Welding feasibility analysis of arc preheating scheme for ITER anaerobic copper TIG welding

-

摘要: 装置内部真空线圈系统 (internal vacuum coil system,IVCS)的内部线圈超导导体接头由于其工作环境恶劣,故对焊缝质量要求较高,接头性能的好坏将直接影响到内部线圈能否正常运行.由于真空室空间受到限制以及对周边环境的要求,最终铜管焊接接头选择采用钨极惰性气体保护焊(tungsten inert gas welding,TIG). 为了验证电弧预热焊接无氧铜铜管的可行性,采用开放式机头,利用机头本身对无氧铜铜管进行电弧预热,以达到铜管焊接时所需要的温度,通过对无氧铜铜管的焊接接头进行无损检测、宏观和显微检查以及焊缝、热影响区和母材的硬度测量,系统地评估了电弧预热对热影响区的影响.结果表明,热影响区与母材硬度无显著差异,焊缝金属硬度稍高,但显微组织有明显差异,在观测范围内电弧预热对热影响区并无显著影响,证明采用电弧预热的方案是可行的.

-

关键词:

- 装置内部真空线圈系统 /

- 电弧预热 /

- 无氧铜铜管焊接 /

- 硬度测量 /

- 显微组织

Abstract: The superconducting joint of the internal coil in the vacuum coil system of the device has a high requirement on weld quality because of its bad working environment. In order to verify the feasibility of welding oxygen free copper pipe with arc preheating method, the method of arc preheating with open head was adopted to preheat oxygen free copper pipe to reach the temperature required for welding copper pipe . Non-destructive testing , macroscopic and microscopic examination, and hardness measurement of weld, heat-affected zone and base metal are performed on copper welded joints. The influence of arc preheating on the heat-affected zone is evaluated. The analysis shows that there is no significant difference between the hardness of the heat affected zone and the base metal, but there is a significant difference in the microstructure. The hardness of weld metal is slightly higher.In the observation range, arc preheating has no significant effect on the heat-affected zone. The results show that arc preheating is feasible. -

0. 序言

ITER国际热核聚变实验堆项目是一种利用磁约束来实现受控核聚变的环形装置,目前已经进入总装阶段,而内部线圈导体以及接头的制作是整个导体线圈安装的最终阶段,同时也是难度最大的部分. ITER 主机的结构主要由超导系统、外真空杜瓦、内外冷屏、真空室及内部部件和磁体等部件组成.但2008年一些物理学家分析指出,超导磁体对等离子体位的控制还存在一些不足,于是在2013年ITER 设计中纳入了内部线圈系统,以提高ITER 装置运行的安全性及稳定性.内部线圈的设置是为了能够主动快速的控制等离子体的稳定性,能够通过在等离子体内产生共振磁扰动而减轻边缘局域模效应的影响,从而降低面对等离子体部件上受到的热冲击载荷,它们被安装在屏蔽模块和真空容器之间,其需要承受辐射(~3000 MGy)和温度(稳定运行期间100 ℃,烘烤期间200 ℃)的恶劣环境中工作.IVCS(internal vacuum coil system)即内部线圈系统是等离子体控制和稳定线圈系统的一部分,在装置内不同位置需要不同的接头形式,这些接头形式将线圈与馈线和其它各部分连接一起,这些接头最终必须在真空室内完成组装焊接.真空室内一共有176个接头,这些接头分别分布在真空室不同的位置,而这些接头中空间位置最小的径向空间只有60 mm,接头端部铜管裸露出来的长度大约为160 mm,分布在接头两端的2个夹具之间的长度最小为220 mm, 而且由于线圈已经安装成形并固定在真空壁上,从而不便于返修,故线圈中无氧铜铜管的焊接接头一次性合格率要求极高[1].

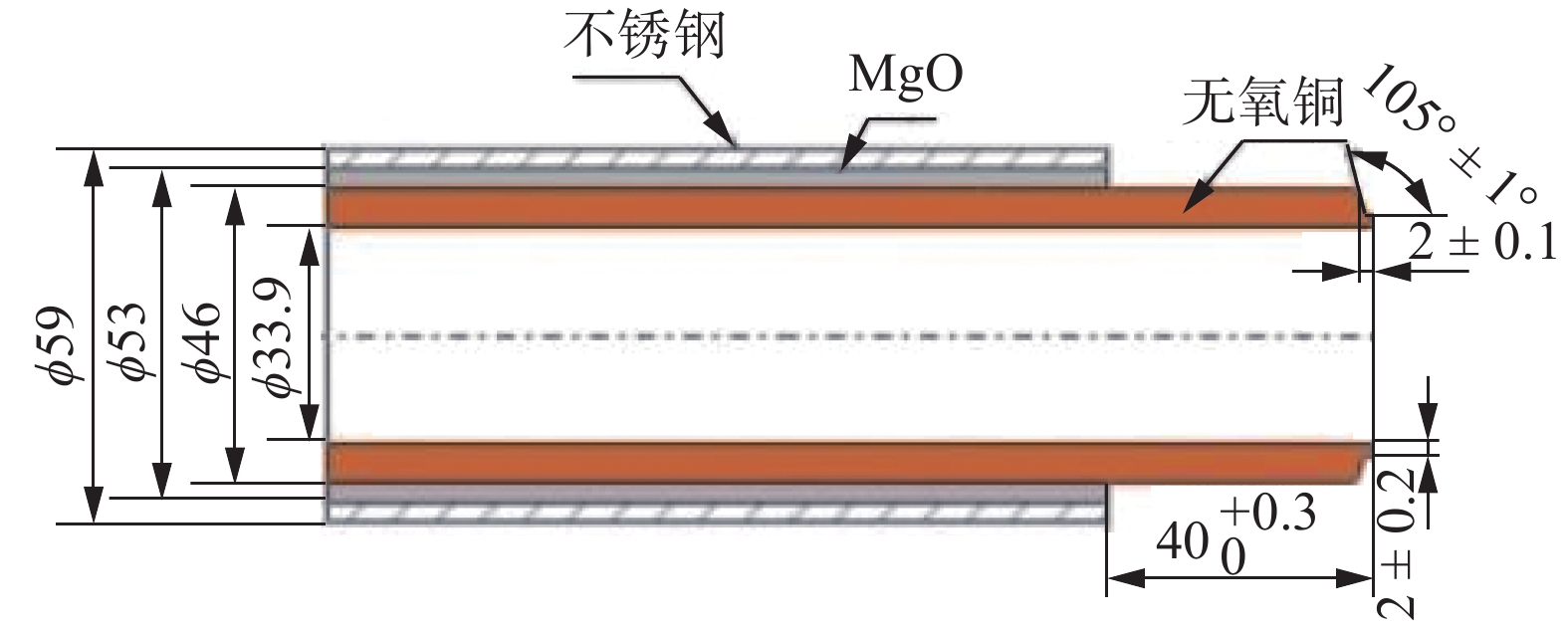

为了适应复杂严峻的运行工况,ITER 内部线圈导体采用了一种特殊的绝缘导体结构,即是由内层的无氧铜铜管、中间层绝缘层MgO以及外部316LN不锈钢铠甲组成的一种类似于三明治的结构.而接头的制造首先要实现铜管的焊接,铜管接头焊接完后再填充MgO,最后套上不锈钢套管利用挤压机对不锈钢套管进行挤压,挤压完成后再焊接不锈钢套管. 整个焊接过程均在狭小空间内完成,所有接头焊缝均需要满足无损检测标准,每个接头制作完成后不能影响线圈的绝缘性能,焊接过程中必须避免对于绝缘层MgO的污染.鉴于铜的导热性很强,焊接时热量很快从加热区传导出去,导致焊件温度难以升高,金属难以熔化,并且填充金属与母材不能良好熔合,另外,铜在高温液态下极容易氧化,且极容易形成气孔,而用于内部线圈接头的铜管厚度达到了6 mm,采用TIG焊能获得较高质量的焊缝,且较容易实现较小焊接空间内的自动化焊接,因此为了满足ITER内部线圈接头设计与制造,最终选择开放式TIG焊接机头,机头上加气体保护装置进行焊接,并且在机头上安装了可跟踪摄像头,以便于观察焊缝熔池.

由于空间的局限性最终选择了电弧预热的方法对铜管进行预热,为了验证电弧预热这种工艺的可行性,文中通过模拟45°和90°空间位置分别进行了焊接试验,对样品进行非破坏性试验(射线检测),检查每个样品的横截面以及分析焊缝和母材的硬度变化规律,发现电弧预热对焊缝热影响区并无明显影响,从而验证了采用电弧预热方案是可行的.

1. 试验方法

选择母材为 ϕ 46 mm × 6 mm 的无氧铜铜管(Cu元素含量大于99.99%)和直径为ϕ1 mm的ERCu焊丝,试验采用法国Ploysoude MUIV64S型开放式全位置窄间隙氩弧焊机,该焊接系统主要由焊接电源 (PC600)、智能水箱、窄间隙机头(包括送丝机构和焊枪)、控制系统、摄像头等组成.由于在真空室内部对于焊接操作有不同的方向和空间上的要求,因此选取的焊接工艺必须适用于最终的工程应用,为此分别选取空间位置45°和90°进行TIG焊试验,如图1所示,铜管坡口示意图如图2所示.为了便于焊接,得到成形质量较好的焊接接头,焊接前,坡口装配间隙≤2 mm,并对焊口两侧清洗,严防漆、锈、油污、表面氧化物等杂物的影响;焊接时,利用机头在铜管坡口两侧预热后,先进行脉冲打底焊再送丝填充.焊接时管内通氩气(纯度99.997%)作为焊缝背面保护气体,采用氩气和氦气(70%Ar + 30%He)作为焊缝正面保护气体,同时机头上加保护气罩装置,气罩内通氩气对焊缝进行保护防止焊缝氧化,预热时使用不带送丝的焊接程序. 利用电弧在焊缝坡口两侧25 mm内各焊接一圈给铜管加热使铜管整体温度上升,铜管的预热温度为300 ~ 400 ℃. 打底焊采用脉冲电流(峰值电流IHp,基值电流ILp),焊接试样时采取的工艺参数见表1[2]. 焊接完成后焊缝表面成形状态以及焊缝内部的成形状态如图3所示,由于焊接铜管过程中温度均较高,焊缝非常容易被氧化,焊缝表面如和铜管本身的颜色相近则最佳,如为黑色则是焊缝被氧化. 铜管焊缝经无损检测合格后,将焊缝余高打磨抛光后,从导体中切割取出所需要进行试验的铜管,再用电火花切割铜管试样,使其焊缝中心在获得的试样中心位置并将试样截面打磨平整.

表 1 焊接工艺参数Table 1. Welding parameters空间位置角度

θ/(°)焊接位置 预热温度

T/℃焊接电流

I/A焊接速度

v/(mm·min−1)送丝速度

vs/(mm·min−1)气体流量Q/(L·min−1) 正面 背面 45 打底焊 300 ~ 450 IHp :260 ~ 320 ILp :180 60 — 20 ~ 25 10 ~ 20 填充焊1 300 ~ 450 250 ~ 305 65 300 ~ 350 20 ~ 25 10 ~ 20 填充焊2 300 ~ 450 230 ~ 290 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊3 300 ~ 450 240 ~ 280 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊4 300 ~ 450 240 ~ 260 70 300 ~ 350 20 ~ 25 10 ~ 20 90 打底焊 300 ~ 450 IHp :280 ~ 340 ILp :180 60 — 20 ~ 25 10 ~ 20 填充焊1 300 ~ 450 200 ~ 285 65 300 ~ 350 20 ~ 25 10 ~ 20 填充焊2 300 ~ 450 200 ~ 280 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊3 300 ~ 450 200 ~ 280 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊4 300 ~ 450 200 ~ 280 70 300 ~ 350 20 ~ 25 10 ~ 20 焊接接头是按照ISO 17636—2:2013《Non-destructive testing of welds-Radiographic testing-Part 2: X- and gamma-ray techniques with digital detectors》进行射线检测[3];热影响区(heat-affected zone,HAZ)根据宏观组织观察和晶粒尺寸变化来评估的,使用Keyence VHX 6000型光学显微镜获得了截面上热影响区的宽度,根据热影响区的宽度,从而得出热影响区的范围.每个试样的横截面先进行机械打磨,然后进行抛光处理,按照 ASTM E407—2007 《Standard practice for microetching metals and alloys》采用体积为10%的过硫酸铵腐蚀剂腐蚀,以显示其微观结构[4].

按 照 ISO 6507-1:2018《 Metallic materials- Vickers hardness test—Partl:Test method》进行试样的显微硬度试验[5],加载载荷为4.9 N.根据 ISO 9015-2:2001《Destructive tests on welds in metallic materials—Hardness testing—Part 2: Microhardness test on arc welded joints》所采用的方法有:一种是使用R方法(压痕法)在每个样品的剖面中间进行测试;另一种是个别的压痕(方法 E) 在焊接的不同 位置进行测试.方法R(压痕法)根据 ISO 9015-2中选择压痕之间的距离为1.13 mm,母材、 焊缝金属和热影响区为了更接近边缘,利用低负荷沿着整个长度的轮廓线进行测量.

2. 试验结果与分析

2.1 无损检测

射线检测焊缝缺陷根据 ISO 10675-1:2013《 Nondestructive testing of welds —Acceptance levels for radiographic testing Part1:Steel,nickel,titanium and their alloys》1级验收等级. 根据 ISO 17636-1:2013 《Non-destructive testing of welds— Radiographic testing — Part 1: X- and gamma-ray techniques with film》对45°和90°试样观察线性气孔以及单个气孔,并进行验收. 45°试样未发现缺陷,90°试样的线性气孔如图4所示,其长度为1.72 mm,单个气孔长度0.51 mm均在标准范围内,根据以上分析可以得出2个位置的试样均合格.

2.2 HAZ 宽度测量

热影响区的评估是基于截面上的晶粒尺寸变化获得了截面上热影响区宏观宽度,其测量结果见表2.事实上电弧预热过程会导致焊缝附近的晶粒尺寸长大,这是由于操作时温度升高导致的,接头和母材的微观组织如图5所示,得出2种接头的微观组织与母材组织之间的差异,并且根据热影响区的组织去判断接头的热影响区的宽度,根据热影响区的晶粒尺寸与焊缝及母材的不同,分析得出热影响区的宽度大小[6].

表 2 热影响区宏观宽度Table 2. Macro width of HAZ试样

编号45°热影响区宽度w1/mm 90°热影响区宽度w2/mm 左侧 右侧 左侧 右侧 1 12.1 11.9 13.7 8.5 2 10.7 14.1 11.4 13.8 2.3 热影响区的显微硬度

采用ISO 9015-2中的 E 方法测量显微硬度如图6所示[7],接头不同区域显微硬度测量结果见表3,接头硬度分布如图7所示.从表3和图7可知,焊缝的硬度稍高于热影响区和母材,热影响区硬度与母材硬度无显著差异,该测量结果与退火的铜管材料具有一定相关性,这是由TIG焊过程中焊道内的凝固速率较高,而填充材料的纯度较低导致的.

表 3 接头的显微硬度H(HV0.5)Table 3. Microhardness of joints空间位置角度θ/(°) 母材区实测值 平均值 热影响区实测值 平均值 焊缝区实测值 平均值 45 55.8,55.8,54.9,56.1 55.65 54.5,54.1,55.4,54.0 54.5 58.6,55.6,56.8 57.0 90 50.8,52.4,52.0,50.6 51.45 53.6,52.3,51.3,52.4 52.4 55.6,54.6,55.2 55.13 通过对2种接头的焊缝、热影响区硬度以及母材的测量,得出3者之间并无明显差异[8].

2.4 焊缝截面特征分析

对焊缝的横截面进行金相组织分析,如图8所示,通过金相组织分析发现2个接头焊缝中的横截面上均存在气孔,可以看到在45°接头的截面中,有直径ϕ0.211 mm 的气孔,而在90°接头的截面中,可以发现有2个小气孔直径大小分别为0.11和0.05 mm,这些气孔由于射线灵敏度不够不能检测出来,但按照ISO5817的B级均在标准范围内.从焊缝的横截面分析可以得出焊缝组织并无异常,焊缝所存在的气孔缺陷在验收标准范围内.

3. 结论

(1)焊缝中存在线性气孔和单个气孔,其尺寸和长度均符合ISO 17636-1:2013中的验收标准,根据这些结果认为空间位置45°和90°的试样均合格.

(2)分别对铜管母材、热影响区和焊缝金属的 硬度进行测量,得出热影响区硬度与母材硬度无显著差异,但显微组织有明显差异,即焊缝区域和热影响区的晶粒尺寸比母材大,而这是由于焊缝及热影响区的温度较高,金属冷却速率较快引起的,焊缝金属硬度相对于母材以及热影响区稍高,由此可知,电弧预热对热影响区没有显著影响.

(3)根据无损检测、微观检测以及显微硬度结果可以得出,采用电弧预热对焊缝和HAZ并无影响,并未对焊缝及热影响区的金属组织成分造成影响,同时也没有影响到焊缝的质量,由此得出这种焊接方法是可行的,是可以运用于工程应用中.

-

表 1 焊接工艺参数

Table 1 Welding parameters

空间位置角度

θ/(°)焊接位置 预热温度

T/℃焊接电流

I/A焊接速度

v/(mm·min−1)送丝速度

vs/(mm·min−1)气体流量Q/(L·min−1) 正面 背面 45 打底焊 300 ~ 450 IHp :260 ~ 320 ILp :180 60 — 20 ~ 25 10 ~ 20 填充焊1 300 ~ 450 250 ~ 305 65 300 ~ 350 20 ~ 25 10 ~ 20 填充焊2 300 ~ 450 230 ~ 290 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊3 300 ~ 450 240 ~ 280 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊4 300 ~ 450 240 ~ 260 70 300 ~ 350 20 ~ 25 10 ~ 20 90 打底焊 300 ~ 450 IHp :280 ~ 340 ILp :180 60 — 20 ~ 25 10 ~ 20 填充焊1 300 ~ 450 200 ~ 285 65 300 ~ 350 20 ~ 25 10 ~ 20 填充焊2 300 ~ 450 200 ~ 280 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊3 300 ~ 450 200 ~ 280 70 400 ~ 450 20 ~ 25 10 ~ 20 填充焊4 300 ~ 450 200 ~ 280 70 300 ~ 350 20 ~ 25 10 ~ 20 表 2 热影响区宏观宽度

Table 2 Macro width of HAZ

试样

编号45°热影响区宽度w1/mm 90°热影响区宽度w2/mm 左侧 右侧 左侧 右侧 1 12.1 11.9 13.7 8.5 2 10.7 14.1 11.4 13.8 表 3 接头的显微硬度H(HV0.5)

Table 3 Microhardness of joints

空间位置角度θ/(°) 母材区实测值 平均值 热影响区实测值 平均值 焊缝区实测值 平均值 45 55.8,55.8,54.9,56.1 55.65 54.5,54.1,55.4,54.0 54.5 58.6,55.6,56.8 57.0 90 50.8,52.4,52.0,50.6 51.45 53.6,52.3,51.3,52.4 52.4 55.6,54.6,55.2 55.13 -

[1] Ambrosino G, Ariola M, Tommasi G D, et al. Design of the Plasma Position and Shape Control in the ITER Tokamak using in-vessel coils[J]. IEEE Transactions on Plasma Science, 2009, 37(7): 1324 − 1331.

[2] 王克鸿, 李建勇, 嵇大圆, 等. 熔化带极自动等离子熔敷焊接纯铜技术[J]. 焊接学报, 2007, 5(5): 13 − 16. doi: 10.3321/j.issn:0253-360X.2007.05.004 Wang Kehong, Li Jianyong, Ji Dayuan, et al. Pure copper coating deposited by automatic plasma welding with melting strip electrode technology[J]. Transactions of the China Welding Institution, 2007, 5(5): 13 − 16. doi: 10.3321/j.issn:0253-360X.2007.05.004

[3] International Organization for Standardization 17636-2-2013. Non-destructive testing of welds - Radiographic testing - Part 2: X- and gamma-ray techniques with digital detectors [S]. Geneva, Switzerland, 2013.

[4] American Society for Testing Materials. E407-2015. Standard Practice for Microetching Metals and Alloys [S]. United States, West Conshohocken, 2015.

[5] International Organization for Standardization 6507-1-2018. Metallic materials-Vickers hardness test-Part 1: Test method [S]. Geneva, Switzerland, 2018.

[6] 雷玉成, 郁雯霞, 李彩辉, 等. 不预热情况下的紫铜TIG焊熔池温度场的数值模拟[J]. 焊接学报, 2006, 27(5): 1 − 4. doi: 10.3321/j.issn:0253-360X.2006.05.001 Lei Yucheng, Yu Wenxia, Li Caihui, et al. Numerical simulation of molten pool temperature field for TIG welding of pure copper without preheating[J]. Transactions of the China Welding Institution, 2006, 27(5): 1 − 4. doi: 10.3321/j.issn:0253-360X.2006.05.001

[7] International Organization for Standardization 9015-2-2016. Destructive tests on welds in metallic materials—Hardness testing-Part 2: Microhardness testing of welded joints [S]. Geneva, Switzerland, 2016.

[8] 王磊, 卫国强, 高洪永, 等. 焊接热输入对纯铜焊缝组织及力学性能的影响[J]. 焊接技术, 2014, 8(12): 10 − 14. Wang Lei, Wei Guoqiang, Gao Hongyong, et al. Effect of welding heat input on microstructure and mechanical properties of pure copper weld[J]. Welding Technology, 2014, 8(12): 10 − 14.

-

期刊类型引用(1)

1. 黄洲扬,孙立新. 创新型不锈钢管线焊接质量评估标准及应用. 现代制造技术与装备. 2024(04): 111-114 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: