Investigation on microstructure characteristics of Ti-48Al alloy fabricated using twin-wire directed energy deposition-plasma arc

-

摘要:

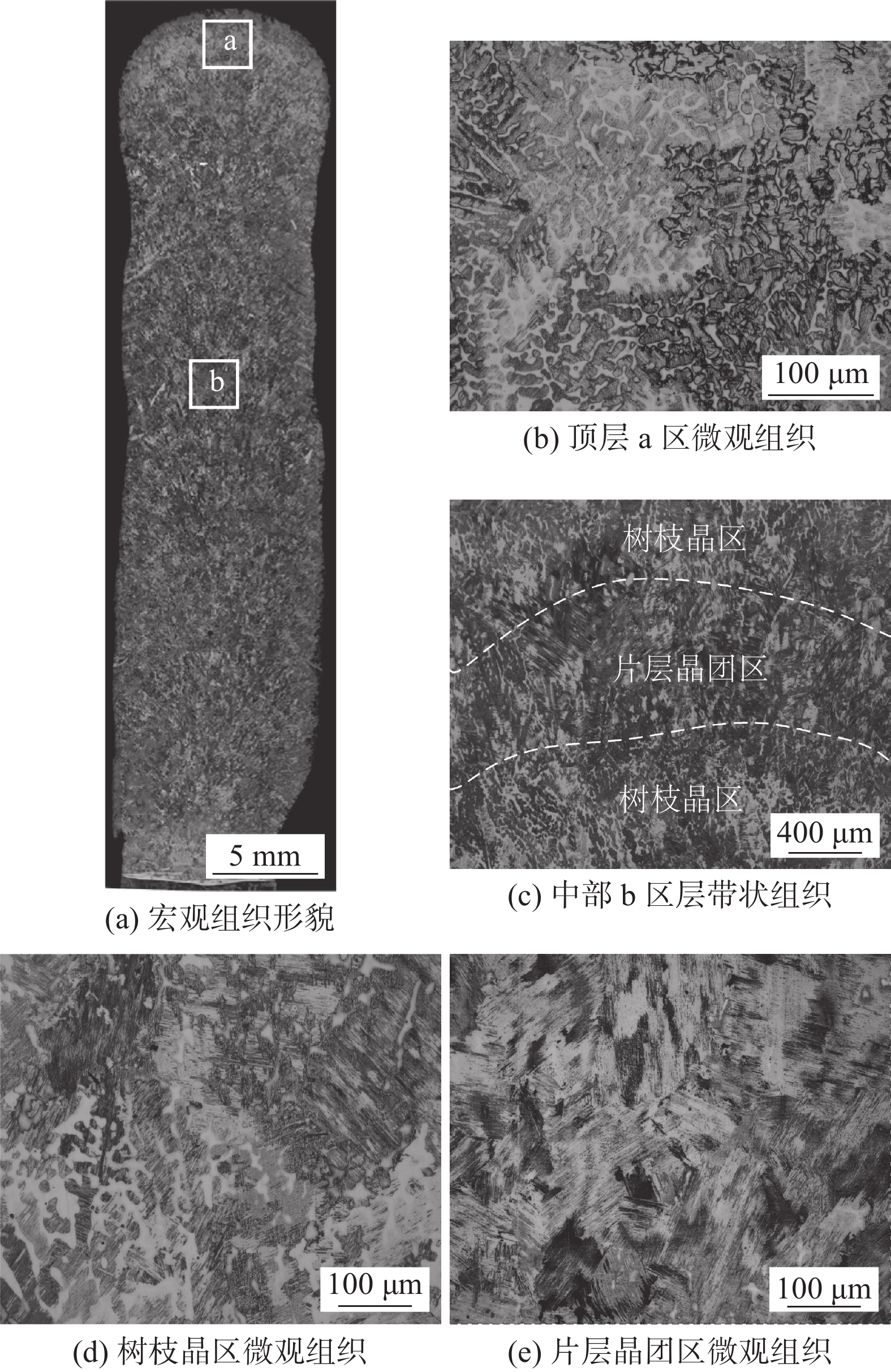

采用等离子电弧双丝增材制造技术成功制备了Ti-48Al合金(at.%),并对其沉积态和热处理后的组织特征进行了系统地研究. 结果表明,沉积态Ti-48Al合金主要由α2相和γ相组成,沿着沉积方向,沉积态组织呈现由树枝晶区和片层晶团区交替分布的不均匀性特征,并且在树枝晶区存在严重的枝晶间Al元素偏析现象. 在1340 ℃/10 h/炉冷热处理后,不均匀的沉积态组织转变为晶粒尺寸细小的双态组织,Ti-48Al合金的微观组织的不均匀性获得明显改善,并且α2相含量显著增加,组织的择优取向减弱.

Abstract:Ti-48Al alloy is fabricated successfully using plasma arc powred twin wire-directed energy deposition-arc, and its microstructure characteristic before and after heat treatment is systematically investigated. The results show that as-deposited Ti-48Al alloy consists of α2 and γ phase. The microstructure is characterized by the alternatively distributed dendritic grain and fully lamellar colony along the building direction for as-deposited Ti-48Al alloy, and there is interdendritic Al element segregation in the dendritic grain region. After heat treatment in 1340 ℃/10 h/furnace cooling, the duplex microstructure with fine grain size is obtained, and the microstructure heterogeneity is significantly improved, the α2 phase content is obviously increased, the preferred orientation of microstructure is also weakened.

-

Keywords:

- directed energy deposition-arc /

- TiAl alloy /

- microstructure /

- heat treatment

-

-

图 3 Ti-Al二元合金相图[23]

Figure 3. Ti-Al binary phase diagram

图 4 沉积态Ti-48Al合金试样横截面(x-z)的组织特征

Figure 4. Microstructure on the cross section (x-z) of as-deposited Ti-48Al alloy. (a) macrostructure morphology; (b) microstructure in the top a region; (c) the banded structure in the middle b region; (d) the dendritic grain microstructure; (e) the fully lamellar colony microstructure

-

[1] 陈玉勇, 时国浩, 杜之明, 等. 增材制造TiAl合金的研究进展[J]. 金属学报, 2023: 1 − 25. doi: 10.11900/0412.1961.2022.00582 Chen Yuyong, Shi Guohao, Du Zhiming, et al. Research progress on additive manufacturing TiAl alloy[J]. Acta metallurgica sinica, 2023: 1 − 25. doi: 10.11900/0412.1961.2022.00582

[2] Emiralioglu A, Unal R. Additive manufacturing of gamma titanium aluminide alloys: a review[J]. Journal of Materials Science, 2022, 57(7): 4441 − 4466. doi: 10.1007/s10853-022-06896-4

[3] Huang H T, Ding H S, Xu X S, et al. Phase transformation and microstructure evolution of a beta-solidified gamma-TiAl alloy[J]. Journal of Alloys and Compounds:An Interdisciplinary Journal of Materials Science and Solid-state Chemistry and Physics, 2021, 860: 158082.

[4] Kothari K, Radhakrishnan R, Wereley N M. Advances in gamma titanium aluminides and their manufacturing techniques[J]. Progress in Aerospace Sciences, 2012, 55(12): 1 − 16.

[5] Soliman H A, Elbestawi M. Titanium aluminides processing by additive manufacturing – a review[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(9-10): 5583 − 5614. doi: 10.1007/s00170-022-08728-w

[6] Cheng F, Wang H M, Wu Y, et al. Microstructure evolution and tensile property of TiAl alloy using continuous direct energy deposition technique[J]. Journal of Alloys and Compounds, 2022, 906: 164309.

[7] Cho K, Kawabata H, Hayashi T, et al. Peculiar microstructural evolution and tensile properties of β-containing γ-TiAl alloys fabricated by electron beam melting[J]. Additive Manufacturing, 2021, 46: 102091. doi: 10.1016/j.addma.2021.102091

[8] Zhang X Y, Li C W, Zheng M Y, et al. Chemical, microstructure, and mechanical property of TiAl alloys produced by high-power direct laser deposition[J]. Journal of Materials Science & Technology, 2022, 117: 99 − 108.

[9] Wimler D, Lindemann J, Reith M, et al. Designing advanced intermetallic titanium aluminide alloys for additive manufacturing[J]. Intermetallics, 2021, 131: 107109. doi: 10.1016/j.intermet.2021.107109

[10] Kan W, Chen B, Jin C, et al. Microstructure and mechanical properties of a high Nb-TiAl alloy fabricated by electron beam melting[J]. Materials & Design, 2018, 160: 611 − 623.

[11] Yue H Y, Chen Y Y, Wang X P, et al. Effect of beam current on microstructure, phase, grain characteristic and mechanical properties of Ti-47Al-2Cr-2Nb alloy fabricated by selective electron beam melting[J]. Journal of Alloys and Compounds, 2018, 750: 617 − 625.

[12] Tang H P, Yang G Y, Jia W P, et al. Additive manufacturing of a high niobium-containing titanium aluminide alloy by selective electron beam melting[J]. Materials Science & Engineering, A. Structural Materials:Properties, Misrostructure and Processing, 2015, 636: 103 − 107.

[13] 蔡笑宇, 董博伦, 王俊哲, 等. 热处理对GTA增材制造TiAl合金组织与性能的调控[J]. 焊接学报, 2022, 43(3): 7 − 12. doi: 10.12073/j.hjxb.20210921002 Cai Xiaoyu, Dong Bolun, Wang Junzhe, et al. Control of the microstructure and mechanical properties of GTA-based wire arc additive manufactured TiAl alloys using post heat treatment[J]. Transactions of the China Welding Institution, 2022, 43(3): 7 − 12. doi: 10.12073/j.hjxb.20210921002

[14] Ma Y, Cuiuri D, Hoye N, et al. The effect of location on the microstructure and mechanical properties of titanium aluminides produced by additive layer manufacturing using in-situ alloying and gas tungsten arc welding[J]. Materials Science & Engineering, A. Structural Materials:Properties, Misrostructure and Processing, 2015, 631: 230 − 240.

[15] Ma Y, Cuiuri D, Shen C, et al. Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding[J]. Additive Manufacturing, 2015, 8: 71 − 77. doi: 10.1016/j.addma.2015.08.001

[16] Ma Y, Cuiuri D, Hoye N, et al. Effects of wire feed conditions on in situ alloying and additive layer manufacturing of titanium aluminides using gas tungsten arc welding[J]. Journal of Materials Research, 2014, 29(17): 2066 − 2071. doi: 10.1557/jmr.2014.203

[17] Cai X Y, Dong B L, Yin X L, et al. Wire arc additive manufacturing of titanium aluminide alloys using two-wire TOP-TIG welding: Processing, microstructures, and mechanical properties[J]. Additive Manufacturing, 2020, 35: 101344. doi: 10.1016/j.addma.2020.101344

[18] 刘齐, 张萌, 付乐琪, 等. 原位合金化双丝电弧增材制造γ-TiAl组织性能研究[J]. 稀有金属材料与工程, 2020, 49(11): 3919 − 3924. Liu Qi, Zhang Meng, Fu Leqi, et al. Microstructure and properties of γ-TiAl fabricated by in-situ alloying assisted double-wire arc additive manufacturing[J]. Rare Metal Materials and Engineering, 2020, 49(11): 3919 − 3924.

[19] Zhao P K, Fang K, Tang C, et al. Effect of interlayer cooling time on the temperature field of 5356-TIG wire arc additive manufacturing[J]. China Welding, 2021, 30(2): 17 − 24.

[20] 蔡笑宇, 董博伦, 殷宪铼, 等. 预热温度对GTA增材制造钛铝合金组织及性能的影响[J]. 焊接学报, 2021, 42(10): 14 − 21. Cai Xiaoyu, Dong Bolun, Yin Xianlai, et al. Influences of preheating temperatures on the microstructures and mechanical properties of GTA additive manufactured TiAl based alloy[J]. Transactions of the China Welding Institution, 2021, 42(10): 14 − 21.

[21] Yue H Y, Peng H, Li R F, et al. Effect of heat treatment on the microstructure and anisotropy of tensile properties of TiAl alloy produced via selective electron beam melting[J]. Materials Science & Engineering, 2021, 803: 140473.

[22] Zhou S D, Peng P, Xu Y L, et al. Investigation on microstructure and mechanical properties of heat-treated Ti-47.5Al–3Nb-3.5Cr alloy[J]. Materials Science & Engineering, 2022, 832: 142366.

[23] Imayev R M, Imayev V M, Oehring M, et al. Alloy design concepts for refined gamma titanium aluminide based alloys[J]. Intermetallics, 2007, 15(4): 451 − 460. doi: 10.1016/j.intermet.2006.05.003

-

期刊类型引用(4)

1. 郑伟,路向琨. 压力采集滤波系统在铝合金电阻点焊中的研究及应用. 热加工工艺. 2024(15): 49-52+58 .  百度学术

百度学术

2. 于鹏,蔡正标,赵明明,刘鹏,张文明. 基于焊接电信号频域特征的焊接过程稳定性评估. 焊接学报. 2023(04): 105-110+135-136 .  本站查看

本站查看

3. 赵大伟,王元勋,梁东杰,Yuriy Bezgans. 基于功率信号动态特征的钛合金电阻点焊熔核直径预测. 焊接学报. 2022(01): 55-59+116-117 .  本站查看

本站查看

4. 刘倩雯,张南峰,阮洁珊,叶广文,张艳喜,高向东. 电阻点焊质量检测技术研究现状. 精密成形工程. 2022(05): 83-93 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: