Formation mechanism and influencing factors of unstable metal transfer in high current MAG welding

-

摘要:

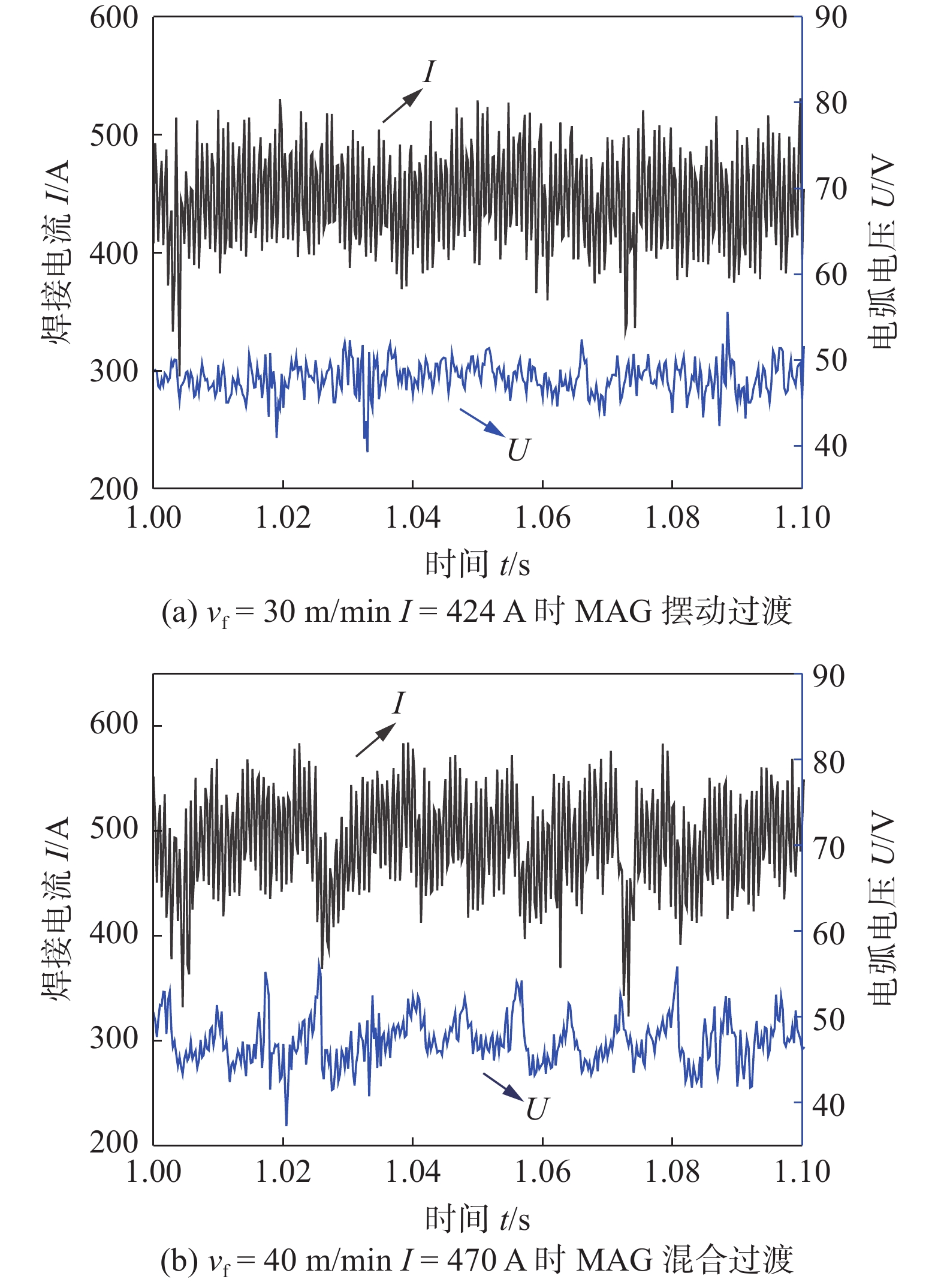

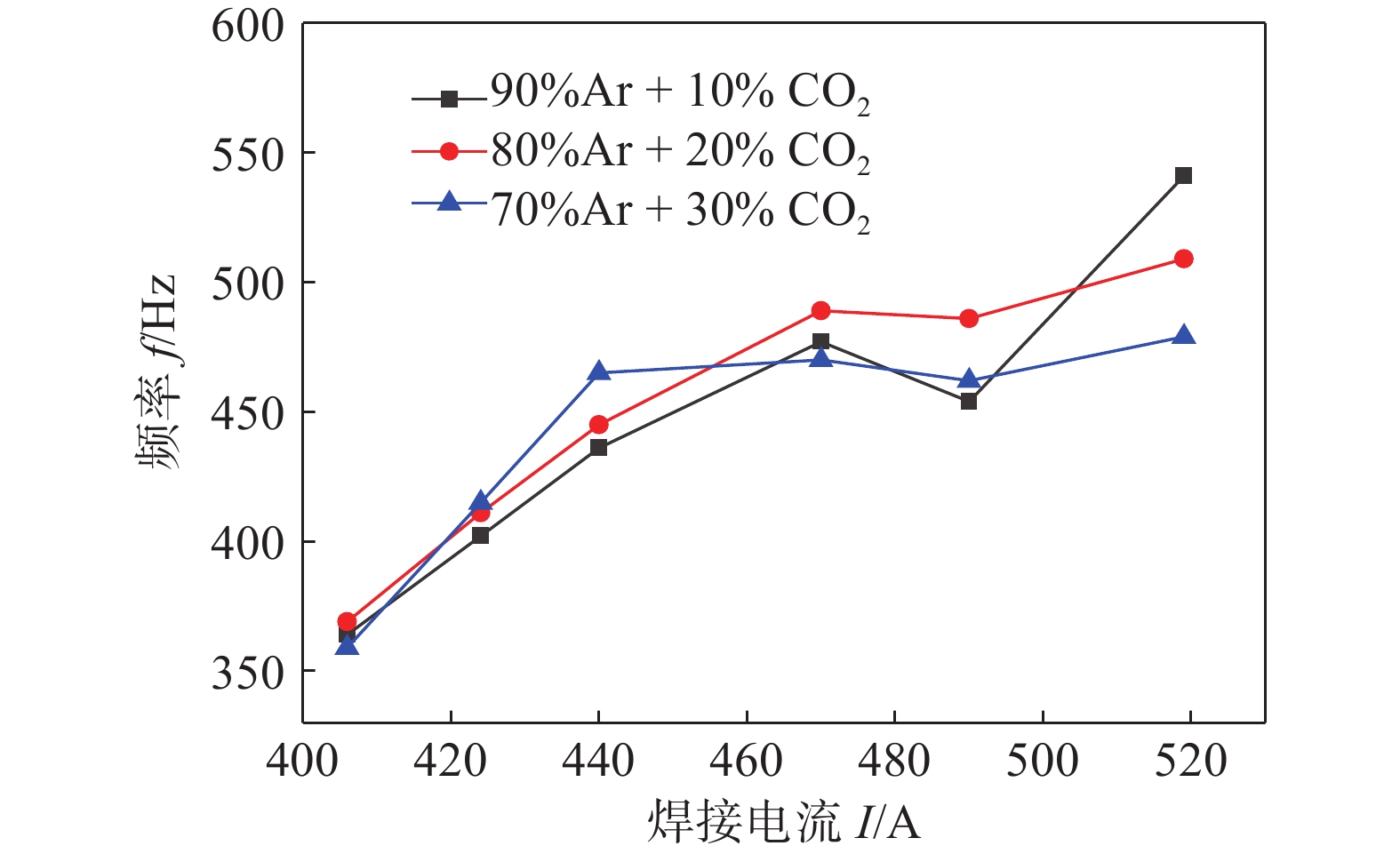

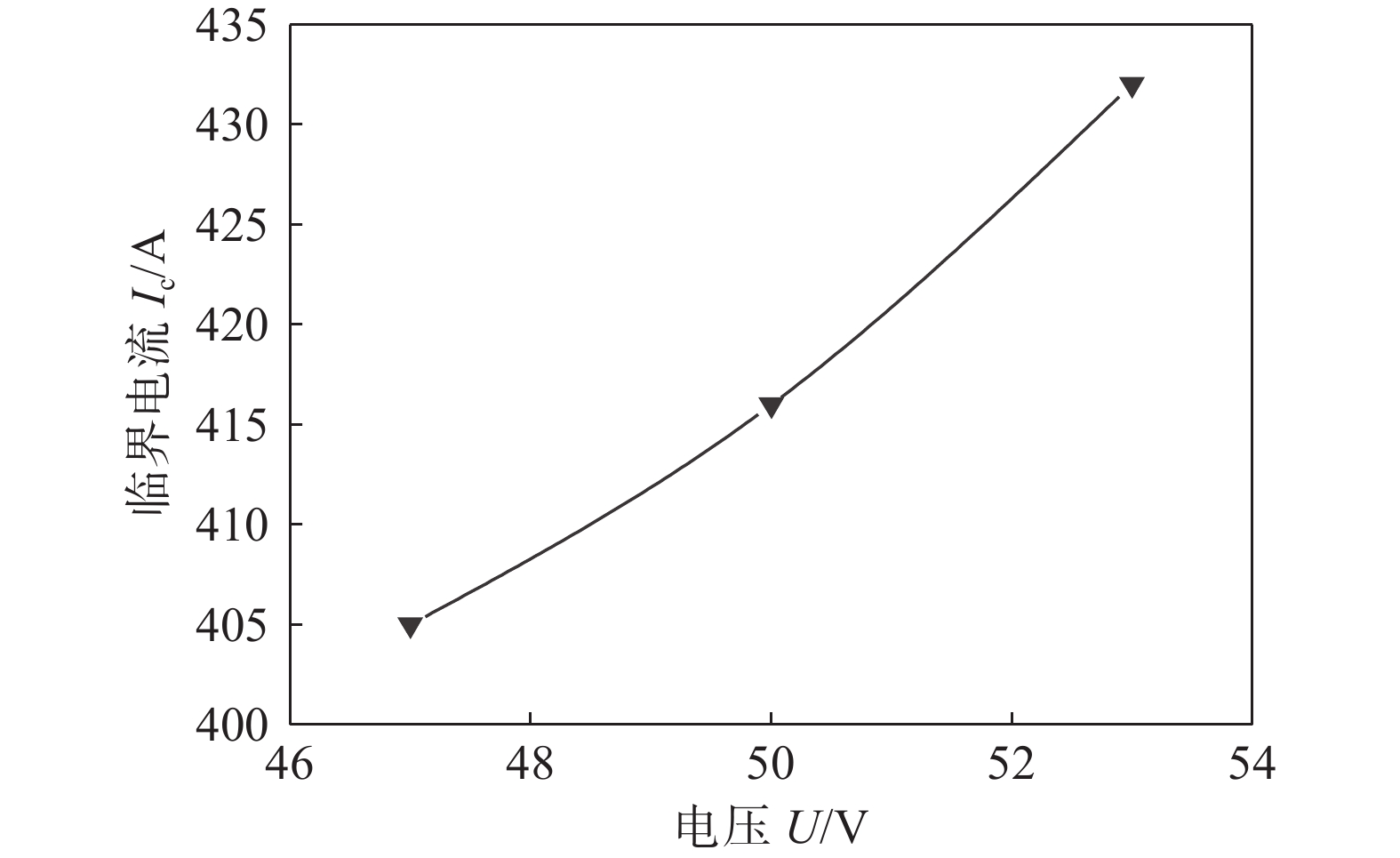

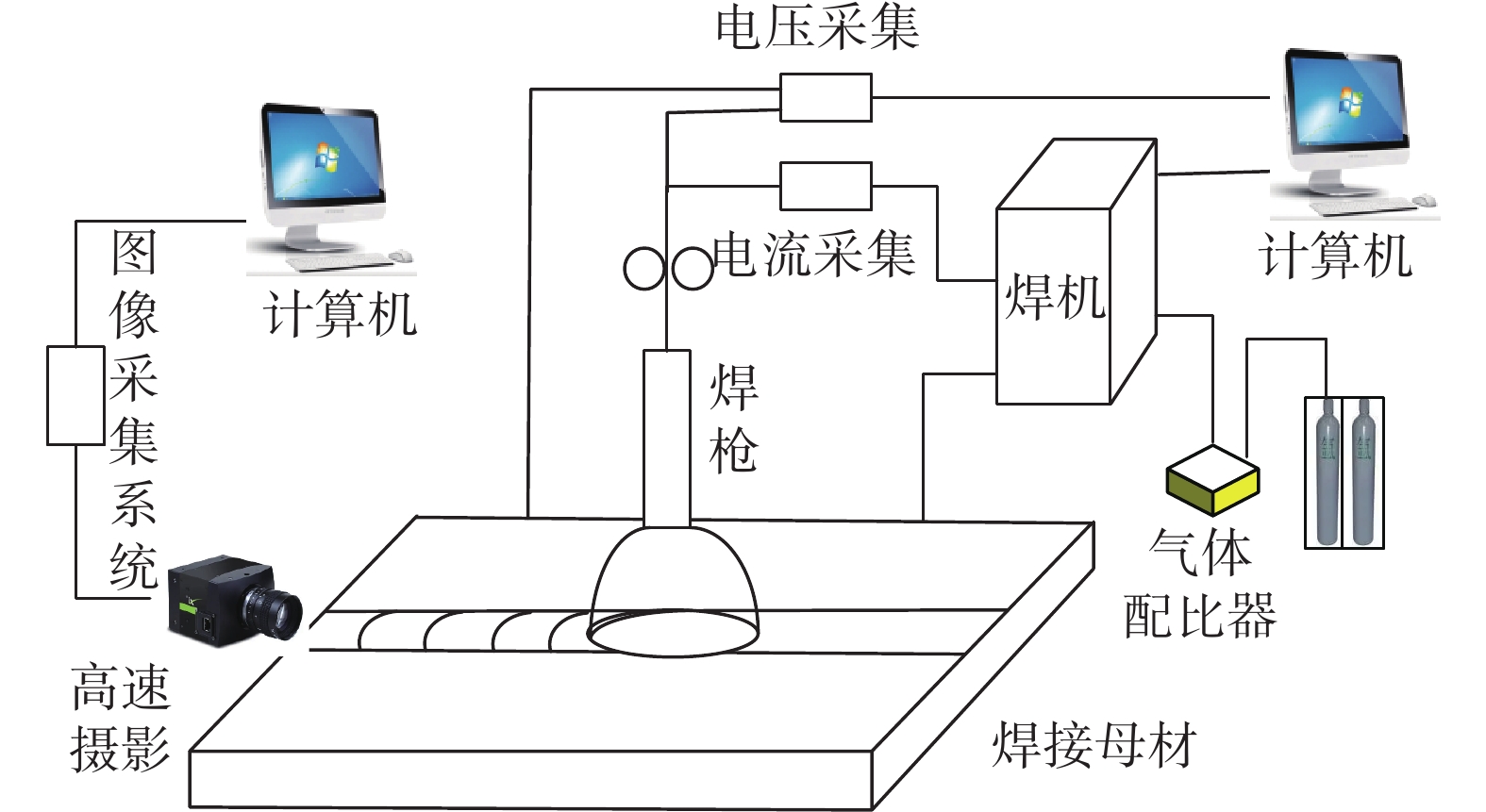

熔滴过渡的稳定性对大电流熔化极活性气体保护焊(MAG)焊接质量至关重要.采用高速摄像系统、电信号采集系统对大电流MAG不稳定熔滴过渡过程、电弧形态及电信号进行研究,揭示不稳定熔滴过渡的形成机理,分析了影响大电流MAG不稳定熔滴过渡临界电流值的因素.结果表明,大电流MAG焊熔滴过渡为摆动过渡和混合过渡的不稳定过渡模式,液锥受强电磁力是失稳偏离焊丝轴向的直接原因,电弧旋转/摆动频率随熔滴过渡模式和电弧形态不同而不同.焊丝伸出长度为影响不稳定熔滴过渡临界电流值的主要因素,且在试验参数内随着焊丝伸出长度的增大临界电流值显著减小.

Abstract:The stability of droplet transfer is crucial for the quality of high current MAG welding. A high-speed camera system and electrical signal acquisition system were used to study the unstable droplet transfer process, arc morphology, and electrical signal of high current MAG. The formation mechanism of unstable droplet transfer was revealed, and the factors affecting the critical current value of unstable droplet transfer in high current MAG were analyzed. The results showed that the droplet transfer in high current MAG welding is an unstable transition mode consisting of swing and mixed transfer. The instability of the liquid cone due to strong electromagnetic force and deviation from the welding wire axis are the direct reasons. The arc rotation/swing frequency varies with the droplet transfer mode and arc shape. Dry elongation is the main factor affecting the critical current value of unstable droplet transfer, and the critical current value significantly decreases with the increase of dry elongation.

-

-

表 1 焊接参数

Table 1 Welding parameters

电弧电压U/V 焊丝伸出长度Lm/mm 送丝速度

vf/(m∙min−1)焊接电流

I/A50 30 20 378 50 30 30 424 50 30 40 470 50 30 45 492 50 30 50 519 表 2 正交试验表及试验结果

Table 2 Orthogonal test table and test results

试验

编号CO2占比

A(%)焊丝伸出长度Lm/mm 焊接电压

U/V临界电流Ic/A 1 10 20 45 433 2 10 25 50 443 3 10 30 55 440 4 20 20 50 470 5 20 25 55 447 6 20 30 45 400 7 30 20 55 520 8 30 25 45 475 9 30 30 50 397 K1 1 316 1 400 1 308 K2 1 317 1 388 1 287 K3 1 392 1 237 1 430 k1 438.67 466.67 436 k2 439 462.67 429 k3 464 412.33 446.67 R 25.33 54.34 17.67 -

[1] 李晓延, 武传松, 李午申. 中国焊接制造领域学科发展研究[J]. 机械工程学报, 2012, 48(6): 19 − 31. doi: 10.3901/JME.2012.06.019 Li Xiaoyan, Wu Chuansong, Li Wushen. Study on the progress of welding science and technology in China[J]. Journal of Mechanical Engineering, 2012, 48(6): 19 − 31. doi: 10.3901/JME.2012.06.019

[2] Lahnsteiner R. The T. I. M. E. process-an innovative MAG welding process[J]. Welding Review International, 1992, 11(1): 17 − 20.

[3] Wu Kaiyuan, He Zuwei, Liang Zhouyong, et al. The dynamic behavior of double arc interference in high-power double wire pulsed GMAW[J]. The International Journal of Advanced Manufacaturing Technology, 2017, 88: 2795 − 2802. doi: 10.1007/s00170-016-8916-6

[4] Stefa Trube, et al. . High performance MAG welding with the LINFAST concept[J]Reports on Science and Technology. 1998(60): 15-21.

[5] 戴宇, 王大锋, 马良超, 等. 超高强度钢激光-MAG复合焊熔滴过渡研究[J]. 兵器材料科学与工程, 2020, 43(2): 67 − 71. doi: 10.14024/j.cnki.1004-244x.20191225.003 Dai Yu, Wang Dafeng, Ma Liangchao, et al. Research on droplet transfer in laser-MAG hybrid welding of ultra-high strength steel[J]. Ordnance Material Science and Engineering, 2020, 43(2): 67 − 71. doi: 10.14024/j.cnki.1004-244x.20191225.003

[6] Wu Kaiyuan, Zhan Jiatong, Cao Xuanwei, et al. Dynamic metal transfer behavior in double-wire DP-GMAW of aluminum alloy under different pulse phases[J]. Journal of Manufacturing Science and Engineering, 2021, 143(4): 1 − 28.

[7] 韩蛟, 韩永全, 洪海涛, 等. 铝合金Plasma-GMAW-P复合焊接电弧特性及熔滴过渡行为[J]. 稀有金属材料与工程, 2022, 51(6): 2027 − 2032. Han Jiao, Han Yongquan, Hong Haitao, et al. Arc characteristic and droplet transfer behavior in Plasma-GMAW-P hybrid welding[J]. Rare Metal Materials and Engineering, 2022, 51(6): 2027 − 2032.

[8] Yosuke Ogino, Yoshinori Hirata, Satoru Asai. Discussion of the effect of shielding gas and conductivity of vapor core on metal transfer phenomena in gas metal arc welding by numerical simulation[J]. Plasma Chemistry and Plasma Processing, 2020, 40(5): 1109 − 1126. doi: 10.1007/s11090-020-10102-1

[9] Liu Guoqiang, Tang Xinhua, Xu Qi, et al. Effects of active gases on droplet transfer and weld morphology in pulsed-current NG-GMAW of mild steel[J]. Chinese Journal of Mechanical Engineering, 2021, 34(4): 249 − 261.

[10] 吴开源, 陈梓威, 黄浩, 等. 低频相位对双丝双脉冲GMAW熔滴过渡和焊缝成形的影响[J]. 焊接学报, 2022, 43(7): 43 − 48. doi: 10.12073/j.hjxb.20211102001 Wu Kaiyuan, Chen Ziwei, Huang Hao, et al. Effect of low frequency phase on droplet transfer and weld formation of twin wire double-pulse GMAW[J]. Transactions of The China Welding Institution, 2022, 43(7): 43 − 48. doi: 10.12073/j.hjxb.20211102001

[11] 刘凯, 宋佳妮. CO2激光-MAG电弧复合焊电弧能量对熔滴过渡特征和焊缝形貌的影响[J]. 应用激光, 2021, 41(1): 155 − 160. Liu Kai, Song Jiani. Effect of arc energy of CO2 laser MAG arc hybrid welding on droplet transfer characteristics and weld morphology[J]. Applied Laser, 2021, 41(1): 155 − 160.

[12] 樊丁, 杨文艳, 肖磊, 等. 高频交变磁场对大电流GMAW熔滴过渡和飞溅率的影响[J]. 焊接学报, 2019, 40(7): 1 − 5. doi: 10.12073/j.hjxb.2019400172 Fan Ding, Yang Wenyan, Xiao Lei, et al. Effect of high-frequency alternating magnetic field on droplet transfer and spatter rate of high current GMAW[J]. Transactions of the China Welding Institution, 2019, 40(7): 1 − 5. doi: 10.12073/j.hjxb.2019400172

[13] 樊丁, 郑发磊, 肖磊, 等. 高效MAG焊接熔滴过渡行为及交变磁场控制试验分析[J]. 焊接学报, 2019, 40(5): 1 − 5. doi: 10.12073/j.hjxb.2019400118 Fan Ding, Zheng Falei, Xiao Lei, et al. Experimental analysis of droplet transfer behavior and alternating magnetic field control in efficient MAG welding[J]. Transactions of the China Welding Institution, 2019, 40(5): 1 − 5. doi: 10.12073/j.hjxb.2019400118

[14] Suban M, Tusek J. Dependence of melting rate in MIG/MAG welding on the type of shielding gas used[J]. Journal of Materials Processing Technology, 2001, 119(1-3): 185 − 192. doi: 10.1016/S0924-0136(01)00940-2

[15] Li Ruoyang, Yue Jun, Sun Ran, et al. A study of droplet transfer behavior in ultra-narrow gap laser arc hybrid welding[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87: 2997 − 3008. doi: 10.1007/s00170-016-8699-9

[16] 徐鲁宁, 殷树言, 卢振洋. T. I. M. E. 焊工艺与高效MAG焊的发展[J]. 电焊机, 2000, 30(5): 3 − 7. doi: 10.3969/j.issn.1001-2303.2000.05.001 Xu Luning, Yin Shuyan, Lu Zhenyang. T. I. M. E. Welding process and development of efficient MAG welding[J]. Electric Welding Machine, 2000, 30(5): 3 − 7. doi: 10.3969/j.issn.1001-2303.2000.05.001

-

期刊类型引用(8)

1. 王磊磊,吕飞阅,高转妮,虞文军,高川云,占小红. 电弧增材制造2319铝合金交叉桁条结构微观组织与拉伸性能研究. 机械工程学报. 2023(01): 267-277 .  百度学术

百度学术

2. 姚宇,张秋菊,陈宵燕,吕青,焦露. 复杂空间曲面焊接机器人自动编程系统. 焊接学报. 2023(05): 122-128+136 .  本站查看

本站查看

3. 董曼淑,朱晗,张晓超,白凯,刘龙,高洪明. 矿用链轮链窝电弧增材制造路径规划. 焊接. 2021(01): 51-55+64 .  百度学术

百度学术

4. 李天旭,王天琪,李亮玉,杨壮. 典型薄壁结构件增材制造焊接路径规划优化算法. 焊接学报. 2021(02): 69-74+101-102 .  本站查看

本站查看

5. 马明亮,刘苏杭,郭纯,王树军,刘茵琪. 电弧增材制造技术的研究进展. 铸造技术. 2021(03): 231-233 .  百度学术

百度学术

6. 舒凤远,牛司成,何鹏,隋少华,张小东. 高熵非晶材料及其增材制造技术研究进展. 焊接学报. 2021(09): 1-8+97 .  本站查看

本站查看

7. 杨东青,王小伟,黄勇,李晓鹏,王克鸿. 熔化极电弧增材制造18Ni马氏体钢组织和性能. 焊接学报. 2020(08): 6-9+21+97 .  本站查看

本站查看

8. 王天琪,张宏宇,耿冬寒,李亮玉,杨壮. 金属桁架结构成形工艺分析. 焊接学报. 2020(11): 25-30+98 .  本站查看

本站查看

其他类型引用(6)

下载:

下载: