Detection of weld defects based on FGT - FBP reconstruction algorithm

-

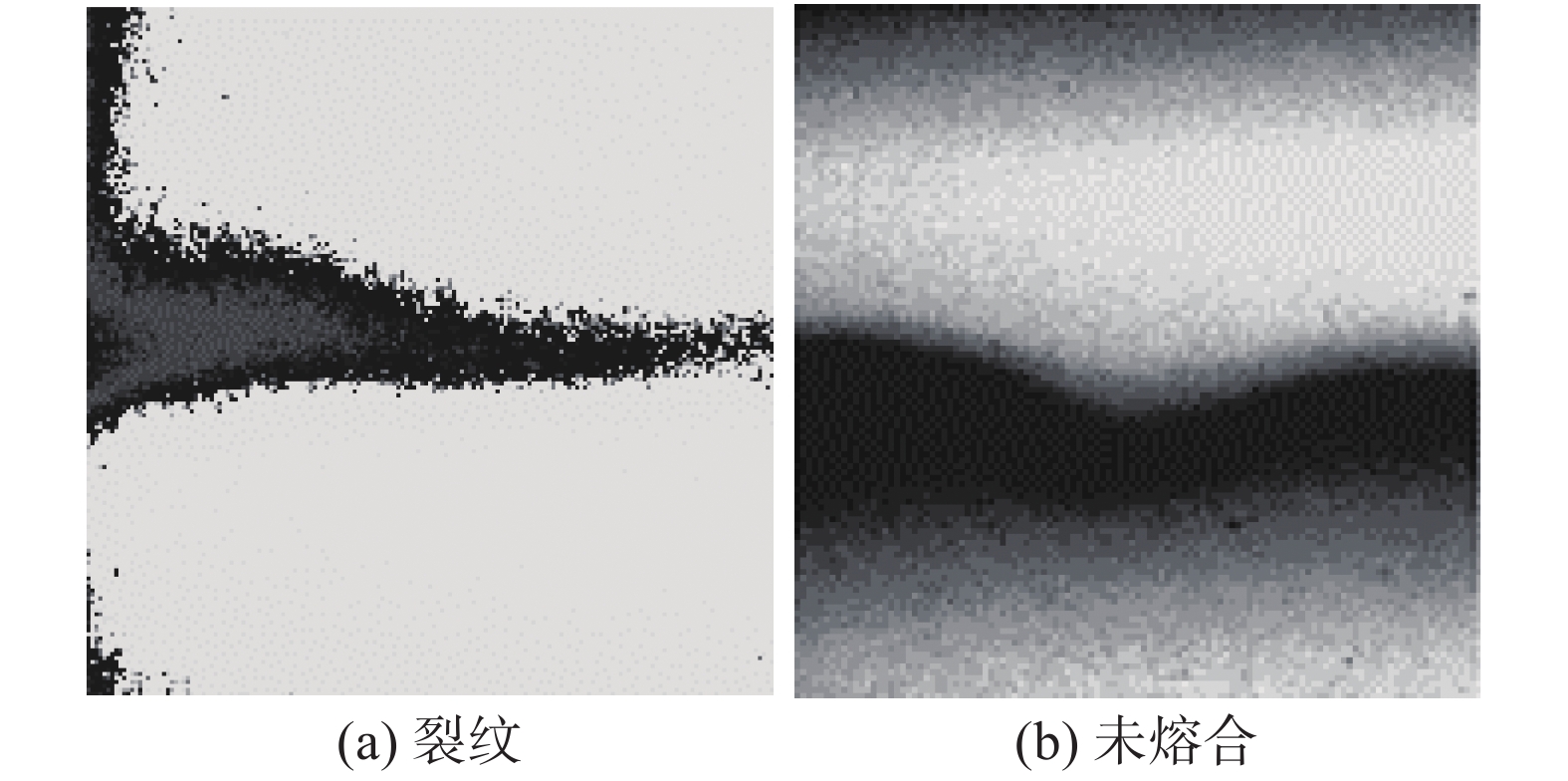

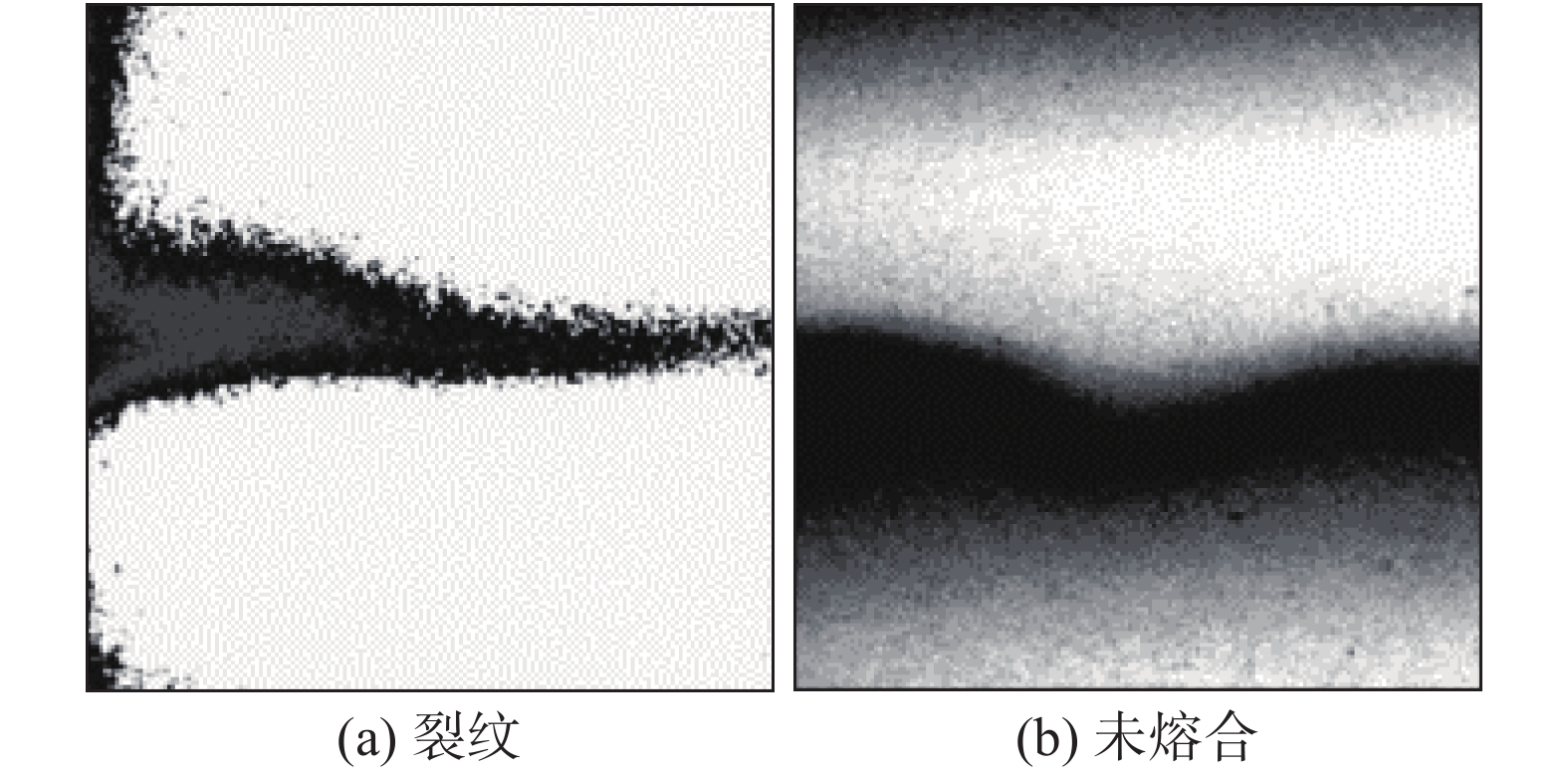

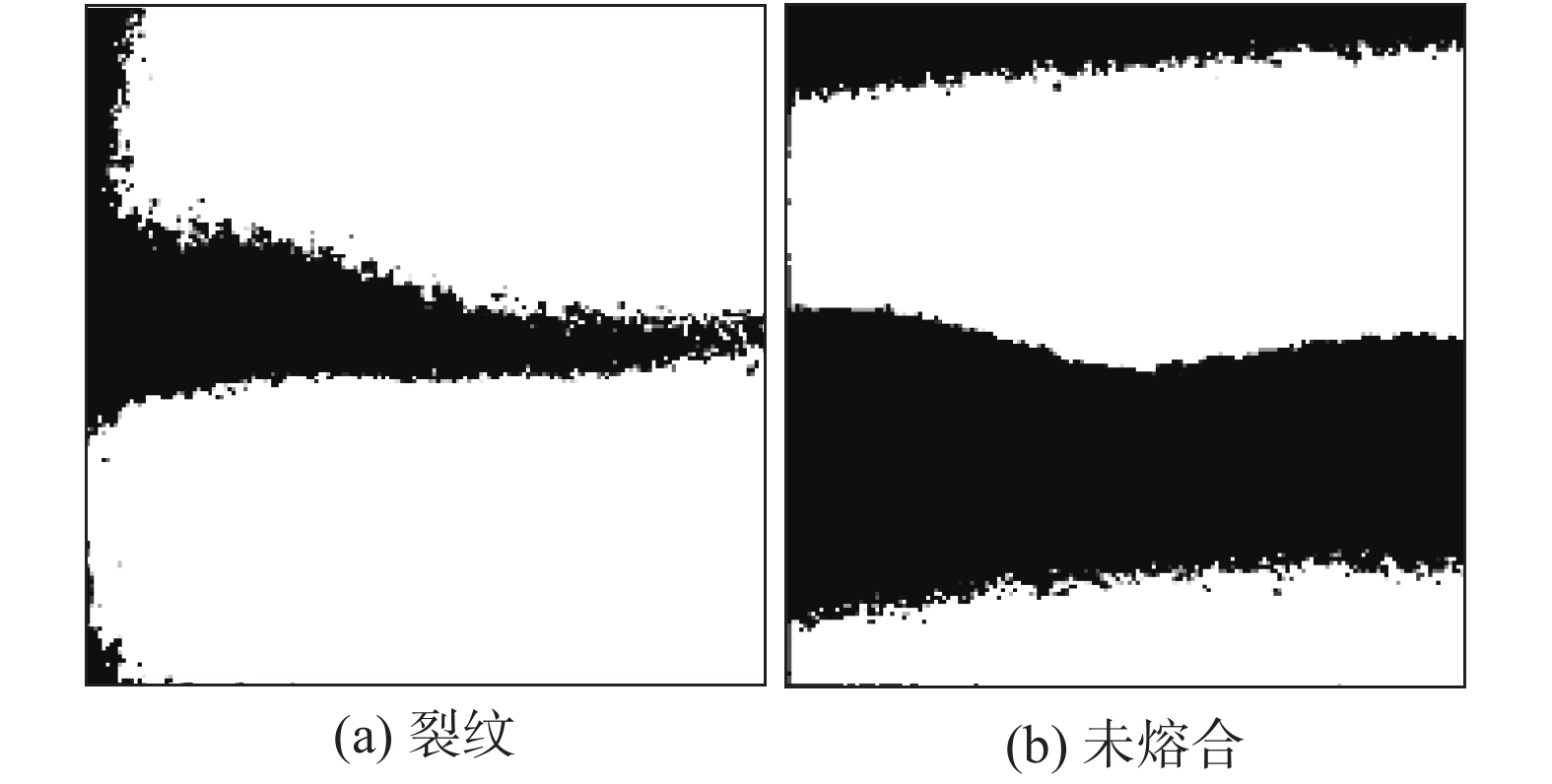

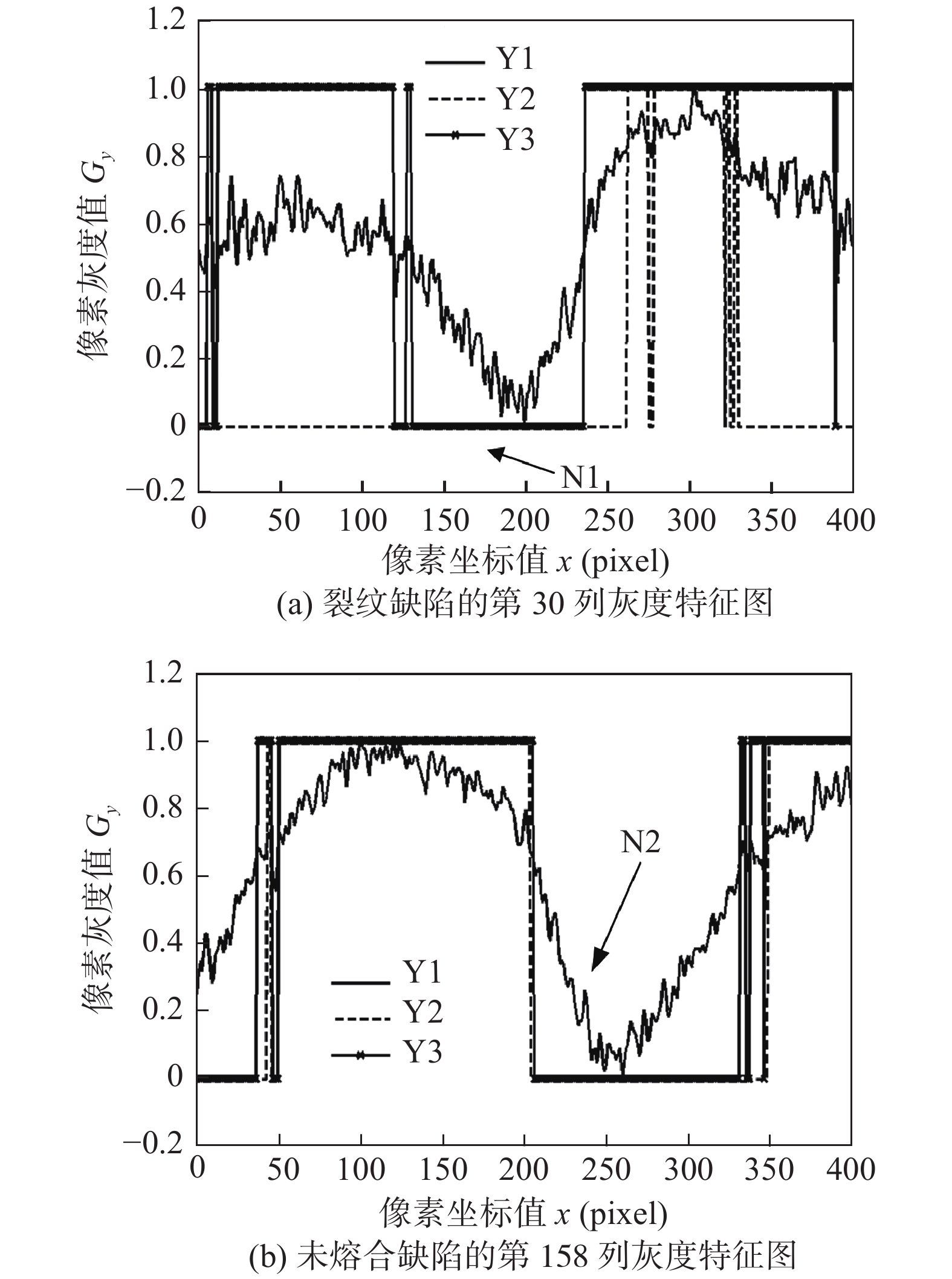

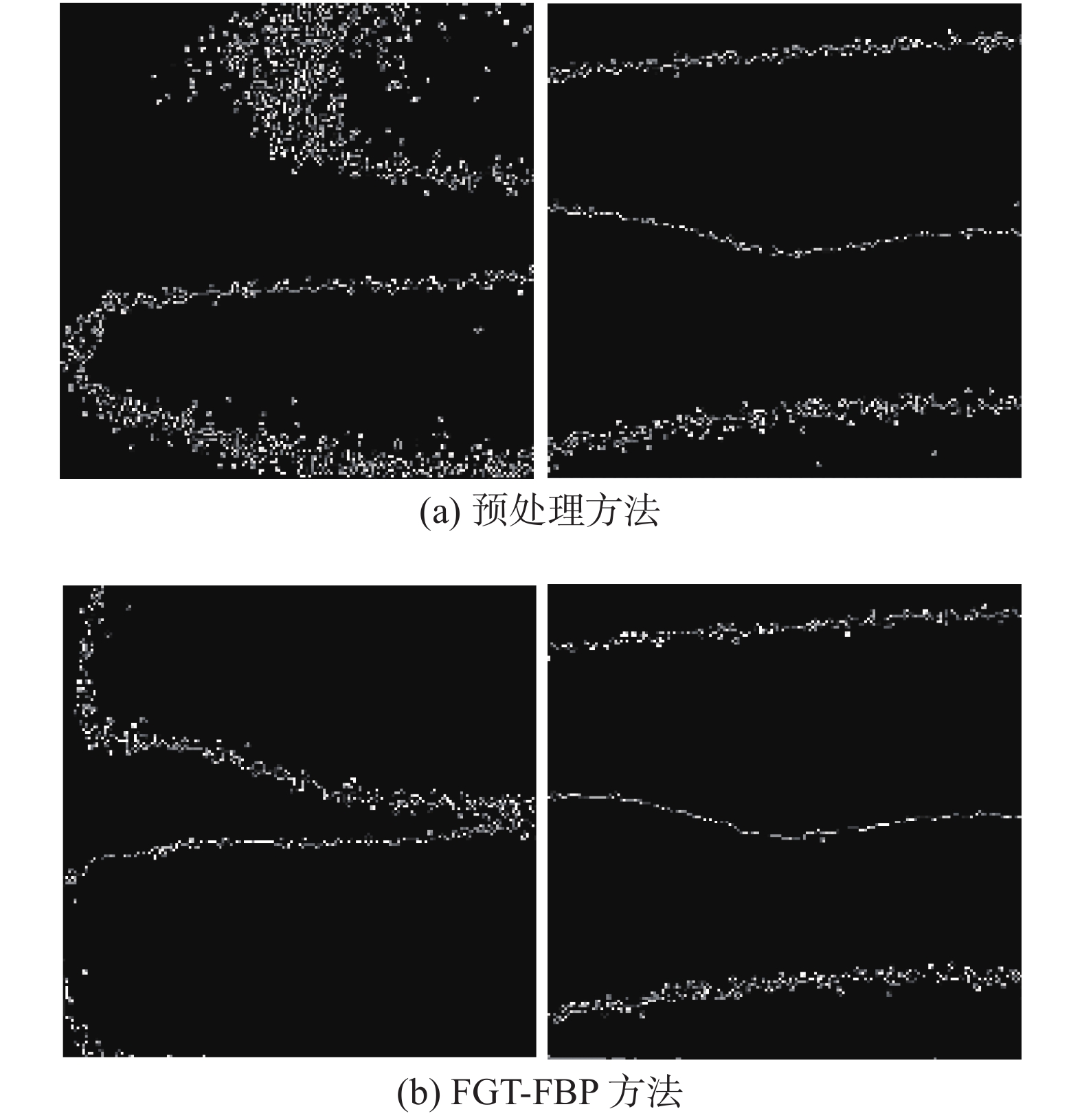

摘要: 针对焊接过程产生的缺陷,提出一种磁光成像传感的模糊灰度变换和滤波反投影(FGT-FBP)重构检测方法. 研究焊接缺陷的几何特征,通过分析裂纹和未熔合两种不同焊接缺陷在交变磁场励磁下的磁光成像特征,设计模糊规则,对磁光图像进行模糊灰度变换. 增强磁光图像对比度,使焊接缺陷形态趋势可视化,实现描述磁光成像焊接缺陷细节的无参考型图像评估方法. 对FGT处理的焊接缺陷磁光图进行旋转投影,并经过快速傅里叶变换和改进的滤波器进行滤波去噪,消除伪影后进行反投影变换实现焊接缺陷图像的重构. 利用滤波反投影重构算法进行去噪,可有效突出焊接缺陷特征. 最后结合阈值分割和边缘检测实现焊接缺陷检测. 结果表明,该方法能较准确检测裂纹和未熔合两种焊接缺陷.Abstract: An innovative detection method based upon fuzzy gray scale transformation and filter back-projection (FGT-FBP) reconstruction is proposed to study the geometrical characteristics of weld defects. By analyzing the characteristics of magneto-optical images with defects such as cracks and incomplete penetration under alternating magnetic field excitation, a fuzzy rule is designed to carry on fuzzy gray scale transformation of the magneto-optical image. The image contrast is improved to visualize the configuration and trend of weld defects. An image evaluation method without reference models that describes weld defect details of magneto-optical images is realized. The weld defect magneto-optical images processed by FGT are rotated and projected. Fast Fourier transform and improved filter are applied for denoising and filtering. Also, the back-projection transform is used to reconstruct weld defect images after eliminate artifacts. Then FGT-FBP is used to denoise by filtering, and extract defect features from the images. Finally, the proposed method is combined threshold segmentation with edge detection to achieve defect detection. Experiment results show that FGT-FBP reconstruction algorithm can detect weld defects such as cracks and incomplete penetration accurately.

-

-

表 1 激光焊接工艺试验参数

Table 1 Experimental parameters of laser welding

缺陷

种类峰值功率

P/kW焊接速度

v/(mm·s−1)脉宽

S/mm气体流量

q/(L·min−1)裂纹 1 2 10 15 未熔合 2.5 2.5 6 15 表 2 图像的灰度平均梯度

Table 2 Gray mean gradient of the image

类别 裂纹 未熔合 直方图均衡化 0.037 7 0.023 3 模糊灰度变换 0.074 4 0.023 5 表 3 磁光图像的信噪比

Table 3 Signal to noise ratio of the magneto-optical image

处理类别 裂纹 未熔合 预处理 1.650 7 2.104 5 FGT 5.538 1 2.870 6 FGT-FBP 5.539 2 2.881 6 -

[1] Zhang Y X, You D Y, Gao X D, et al. Welding defects detection based on deep learning with multiple optical sensors during disk laser welding of thick plates[J]. Journal of Manufacturing Systems, 2019, 51: 87 − 94. doi: 10.1016/j.jmsy.2019.02.004

[2] Chen Y Q, Gao X D, Xiao Z L, et al. Experimental study of weld position detection based on keyhole infrared image during high power fiber laser welding[J]. China Welding, 2015, 24(3): 45 − 51.

[3] Wang J J, Fu P L, Gao R X. Machine vision intelligence for product defect inspection based on deep learning and Hough transform[J]. Journal of Manufacturing Systems, 2019, 51: 52 − 60. doi: 10.1016/j.jmsy.2019.03.002

[4] Bernieri A, Ferrigno L, Laracca M, et al. Ultrasonic NDT on aluminum bars: an experimental performance comparison of excitation and processing techniques[J]. Measurement, 2018, 128: 393 − 402. doi: 10.1016/j.measurement.2017.10.040

[5] Ai Y, Jiang P, Wang C, et al. Investigation of the humping formation in the high power and high speed laser welding[J]. Optics and Lasers in Engineering, 2018, 107: 102 − 111. doi: 10.1016/j.optlaseng.2018.03.010

[6] Li E, Kang Y, Tang J. A new micro magnetic bridge probe in magnetic flux leakage for detecting micro-cracks[J]. Journal of Nondestructive Evaluation, 2018, 37(3): 46:1 − 9.

[7] Gao X D, Lan C Z, You D Y, et al. Weldment nondestructive testing using magneto-optical imaging induced by alternating magnetic field[J]. Journal of Nondestructive Evaluation, 2017, 36(3): 55:1 − 11.

[8] Gao X D, Ma N J, Du L L. Magneto-optical imaging characteristics of weld defects under alternating magnetic field excitation[J]. Optics Express, 2018, 26(8): 9972 − 9983. doi: 10.1364/OE.26.009972

[9] Deng Y, Liu X, Udpa L. Magneto-optic imaging for aircraft skins inspection: a probability of detection study of simulated and experimental image data[J]. IEEE Transactions on Reliability, 2012, 61(4): 901 − 908. doi: 10.1109/TR.2012.2221613

[10] 刘习文, 陈显明, 刘超英. 基于拉东变换和模糊增强的结构光焊缝跟踪图像处理[J]. 焊接学报, 2017, 38(2): 19 − 22. Liu Xiwen, Chen Xianming, Liu Chaoying. Image processing in welding seam tracking with structure light based on radon transform and fuzzy-enhancement[J]. Transactions of the China Welding Institution, 2017, 38(2): 19 − 22.

[11] Pal S K, King R A. Image enhancement using smoothing with fuzzy sets[J]. IEEE Transactions on Systems Man & Cybernetics, 2007, 11(7): 494 − 501.

[12] Qu H Y, Xu F, Hu X F, et al. A novel denoising method based on Radon transform and filtered back-projection reconstruction algorithm[J]. Optics & Lasers in Engineering, 2012, 50(4): 593 − 598.

下载:

下载: