Effect of scanning characteristic parameters on surface morphology of selective laser melting 316L

-

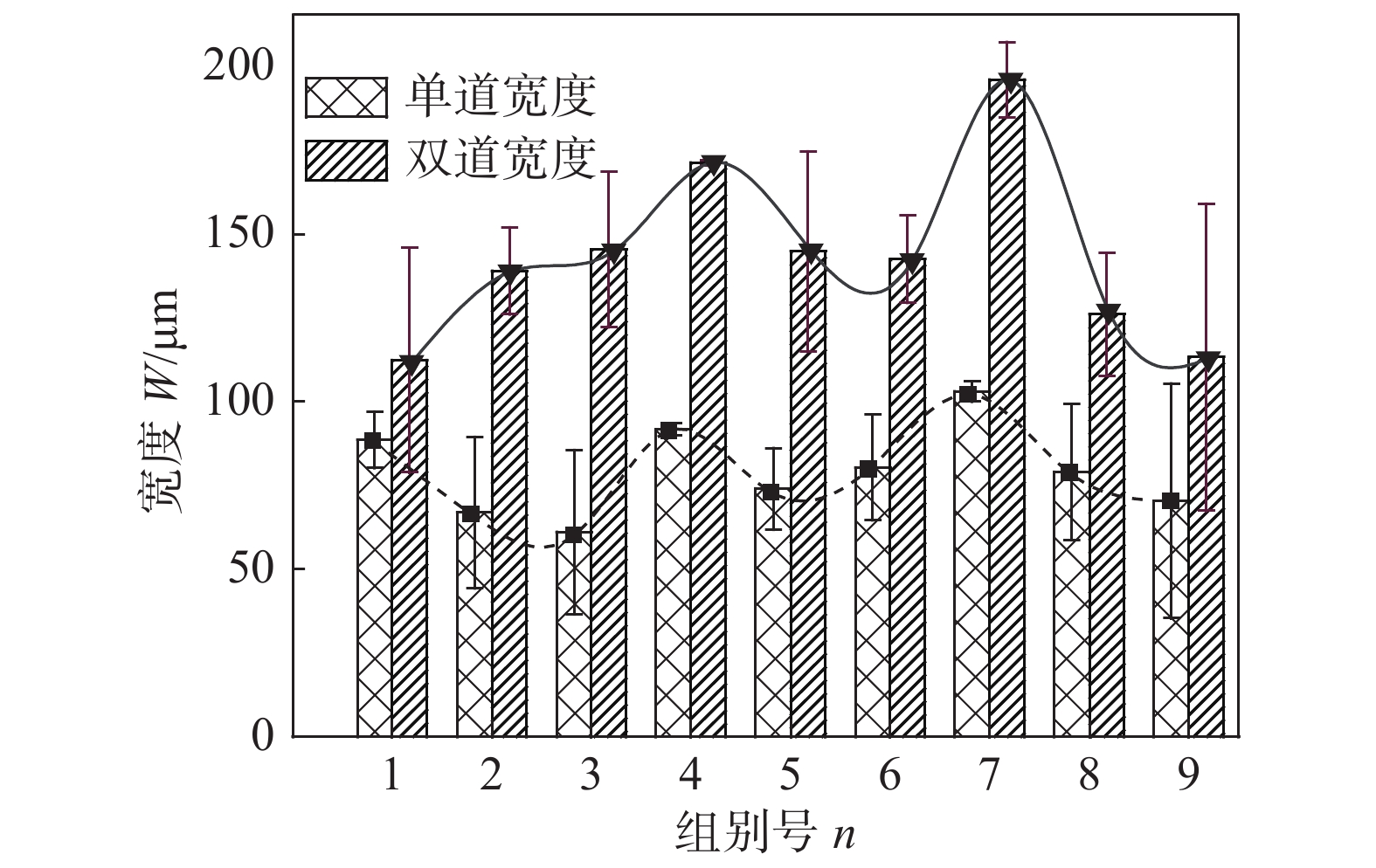

摘要: 为研究不同扫描特征参数组合对选区激光熔化(selective laser melting, SLM)表面形貌的影响,以316L不锈钢粉末为例,进行介观尺度的单层双道数值模拟研究.基于离散元法建立单层的粉床数值模型.使用流体体积法对粉床受热部分粉末的熔化过程中的熔化、流动和凝固过程进行计算.考虑激光功率、扫描速度和扫描间距3个扫描特征参数,设计并进行正交试验,从熔道形貌特征和熔道宽度2个方面研究所选扫描特征参数对成形件表面的熔道形貌影响.依据数值模拟中的参数进行实际打印及形貌观察试验,验证数值模拟的有效性.结果表明,在313 ~ 500 J/m的线能量密度和50 ~ 90 μm的扫描间距范围内,可以得到平整连续局部缺陷少的熔道形貌,且该区间内的参数组合依次线性对应;对熔道形貌的完整性影响由大到小依次为扫描速度、扫描间距和激光功率.Abstract: In order to study the influence of different scanning characteristic parameters on the surface morphology of selective laser melting (SLM), 316L stainless steel powder was taken as an example to carry out the single-layer and double-track numerical simulation at the mesoscopic scale. Based on the Discrete Element Method, the numerical model of powder bed is established. The Volume of Fluid method is used to calculate the melting, flow and solidification process of heated powder in powder bed. Considering the three scanning characteristic parameters of laser power, scanning speed and scanning spacing, the orthogonal experiment was designed and carried out to study the influence of selected scanning characteristic parameters on the tracks morphology on the surface of the formed part was studied from the two aspects of the tracks morphology and the tracks width.The effectiveness of numerical simulation was verified by actual printing and morphology observation experiments. The results show that in the range of linear energy density of 313 ~ 500 J/m and scanning interval of 50 ~ 90 μm, the morphology of melting tracks with smooth continuous local defects can be obtained, and the parameter combination in this interval is linearly corresponding in turn. In terms of the influence on the integrity of the weld morphology, scanning speed > scanning spacing > laser power.

-

-

图 2 数值模拟熔道形貌

Figure 2. Numerical simulation of melt tracks morphology. (a) group No. 1 No. A1B1C1; (b) group No. 2 No. A1B2C2; (c) group No. 3 No. A1B3C3; (d) group No. 4 No. A2B1C2; (e) group No. 5 No. A2B2C3; (f) group No. 6 No. A2B3C1; (g) group No. 7 No. A3B1C3; (h) group No. 8 No. A3B2C1; (i) group No. 9 No. A3B3C2

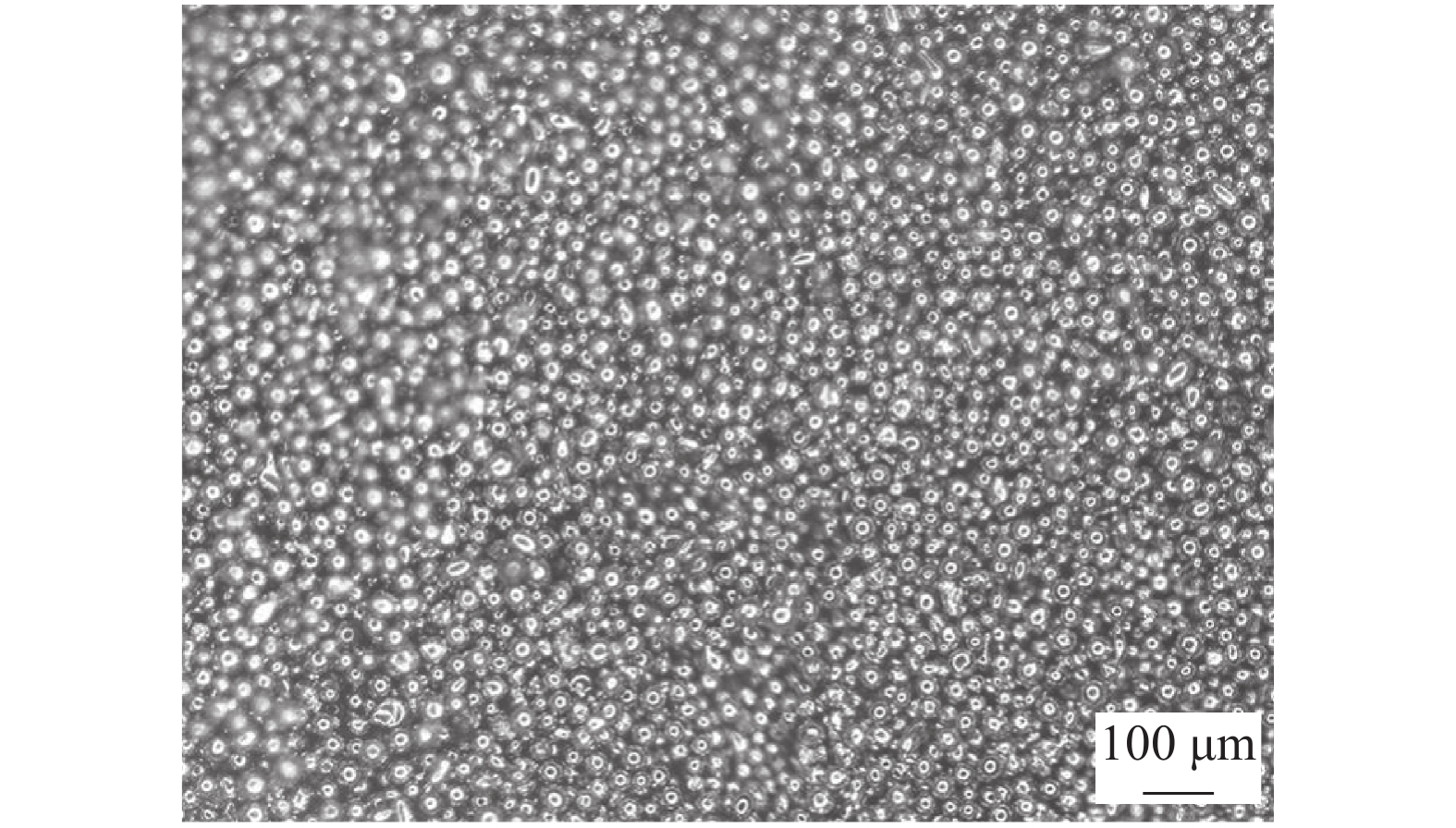

图 8 不同参数组合下的成形件表面形貌

Figure 8. Forming surface topography under the different parameters combination conditions. (a) group No. 1 No. A1B1C1; (b) group No. 2 No. A1B2C2; (c) group No. 3 No. A1B3C3; (d) group No. 4 No. A2B1C2; (e) group No. 5 No. A2B2C3; (f) group No. 6 No. A2B3C1; (g) group No. 7 No. A3B1C3; (h) group No. 8 No. A3B2C1; (i) group No. 9 No. A3B3C2

表 1 316L材料参数

Table 1 316L material parameters

固相密度ρ/(kg·m−3) 固相温度T/K 液相温度T/K 沸点温度T/K 熔化潜热Hf /(J·kg−1) 蒸发潜热Hv /(J·kg−1) 表面张力r /(N·m−1) 吸收率A 7 850 1 658 1 723 3 090 2.7 × 105 7.45 × 106 1.6 0.25 表 2 正交试验设计

Table 2 Experimental design using orthogonal table

参数变量 A功率P/W B速度v/(m·s−1) C间距S/μm 水平1 200 0.6 50 水平2 250 0.9 70 水平3 300 1.2 90 表 3 试验参数及编组

Table 3 Experimental parameters and grouping

组号 功率 P/W 速度 v /(m·s−1) 间距 S /μm 编号 1 200 0.6 50 A1B1C1 2 200 0.9 70 A1B2C2 3 200 1.2 90 A1B3C3 4 250 0.6 70 A2B1C2 5 250 0.9 90 A2B2C3 6 250 1.2 50 A2B3C1 7 300 0.6 90 A3B1C3 8 300 0.9 50 A3B2C1 9 300 1.2 70 A3B3C2 -

[1] Niendorf T, Leuders S, Riemer A, et al. Highly anisotro pic steel processed by selective laser melting[J]. Metallurgical & Materials Transactions B, 2013, 44(4): 794 − 796.

[2] 高倩. 激光选区熔化316L不锈钢微观组织与机械性能研究[D]. 西安科技大学, 2020. Gao Qian. Microstructure and mechanical properties of selective laser melting 316L stainless steel[D]. Xi’an University of Science and Technology, 2020.

[3] 宋亚男. SLM增材制造表面激光抛光机理与工艺研究[D]. 山东大学, 2021. Song Yanan. Research on laser polishing mechanism and process of SLM additive manufacturing surface[D]. Shandong University, 2021.

[4] Liu Binqi, Fang Gang, Lei Liping. An analytical model for rapid predicting molten pool geometry of selective laser melting (SLM)[J]. Applied Mathematical Modelling, 2021, 92: 505 − 524. doi: 10.1016/j.apm.2020.11.027

[5] Körner C, Attar E, Heinl P. Mesoscopic simulation of selective beam melting processes[J]. Journal of Materials Processing Technology, 2011, 211(6): 978 − 987. doi: 10.1016/j.jmatprotec.2010.12.016

[6] Wu Y C, Hwang W S, San C H, et al. Parametric study of surface morphology for selective laser melting on Ti6Al4V powder bed with numerical and experimental methods[J]. International Journal of Material Forming, 2018, 11(6): 807 − 813. doi: 10.1007/s12289-017-1391-2

[7] Wu Y C, San C H, Chang C H, et al. Numerical modeling of melt-pool behavior in selective laser melting with random powder distribution and experimental validation[J]. Journal of Materials Processing Technology, 2018, 254: 72 − 78. doi: 10.1016/j.jmatprotec.2017.11.032

[8] 向羽, 张树哲, 李俊峰, 等. Ti6Al4V的激光选区熔化单道成形数值模拟与实验验证[J]. 浙江大学学报(工学版)(自然科学版), 2019, 53(11): 2102 − 2109. Xiang Yu, Zhang Shuzhe, Li Junfeng, et al. Numerical simulation and experimental verification for selective laser single track melting forming of Ti6Al4V[J]. Journal of Zhejiang University (Engineering Science)(Natural Science Edition), 2019, 53(11): 2102 − 2109.

[9] 单雨薇. 选择性激光熔化中表层粉末熔池热力学特性3维数值模拟研究[D]. 上海交通大学, 2020. Shan Yuwei. 3D numerical modeling of thermodynamic characteristics of surface powder melt pool in selective laser melting[D]. Shanghai Jiao Tong University, 2020.

[10] 叶唯娟. 激光选区熔化过程中熔池温度场及形貌演化的数值模拟[D]. 西安理工大学, 2019. Ye Weijuan. Numeriacl simulation on temperature field and morphology evolution of molten pool during selective laser melting processing[D]. Xi’an University of Technology, 2019.

[11] Hen Xuehui, Mu Weihao, Xu Xin, et al. Numerical analysis of double track formation for selective laser melting of 316L stainless steel[J]. Applied Physics A, 2021, 127(8): 1 − 13.

[12] Xiang Y, Zhang S, Wei Z, et al. Forming and defect analysis for single track scanning in selective laser melting of Ti6Al4V[J]. Applied Physics A, 2018, 124(10): 1 − 12.

[13] Cao L, Yuan X. Study on the numerical simulation of the SLM molten pool dynamic behavior of a nickel-based superalloy on the workpiece scale[J]. Materials, 2019, 12(14): 2272. doi: 10.3390/ma12142272

[14] 胡国明. 颗粒系统的离散元素法分析仿真: 离散元素法的工业应用与EDEM 软件简介[M]. 武汉: 武汉理工大学出版社出版, 2010. Hu Guoming. Analysis and simulation of granular system by discrete element method using EDEM[M]. Wuhan: Wuhan University of Technology Press, 2010.

[15] Dai Donghua, Gu Dongdou. Influence of thermodynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites[J]. International Journal of Machine Tools and Manufacture, 2016, 100: 14 − 24. doi: 10.1016/j.ijmachtools.2015.10.004

[16] 梁祖磊, 孙中刚, 张少驰, 等. 数值模拟在激光选区熔化中的应用及研究现状[J]. 航空制造技术, 2018, 61(22): 87 − 91. doi: 10.16080/j.issn1671-833x.2018.22.087 Liang Zulei, Sun Zhonggang, Zhang Shaochi, et al. Application and research status of numerical simulation in laser selective melting[J]. Aeronautical Manufacturing Technology(Natural Science Edition), 2018, 61(22): 87 − 91. doi: 10.16080/j.issn1671-833x.2018.22.087

[17] 邱云基, 申梦清, 牛晓峰, 等. 选区激光熔化316L粉末过程数值模拟研究[J]. 特种铸造及有色合金, 2021, 41(9): 1092 − 1096. doi: 10.15980/j.tzzz.2021.09.007 Qiu Yunji, Shen Mengqing, Niu Xiaofeng, et al. Numerical simulation of the melting process of selective laser melting 316L powders[J]. Special Casting & Nonferous Alloys(Natural Science Edition), 2021, 41(9): 1092 − 1096. doi: 10.15980/j.tzzz.2021.09.007

[18] 曹志伟. 激光选区熔化单熔道成型数值模拟及缺陷分析[D]. 天津理工大学, 2019. Cao Zhiwei. Numerical simulation of single track formation and defects analysis in selective laser melting[D]. Tianjin University of Technology, 2019.

[19] Wang Wenhao, Liu Xinyu, Pan Lu. Effect of linear energy density on bubble-defect of 316L stainless steel by selective laser melting[J]. Key Engineering Materials, 2019, 4834: 32 − 36.

[20] Shi Xiaojie, Liu Xin, Ren Shuai, et al. Selective laser melting fabricated tungsten with thin-walled structure: role of linear energy density on temperature evolution and manufacturing quality[J]. International Journal of Material Forming, 2022, 15(1): 1 − 11. doi: 10.1007/s12289-021-01647-3

[21] Gusarov A V, Smurov I. Modeling the interaction of laser radiation with powder bed at selective laser melting[J]. Physics Procedia, 2010, 5: 381 − 394. doi: 10.1016/j.phpro.2010.08.065

[22] Olakanmi E O, Cochrane R F, Dalgarno K W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties[J]. Progress in Materials Science, 2015, 74: 401 − 477. doi: 10.1016/j.pmatsci.2015.03.002

[23] Yuan W H, Chen H, Cheng T, et al. Effects of laser scanning speeds on different states of the molten pool during selective laser melting: Simulation and experiment[J]. Materials & Design, 2020, 189: 108542.

[24] Yao N N, Peng X H. The preparation method of metal powder for 3D printing[J]. Sichuan Nonferrous Metals, 2013, 4: 48 − 51.

[25] Seyda V, Herzog D, Emmelmann C. Relationship between powder characteristics and part properties in laser beam melting of Ti–6Al–4V, and implications on quality[J]. Journal of Laser Applications, 2017, 29(2): 022311. doi: 10.2351/1.4983240

-

期刊类型引用(5)

1. 武靖伟,王有银,厚喜荣,王志刚,车文斌,张建晓,朵元才. N06200镍基合金与S32168不锈钢界面金属间化合物的生长行为. 焊接学报. 2024(02): 121-128+136 .  本站查看

本站查看

2. 陈松,李晓杰. 异种金属爆炸焊接的研究与发展. 爆破. 2023(02): 144-152 .  百度学术

百度学术

3. 郑洋,宿振宇,张璇. 铝/镁异质金属搅拌摩擦焊技术研究进展. 材料导报. 2021(S2): 346-352 .  百度学术

百度学术

4. 张忠科,武靖伟,赵华夏. 焊后热处理对钛/铝FSB接头组织及性能的影响. 中国有色金属学报. 2020(04): 739-749 .  百度学术

百度学术

5. 邓清洪,李志明,蒋习均,周长兴,付瑞东. 退火对Al-Mg搅拌摩擦焊接头组织及力学性能的影响. 电焊机. 2018(10): 36-43 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: