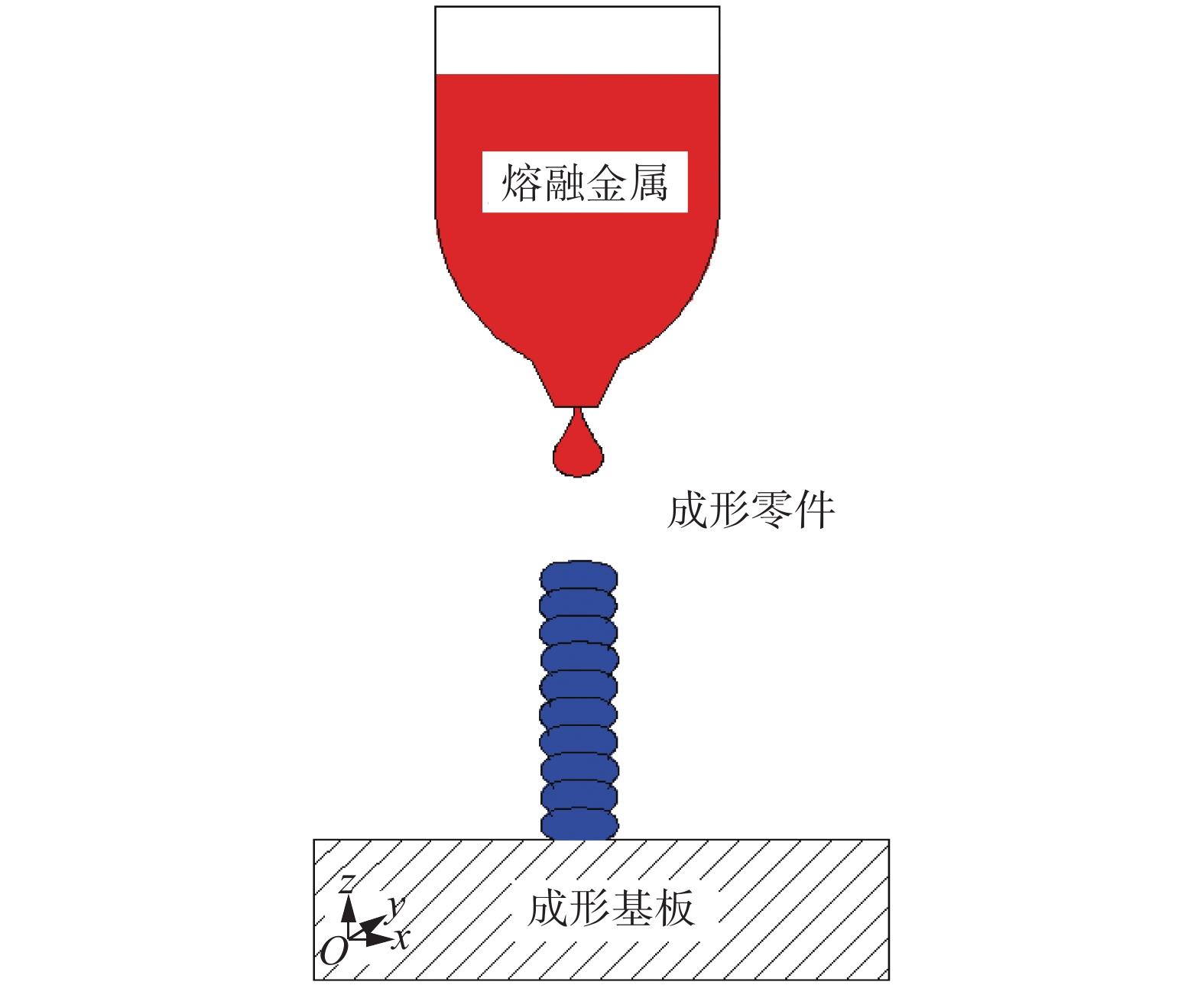

Process of metal droplet upright accumulation

-

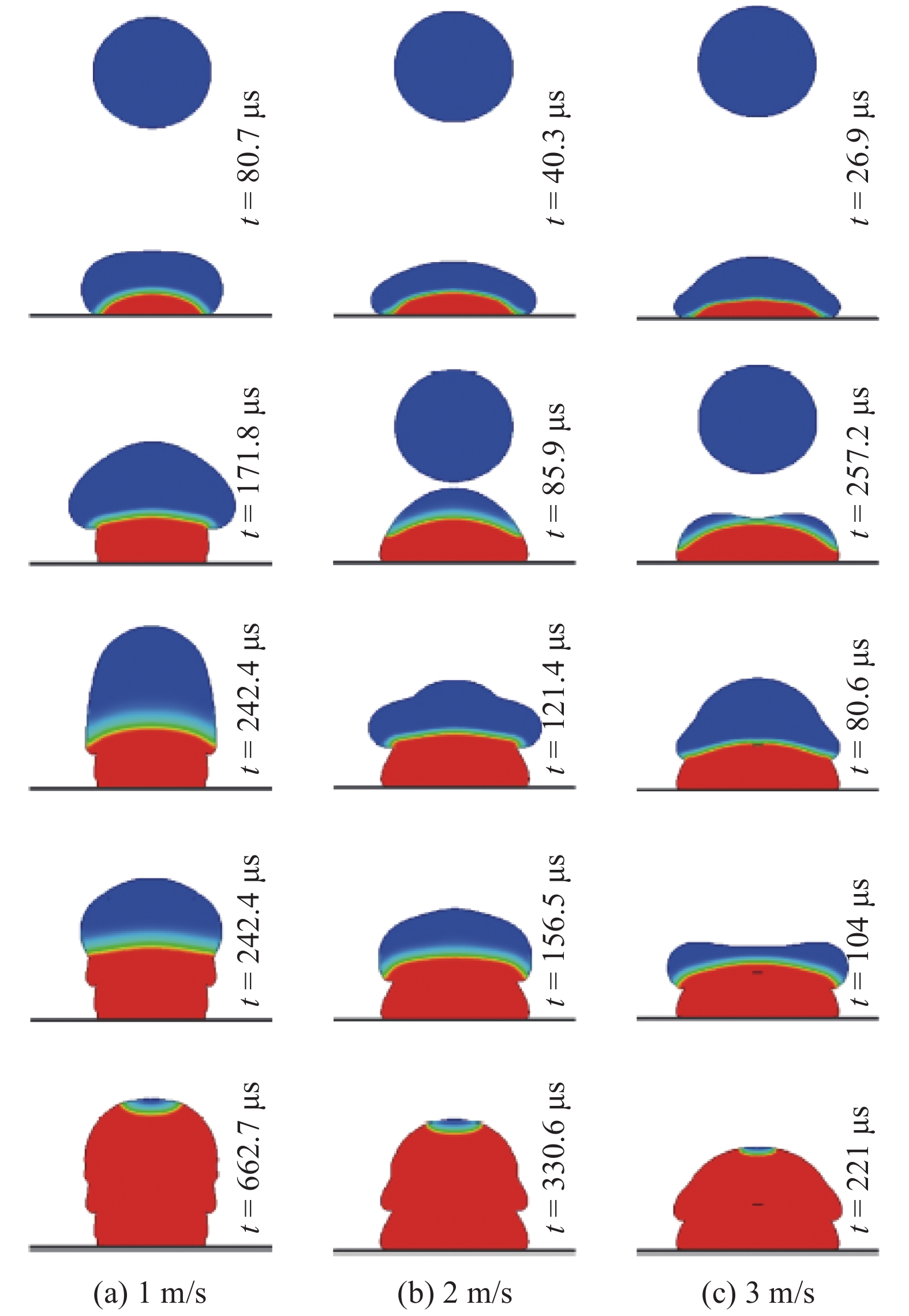

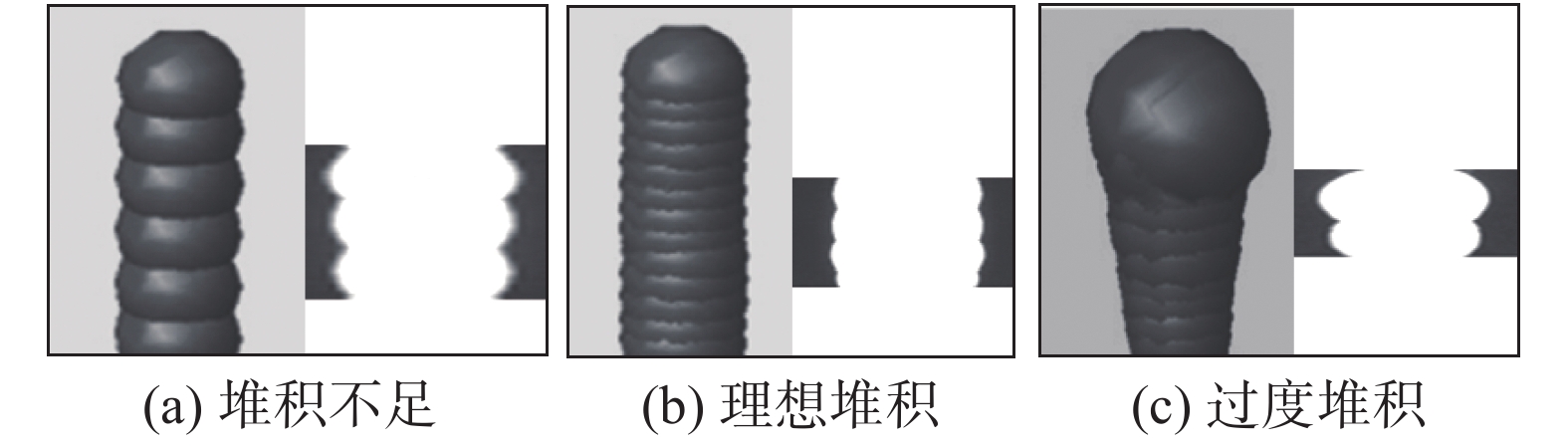

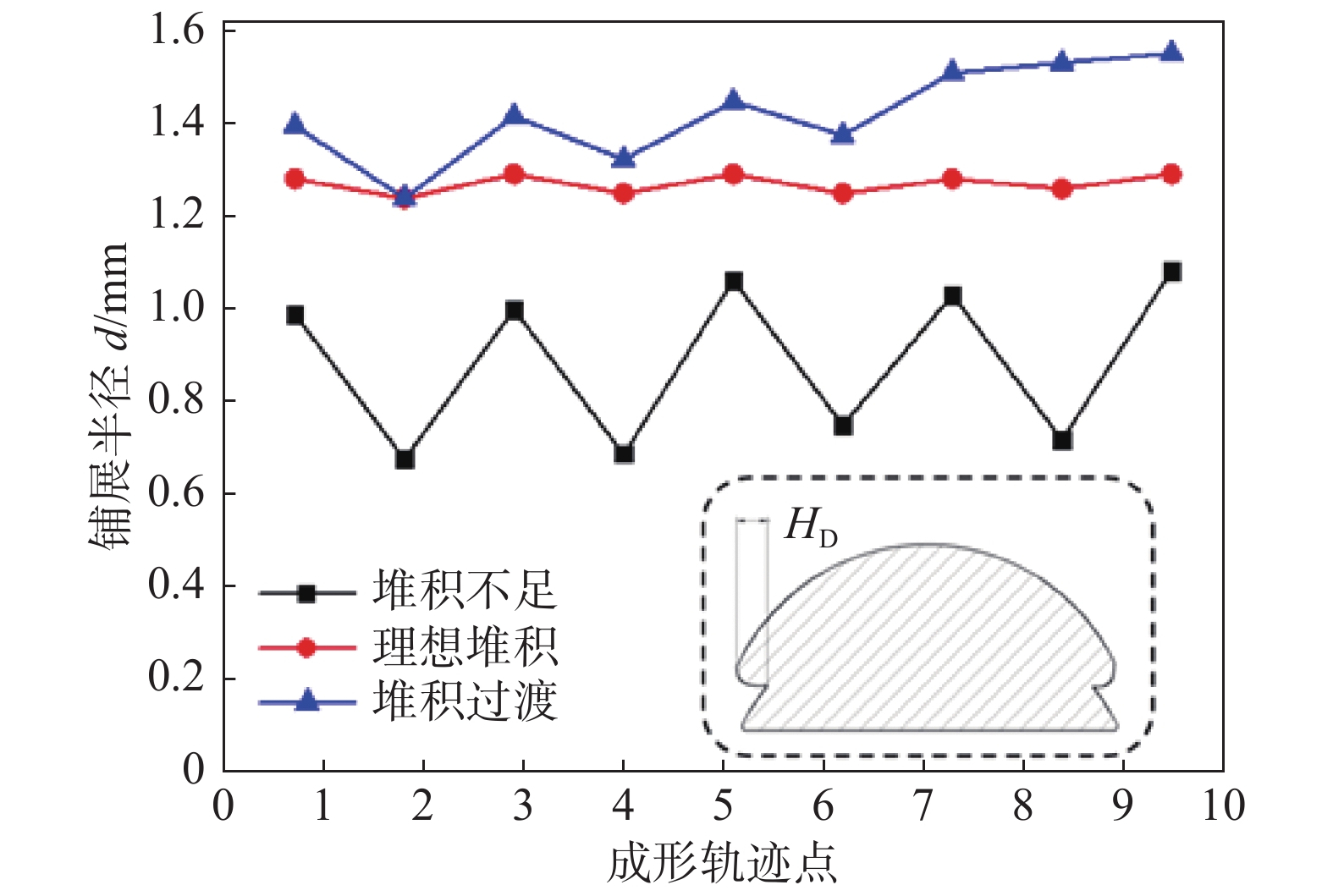

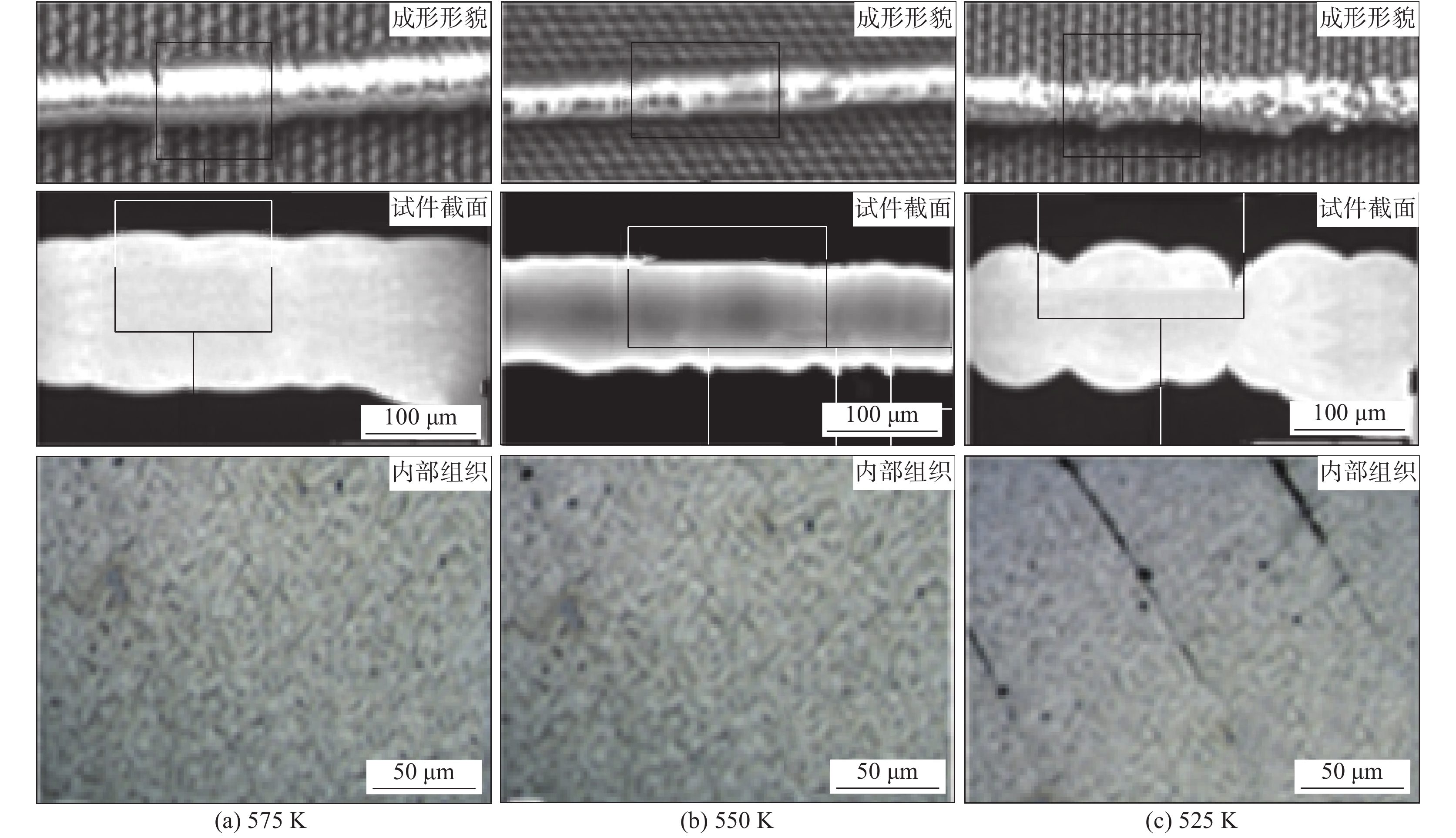

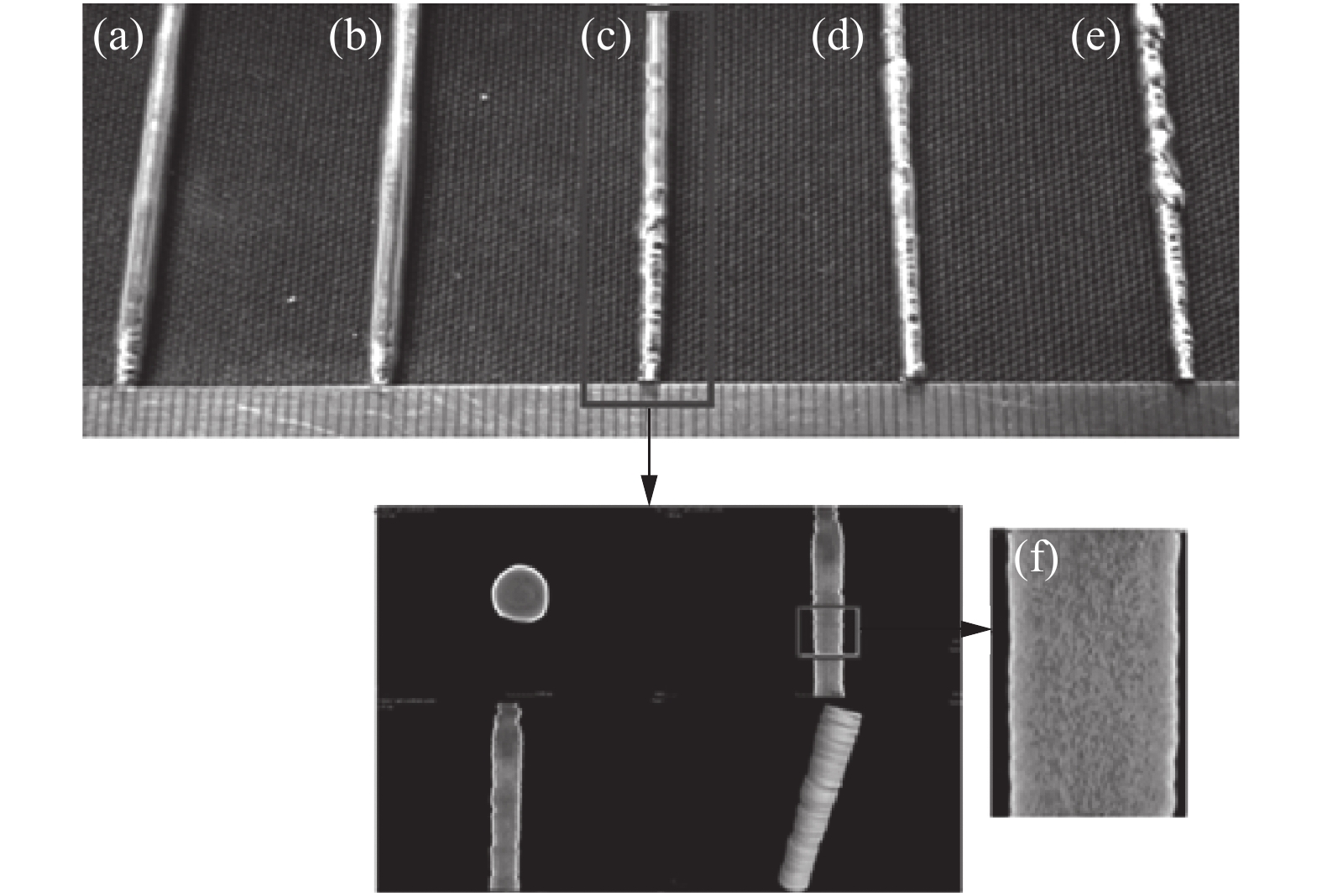

摘要: 通过对金属微液滴竖直堆积行为的研究,探索不同成形工艺参数下,金属微液滴竖直搭接堆积、铺展形貌的变化规律,采用有限元模拟与试验验证相结合的方法,揭示金属微液滴在较大的温度梯度及较小的成形空间下竖直搭接堆积成形过程中,熔体喷射、堆积、搭接相互影响机制机理. 结果表明,在金属微液滴竖直堆积过程中,熔体加热温度、基板与喷头的距离、扫描速度、扫描路径等工艺参数都会对成形零件的表面精度和内部质量产生很大影响,因此其工艺的匹配性研究对于提高金属微液滴堆积成形的3D打印零件精度和质量有很大的理论和实际指导意义.Abstract: The vertical stacking behavior of metal micro droplet was studied to explore the vertical stacking and spreading morphology of metal micro droplet under different forming process parameters. The method of finite element simulation and experimental verification was used to reveal the metal droplet vertical under large temperature gradient and small forming space The results showed that heating temperature, distance between substrate and nozzle, scanning speed, scanning path and other technological parameters will have a great impact on the surface accuracy and internal quality of the formed parts in the vertical stacking process of metal micro droplet. Therefore, the research on the matching of the technology is of great theoretical and practical significance for improving the precision and quality of 3D printing parts with metal droplet stacking.

-

Keywords:

- metal micro droplet /

- vertical lap /

- forming process /

- lap rate /

- flatness

-

-

表 1 堆积试验相关工艺参数

Table 1 Process parameters of sedimentary experiment

熔体温度Td/K 基板温度T/K 基板距离hs/mm 脉冲压力p/MPa 脉冲频率f/Hz 525,550,575 400 10 0.3 30 表 2 hs试验参数

Table 2 Parameters hs of the deposition experiment

熔体温度Td/K 基板温度T/K 基板距离hs/mm 脉冲压力p/MPa 脉冲频率f/Hz 550 400 25,20,15 0.3 30 表 3 不同参数组合试验

Table 3 Parameters of deposition experiment

序号 熔体温度Td/K 基板温度T/K 基板距离hs/mm 脉冲压力p /MPa 脉冲频率f/Hz (a) 550 400 10 0.3 30 (b) 520 400 15 0.3 30 (c) 500 400 20 0.3 30 (d) 480 400 22 0.3 30 (e) 475 400 25 0.3 30 -

[1] Li Suli, Wei Zhengying, Du Jun, et al. The fusion process of successive droplets impinging onto a substrate surface[J]. Journal of Appl. Phys. A, 2015, 120: 35 − 42. doi: 10.1007/s00339-015-9146-8

[2] 贾亚洲, 肖珺, 陈树君, 等. 2219铝合金激光驱动GMAW熔滴过渡行为[J]. 焊接学报, 2019, 40(3): 59 − 64. doi: 10.12073/j.hjxb.2019400012 Jia Yazhou, Xiao Jun, Chen Shujun, et al. laser driven GMAW droplet transition behavior of 2219 aluminum alloy[J]. Transactions of the China Welding Institution, 2019, 40(3): 59 − 64. doi: 10.12073/j.hjxb.2019400012

[3] 李素丽, 刘伟, 杨来侠, 等. 金属熔滴沉积成形三维零件的工艺研究[J]. 稀有金属材料与工程, 2019, 48(2): 626 − 631. Li Suli, Liu Wei, Yang Laixia, et al. Research on the process of forming three-dimensional parts by metal droplet deposition[J]. Rare Metal Materials and Engineering, 2019, 48(2): 626 − 631.

[4] 蒋小珊. 均匀金属液滴流的产生及其稳定喷射研究[D]. 西安: 西北工业大学, 2010. [5] 汪应玲. TiNi形状记忆合金与不锈钢瞬间液相扩散焊工艺及接头性能[D]. 北京: 北京工业大学, 2009. [6] Du Jun, Wei Zhengying, Chen Zhen, et al. Numerical investigation of pileup process in metal microdroplet deposition manufacture[J]. Micromachines, 2014, 31(2): 021601 − 1.

[7] Li Z Y. Study on manufacturing tiny copper balls by using uniform droplet spray method [D]. Dissertation for Master Degree. Taipei: National Cheng Kung University, 2009.

[8] 李素丽, 魏正英, 卢秉恒. 基于ANSYS的车身柔性件点焊装配应力分析[J]. 焊接学报, 2014, 35(11): 55 − 58. Li Suli, Wei Zhengying, Lu Bingheng. Stress analysis of Spot welding assembly of body flexible parts based on ANSYS[J]. Transactions of the China Welding Institution, 2014, 35(11): 55 − 58.

[9] 卢振洋, 李艳, 黄鹏飞, 等. 短路过渡气体保护焊参数优化[J]. 焊接学报, 2009, 30(3): 17 − 20. doi: 10.3321/j.issn:0253-360X.2009.03.005 Lu Zhenyang, Li Yan, Huang Pengfei, et al. Optimum parameters of short circuit droplet transfer gas metal arc welding[J]. Transactions of the China Welding Institution, 2009, 30(3): 17 − 20. doi: 10.3321/j.issn:0253-360X.2009.03.005

[10] 马少俊, 吴学仁, 刘建中, 等. TC21 钛合金的微观组织对力学性能的影响[J]. 航空材料学报, 2006, 26(5): 22 − 25. doi: 10.3969/j.issn.1005-5053.2006.05.006 Ma Shaojun, Wu Xueren, Liu Jianzhong, et al. Influence of microstructures on mechanical properties for TC21 titanium alloy[J]. Journal of Aeronautical Materials, 2006, 26(5): 22 − 25. doi: 10.3969/j.issn.1005-5053.2006.05.006

[11] 祝力伟, 王新南, 朱知寿. 不同热处理工艺下TC4-DT 钛合金的显微组织及力学性能[J]. 钛工业进展, 2011, 29(1): 9 − 12. Zhu Liwei, Wang Xinnan, Zhu Zhishou. Effect of heat treatment on microstructure and mechanical properties of TC4-DT alloy[J]. Titanium Industry Process, 2011, 29(1): 9 − 12.

下载:

下载: