Study on temperature field, microstructure and properties of electroslag surfacing high chromium cast iron

-

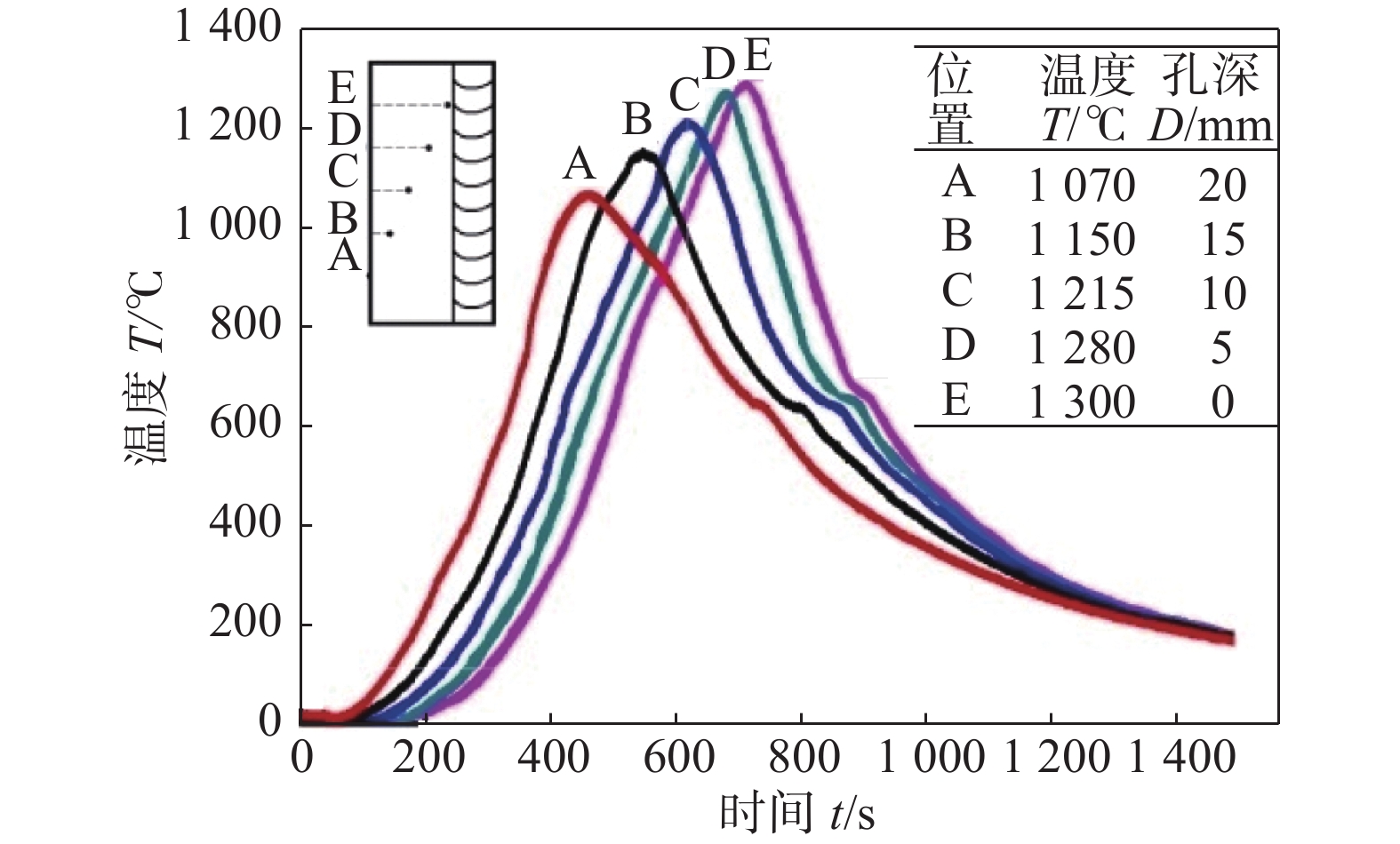

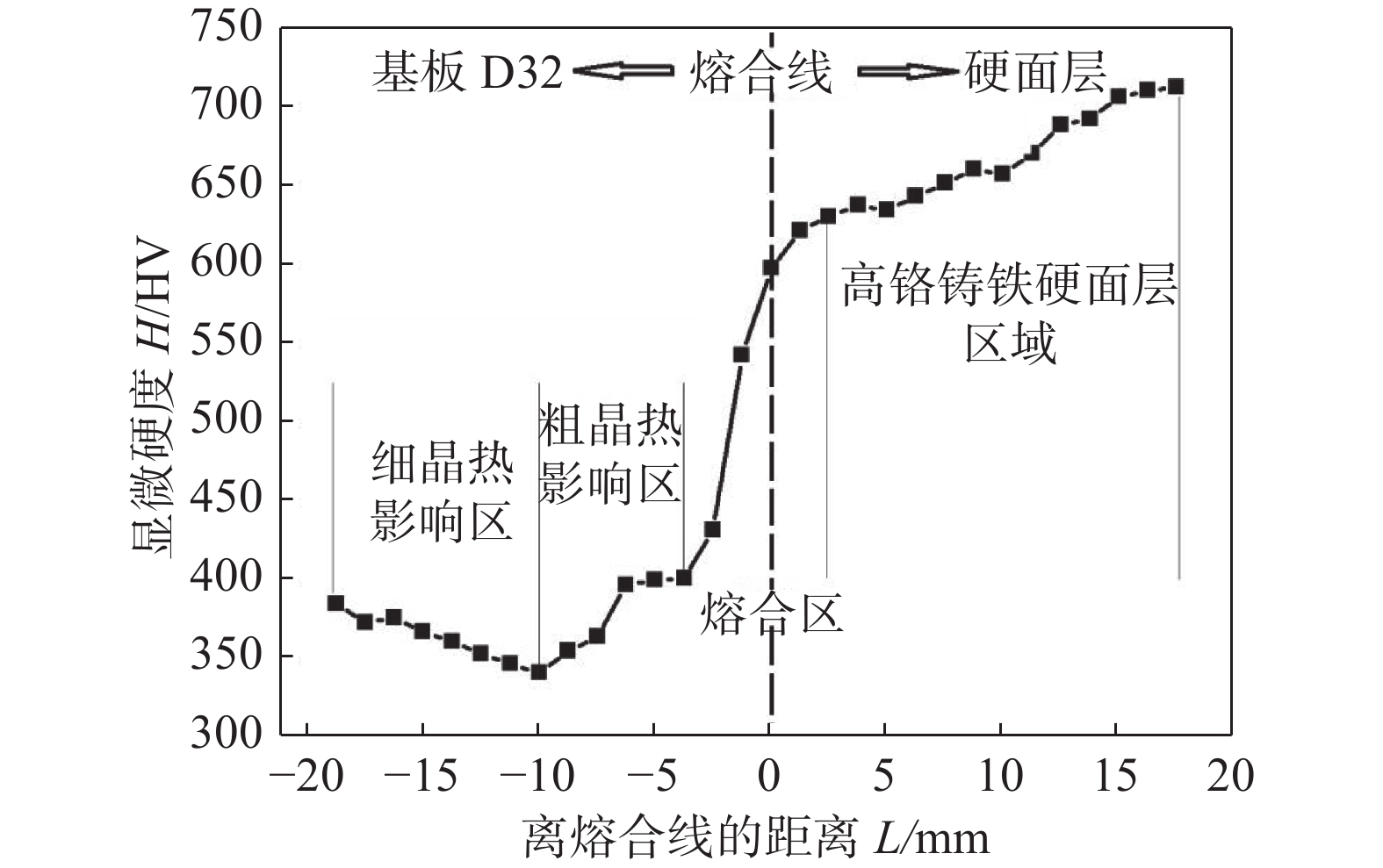

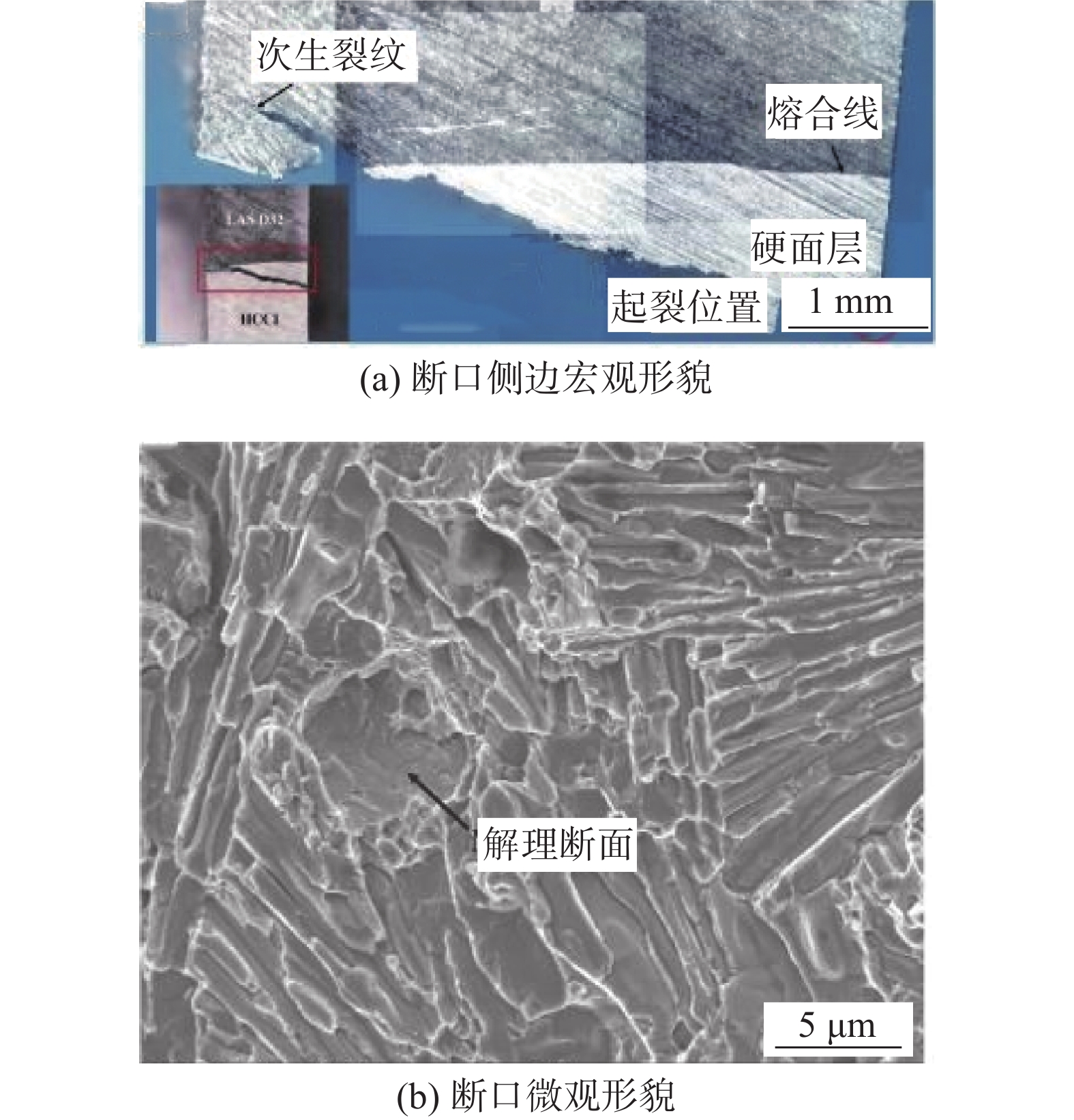

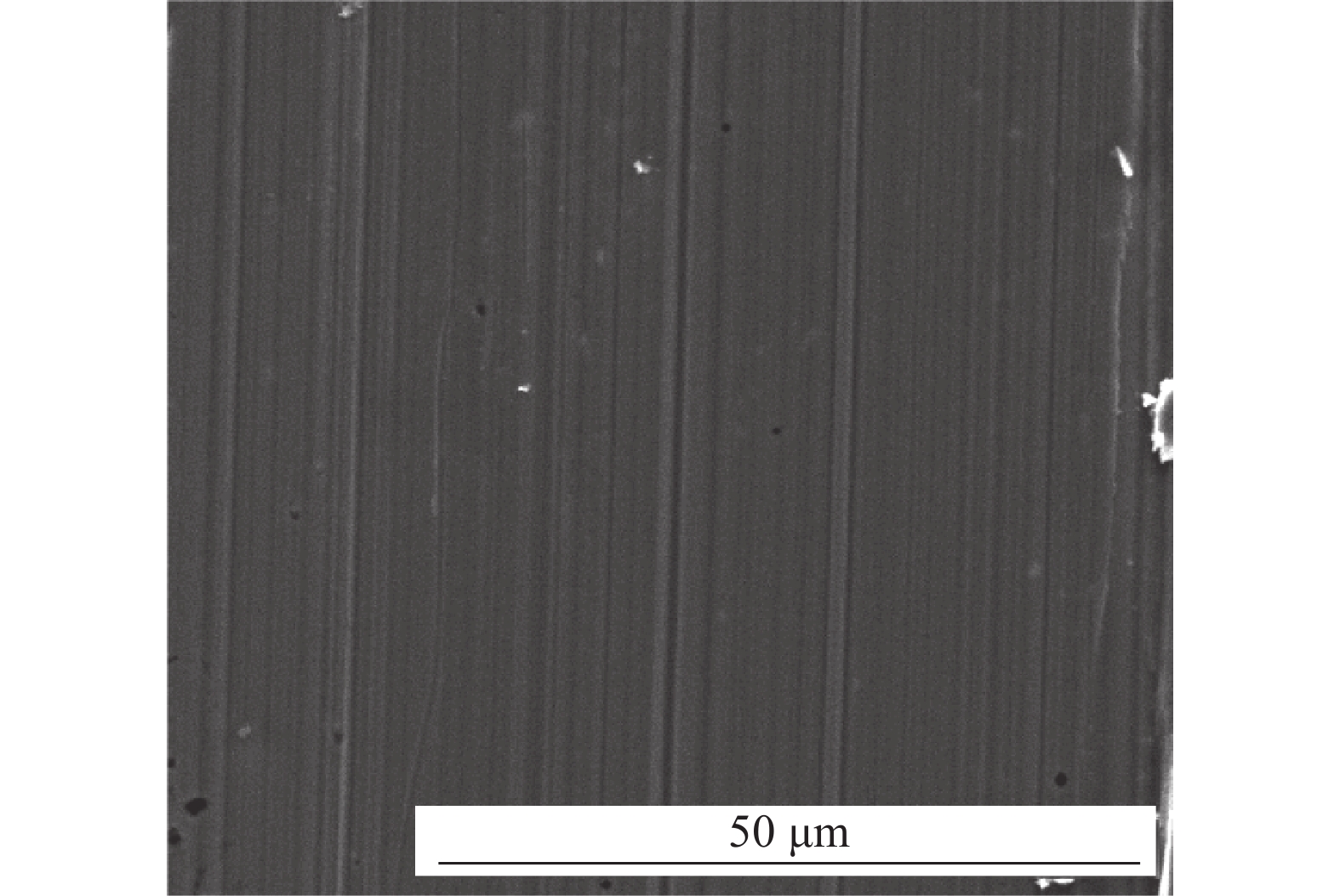

摘要: 用电渣堆焊的方法在D32低合金钢表面堆焊高铬铸铁硬面层,测量了堆焊过程中热影响区的温度场,研究了热影响区、复合界面及硬面层的微观组织和力学性能. 结果表明,电渣堆焊加热和冷却速度较慢,稳定阶段时低合金钢基材温度分布均匀,在堆焊方向最大温度梯度为−21.25 ℃/mm;低合金钢基板内最大热应力为53.4 MPa,低于低合金钢的抗拉强度,有效避免了裂纹的产生;复合界面平整清晰,存在宽度约50 μm的奥氏体带状区;热影响区晶粒有所长大,为铁素体加珠光体组织;高铬铸铁硬面层由奥氏体、碳化物和少量马氏体组成,M7C3型碳化物细小且均匀分布于奥氏体晶界;复合界面结合强度为96 MPa;试样熔合区的冲击吸收能量(53 J)较硬面层冲击吸收能量(10.7 J)明显提高;亚共晶高铬铸铁硬面层在较大磨损载荷下发生马氏体相变,硬度提高,耐磨粒磨损性能优良.Abstract: In this paper, the high chromium cast iron (HCCI) hardfacing layer is deposited on the surface of D32 low-alloy steel by electroslag surfacing method. Combined with the temperature field measurement of the heat-affected zone (HAZ) during the surfacing process, the microstructure and mechanical properties of the HAZ, composite interface and hardfacing layer are studied. The results show that: the heating and cooling rates are slower during the electroslag surfacing, and the temperature distribution in the low alloy steel substrate during the stabilizing stage is uniform; the maximum temperature gradient in the surfacing direction is 23.1 ℃/mm. The maximum thermal stress in the low-alloy steel substrate is 25.9 MPa, lower than its tensile strength, which effectively avoids the occurrence of cracks; the composite interface is smooth and clear, with an austenite band region, about 50 μm in width; The grains of HAZ have grown, whose microstructure is a mixture of ferrite and pearlite. The microstructure of HCCI hardfacing layer is composed of austenite, carbides and a small amount of martensite. The M7C3 type carbides are small and uniformly distributed in austenite grain boundaries. The bonding strength of the composite interface is 96 MPa; the impact energy (53 J) of the composite sample is significantly higher than that of the HCCI hardfacing layer (10.7 J). During abrasion, the HCCI hardfacing layer undergoes martensitic transformation under a large load, the hardness is improved, and an excellent performance in wear resistance was obtained.

-

Keywords:

- electroslag surfacing /

- high chromium cast iron /

- temperature field /

- microstructure /

- properties

-

0. 序言

由多个主要元素构成的高熵合金(high entropy alloys, HEA)在设计具有出色性能的材料时具有极大的灵活性,被认可为航空、生物医学、原子能领域的潜在结构和功能材料[1-3]. AlxCoCrFeNi高熵合金的结构稳定性、力学和电化学性能已被进行了详细研究[4-5]. AlxCoCrFeNi高熵合金在超临界热电厂、地热发电厂和核电厂具有极大的应用前景[6-7]. 离子辐射环境下AlxCoCrFeNi高熵合金的结构稳定性,单相Al0.1CoCrFeNi高熵合金在辐照下表现出高相稳定性[7]. Al0.1CoCrFeNi高熵合金在铸态下的组织演变被广泛研究,但其焊接后的组织演变目前研究较少[8-9].

高熵合金的工程应用关键在于焊接技术的研究[10].目前,已有钨极氩弧焊[11-12]、激光焊[13]、电子束焊[12]和搅拌摩擦焊[13-14]等焊接方法被应用于高熵合金焊接性能的研究,显示出作为结构材料的巨大潜力.目前,AlxCoCrFeNi[15-16],CoCrFeMnNi[17]和AlxCoCrCuyFeNi合金[18]等高熵合金在熔化焊方法的焊接性已有相关研究,但其有关固态焊方法的焊接性研究较少.

与电弧焊、激光焊和电子束焊等熔化焊不同,爆炸焊接是一种固态结合技术,其中两个相对的工件通过炸药能量的加速作用在高速碰撞下进行结合[19-20]. 由于固态连接的特性,爆炸焊接可以有效地避免在熔化焊中常见的各种焊接缺陷,例如气孔和裂纹[21-22].然而,爆炸焊接过程中射流的周期性运动导致了界面沿着爆炸焊接方向的波浪形貌以及具有方向性特征的微观结构产生[23-24].研究表明,AlxCoCrFeNi 和AlxCoCuyCrFeNi具有凝固裂纹倾向,且随着Al,Cu含量的增加更加明显[17, 25]. 最近的大多数研究都集中在高熵合金的焊接性上,但没有研究集中在高熵合金的异种焊接界面的方向性分布特征上.对高熵合金爆炸焊接方向特征以及区域性特征的研究有助于有效开发不同基材和接头配置的爆炸焊接技术,对于高熵合金的潜在应用至关重要.文中对爆炸焊接接头进行精细地抛光从法向截面与纵向截面研究了微观结构和硬度分布特征,不仅成功地制备了Al0.1CoCrFeNi高熵合金/Cu爆炸焊接复合材料,而且为其它成分高熵合金的爆炸焊接提供了基础.

1. 试验方法

文中所用的Al0.1CoCrFeNi高熵合金由感应熔炼制备. 将铸锭切割成尺寸为50 mm × 16 mm × 2 mm的板状,并进行表面抛光,然后作为爆炸焊接原料. 使用固定间隙为2 mm的平行结构进行爆炸焊接,如图1所示,使用的炸药是由质量分数为25%中空玻璃微球(hollow glass microspheres,HGMs)和75%乳化基质构成. 乳化基质[23]的组成成分为:75%NH4NO3 + 10%NaNO3 + 8%H2O + 4%C18H38 + 2%C24H44O6 + 1%C12H26(质量分数). 将乳化基质放入厚度为8 mm,六边形胞格(边长6 mm,壁厚60 μm)的铝蜂窝中制成铝蜂窝结构炸药. 在铝蜂窝炸药与覆板间插入2 mm厚度的纸板,选择软材料作为缓冲层避免炸药对覆板的直接损伤[26]. 以50 mm × 16 mm × 2 mm 的高熵合金和150 mm × 100 mm × 1 mm 的工业纯铜板分别作为基板和覆板来制造Cu/HEA复合材料. 此外,雷管被放置在炸药的短边中间位置.

将爆炸焊接后的Cu/HEA复合材料沿爆炸焊接方向切开观察.使用Gemini500型扫描电子显微镜(scanning electron microscope,SEM)和JSM-7800F型电子背散射衍射(electron backscatter diffraction,EBSD)检查键合界面的微观结构. 使用G200型测试仪在最大负载 15 mN和稳定负载速度500 µN/s下进行纳米压痕测试.

2. 试验结果与分析

2.1 界面形貌和微观结构

Cu/Al0.1CoCrFeNi高熵合金复合板通过爆炸焊接工艺成功制造.通过SEM技术在贯穿波形区的法向截面和沿着爆炸焊接方向的纵向截面,分别揭示了键合界面的形态和微观结构.

图2为法向和纵向截面的SEM图像. 从图2可以看出,法向和纵向界面具有相似的界面粘结形状,即界面上两种材料的交替分布和波浪状结合.在爆炸焊接过程中,界面附近的温度升高应足够高以熔化材料并导致形成熔化区[27]. 这说明在爆炸焊接后铜覆板和高熵合金基板之间形成了冶金结合[28]. 沿着爆炸焊接方向,高熵合金、熔化区、铜周期性出现(不同区域如虚线红色圆圈所示). 如图2a所示,类似于正弦波的Cu/Al0.1CoCrFeNi高熵合金复合板的界面形态中,沿着横向方向呈波浪状,并非是平直的,而是有着不规则的结合面,并沿着爆轰方向(纵向)波动变化(图3). 从法向截面和纵向截面测得的波长参数分别约为94 μm和89 μm,统计得到的波长无明显不同(图4). 图2a显示局部熔化区在横向方向(transverse direction,TD)上非均匀分布.

2.2 界面区域性特征

为了分析界面结合,使用EDS对图5所示位置进行了线扫描,结果表明过渡层厚度小于2 μm,因此两种材料在爆炸焊接过程中并未发生大规模熔化[29].

为了进一步研究Cu/Al0.1CoCrFeNi高熵合金界面处的微观结构,进行了EBSD测试,EBSD测试区域在图6中用白色虚线框标出.图5和图7显示了元素分布的测试区域,其中面扫描结果分别显示在图8和图9中. 面扫描和线扫描对应位置的元素测试结果分别显示在表1和图10中.

表 1 Al0.1CoCrFeNi/Cu界面的元素组成(质量分数, %)Table 1. Element compositions of Al0.1CoCrFeNi/Cu interface位置 Cu Fe Co Ni Cr Al P1 100 — — — — — P2 3.28 22.64 22.58 23.80 24.89 2.82 P3 3.19 22.86 22.56 23.62 24.92 2.96 P4 100 — — — — — P5 3.12 23.64 22.98 22.80 24.61 2.85 P6 49.18 12.44 12.88 11.78 12.42 1.29 P7 53.58 11.25 11.89 10.31 11.62 1.35 图5为铜侧区域1的微观结构,可以发现远离界面处铜的晶粒未发生明显变形. 如图6所示,Cu/Al0.1CoCrFeNi高熵合金的结合界面呈现出带有旋涡的正弦波形,且波形界面两侧出现局部熔化区域,如图5和图7所示. 旋涡结构的形成可能是由于爆炸焊接过程中较大的间隔距离导致的大塑性变形和界面处的局部高温分布所致[30]. 在爆炸焊接过程中,大多数射流都向前移动.然而,一部分铜改变了方向,并由于较大的塑性变形而回旋,并不断地穿透以形成涡流[31].这一分布特性与元素面分布特征一致,如图8和图9所示,即铜包裹着高熵合金在旋涡中心形成混合区. 在靠近界面平坦部分(波底部),这些图显示了与较早在旋涡区域中观察到的相同的变形的微结构. 在铜侧细晶粒的薄层直接附着于高熵合金板材,并且沿着界面倾斜分布.相对于波前位置,波后区域铜片的严重变形层很薄,由微带以及沿界面拉长的扁平晶粒组成.随着距界面的距离增加,应变硬化效果很快消失[32].

图11为不同区域下EBSD结果. 如图11所示,铜侧的伸长区由细长晶粒组成,这些扁平的晶粒强烈弯曲,并沿着波形趋势分布. 图11a中的铜基体部分基本由大于5 μm的晶粒构成,图11b和图11c中的变形区中小于5 μm的晶粒占比分别提高到25%和48%. 扁平晶粒的尺寸相对原理界面铜晶粒的尺寸因变形和动态再结晶发生了细化[33]. 在旋涡中观察到的最典型特征是形成细晶区域,该细层由直径小于5 μm的细等轴晶粒组成(图11d).由于爆炸焊接高速碰撞过程中引起的高温会在界面产生温度梯度,因此在严重变形的旋涡区可能会出现新的再结晶晶粒成核[34]. 在旋涡中的元素混合区域附近,扁平晶粒被等轴晶粒代替.

2.3 界面硬度分布特征

图12为爆炸焊接界面的法向截面特征,沿着爆炸焊接方向铜、高熵合金、混合区、铜交替分布. 为了研究硬度周期性变化趋势,沿着爆炸焊接方向进行了纳米压痕试验测试,并与显微硬度测试结果进行了对比.如图13所示,界面上沿着爆炸焊接方向硬度数值周期性起伏.在分析显微硬度值时,对严重变形的层中动态恢复和再结晶过程的精确分析变得更加清晰. 在传统金属的复合界面中,由于脆性金属间化合物的产生,旋涡区的硬度值一般远高于两侧基体[35]. 然而,界面附近的旋涡区硬度介于两侧基体的硬度之间. 这可能与重结晶引起的软化有关[30]. 这一特征表明Cu/Al0.1CoCrFeNi高熵合金界面的混合区(图14)不同于常见的金属间化合物高硬度特征[36-37].

3. 结论

(1) Al0.1CoCrFeNi/Cu复合板的爆炸焊接界面呈现出波状结合,且旋涡区中未出现传统材料复合界面中脆性金属间化合物引起的裂纹.

(2) Al0.1CoCrFeNi/Cu复合板的爆炸焊接界面具有纵向周期性的结构分布以及横向不规则的边界.在Al0.1CoCrFeNi和铜的交界处,元素含量具有明显的分界.

(3)爆炸焊接界面纵向波峰两侧具有拉长的晶粒,旋涡区具有再结晶的等轴细晶.随着晶粒变形程度的增加,相应区域细晶的比例随之增加.

(4)爆炸焊接界面的硬度呈现周期性的变化.此外,Cu/Al0.1CoCrFeNi高熵合金界面的混合区硬度介于铜与高熵合金两侧的硬度之间.

-

表 1 低合金钢基板D32, ISO101熔嘴钢管和高铬铸铁硬面层的化学成分(质量分数,%)

Table 1 Chemical compositions of low alloy steel substrate D32, fusion nozzle steel pipe ISO101 and high chromium cast iron hardfacing layer

材料 C Si Mn Cu Cr Ni V Mo Al Fe 熔嘴 0.08 0.21 0.35 0.08 0.07 0.20 — — — 余量 基板 0.13 0.22 1.30 0.32 0.20 0.39 0.08 0.05 0.02 余量 硬面层 2.03 0.68 2.06 0.06 25.33 — — 0.88 0.07 余量 表 2 电渣堆焊过程焊接热循环特征参数

Table 2 Characteristic parameters of welding thermal cycle during electroslag surfacing

位置 峰值温度Tmax/℃ 高温停留时间(T = 1 000 ℃) t/s 800 ~ 500 ℃冷却时间t8/5/s 平均晶粒直径d/μm A 1 070 56 209 3 B 1 150 143 208 47 C 1 215 156 205 105 D 1 280 169 201 173 E 1 300 182 199 228 表 3 复合试样不同位置的冲击吸收能量Akv(25 ℃)(J)

Table 3 Impact absorption energy at different positions of the composite specimen Akv(25 ℃)

测试区 试样1 试样2 试样3 平均值 D32 166 162 164 164.0 熔合区 46 58 55 53.0 细晶热影响区 190 193 186 189.7 硬面层 11 10 11 10.7 -

[1] Tang X H, Chung R, Pang C J, et al. Microstructure of high (45wt.%) chromium cast irons and their resistances to wear and corrosion[J]. Wear, 2011, 271(9): 1426 − 1431.

[2] Tang X H, Chung R, Li D Y, et al. Variations in microstructure of high chromium cast irons and resultant changes in resistance to wear, corrosion and corrosive wear[J]. Wear, 2009, 267(1): 116 − 121.

[3] 苏允海, 梁学伟, 邓越, 等. FeAlCuCrNiNbx系高熵合金堆焊层的组织及性能分析[J]. 焊接学报, 2020, 41(4): 38 − 43,50. doi: 10.12073/j.hjxb.20191015001 Su Yunhai, Liang Xuewei, Deng Yue, et al. Microstructure and property analysis of FeAlCuCrNiNbx high-entropy alloy surfacing layer[J]. Transactions of the China Welding Institution, 2020, 41(4): 38 − 43,50. doi: 10.12073/j.hjxb.20191015001

[4] Wang S, Li Y M, Wang J, et al. Effect of in-situ (Ti & W) C multiphase particles on three-body abrasive wear of high chromium cast iron[J]. Materials Chemistry and Physics, 2023, 295(2): 127 − 161.

[5] Feng A X, Wei Y C, Liu B J, et al. Microstructure and mechanical properties of composite strengthened high-chromium cast iron by laser quenching and laser shock peening[J]. Journal of Materials Research and Technology, 2022, 20: 4342 − 4355.

[6] 魏建军, 黄智泉, 杨威. 高碳高铬铸铁堆焊合金组织分析[J]. 焊接学报, 2008, 29(3): 145 − 148. doi: 10.3321/j.issn:0253-360X.2008.03.037 Wei Jianjun, Huang Zhiquan, Yang Wei. Microstructures of high chromium cast iron for surfacing[J]. Transactions of the China Welding Institution, 2008, 29(3): 145 − 148. doi: 10.3321/j.issn:0253-360X.2008.03.037

[7] Chatterjee S, Pal T K. Weld procedural effect on the performance of iron based hardfacing deposits on cast iron substrate[J]. Journal of Materials Processing Technology, 2006, 173(1): 61 − 69. doi: 10.1016/j.jmatprotec.2005.10.025

[8] Sapate S G, RamaRao A V. Erosive wear behaviour of weld hardfacing high chromium cast irons: effect of erodent particles[J]. Tribology International, 2006, 39(3): 206 − 212. doi: 10.1016/j.triboint.2004.10.013

[9] Liu J B, Wang L M, Liu J H. Influence of process parameters on microstructure of reactive plasma cladding TiC-Fe-Cr coating[J]. China Welding, 2021, 30(2): 35 − 41.

[10] 刘西洋, 孙凤莲, 王君宇, 等. 自保护药芯焊丝激光-电弧复合热源堆焊参数对焊道表面成形的影响[J]. 焊接学报, 2018, 39(3): 83 − 88. doi: 10.12073/j.hjxb.2018390074 Liu Xiyang, Sun Fenglian, Wang Junyu, et al. Influence of the surfacing process of laser-arc hybrid welding with self-shielded flux-cored wire on the bead appearance[J]. Transactions of the China Welding Institution, 2018, 39(3): 83 − 88. doi: 10.12073/j.hjxb.2018390074

[11] Xie G, Sheng H, Han J T, et al. Fabrication of high chromium cast iron/low carbon steel composite material by cast and hot rolling process[J]. Materials & Design, 2010, 31(6): 3062 − 3066.

[12] Xiong B W, Cai C C, Wang H, et al. Fabrication of high chromium cast iron and medium carbon steel bimetal by liquid-solid casting in electromagnetic induction field[J]. Materials & Design, 2011, 32(5): 2978 − 2982.

[13] Rodionova I G, Sharapov A A, Puzachev V I, et al. Use of electroslag hard-facing to improve the quality of corrosion-resistant bimetal[J]. Chemical and Petroleum Engineering, 1998, 34(2): 139 − 143. doi: 10.1007/BF02418175

-

期刊类型引用(5)

1. 周立成,冯志军,谢广明,吴华锋,李泽华,胡大川. 水下搅拌摩擦焊对铝/铜接头组织与性能的影响. 精密成形工程. 2023(03): 97-104 .  百度学术

百度学术

2. 张茗瑄,马志鹏,陈桂娟,夏法锋,于心泷. 电磁超声作用下Sn-9Zn钎料在SiC表面铺展分析. 焊接学报. 2022(02): 55-60+117 .  本站查看

本站查看

3. 邓呈敏,程东海,张华,王非凡,刘德博. 焊丝成分对铝/铜激光熔钎焊接头组织和性能的影响. 焊接学报. 2022(01): 16-21+114 .  本站查看

本站查看

4. 陈克选,杜茵茵,陈彦强. 交变磁控电源的设计与仿真. 电焊机. 2022(03): 93-98 .  百度学术

百度学术

5. 于江,潘俊林,苗惺林,张洪涛,高建国,苏昭方. 铝/铜异种金属电阻热辅助超声波缝焊工艺特性. 焊接学报. 2022(07): 76-81+117-118 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: