IMCs的生成. 因此,近年来,引入中间层元素成为铝/镁异种金属FSW研究领域的热点. Niu 等人[14]和Gan等人[15]研究了锌中间层对铝/镁异种金属FSW接头微观组织分布特征的影响,结果表明,引入锌中间层改变了IMCs种类,接头中弥散分布的Mg-Zn IMCs代替了脆性Al-Mg系IMCs,接头抗剪强度明显提高. Zheng等人[16]研究了锡中间层对铝/镁异种金属FSW搭接接头微观组织和力学性能的影响. 结果表明,含锡接头中生成了Mg2Sn,取代了Al-Mg系IMCs,接头最大断裂载荷达3.72 kN. Liu等人[17]探讨了锌中间层厚度对铝/镁FSW接头抗拉强度的影响规律,研究发现,当中间层厚度为0.05 mm时,接头中连续分布的Al-Mg系IMCs被Mg-Zn系IMCs和Al-Mg-Zn三元系共晶组织完全取代,接头抗拉强度最高.

文献[18]表明Ni在Al和Mg中具有相当大的溶解度,在640和506 ℃时分别发生共晶反应生成Al-Ni系和Mg-Ni系IMCs. 基于此,引入0.05 mm镍中间层,采用不同FSW焊接工艺参数对铝/镁异种金属进行平板对接,对接头进行系列微观组织表征及力学性能测试,探讨工艺参数对接头中镍分布状态、IMCs种类与分布及接头强度的影响规律.

1. 试验方法

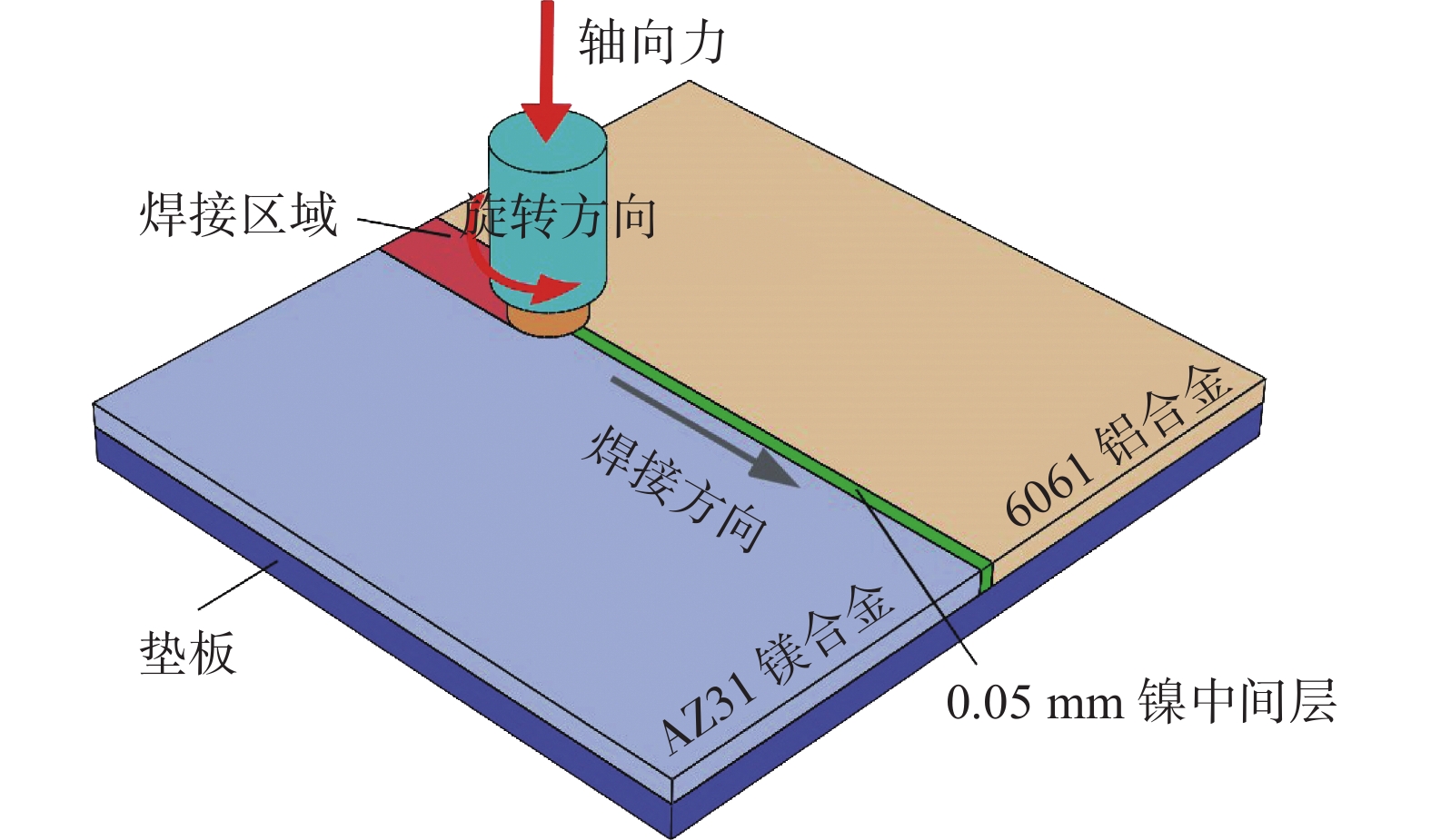

试验材料选用厚度为4 mm的AZ31镁合金和6061铝合金(供货状态T6),化学成分如表1所示. 焊件尺寸为280 mm × 150 mm × 4 mm,焊接方式为平板对焊,FSW装配示意图如图1所示. 搅拌针材质为H13钢,轴肩直径12 mm,根部直径5 mm,端部直径2 mm,针长3.7 mm. 镁合金置于前进侧,焊接工艺参数如表2所示. 金相试样用4%的硝酸酒精腐蚀镁侧10 s,用Keller试剂(6 mL HCl + 2.5 mL HNO3 + 1 mL HF)腐蚀铝侧90 s. 采用SU8010型扫描电镜(scanning electron microscope, SEM)对FSW接头微观组织进行分析,借助E1506-C2B型能谱仪(energy dispersive spectrometer, EDS)和D8 ADVANCE型X射线衍射仪(X-ray diffractometer, XRD)对接头中IMCs种类进行精确表征. 采用CMT5105型微机控制电子万能试验机对接头进行抗拉强度测试,拉伸速率为0.5 mm/min,为保证实验数据可靠性,每种焊接条件下制备了3组平行试样,测试结果取均值.

表 1 6061铝合金和AZ31镁合金的化学成分(质量分数,%)Table 1. Chemical compositions of 6061 aluminum alloys and AZ31 magnesium alloys材料 Si Fe Cu Mn Cr Zn Ti Ni Al Mg 6061 0.55 0.4 0.25 0.074 0.08 0.12 0.08 — 余量 0.8 AZ31 0.28 0.001 0.002 0.33 — 0.71 — 0.0005 2.8 余量 表 2 焊接工艺参数Table 2. Welding process parameters转速

n/(r·min−1)焊接速度

v/(mm·min−1)偏铝侧偏移量

d/mm下压量

h/mm倾角

α(°)450,550,650,

750,85020 0.3 0.2 2.5 2. 结果与讨论

2.1 引入镍中间层FSW接头微观组织

图2为不同转速下引入镍中间层铝/镁FSW接头WNZ微观组织形貌. 从图2可以看出,WNZ内母材发生明显的塑性流动而形成带状组织[19],转速不同,带状组织形貌不同.

当转速为450 r/min时,由于转速相对较低,热输入不足,致使母材塑性流动不充分,在WNZ内铝合金基体中分布着大量未完全破碎的片状镍箔颗粒,如图2a所示. 当转速增加到550 r/min时,母材塑性流动能力增强,大片状镍箔颗粒数量有所减少,且分布较为离散,如图2b所示. 转速增至850 r/min时,由于热输入过高,热塑性金属在搅拌针搅拌和轴肩挤压的双重作用下沿轴肩边缘溢出,使得WNZ内母材塑化体积减小,从而在该区域内形成了“隧道型空洞”[4].

在转速650和750 r/min时得到铝/镁异种金属FSW接头中WNZ微观组织上未观察到明显缺陷,形成了良好的机械互锁且镍元素分布较为均匀,如图2c和图2d所示. 从图2可以看出,随着转速增加,镍元素在WNZ内分布愈加均匀,但接头仍然存在片状镍箔颗粒. 相比转速650 r/min,转速为750 r/min的接头WNZ中带状组织机械互锁程度更高,而接头强度很大程度上取决于带状组织[20].

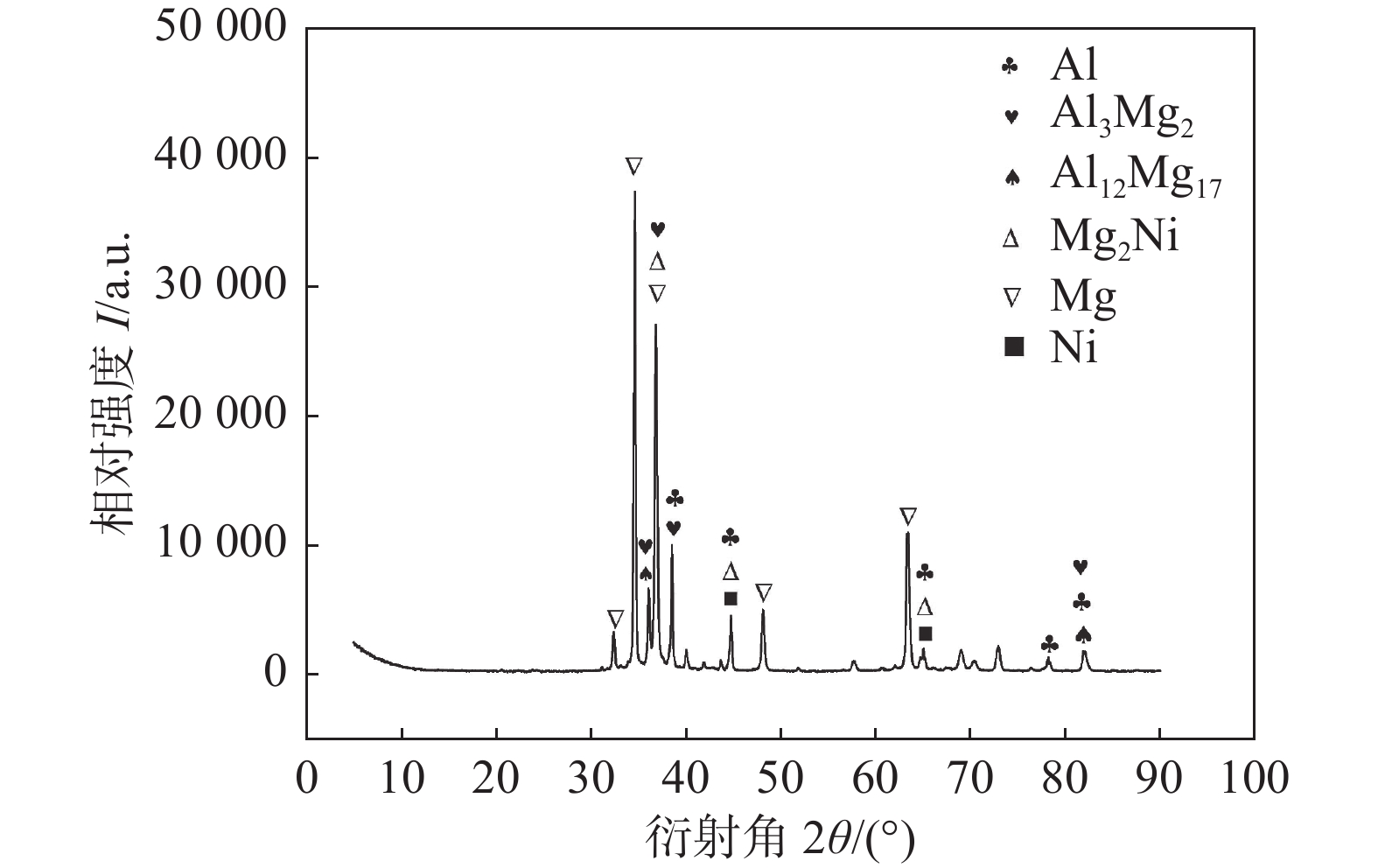

为进一步探明接头WNZ中带状组织的微观组织构成,对转速为750 r/min时接头WNZ微观组织进行SEM观察,如图3所示. 图3a为WNZ近镁侧边界处的微观组织形貌,图3b和图3c为相应的放大视图,可以看出,WNZ由呈明暗交替的黑色条带和白色IMCs所构成. 为确定IMCs种类,对接头WNZ进行XRD分析,结果如图4所示. 从图4可以看出,铝/镁异种金属FSW接头中IMCs主要为Al3Mg2,Al12Mg17及Mg2Ni,但未发现Al-Ni系IMCs. 这是由于Al-Ni系IMCs的最低生成温度约为640 ℃[21],高于铝/镁异种金属正常FSW工艺条件下的峰值温度,在焊接过程中难以形成所致.

为进一步确定接头中IMCs种类,选取图3所示5个位置,对WNZ典型IMCs进行了EDS分析,其EDS结果如表3所示. 由表3可知,白色絮状IMCs为Al12Mg17,颗粒状IMCs为Mg2Ni,灰色层状IMCs为Al3Mg2. 综上所示,镍中间层可以改变铝/镁异种金属FSW接头IMCs种类,生成颗粒状Mg2Ni抑制脆性层状Al3Mg2的形成.

表 3 WNZ内典型IMCs EDS分析结果(原子分数,%)Table 3. EDS results of typical IMCs in WNZ位置 Al Mg Ni 相 1 57.52 42.28 0.20 Al3Mg2 2 56.29 42.60 1.11 Al3Mg2 3 3.02 96.52 0.46 Mg基体 4 35.27 64.62 0.11 Al12Mg17 + Mg 5 2.16 92.47 5.37 Mg2Ni + Mg 图5为不同焊接工艺参数下铝/镁异种金属FSW接头WNZ微观组织形貌. 当转速为450 r/min时,大量镁合金条带在搅拌针的作用下沉积于WNZ底部,降低了母材的冶金结合. 当转速增加至550 r/min时,接头冶金结合效果明显改善,但大量脆性层状Al3Mg2呈长而直形态连续分布于近镁合金侧热力影响区(thermo mechanical affected zone, TMAZ)和WNZ边界处,如图5b所示. 由于Al3Mg2具有较大的室温脆性[22],在拉伸加载过程中裂纹往往于此处萌生扩展. 此外,当转速增加到650和750 r/min时,脆性层状Al3Mg2数量显著减少,且其连续分布状态得到明显改善,在WNZ内呈断续分布,如图5c和图5d所示. 由于Mg2Ni先于Al3Mg2形成[23],而Ni在WNZ内的均匀分布,促进了Mg和Ni的结合,从而抑制了脆性层状Al3Mg2的形成.

2.2 引入镍中间层FSW接头力学性能

图6为不同转速下引入镍中间层铝/镁异种金属FSW接头工程应力—应变曲线和抗拉强度. 从图6可以看出,随着转速增加,接头抗拉强度先增大后减小,当转速为750 r/min时,接头抗拉强度达到最大值121 MPa. 在较低转速下,由于材料混合不充分,致使WNZ出现“隧道型空洞”,降低了接头冶金结合效果. 在拉伸过程中,缺陷边缘处存在应力集中,严重影响接头强度. 此外,由图5b可知,在近镁合金侧TMAZ和WNZ边界处存在大量连续分布的脆性层状Al3Mg2,为裂纹的萌生和扩展提供了有利场所,加速了接头断裂失效,所以其抗拉强度较低,如图6b所示. 而在转速650 r/min下得到的FSW接头,虽无任何明显缺陷且脆性Al3Mg2数量及分布状态得到显著改善,但由于在其WNZ内存在较大体积未发生冶金反应的铝合金条带(图2c),一定程度上阻碍了母材的有效结合,机械互锁效应减弱,使得拉伸加载过程中相邻区域变形不协调,产生应力集中,加速裂纹的萌生和扩展.

当转速增加至850 r/min时,热塑性变形金属以“飞边”形式于轴肩边缘溢出,使得其在WNZ形成了“隧道型空洞”缺陷,严重降低接头强度. 而当转速为750 r/min时,接头WNZ组织均匀致密,形成了良好的机械互锁,镍的分布更加均匀,有效抑制了脆性层状Al3Mg2的生成,且断续的Al3Mg2在WNZ内呈弥散分布,显著增加了裂纹扩展阻力,因而其具有最高抗拉强度,达到镁合金的56.9%.

2.3 未引入镍中间层FSW接头组织和力学性能

图7为转速750 r/min、焊接速度20 mm/min下铝/镁异种金属FSW接头WNZ微观组织形貌. 从图7可以看出,未引入镍中间层接头WNZ存在大量呈长而直形态连续分布的脆性层状Al3Mg2,在拉伸加载过程中裂纹往往形核于此,并依附于脆性IMCs迅速扩展,严重降低接头强度,接头抗拉强度仅65 MPa,如图6b所示. 而引入镍中间层接头WNZ内Al3Mg2含量显著减少,且多为断续形态弥散分布于WNZ内,增大了裂纹扩展阻力. 此外,由于Mg-Ni系IMCs较于Al-Mg系IMCs具有较低的脆硬性[24],因而其接头强度较高.

3. 结论

(1) 与未引入中间层接头相比,引入镍改变了铝/镁异种金属FSW接头WNZ中IMCs种类及分布,WNZ存在明显的镁合金与铝合金相间的带状组织,其上分布着絮状Al12Mg17、颗粒状Mg2Ni、层状Al3Mg2及大小不一的镍箔颗粒.随着转速增加,镍箔颗粒分布愈加均匀,Al3Mg2数量相对减少,且脆性Al3Mg2由连续分布逐渐演变为断续分布.

(2) 当转速为750 r/min时,接头抗拉强度达到最大值,与未引入中间层接头相比,引入镍中间层接头抗拉强度提高了56 MPa,达到镁合金的56.9%.

-

表 1 6061铝合金和AZ31镁合金的化学成分(质量分数,%)

Table 1 Chemical compositions of 6061 aluminum alloys and AZ31 magnesium alloys

材料 Si Fe Cu Mn Cr Zn Ti Ni Al Mg 6061 0.55 0.4 0.25 0.074 0.08 0.12 0.08 — 余量 0.8 AZ31 0.28 0.001 0.002 0.33 — 0.71 — 0.0005 2.8 余量 表 2 焊接工艺参数

Table 2 Welding process parameters

转速

n/(r·min−1)焊接速度

v/(mm·min−1)偏铝侧偏移量

d/mm下压量

h/mm倾角

α(°)450,550,650,

750,85020 0.3 0.2 2.5 表 3 WNZ内典型IMCs EDS分析结果(原子分数,%)

Table 3 EDS results of typical IMCs in WNZ

位置 Al Mg Ni 相 1 57.52 42.28 0.20 Al3Mg2 2 56.29 42.60 1.11 Al3Mg2 3 3.02 96.52 0.46 Mg基体 4 35.27 64.62 0.11 Al12Mg17 + Mg 5 2.16 92.47 5.37 Mg2Ni + Mg -

[1] Zhao Y, Lu Z P, Yan K, et al. Microstructural characterizations and mechanical properties in underwater friction stir welding of aluminum and magnesium dissimilar alloys[J]. Materials & Design, 2015, 65: 675 − 681.

[2] 陈影, 沈长斌, 葛继平. Mg/Al异种金属焊接的研究现状[J]. ·稀有金属材料与工程, 2012, 41(supplement 2): 109 − 11. Chen Ying, Shen Changbin, Ge Jiping. Research progress on the welding of Mg/Al dissimilar metals[J]. Rare Metal Materials and Engineering, 2012, 41(supplement 2): 109 − 11.

[3] Dorbane A, Mansoor B, Ayoub G, et al. Mechanical, microstructural and fracture properties of dissimilar welds produced by friction stir welding of AZ31B and Al6061[J]. Materials Science & Engineering A, 2015, 650: 720 − 733.

[4] Rao H M, Ghaffari B, Yuan W, et al. Effect of process parameters on microstructure and mechanical behaviors of friction stir linear welded aluminum to magnesium[J]. Materials Science & Engineering A, 2016, 651: 27 − 36.

[5] Fu B L, Qin G L, Li F. Friction stir welding process of dissimilar metals of 6061-T6 aluminum alloy to AZ31B magnesium alloy[J]. Journal of Materials Processing Technology, 2015, 218: 38 − 47. doi: 10.1016/j.jmatprotec.2014.11.039

[6] Mo S X, Dong S K, Zhu H, et al. Corrosion behavior of aluminum/steel dissimilar metals friction stir welding joint[J]. China Welding, 2021, 30(3): 20 − 30.

[7] 许志武, 李政玮, 冯艳, 等. 静轴肩辅助铝镁搅拌摩搭接接头的组织与性能[J]. 焊接学报, 2017, 38(4): 1 − 6. Xu Zhiwu, Li Zhengwei, Feng Yan, et al. Microstructure and mechanical properties of Mg/Al friction stir lap welding joint assisted by stationary shoulder[J]. Transactions of the China Welding Institution, 2017, 38(4): 1 − 6.

[8] 李达, 孙明辉, 崔占全. 工艺参数对铝镁搅拌摩擦焊焊缝成形质量的影响[J]. 焊接学报, 2011, 32(8): 97 − 100. Li Da, Sun Minghui, Cui Zhanquan. Effect of parameters on friction stir welding joint of Al and Mg[J]. Transactions of the China Welding Institution, 2011, 32(8): 97 − 100.

[9] Verma J, Taiwade R V, Reddy C, et al. Effect of friction stir welding process parameters on Mg-AZ31B/Al-AA6061 joints[J]. Materials and Manufacturing Processes, 2018, 33(3): 308 − 314. doi: 10.1080/10426914.2017.1291957

[10] Sachin K, Wu C S. Suppression of intermetallic reaction layer by ultrasonic assistance during friction stir welding of Al and Mg based alloys[J]. Journal of Alloys and Compounds, 2020, 827: 154343. doi: 10.1016/j.jallcom.2020.154343

[11] Boccarusso L, Astarita A, Carlone P, et al. Dissimilar friction stir lap welding of AA 6082-Mg AZ31: Force analysis and microstructure evolution[J]. Journal of Manufacturing Processes, 2019, 44: 376 − 388. doi: 10.1016/j.jmapro.2019.06.022

[12] Sun T, Wu S Y, Shen Y F, et al. Effect of traverse speed on the defect characteristic, microstructure, and mechanical property of friction stir welded T-joints of dissimilar Mg/Al alloy[J]. Advances in Materials Science and Engineering, 2020, 2020(3): 1 − 15.

[13] Bandi A, Bakshi S R. Effect of pin length and rotation speed on the microstructure and mechanical properties of friction stir welded lap joints of AZ31B-H24 Mg alloy and AA6061-T6 Al alloy[J]. Metallurgical and Materials Transactions A, 2020, 51(12): 6269 − 6282. doi: 10.1007/s11661-020-06020-8

[14] Niu S Y, Ji S D, Yan D J, et al. AZ31B/7075-T6 alloys friction stir lap welding with a zinc interlayer[J]. Journal of Materials Processing Technology, 2019, 263: 82 − 90. doi: 10.1016/j.jmatprotec.2018.08.009

[15] Gan R G, Jin Y H. Friction stir-induced brazing of Al/Mg lap joints with and without Zn interlayer[J]. Science and Technology of Welding and Joining, 2018, 23(2): 164 − 171. doi: 10.1080/13621718.2017.1354545

[16] Zheng B, Zhao L, Lv Q Q, et al. Effect of Sn interlayer on mechanical properties and microstructure in Al/Mg friction stir lap welding with different rotational speeds[J]. Materials Research Express, 2020, 7(7): 076504. doi: 10.1088/2053-1591/ab9fbb

[17] Liu J L, Niu S Y, Ren R, et al. Improving joint morphologies and tensile strength of Al/Mg dissimilar alloys friction stir lap welding by changing zn interlayer thickness[J]. Acta Metallurgica Sinica (English Letters), 2019, 32(11): 1385 − 1395. doi: 10.1007/s40195-019-00937-9

[18] Zhang J, Luo G Q, Wang Y Y, et al. An investigation on diffusion bonding of aluminum and magnesium using a Ni interlayer[J]. Materials Letters, 2012, 83: 189 − 191. doi: 10.1016/j.matlet.2012.06.014

[19] Shi H, Chen K, Liang Z Y, et al. Intermetallic compounds in the banded structure and their effect on mechanical properties of Al/Mg dissimilar friction stir welding joints[J]. Journal of Materials Science and Technology, 2017, 33(4): 359 − 366. doi: 10.1016/j.jmst.2016.05.006

[20] 朱浩, 张二龙, 莫淑娴, 等. 带状组织对铝/镁异种金属搅拌摩擦焊接头力学性能的影响[J]. 焊接学报, 2020, 41(1): 34 − 38,66. Zhu Hao, Zhang Erlong, Mo Shuxian, et al. Effect of banded structure on mechanical properties of aluminum/magnesium dissimilar metal friction stir welding joint[J]. Transactions of the China Welding Institution, 2020, 41(1): 34 − 38,66.

[21] Dupin N, Ansara I, Sundman B. Thermodynamic re-assessment of the ternary system Al-Cr-Ni[J]. Calphad, 2001, 25(2): 279 − 298. doi: 10.1016/S0364-5916(01)00049-9

[22] Peng P, Wang W, Zhang T, et al. Effects of interlayer metal on microstructures and mechanical properties of friction stir lap welded dissimilar joints of magnesium and aluminum alloys[J]. Journal of Materials Processing Technology, 2021, 299: 117362.

[23] Hajjari E, Divandari M, Razavi S H, et al. Dissimilar joining of Al/Mg light metals by compound casting process[J]. Journal of Materials Science, 2011, 46(20): 6491 − 6499. doi: 10.1007/s10853-011-5595-4

[24] Chang W S, Rajesh S R, Chun C K, et al. Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy[J]. Journal of Materials Science and Technology, 2011, 27(3): 199 − 204. doi: 10.1016/S1005-0302(11)60049-2

-

期刊类型引用(3)

1. 陈书锦,何亚斌,徐洋,田雄文,赵浩钰. 中间层对铝/镁搅拌摩擦焊界面组织与性能的影响. 焊接学报. 2025(02): 46-54 .  本站查看

本站查看

2. Jian Zhang,Huan Li,Shiying Wu. Research progress of aluminum and magnesium ultrasonic welding. China Welding. 2025(01): 74-84 .  必应学术

必应学术

3. 雷声,崔召杰,李云,张海浪,方继根,张翔. WE43/Zn/1060异种金属搅拌摩擦焊接头组织及性能研究. 兵器材料科学与工程. 2024(02): 64-69 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: