Non-teaching automatic welding system based on DXF file parsing and point cloud data processing

-

摘要:

传统示教焊接方式存在操作过程繁琐,效率低下以及人工依赖度高的问题,为此提出了一种基于Drawing Exchange Format (DXF)文件解析与点云数据处理的无示教自动焊接系统,该系统通过对工件DXF文件进行解析,以获取理想焊缝位置及焊缝类型信息,求解多坐标系转换关系实现机器人焊缝初始定位,在此基础上,提出一种考虑机器人实时位姿的激光视觉传感器焊件点云获取方法,进一步开发一种基于平面检测的点云焊缝检测算法,获取实际焊缝位置信息,实现机器人无示教焊接. 结果表明,该系统可准确获取焊件点云信息,同时焊缝提取方法误差0.20 mm,满足实际焊接需求.

Abstract:The traditional teaching welding method has a cumbersome operation process, which leads to low efficiency and high dependence on manual labor. To address these issues, this paper proposed a non-teaching automatic welding system based on DXF file parsing and point cloud data processing. The system parses the DXF file of the workpiece to obtain the ideal weld position and weld type information, and achieves the initial positioning of the robot weld by solving the multi coordinate system transformation relationship. On this basis, a laser vision sensor welding point cloud acquisition method considering real-time robot pose is proposed, and a point cloud welding seam detection algorithm based on plane detection is developed to obtain actual welding seam position information and achieve robot non-teaching welding. The results showed that the system can accurately obtain the point cloud information of the weldment, and the error of the weld seam extraction method is less than 0.16 mm, which meets the welding requirements.

-

Keywords:

- non-teaching welding /

- DXF parsing /

- point cloud processing /

- weld seam detection

-

0. 序 言

随着国内制造业的战略转型,工业机器人技术得到了迅速的发展,其中焊接机器人在焊接工作中也得到了较为明显的应用,相较于人工焊接,焊接机器人拥有更高的稳定性以及更高的质量保证,同时可以在恶劣环境下持续工作,提高生产力[1-2].

所使用的机器人目前大部分是“示教—再现”[3],即在焊接工作前通过示教器逐点记录焊接路径及不同点位的焊接动作,接着焊接机器人通过示教器得到的数据进行焊接工作[4]. 传统示教焊接方式应用广泛,但随着焊缝数量剧增,难以满足实际焊接需求,示教操作过程繁琐,焊缝需大量重复操作,操作复杂且效率低下. 示教严重依赖人工的技术和状态,其精度及稳定性难以保证,同时由于存在工件装夹精度问题,工件装夹误差难以避免,严重影响焊接质量[5-7].

胡石[8]通过对机器人进行标定将激光视觉传感器下的坐标转换为工业机器人的坐标,但是其实时性不佳;李秉聪和张园凯等人[9-10]使用传感器可直接获取点云模型,然而,上述方法获取点云模型未考虑机器人实时姿态,导致点云模型与实际焊件误差难以保证.

为实现自动化焊接,文中设计了基于DXF文件解析与点云数据处理的无示教自动焊接系统,针对在复杂空间中人工示教方式寻找焊缝位置效率低、精度差的问题,将工件的DXF文件作为输入文件,对其实体段信息进行提取与解析从而获得焊缝的理想位置信息. 在此基础上,提出一种考虑机器人实时位姿的激光视觉传感器焊件点云获取方法,在获取数据同时采集机器人实时位姿信息,实现焊件点云模型准确构建. 进一步使用Ransac算法对获取到的点云进行分割,紧接着对分割后的点云进行平面拟合并求出焊缝的实际位置信息,从而完成焊缝检测.

1. 系统结构

1.1 整体结构

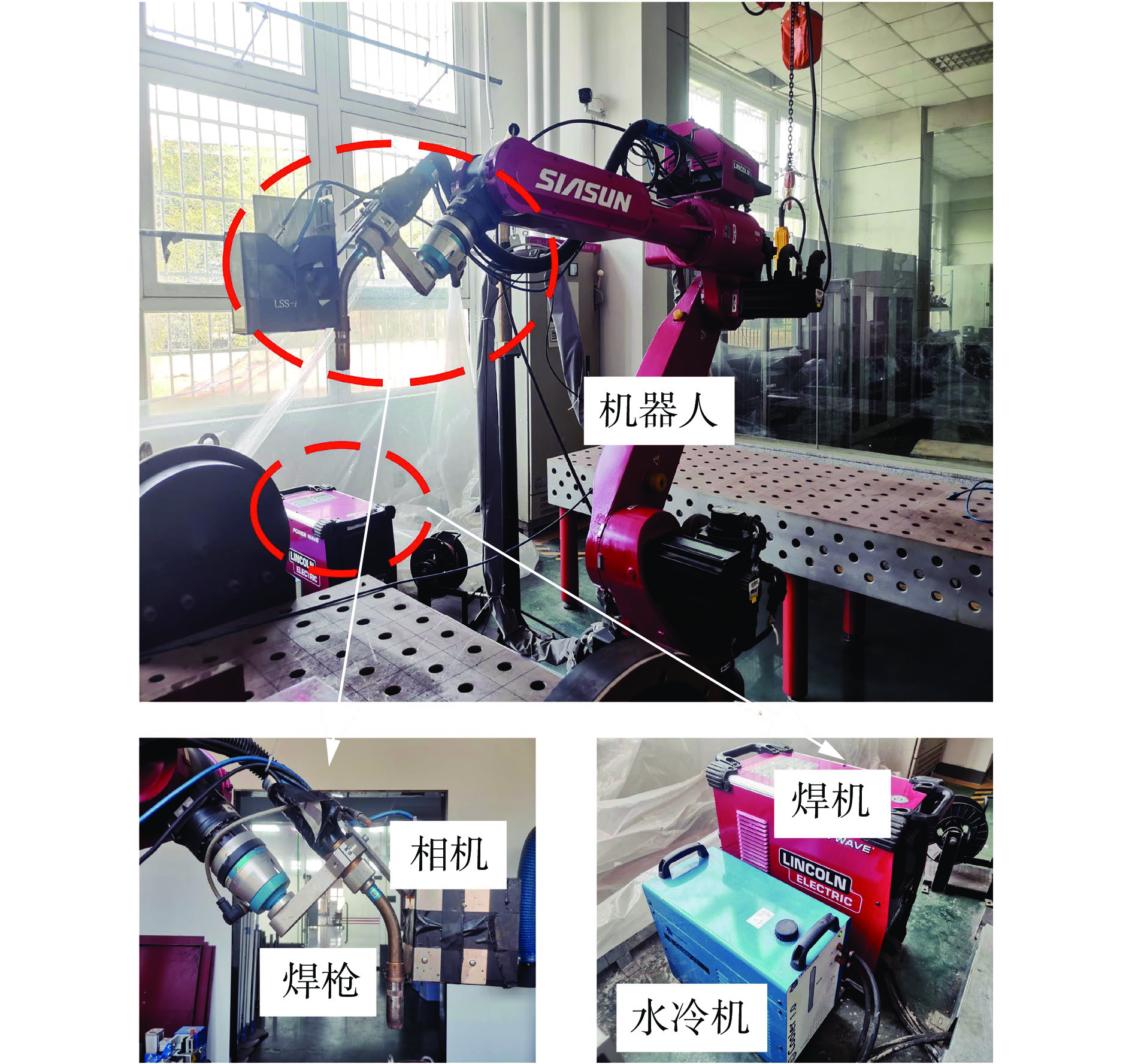

文中设计了基于DXF文件解析与点云数据处理的无示教自动焊接系统,系统整体结构如图1所示,主要由焊接机器人、焊枪、焊机、水冷机、上位机、视觉传感器组成,其中焊枪固定在焊接机器人法兰盘上,视觉传感器通过连接件固定在焊枪上. 视觉传感器跟随机器人依据上位机轨迹完成运动,实现点云的采集. 在焊接时,焊枪跟随焊接机器人按点云处理得到的轨迹进行焊接操作.

1.2 系统架构

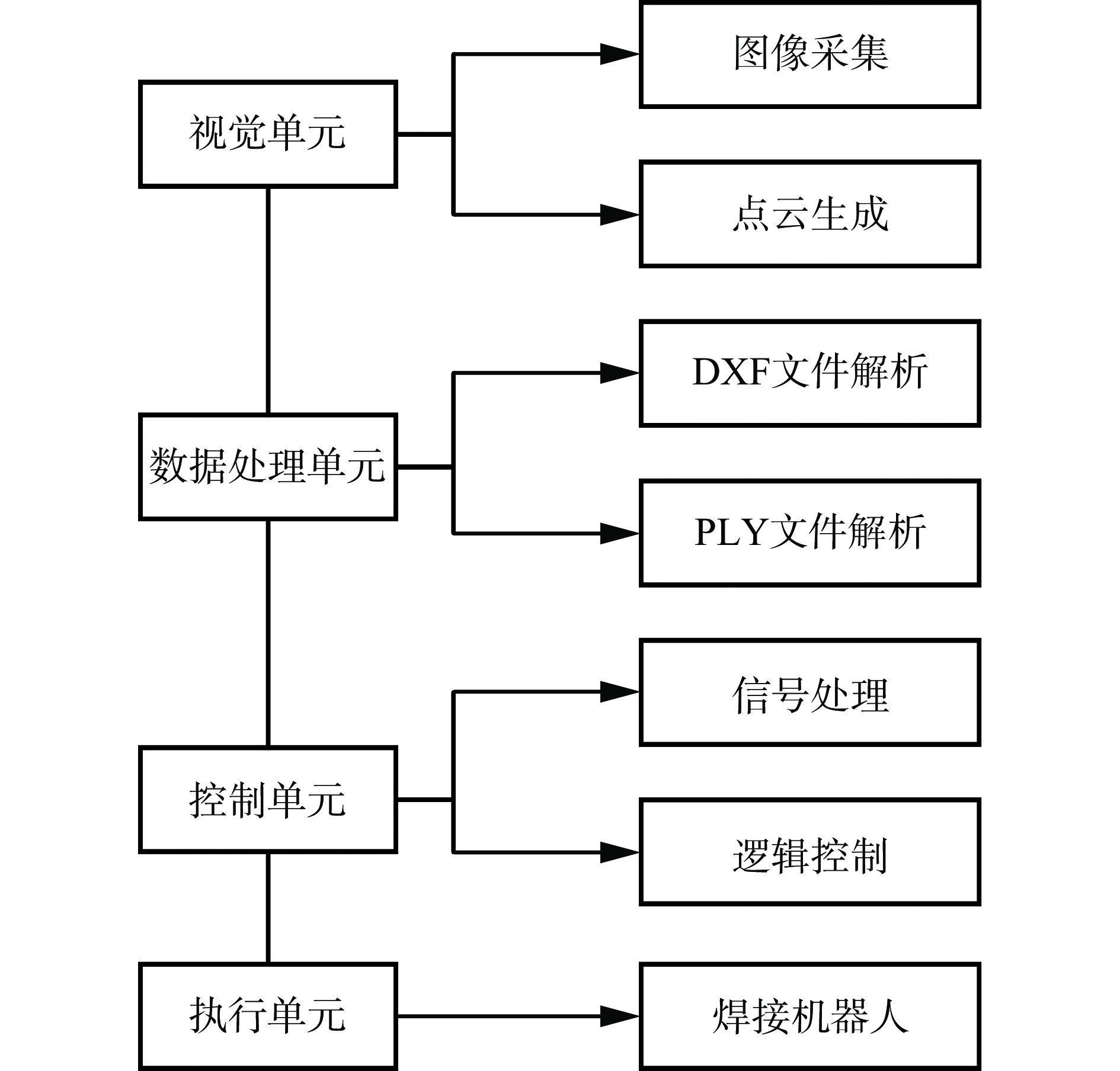

基于DXF文件解析与点云数据处理的无示教自动焊接系统,主要有视觉单元、数据处理单元、控制单元和执行单元组成,系统架构如图2所示.

视觉单元的功能包括图像采集以及点云的生成,该功能由激光视觉传感器实现,激光视觉传感器包括工业相机和线激光,工业相机通过调整曝光采集线激光扫描的位置得到图像,通过数据处理即可得到点云图.

数据处理单元功能包括DXF文件解析和点云数据处理,其中DXF文件解析旨在通过对导入的DXF文件进行解析获取焊缝理想位置,从而规划出激光视觉传感器扫描时的轨迹. 点云数据处理是通过对激光视觉传感器获取的点云进行处理从而得到焊缝的实际位置,即得到示教结果.

控制单元的功能包括信号处理和逻辑控制,该功能由上位机和焊接机器人控制柜实现,其中信号处理主要是焊接机器人在获取实时位置时给相机发送一个下降沿信号,触发相机采集图像,示教的整个过程由上位机进行逻辑控制.

执行单元的功能带动激光视觉传感器和焊枪进行运动,其功能实现主要依靠焊接机器人完成.

1.3 激光视觉传感器

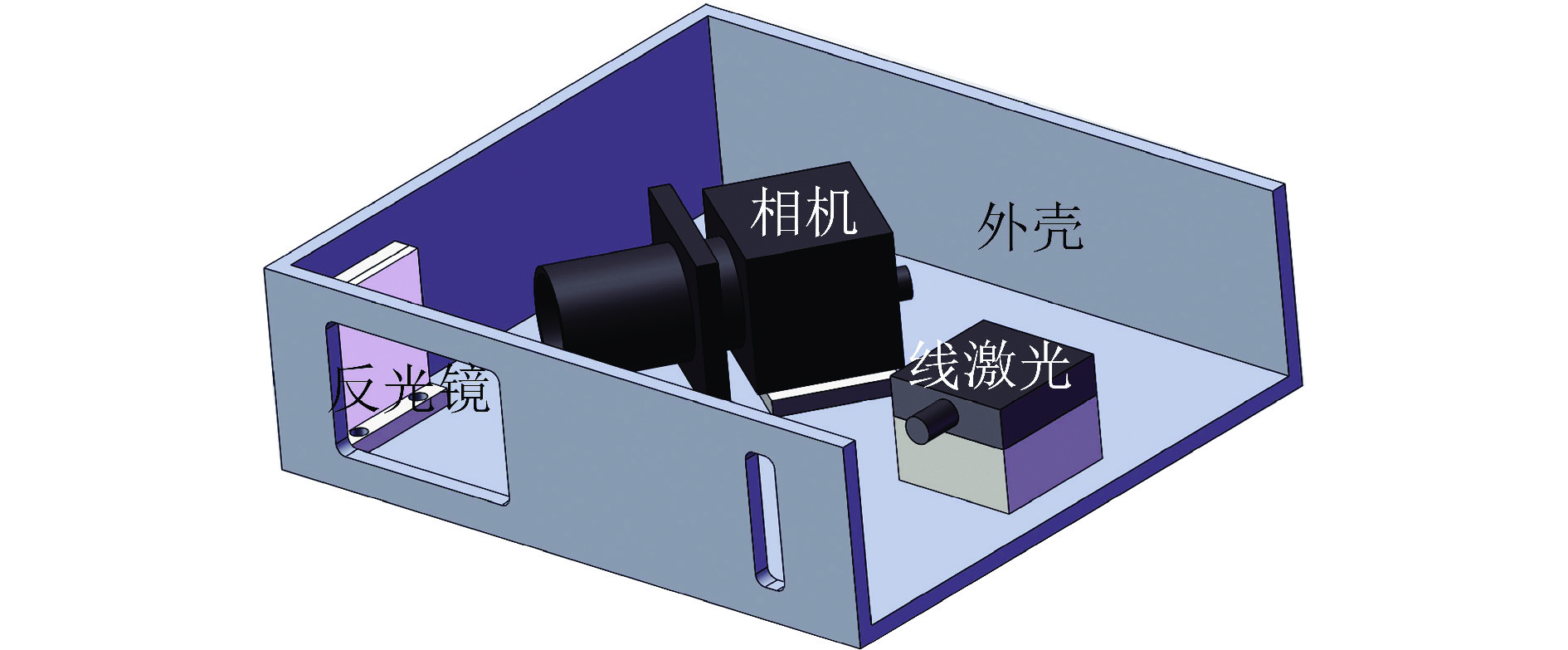

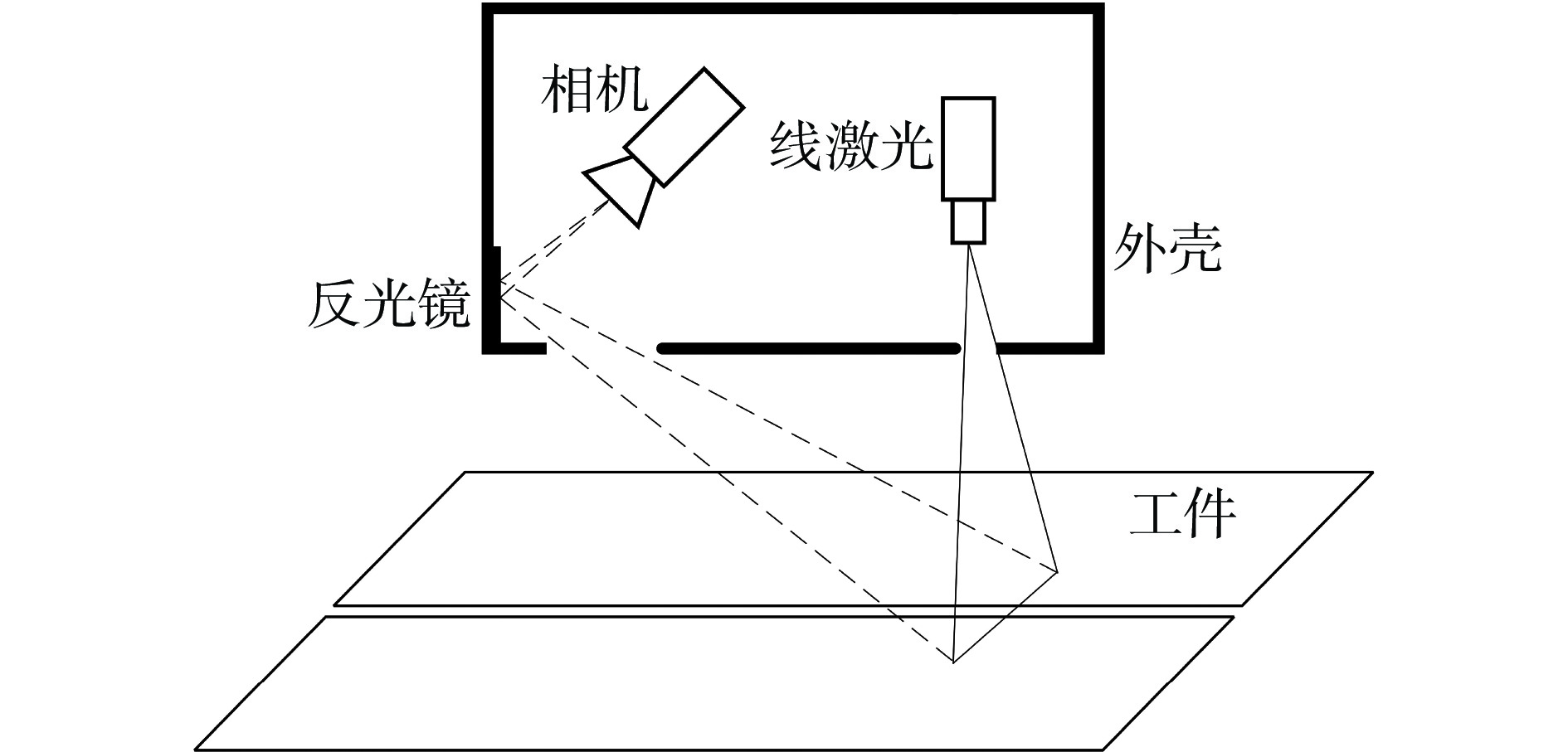

激光视觉传感器主要由相机、镜头、线激光发射器、反光镜、外壳和连接件组成,如图3所示. 为使视觉传感器占用更小的空间以适用于更多工业场景,采用一块反光镜用于将线激光反射到相机.

视觉传感器工作时,线激光发射器会将激光打在需要采集的工件上面,激光通过工件漫反射之后部分进入视觉传感器中,通过反光镜将光线射入到相机之中,从而完成图像的采集,如图4所示.

1.4 软件系统

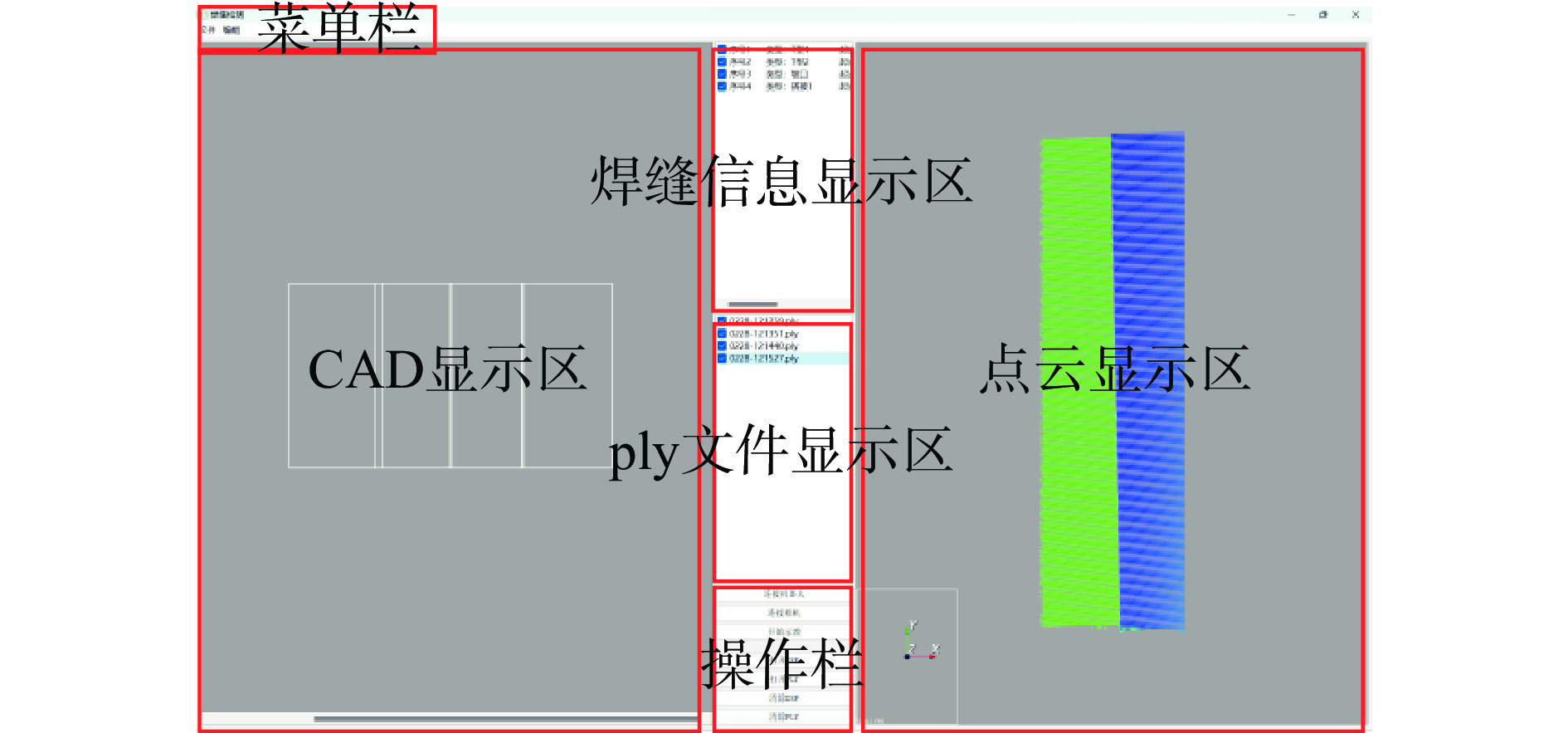

设备上位机软件是基于QT和Visual Studio联合进行编写,上位机软件界面布局,如图5所示,软件界面分为菜单栏、操作栏、CAD显示区、焊缝信息和点云文件显示区,其中菜单区和控制区主要用于对文件操作和控制设备,显示区用于对文件相关信息展示,软件采用分块化设计的编程思想,各个按钮都有对相应的函数可供调取,操作人员可根据实际情况进行使用.

2. 焊缝检测方法

2.1 焊缝检测流程

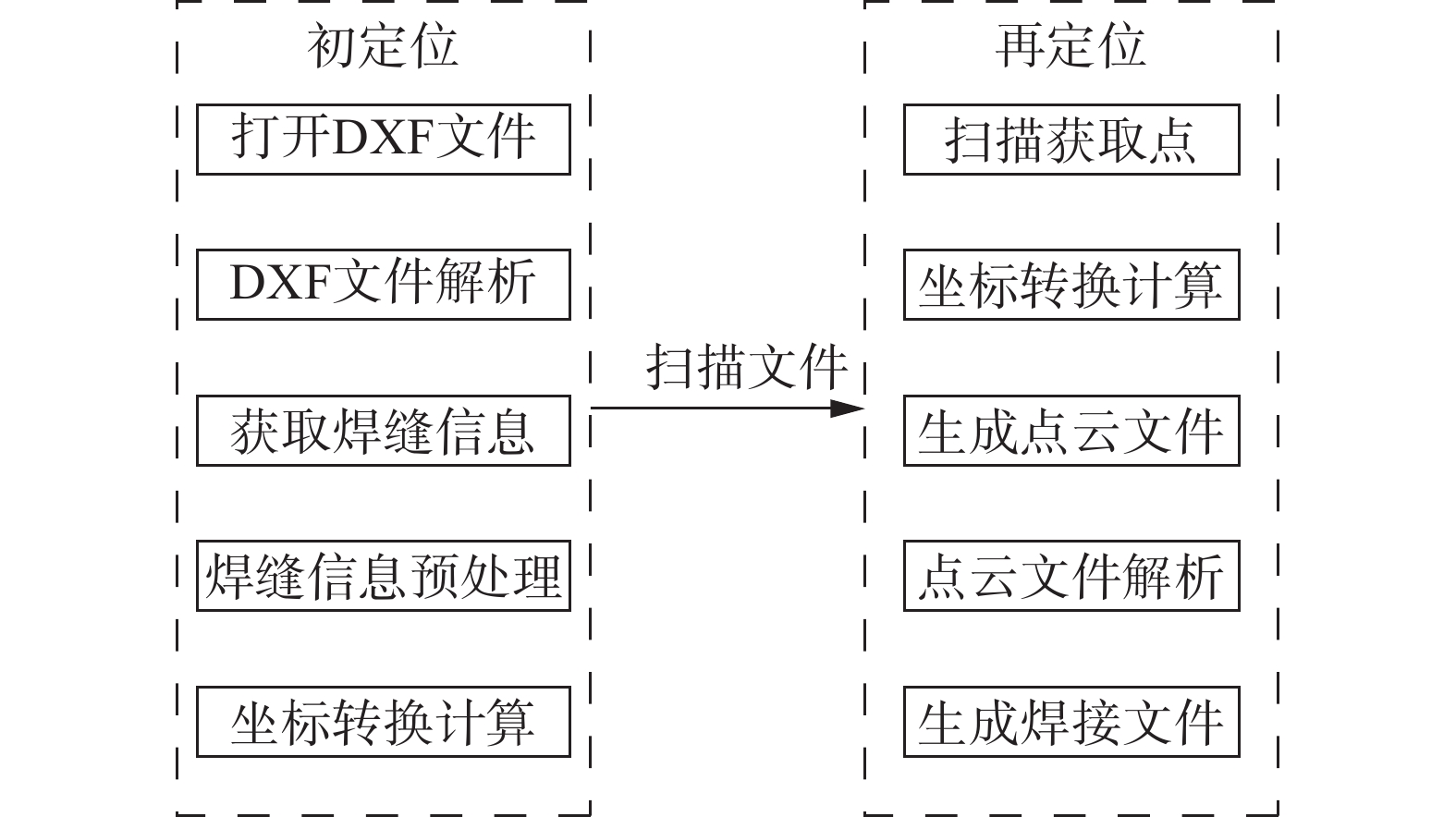

基于DXF文件解析与点云数据处理的无示教自动焊接系统的免示教包括2个流程,如图6所示. 首先针对不同工件其焊缝位置和焊缝种类不同采用DXF文件进行初定位,即通过解析DXF文件得到焊缝的理论位置和焊缝类型信息,进一步针对相同工件装夹时的误差采用激光视觉传感器进行再定位,即先通过视觉传感器采集点云,接着对点云进行处理得到实际焊缝位置信息.

2.2 基于DXF解析的焊缝初定位

2.2.1 焊缝信息数据提取

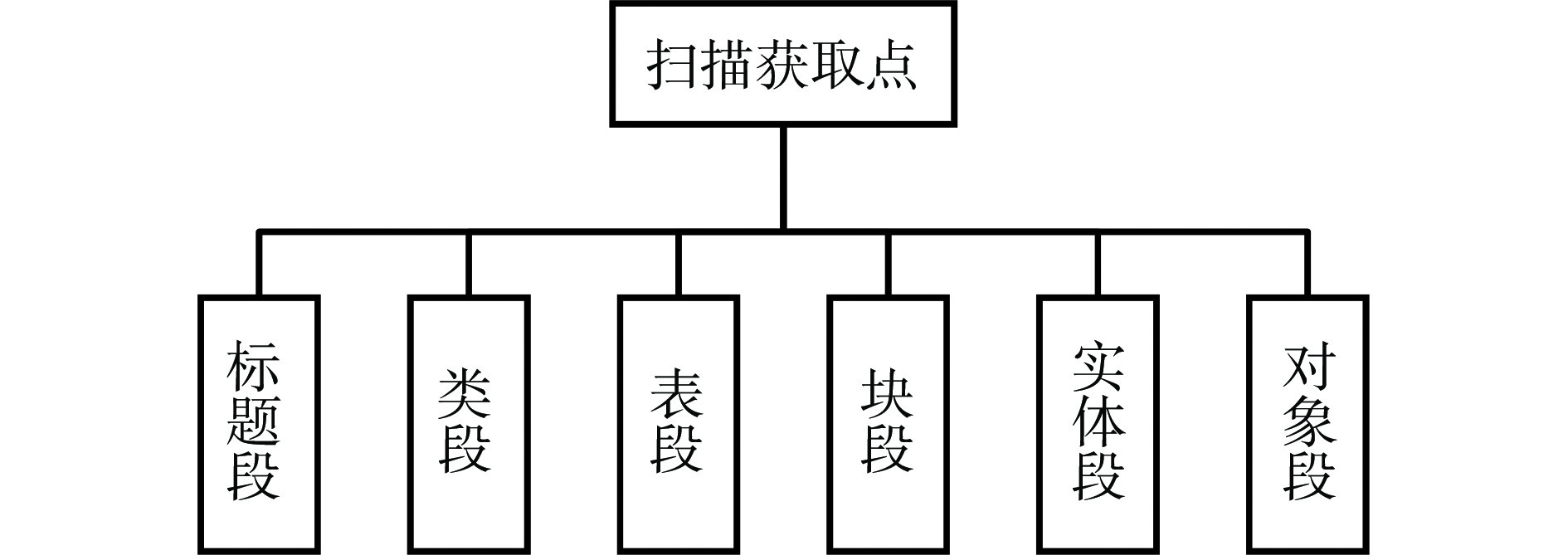

工件初定位时所需的焊缝信息包含在DXF文件中,DXF文件中包含多种数据类型[11],具体类型如图7所示. 扫描时所需的焊缝信息位于实体段数据类型中,因此在对DXF文件进行解析时只需对DXF文件中实体段信息进行提取与解析,经过提取后每一条焊缝信息包含焊缝的起点终点坐标以及焊缝类型,这些信息将用于确定焊缝扫描时机器人的位置与姿态.

2.2.2 二维平面坐标转换

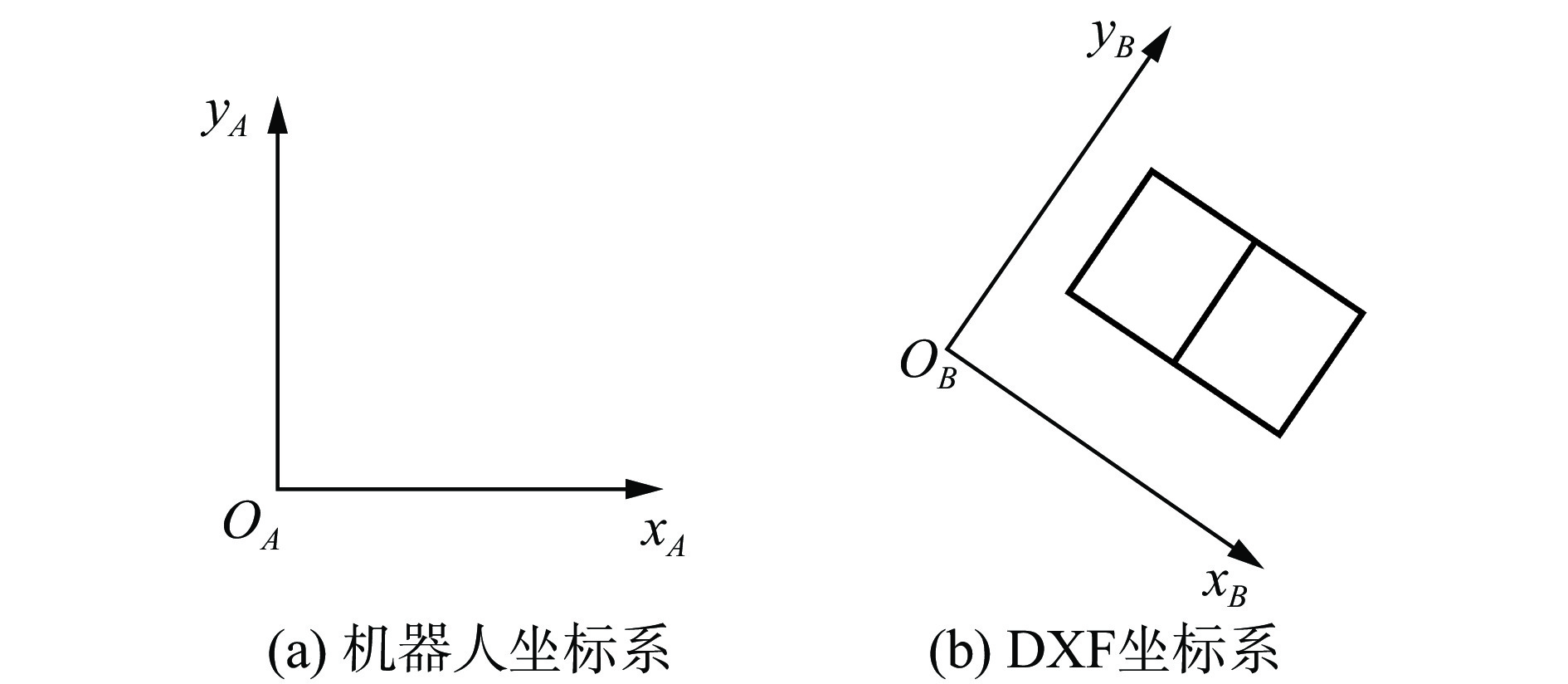

在绘制DXF文件时一般是根据CAD坐标系进行绘制,然而工件进行加工时按照机器人坐标系进行,因此在得到DXF文件解析的焊缝坐标后还需要对其进行转换才能满足加工需求. 考虑到DXF文件所包含的信息是二维的,因此在坐标转换时不考虑其z值. 坐标转换关系如图8所示,其中图8(a)为机器人的坐标系,图8(b)为DXF文件坐标系.

在坐标系B中任取一点$ {}^Bp(m,n) $,该点在坐标系A中对应的位置为$ {}^Ap(m,n) $,其中点$ {}^Bp $是通过DXF文件解析得到的,点$ {}^Ap $是通过坐标转换得到的,对于点的转换矩阵只需要得到2个坐标的转换算子便可以求得. 从坐标B到坐标A经历了一个旋转变换$ {}_B^A{\boldsymbol{R}} $和一个平移变换$ ^A{{\boldsymbol{P}}_B} $,为了方便计算,将其转换为齐次变换矩阵,即

$$ {}_B^A{\boldsymbol{T}} = \left( {\begin{array}{*{20}{c}} {{}_B^A{\boldsymbol{R}}}&{^A{{\boldsymbol{P}}_B}} \\ 0&1 \end{array}} \right) $$ (1) 式中:齐次变换矩阵$ {}_B^A{\boldsymbol{T}} $是3 × 3的方阵,通过该齐次变换矩阵便可以通过$ ^Bp $求得$ ^Ap $,即

$$ \left[ {\begin{array}{*{20}{c}} {^Ap} \\ 1 \end{array}} \right] = \left[ {\begin{array}{*{20}{c}} {_B^A{\boldsymbol{R}}}&{^A{{\boldsymbol{P}}_B}} \\ 0&1 \end{array}} \right] \cdot \left[ {\begin{array}{*{20}{c}} {^Bp} \\ 1 \end{array}} \right] $$ (2) 2.3 基于焊缝点云数据处理的焊缝再定位

2.3.1 焊缝点云数据采集

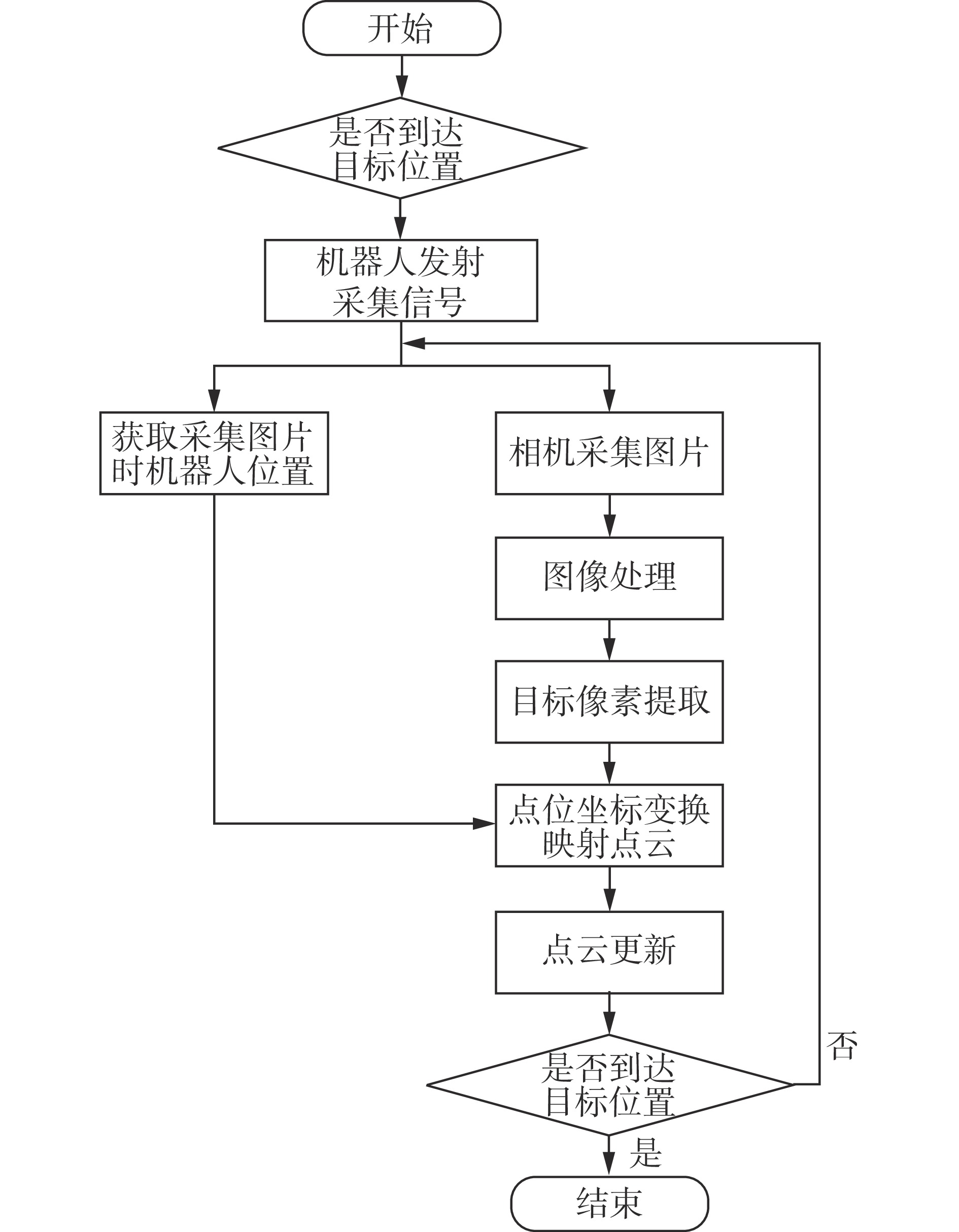

通过上一节对DXF文件的处理,得到了焊缝在机器人坐标系中的坐标位置,在对焊缝进行点云采集时,先将焊缝理想位置信息传递给机器人,接着机器人根据焊缝理想位置信息带着激光视觉传感器进行点云采集[12],具体流程如图9所示. 当机器人到达焊缝起点时,机器人开始给传感器传递采集信号,同时机器人储存采集时机器人所处的位置信息,通过对采集的图像进行处理得到目标像素点,并将这些点和机器人位置信息进行对应便可以得到点的实际位置,当机器人到达焊缝终点时停止采集,通过对采集得到的点进行三位重建即可获得焊缝点云数据.

2.3.2 三维空间坐标转换

视觉传感器通过采集单帧点云存储在点云序列中,这些点云的点的位置坐标是空间相对于相机的位置信息,为了得到焊缝的实际位置信息,需要对点云进行三维空间的坐标转换,将每次采集时的位置信息和单帧图片处理得到的单帧点云进行映射,得到焊件真实点云模型.

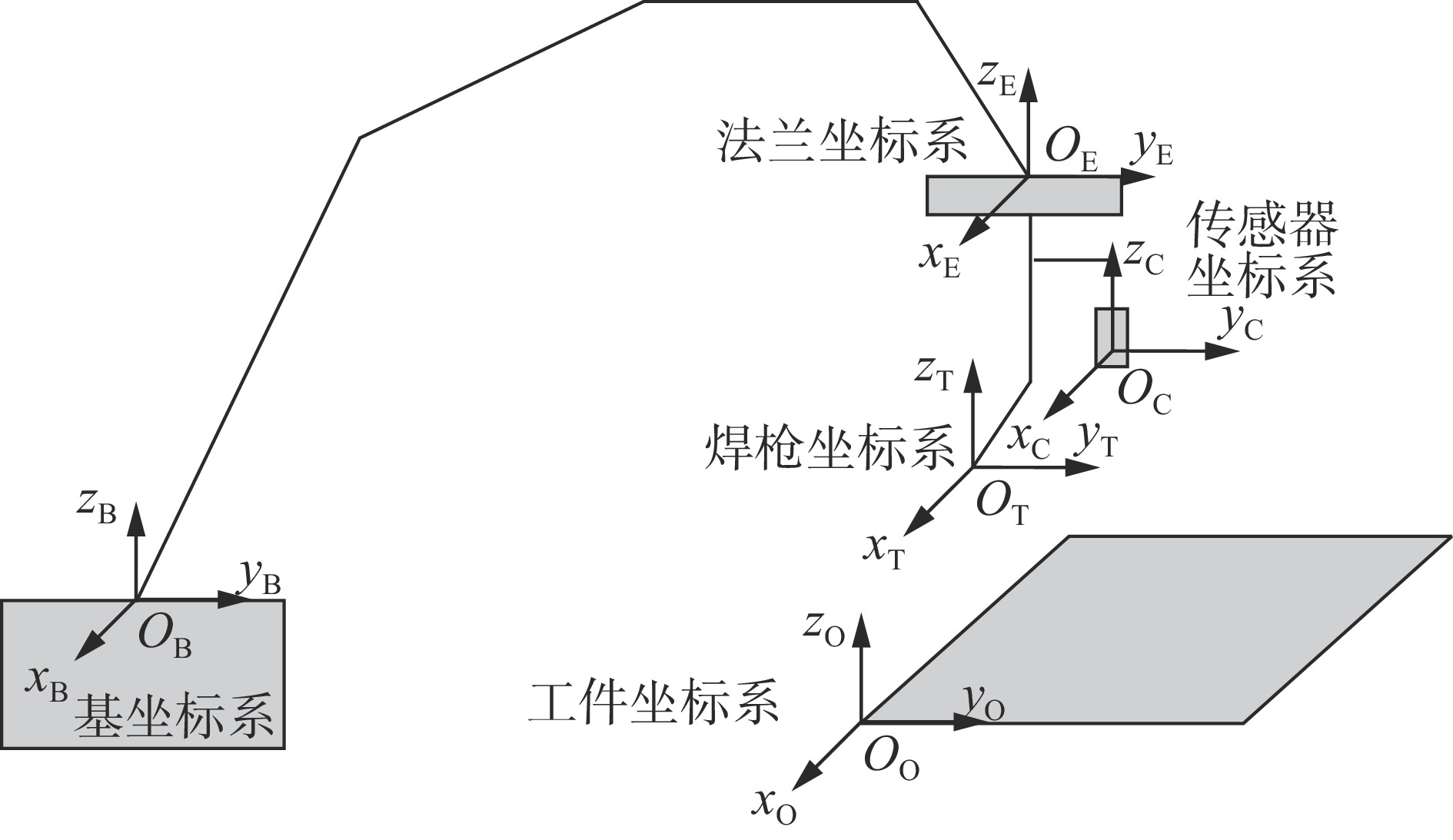

在点云的坐标转换中包含5个坐标系,如图10所示,分别是机器人的基坐标系、加工平面坐标系即工件坐标系、机器人末端坐标系即法兰盘坐标系以及2个工具坐标系即焊枪坐标系和传感器坐标系. 为了对点云坐标进行转换需要求得各坐标之间的转换矩阵,并以其为算子进行点云坐标转换.

通过视觉传感器采集的空间坐标可以表示为$ {\boldsymbol{P}} = {\left[ {\begin{array}{*{20}{c}} x&y&z \end{array}} \right]^{\rm{T}}} $,为方便后续坐标变换,对坐标进行升高一维处理,即$ {\left[ {\begin{array}{*{20}{c}} x&y& z&1 \end{array}} \right]^{\rm{T}}} $的形式,升维之后的三维空间的变换为

$$ \left[ {\begin{array}{*{20}{c}} {x'} \\ {y'} \\ {z'} \\ 1 \end{array}} \right] = \left[ {\begin{array}{*{20}{c}} R&B \\ 0&1 \end{array}} \right] \left[ {\begin{array}{*{20}{c}} x \\ y \\ z \\ 1 \end{array}} \right] $$ (3) 通过对传感器的工件坐标系进行标定可以得到法兰盘坐标系和机器人坐标系之间的转换矩阵,以及传感器和机器人坐标系之间的转换矩阵. 在机器人带动激光视觉传感器扫描时,每采集一帧图片获取一次法兰盘的位置信息,获取值即为法兰盘坐标系和机器人坐标系,这里所读取得到的坐标是欧拉角形式,为方便计算需要将得到的欧拉角转换为齐次变换矩阵,设读取得到的参数是$ (x,y,z,a,b,c) $,其平移向量为$ _t^bB = {(x,y,z)^t} $,其旋转矩阵为

$$ \begin{split} & _t^b{R_{xyz}}(c,b,a) = \left[ {\begin{array}{*{20}{c}} {ca \cdot cb}&{ca \cdot sb \cdot sc - sa \cdot cc}&{ca \cdot sb \cdot cc + sa \cdot sc} \\ {sa \cdot sb}&{sa \cdot sb \cdot sc + ca \cdot cc}&{sa \cdot sb \cdot cc - ca \cdot sc} \\ { - sb}&{cb \cdot sc}&{cb \cdot cc} \end{array}} \right] \end{split} $$ (4) 式中:c为cos;s为sin. 将平移向量和旋转矩阵合并为齐次变换矩阵为

$$ _t^bT = \left[ {\begin{array}{*{20}{c}} {_t^b{R_{xyz}}(c,b,a)}&{_t^bB} \\ 0&1 \end{array}} \right] $$ (5) 同理可得$ _c^bT $,根据图中的坐标关系有$ T_t^b \cdot T_c^t = T_c^b $,根据此式可以得到相机坐标和法兰盘坐标系之间的转换矩阵$ _c^tT $.

在获得这些数据之后通过计算就可以得到点云的实际坐标.

$$ \left[ {\begin{array}{*{20}{c}} {x'} \\ {y'} \\ {z'} \\ 1 \end{array}} \right] = _t^bT \cdot _c^tT \cdot \left[ {\begin{array}{*{20}{c}} x \\ y \\ z \\ 1 \end{array}} \right] $$ (6) 2.3.3 焊缝点云数据处理

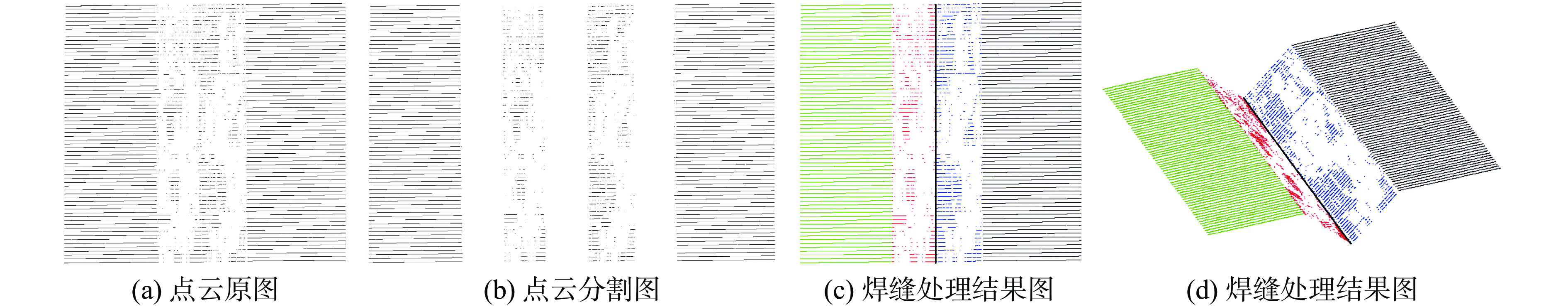

文中采集得到的点云数据中包含工件表面和焊缝表面信息,因此在点云处理时需要对点云进行分割以得到焊缝表面点云. 得到焊缝表面点云之后,对表面点云进行平面拟合,通过求平面的交线即可得到焊缝的实际位置.

点云的分割算法基本上可以分为基于边界的算法[13]和基于面域的算法两大类[14],文中所使用的点云分割算法是基于面域生长算法中的Ransac[15]算法. Ransac算法将采集样本分为两类,一类为符合模型的点集数据,称为内点;另一类为不符合模型的数据,称为外点,其基本原理[16]如下.

假设所有点的数据集为A,从中随机抽取一个子样本集,其中最小样本数为$ m(m \geqslant 3) $,使用最小二乘法计算这个子集的模型参数,并作为初始化模型参数,接着计算所有的样本与该模型的偏差,并与预先定义的阈值进行比较,当偏差值小于预定阈值时说明该点为模型内点,反之为模型外点,并将其去除,同时记录此时的内点数. 接着重复上述操作过程,根据实际的情况确定迭代次数N,迭代过程完成后根据前面步骤的结果计算出最佳模型参数.

在用最小二乘法计算模型参数时,先将平面

$$ Ax + By + Cz + D = 0(C \ne 0) $$ (7) 转换得到

$$ z = - \frac{A}{C}x - \frac{B}{C}y - \frac{D}{C} $$ (8) 记$ a = - \dfrac{A}{C} $,$ b = - \dfrac{B}{C} $,$ C = - \dfrac{D}{C} $,则有

$$ z = ax + by + c $$ (9) 对于模型的n个点$ (n \geqslant 3):({x_i},{y_i},{z_i}),i = 0, 1,\cdots , n - 1 $,用这些点拟合计算平面方程需最小.

$$ M = \sum\limits_0^{n - 1} {{{(ax + by + c - z)}^2}} $$ (10) 可得线性方程组

$$ \left[ {\begin{array}{*{20}{c}} {\sum {x_i^2} }&{\sum {{x_i}{y_i}} }&{\sum {{x_i}} } \\ {\sum {{x_i}{y_i}} }&{\sum {y_i^2} }&{\sum {{y_i}} } \\ {\sum {xi} }&{\sum {{y_i}} }&n \end{array}} \right]\left[ {\begin{array}{*{20}{c}} a \\ b \\ c \end{array}} \right] = \left[ {\begin{array}{*{20}{c}} {\sum {{x_i}{z_i}} } \\ {\sum {{y_i}{z_i}} } \\ {\sum {{z_i}} } \end{array}} \right] $$ (11) 求解上述方程组,可以得到a,b,c.

通过对点云进行分割得到各平面点云,接着选出焊缝平面,并求出焊缝平面的平面拟合参数,并以此计算焊缝所在的直线方程,获得直线方程之后便可以找到焊缝的实际位置,具体云数据处理如图11所示.

3. 系统测试

3.1 测试过程

为验证试验文中算法有效性,对免示教效果进行测试,首先需要验证系统根据对DXF文件解析得到的数据进行点云采集的效果,采集得到焊缝点云数据之后,需要进一步验证对点云解析得到的实际焊缝位置是否正确.

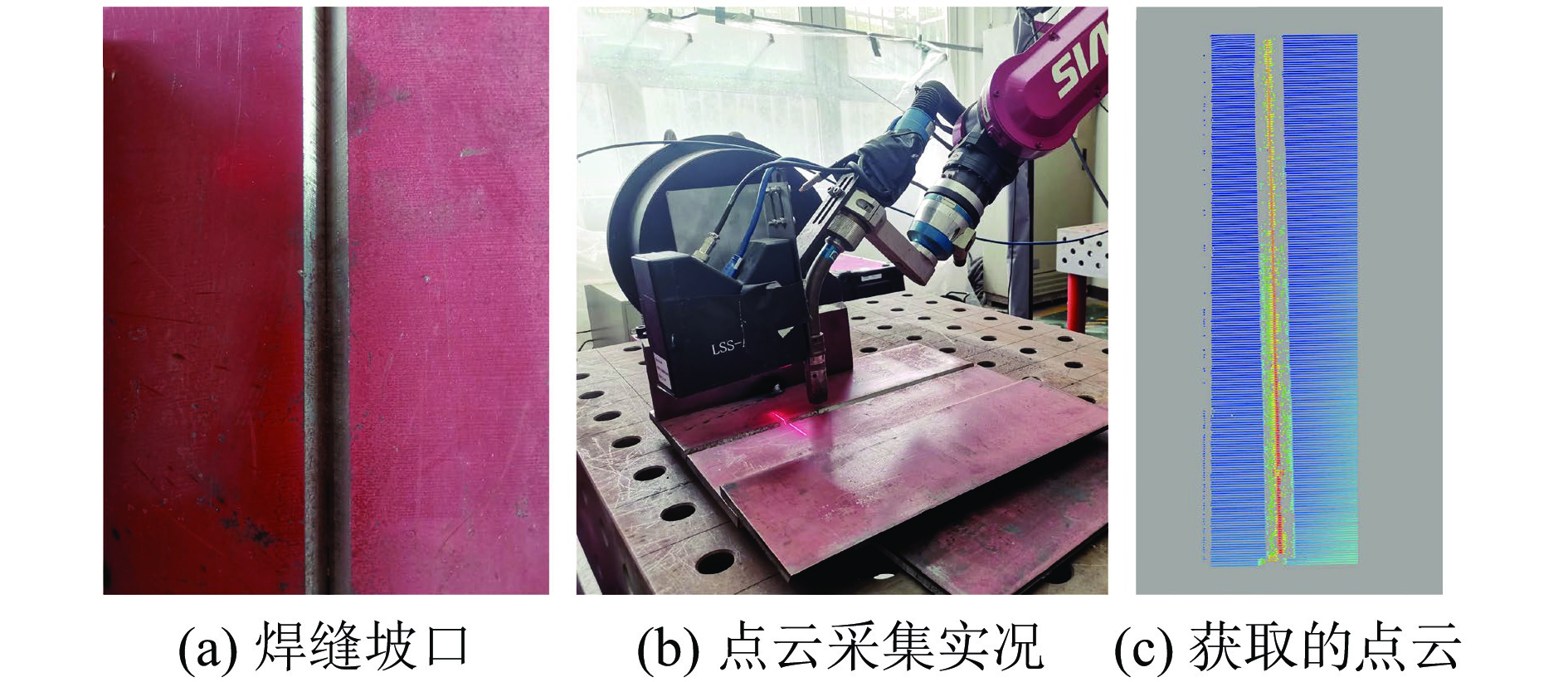

根据图9所示的流程进行点云采集,扫描时的状态图,如图12所示,图12(a)为一个坡口焊缝;图12(b)为焊接机器人根据DXF得到的理想焊缝轨迹带着相机进行点云采集的一个状态;图12(c)为激光视觉传感器采集焊缝信息得到的点云.

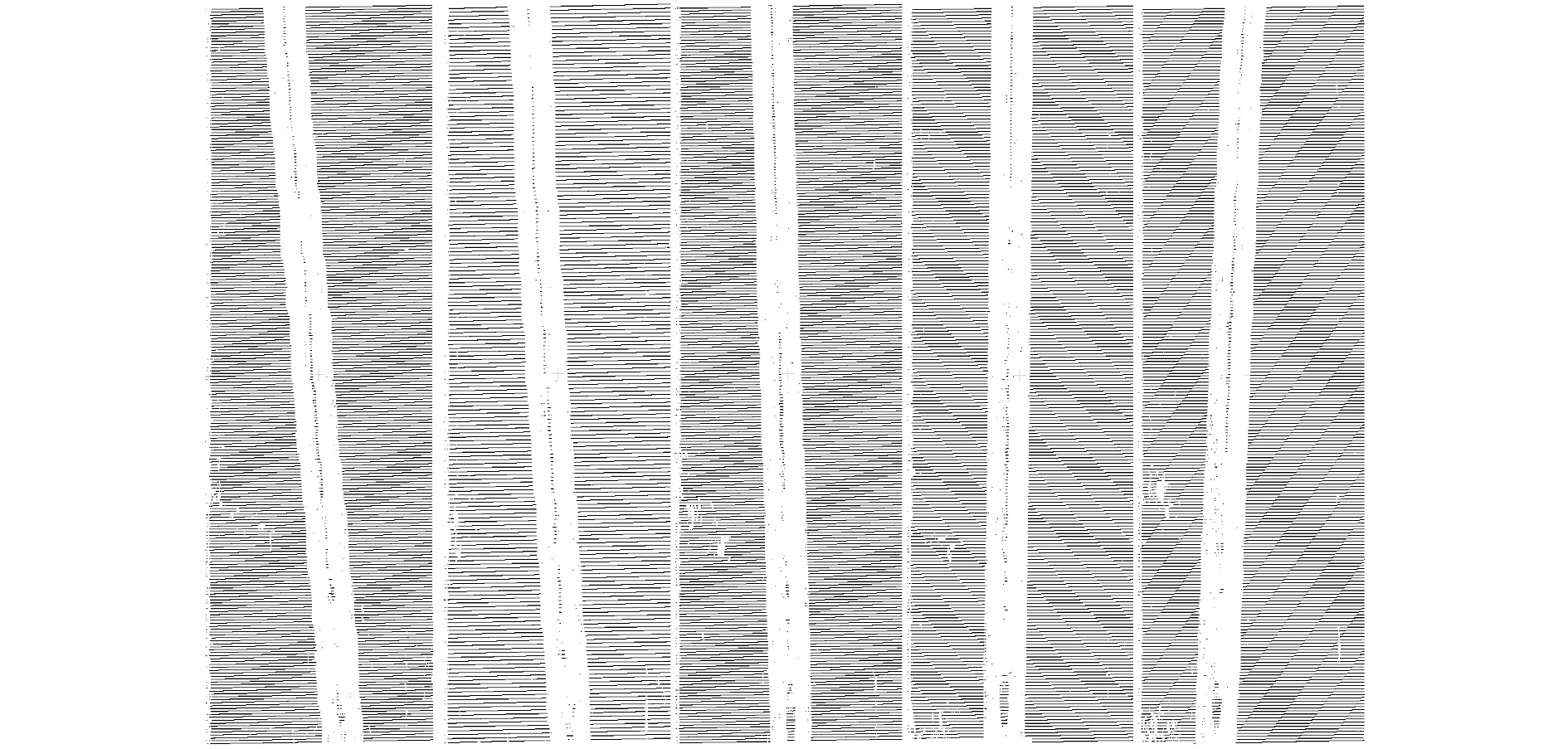

为了贴合实际工况,试验过程中将工件人为随机偏转一个角度,如图13所示,工件理想位置见图13(a),焊缝的位置与下面的线是重合的,考虑到工作时很难将工件放入到理想位置,因此在进行试验时将工件放置在图13(b)的位置,工件与理想位置偏转一个角度,以此验证设计方法的准确性,具体采集的点云图,如图14所示.

3.2 结果分析

为验证获取点云的准确性,对点云的长度进行对比分析,试验工件的长度为240 mm,将前面所获得的点云文件导入CloudCompare软件进行长度测量,获取结果见表1,对比点云的测量长度和实际的焊缝长度,可以发现点云采集的平均误差百分比仅为0.06%,相对于实际工况来说其误差在可以接受范围内,这表明所使用的点云坐标转换方法可以真实的还原出工件的实际信息.

表 1 焊缝点云长度误差Table 1. Deviation of weld point cloud length位置 实际长度L1/mm 点云长度L2/mm 绝对误差L3/mm 误差百分比A(%) 1 240.00 240.17 0.170 0.070 2 240.00 240.01 0.010 0.004 3 240.00 239.95 0.050 0.020 4 240.00 239.97 0.030 0.010 5 240.00 240.39 0.390 0.160 6 240.00 240.28 0.280 0.120 平均 — — 0.155 0.060 通过CloudCompare软件可获取点云焊缝实际坐标见表2,将点云处理得到的坐标值同时记录在表2中,对两种方法得到的坐标值进行对比,从表中数据可以看出,点云处理方法在x方向的平均误差仅为0.20 mm,在y方向的平均误差仅为0.01 mm,结果表明点云处理方法可以准确的获取焊缝点云的实际位置坐标.

表 2 焊缝点云处理结果Table 2. Result of weld point cloud processing位置 起/终点 焊缝实际坐标 点云处理坐标 x方向误差εx/mm y方向误差εy/mm 1 起点 (−3.95,−1 399.52) (−4.00,−1 399.52) 0.05 0 终点 (−23.64,−1 159.94) (−23.88,−1 159.94) 0.24 0 2 起点 (−5.41,−1 399.59) (−5.24,−1 399.56) −0.17 −0.03 终点 (−20.10,−1 159.87) (−20.10,−1 159.87) 0 0 3 起点 (−8.84,−1 399.64) (−8.55,−1 399.62) −0.29 −0.02 终点 (−18.94,−1 159.85) (−18.94,−1 159.85) 0 0 4 起点 (−10.31,−1 399.65) (−10.31,−1 399.65) 0 0 终点 (−20.16,−1 159.88) (−20.22,−1 159.88) 0.06 0 5 起点 (−11.63,−1 399.70) (−10.59,−1 399.68) −0.04 −0.02 终点 (−17.78,−1 159.83) (−17.90,−1 159.83) 0.12 0 6 起点 (−18.28,−1 399.81) (−18.07,−1 399.81) 0.21 0 终点 (−9.77,−1 159.68) (−9.88,−1 159.68) 0.11 0 平均 — — — 0.20 0.01 4. 结 论

(1)建立基于DXF文件解析与点云数据处理的无示教自动焊接系统,通过基于DXF文件解析的焊缝初定位和基于点云处理的焊缝再定位,完成对实际焊缝位置信息的提取,解决了依靠人工示教的问题,提高了焊接自动化水平.

(2)提出一种考虑机器人实时位姿的激光视觉传感器焊件点云获取方法,以提高准确性,通过对机器人位姿和激光视觉传感器采集的点云进行空间坐标转换,可以获得焊件准确点云模型,平均误差0.06%.

(3)提出一种基于平面检测的点云焊缝检测方法,采用Ransac算法对点云进行分割处理,获取点云平面信息,进而实现焊缝检测,焊缝位置检测误差0.20 mm,满足实际焊接要求.

-

表 1 焊缝点云长度误差

Table 1 Deviation of weld point cloud length

位置 实际长度L1/mm 点云长度L2/mm 绝对误差L3/mm 误差百分比A(%) 1 240.00 240.17 0.170 0.070 2 240.00 240.01 0.010 0.004 3 240.00 239.95 0.050 0.020 4 240.00 239.97 0.030 0.010 5 240.00 240.39 0.390 0.160 6 240.00 240.28 0.280 0.120 平均 — — 0.155 0.060 表 2 焊缝点云处理结果

Table 2 Result of weld point cloud processing

位置 起/终点 焊缝实际坐标 点云处理坐标 x方向误差εx/mm y方向误差εy/mm 1 起点 (−3.95,−1 399.52) (−4.00,−1 399.52) 0.05 0 终点 (−23.64,−1 159.94) (−23.88,−1 159.94) 0.24 0 2 起点 (−5.41,−1 399.59) (−5.24,−1 399.56) −0.17 −0.03 终点 (−20.10,−1 159.87) (−20.10,−1 159.87) 0 0 3 起点 (−8.84,−1 399.64) (−8.55,−1 399.62) −0.29 −0.02 终点 (−18.94,−1 159.85) (−18.94,−1 159.85) 0 0 4 起点 (−10.31,−1 399.65) (−10.31,−1 399.65) 0 0 终点 (−20.16,−1 159.88) (−20.22,−1 159.88) 0.06 0 5 起点 (−11.63,−1 399.70) (−10.59,−1 399.68) −0.04 −0.02 终点 (−17.78,−1 159.83) (−17.90,−1 159.83) 0.12 0 6 起点 (−18.28,−1 399.81) (−18.07,−1 399.81) 0.21 0 终点 (−9.77,−1 159.68) (−9.88,−1 159.68) 0.11 0 平均 — — — 0.20 0.01 -

[1] 姚宇, 张秋菊, 陈宵燕, 等. 复杂空间曲面焊接机器人自动编程系统[J]. 焊接学报, 2023, 44(5): 122 − 128. doi: 10.12073/j.hjxb.20220623003 Yao Yu, Zhang Qiuju, Chen Xiaoyan, et al. Automatic programming system of complex space trajectory welding robot[J]. Transactions of the China Welding Institution, 2023, 44(5): 122 − 128. doi: 10.12073/j.hjxb.20220623003

[2] Zhang Y, Geng Y, Tian X, et al. Feature extraction and robot path planning method in 3D vision-guided welding for multi-blade wheel structures[J]. Optics and Lasers in Engineering, 2024, 176: 108066. doi: 10.1016/j.optlaseng.2024.108066

[3] Zhang J, Wang Y, Xiong R. Industrial robot programming by demonstration[J]. 2016 International Conference on Advanced Robotics and Mechatronics (ICARM), Macau, China, 2016: 300 − 305.

[4] Wang H, Chen C, Liu Y, et al. A novel approach for robotic welding trajectory recognition based on pseudo-binocular stereo vision[J]. Optics and Laser Technology, 2024, 174: 110669. doi: 10.1016/j.optlastec.2024.110669

[5] Senicic M, Matijevic M, Nikitovic M. Teaching the methods of object detection by robot vision[C]// 2018 41st International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO). IEEE, 2018.

[6] 陈鑫. 基于激光视觉的焊缝识别与跟踪系统研究[D]. 济南: 山东大学, 2021. Chen Xin. Research on weld seam recognition and tracking system based on laser vision[D]. Jinan: Shan Dong University, 2021.

[7] 杜鹏, 高群山. 大截面箱形钢柱机器人自动焊接施工技术[J]. 建筑施工, 2021, 43(7): 1253 − 1255. Du Peng, Gao Qunshan. Construction technology of automatic welding of large-section box-shaped steel column robot[J]. Building Construction, 2021, 43(7): 1253 − 1255.

[8] 胡石. 基于激光扫描的工业机器人焊接焊缝跟踪方法[J]. 重庆科技学院学报(自然科学版), 2023, 25(5): 69 − 75. Hu Shi. Weld seam tracking method for industrial robot welding based on laser scanning[J]. Journal of Chongqing University of Science and Technology (Natural Science Edition), 2023, 25(5): 69 − 75.

[9] 李秉聪, 夏卫生, 许晓群, 等. 基于点云数据驱动的中厚板机器人焊接路径规划[J]. 电焊机, 2023, 53(9): 78 − 83. doi: 10.7512/j.issn.1001-2303.2023.09.10 Li Bingcong, Xia Weisheng, Xu Xiaoqun, et al. Path planning for robot welding of medium-thick plates based on point cloud data[J]. Electric Welding Machine, 2023, 53(9): 78 − 83. doi: 10.7512/j.issn.1001-2303.2023.09.10

[10] 张园凯, 马立新, 王秀晶, 等. 基于点云的机器人钢网焊接路径规划方法[J]. 金属加工(热加工), 2021(6): 17 − 22. Zhang Yuankai, Ma Lixin, Wang Xiujing, et al. A method of welding path planning of steel mesh based on point cloud for welding robot[J]. NW Metal Forning, 2021(6): 17 − 22.

[11] Wang Y, Li X, Zhang Y. An automation solution to convert CAD engineering drawings into railroad station models[J]. Computer-aided Civil and Infrastructure Engineering, 2024, 39: 679 − 691. doi: 10.1111/mice.13091

[12] 余凌波. 基于线结构光的单目3D视觉机器人制鞋喷胶技术研究[D]. 武汉: 华中科技大学, 2019. Yu Lingbo. Research on robot shoe gluing technology of monocular 3D vision based on line structure light[D]. Wuhan: Huazhong University of Science and Technology, 2019.

[13] Zong W, Li M, Li G, et al. Toward efficient and complete line segment extraction for large-scale point clouds via plane segmentation and projection[J]. IEEE Sensors Journal, 2023, 23: 7217 − 7232

[14] Zhong Y, Zhao D, Cheng D, et al. A fast and precise plane segmentation framework for indoor point clouds[J]. Remote Sensing, 2022, 14: 15.

[15] Martin A Fischler, Robert C Bolles. Random sample consensus[J]. Communications of the ACM, 1981, 24(6): 381 − 395.

[16] Wu Q, Liu J, Gao C, et al. Improved RANSAC point cloud spherical target detection and parameter estimation method based on principal curvature constraint[J]. Sensors, 2022, 22(15): 5850.

-

期刊类型引用(3)

1. 胡岭,余丁坤,卜永周,罗庆澄,薛松柏. Sn和Ce元素复合添加对BAg5CuZn钎料钎缝组织与性能影响. 焊接学报. 2024(04): 101-108+135 .  本站查看

本站查看

2. 汪小钰,王轶,操齐高,孟晗琪,郑晶,苏瑾,胡建华,张志霄. 熔炼气雾化制备钴基粉末钎料在GH4169合金钎焊中应用. 电焊机. 2024(05): 46-51 .  百度学术

百度学术

3. 李淳,陈雷,司晓庆,亓钧雷,曹健. 陶瓷-金属接头残余应力调控研究综述. 机械工程学报. 2024(22): 21-39 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: