Microstructure and properties of MAG and oscillating laser arc hybrid welded X80 steel

-

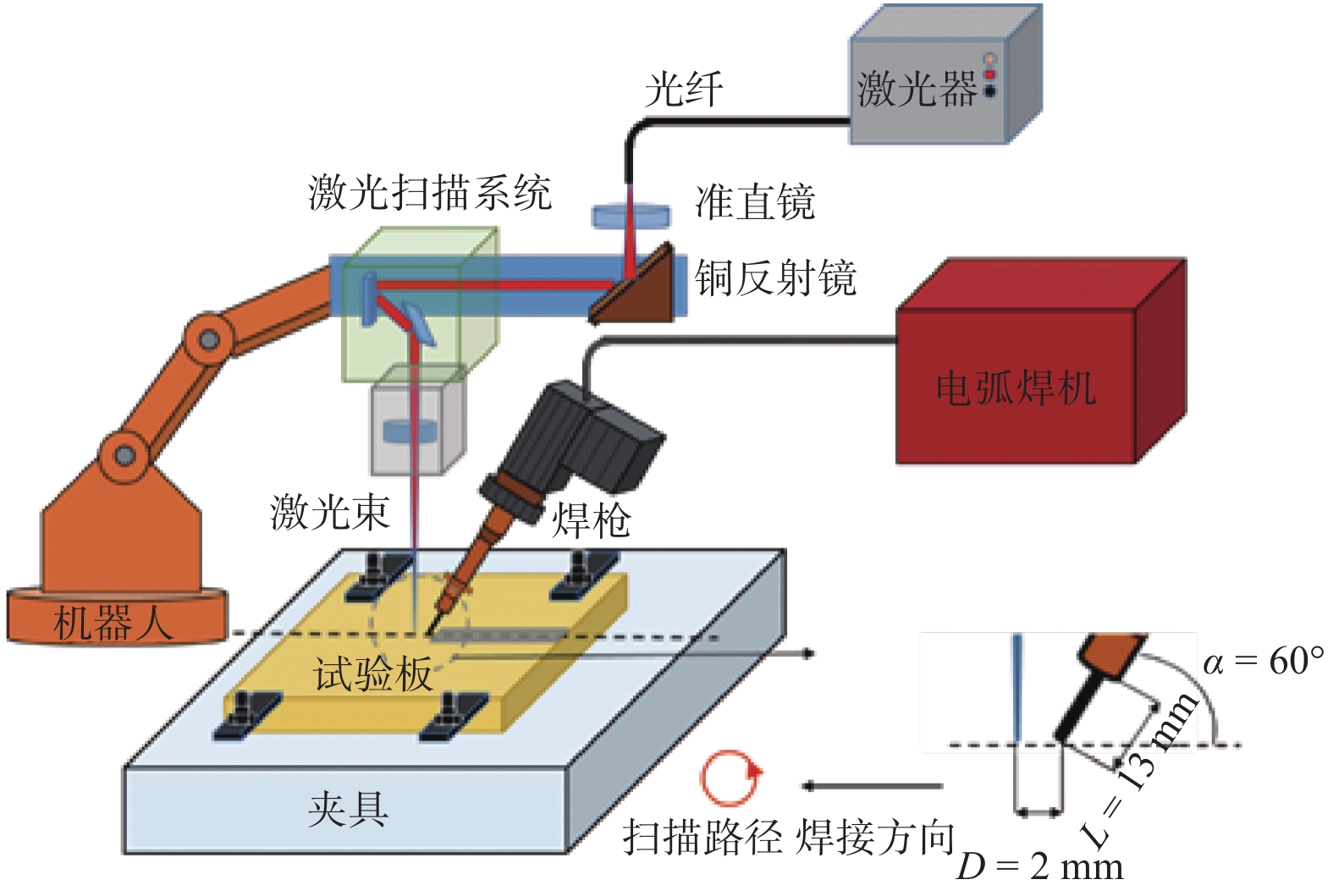

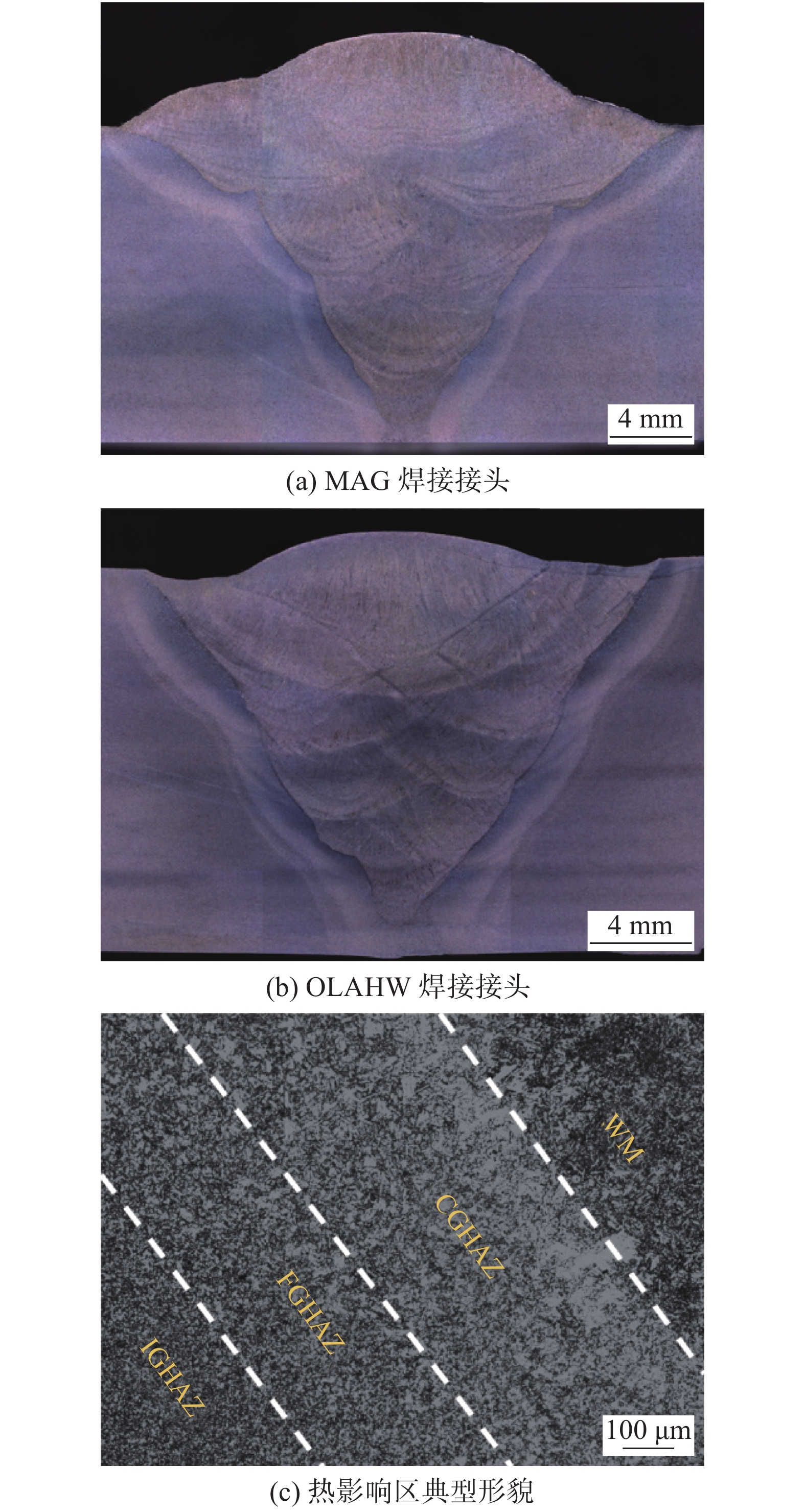

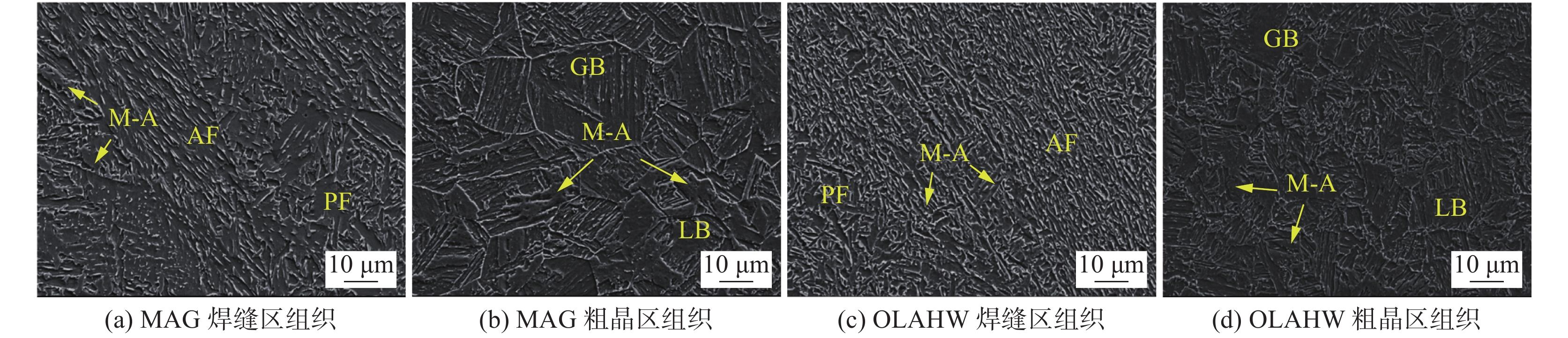

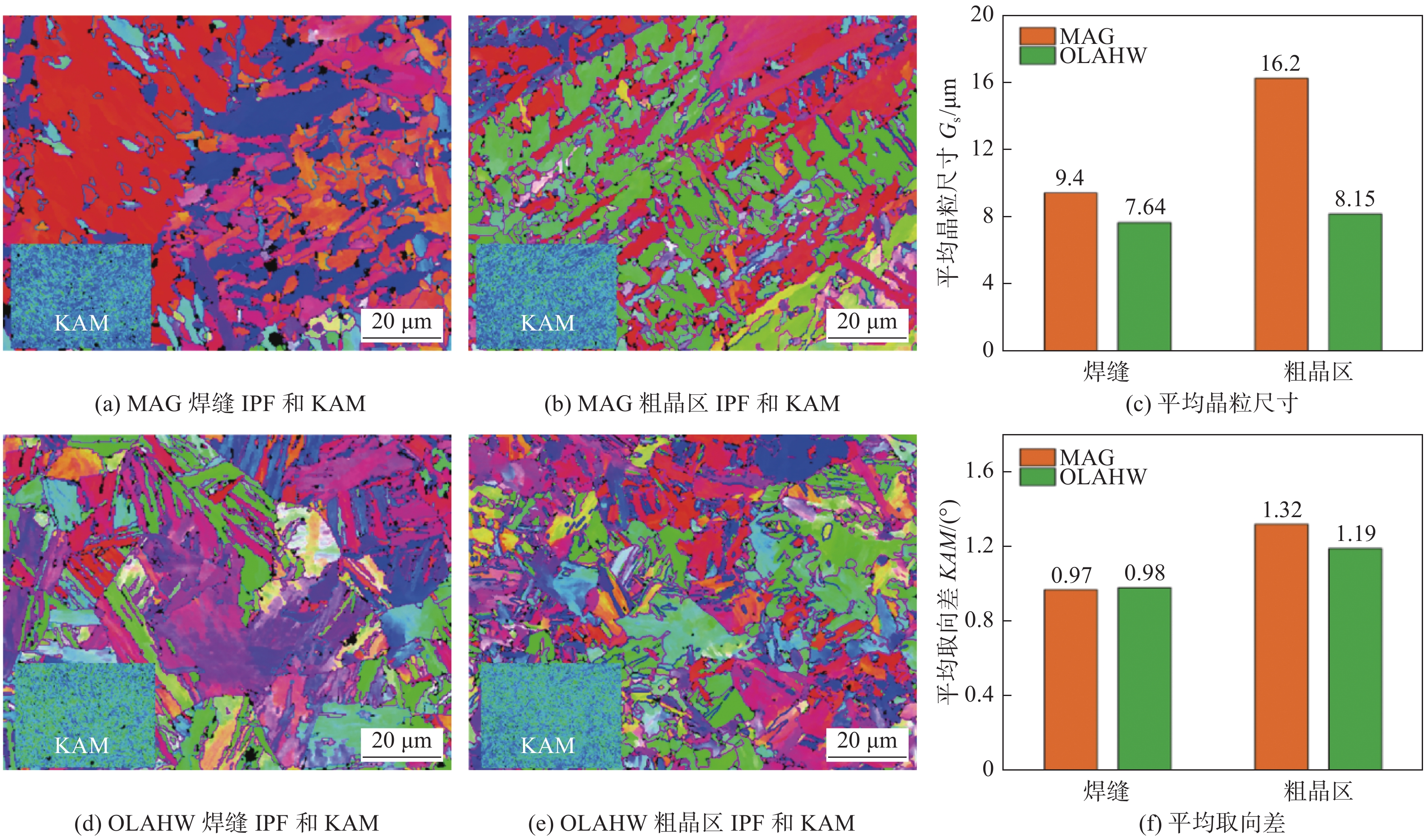

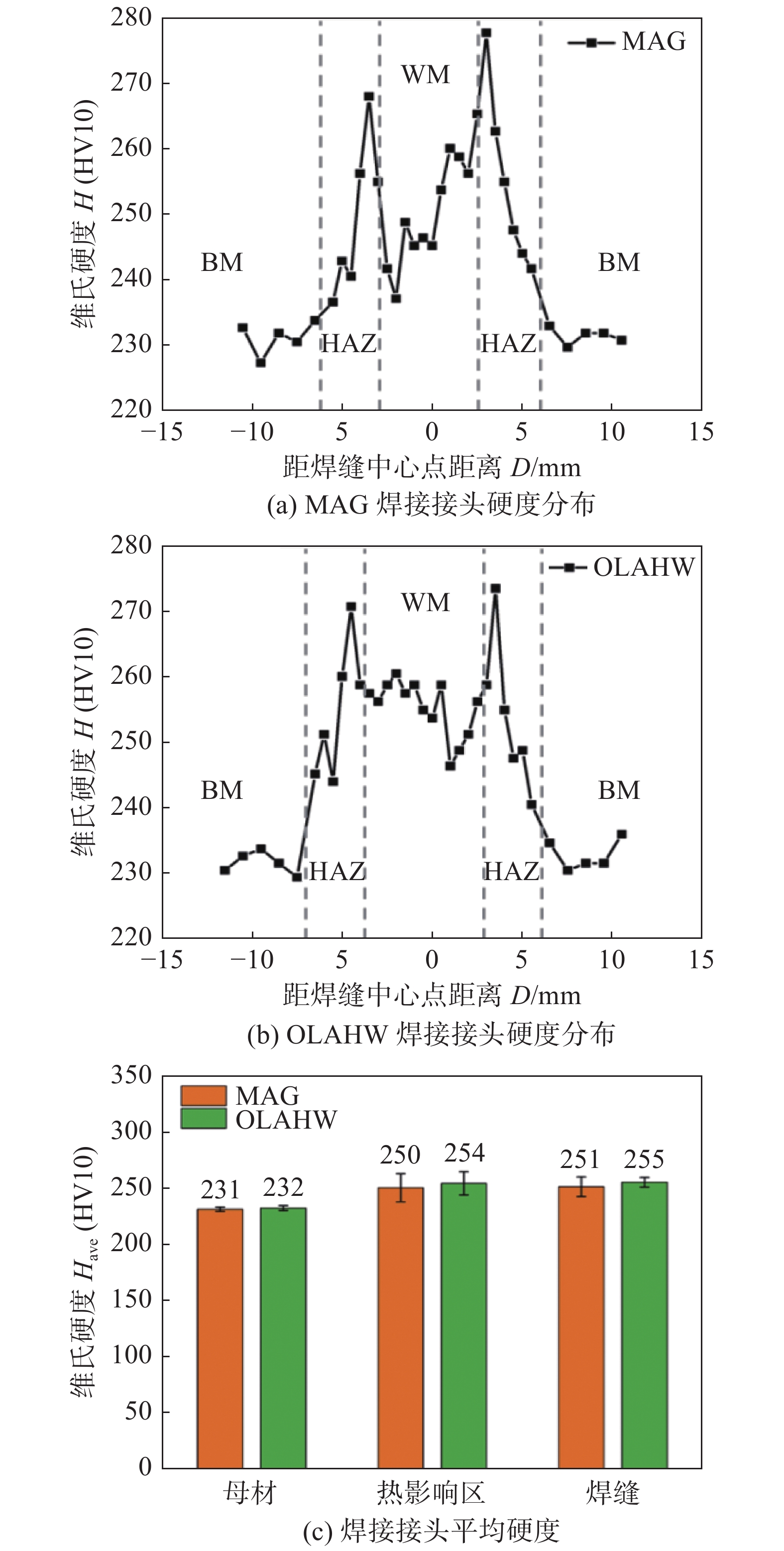

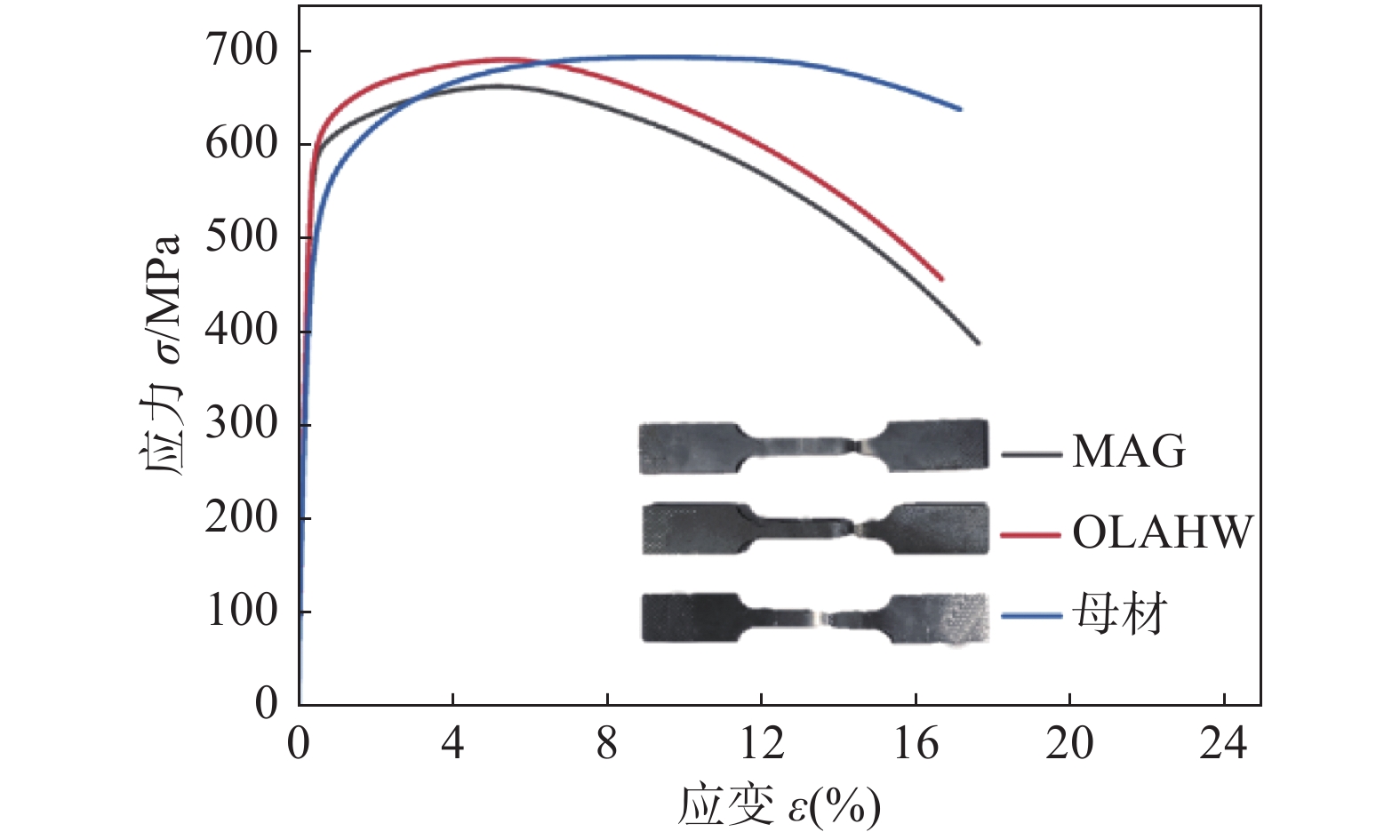

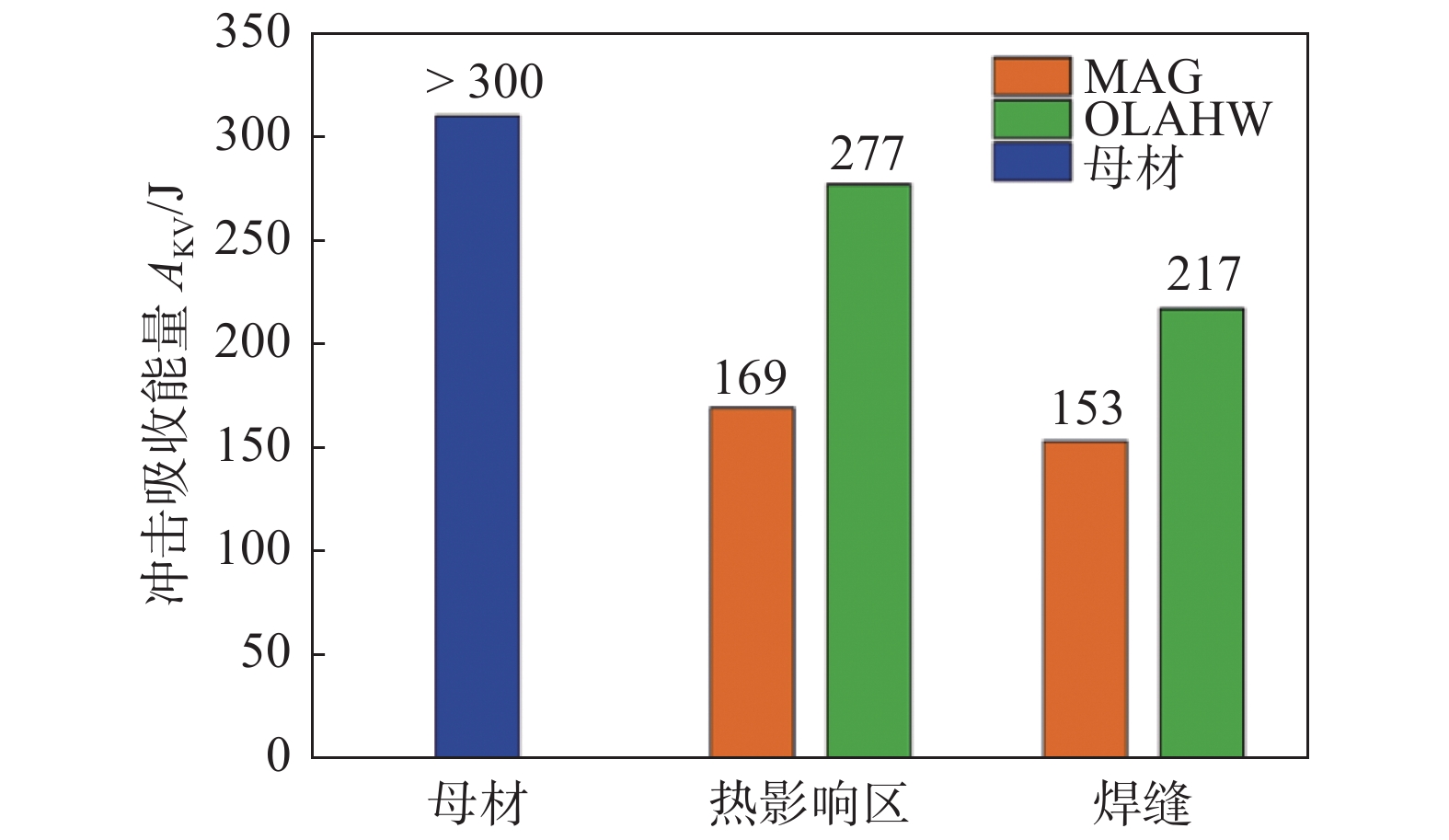

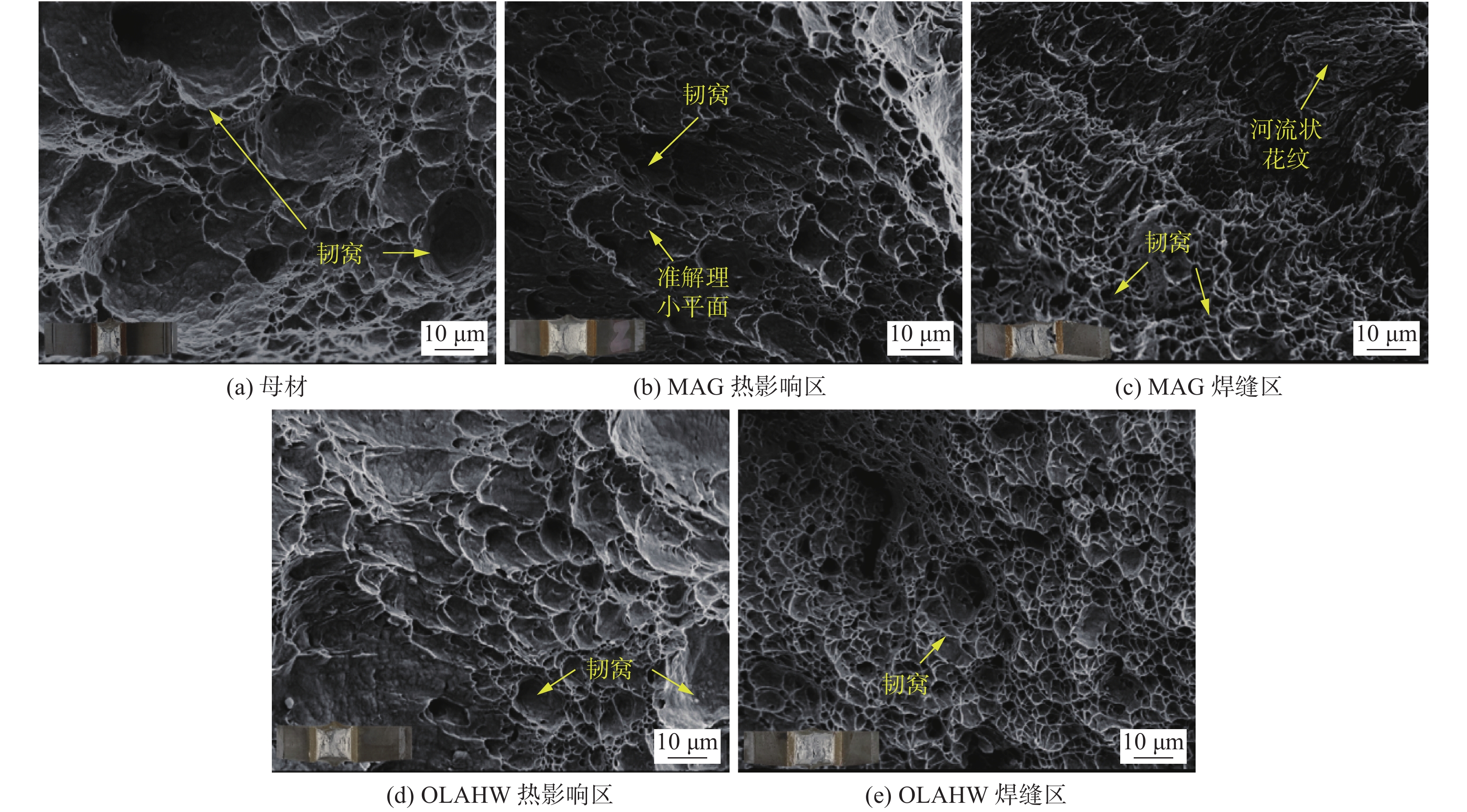

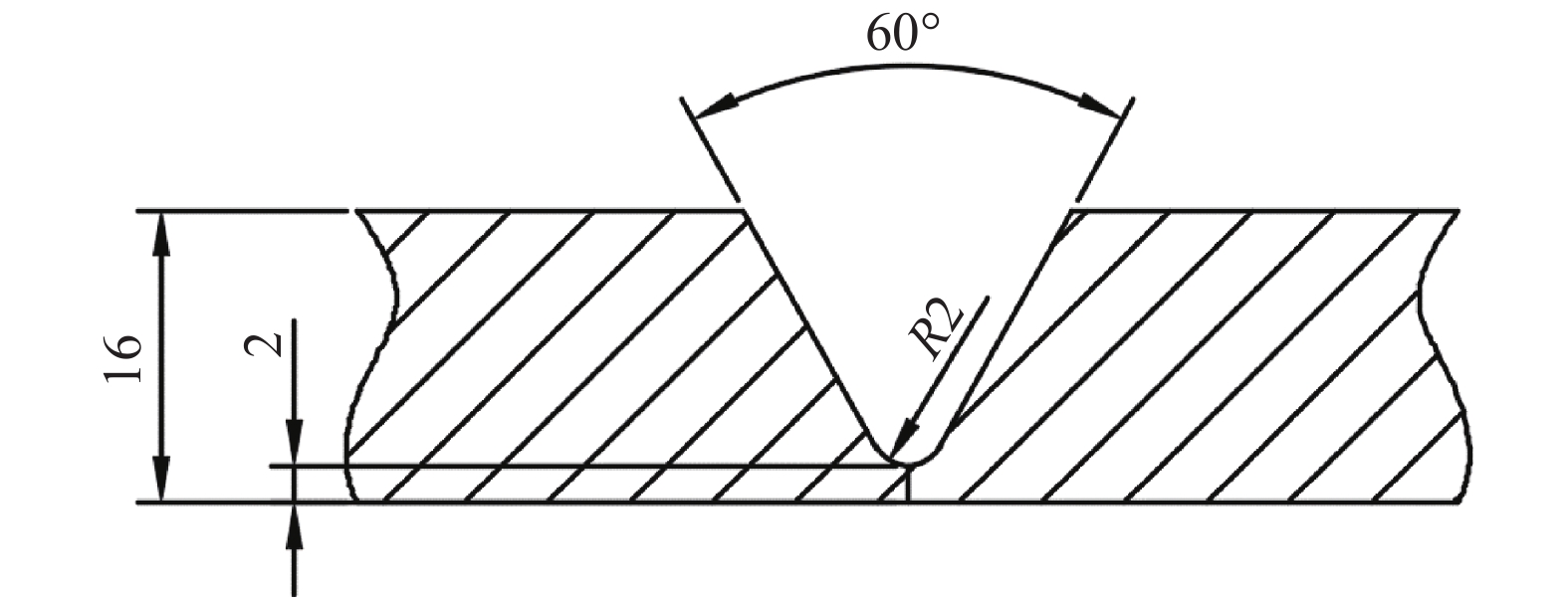

摘要: 在激光焊接打底情况下,对比研究了熔化极活性气体保护电弧焊(MAG)和激光扫描-电弧复合焊(OLAHW)工艺对X80管线钢接头成形、显微组织和力学性能(显微硬度、拉伸性能和冲击韧性)的影响规律. 结果表明,两种工艺下均能获得无气孔、夹渣和裂纹缺陷,成形良好的焊接接头,接头组织均主要由针状铁素体(AF)和M-A组元组成. 因为更小的焊接热输入和更快的冷却速度,以及激光束扫描促进形核作用,OLAHW填充接头组织中形成较MAG填充接头更多的针状铁素体和更细小的M-A组元. MAG和OLAHW两种填充工艺下接头平均显微硬度和拉伸强度接近,但OLAHW焊接接头的硬度变化相对MAG接头更平缓、硬度值波动较小,且OLAHW填充接头热影响区和焊缝区冲击吸收能量分别为277和217 J,较MAG填充接头分别提高了64%和42%.

-

关键词:

- X80管线钢 /

- MAG焊 /

- 激光扫描-电弧复合焊接 /

- 微观组织 /

- 冲击韧性

Abstract: Metal active gas welding (MAG) and oscillating laser arc hybrid welding (OLAHW) of X80 pipeline steel were carried out with backing weld by laser, the joint formation, microstructure and mechanical properties (microhardness, tensile properties and impact toughness) were studied. The results showed that sound joints without defects of pores, slag inclusion and crack were obtained by both the two processes. The joint microstructure was mainly composed of acicular ferrite (AF) and M-A components. Because of lower heat input, faster cooling rate and more nucleation sites promoted by the oscillated laser, more acicular ferrite and finer M-A components were formed within the OLAHW filled joints than those within MAG filled joints. The average microhardness and tensile strength of the joints obtained by the two filling processes were almost the same, but the hardness variation of OLAHW joints is gentler with less fluctuation. The impact energy of heat affected zone and weld zone of OLAHW filled joints were 277 and 217 J respectively, which is 64% and 42% higher than those of MAG filled joints. -

-

图 5 X80焊接接头EBSD结果

Figure 5. EBSD results of X80 welded joint. (a) IPF and KAM diagram of weld zone in MAG welding; (b) IPF and KAM diagram of coarse grain zone in MAG welding; (c) average grain size; (d) IPF and KAM diagram of weld zone in OLAHW welding; (e) IPF and KAM diagram of coarse grain zone in OLAHW welding; (f) average KAM value

表 1 母材和焊丝化学成分(质量分数,%)

Table 1 Chemical composition of base metal and welding wire

类别 C Si Mn Cu Cr Ni Mo Nb V Al Ti + Zr Fe X80 0.048 0.22 1.72 0.13 0.17 0.20 0.15 0.052 — 0.048 0.013 余量 JM-58 0.072 0.78 1.43 0.35 0.15 0.15 0.15 — 0.03 0.02 0.15 余量 表 2 MAG填充层焊接工艺参数

Table 2 Welding process parameters of MAG

焊接

次序焊接速度

v/(mm·s−1)送丝速度

vw/(m·min−1)焊枪摆动幅度

AM/mm焊枪摆动频率

fM/Hz2 10 5.0 1.5 10.0 3 ~ 5 5 7.0 2.0 8.0 6 ~ 8 5 8.0 3.0 8.0 表 3 OLAHW填充层焊接工艺参数

Table 3 Welding process parameters of OLAHW

焊接

次序激光功率

P/kW焊接速度

v/(mm·s−1)送丝速度

vw/(m·min−1)激光离焦量

∆f/mm2 1.0 10 4.0 + 25 3 1.0 10 7.0 0 4 ~ 7 1.5 10 8.0 0 8 ~ 10 1.5 8 8.0 0 -

[1] Devaney R J, Connaire A, O'Donoghue P E, et al. Process-structure-property fatigue characterisation for welding of X100 steel catenary risers[C]//International Conference on Offshore Mechanics and Arctic Engineering. American Society of Mechanical Engineers, 2019: V004T03A021.

[2] 周灿丰, 焦向东, 曹静, 等. 海洋深水立管环缝疲劳性能研究现状及建议[J]. 焊接, 2011(4): 5 − 10. Zhou Canfeng, Jiao Xiangdong, Cao Jing, et al. Research status and suggestions on circumferential seam fatigue performance of marine deepwater riser[J]. Welding & Joining, 2011(4): 5 − 10.

[3] Qiang B, Wang X. Ductile crack growth behaviors at different locations of a weld joint for an X80 pipeline steel: A numerical investigation using GTN models[J]. Engineering Fracture Mechanics, 2019, 213: 264 − 279. doi: 10.1016/j.engfracmech.2019.04.009

[4] Yang Y H, Shi L, Xu Z, et al. Fracture toughness of the materials in welded joint of X80 pipeline steel[J]. Engineering Fracture Mechanics, 2015, 148: 337 − 349. doi: 10.1016/j.engfracmech.2015.07.061

[5] 徐凯. X80焊管焊接接头疲劳性能的综合性研究[D]. 秦皇岛: 燕山大学, 2020. Xu Kai. Comprehensive study on fatigue properties of welded joints of X80 welded pipe[D]. Qinhuangdao: Yanshan University, 2020.

[6] Yang M, Liu Y, Zhang J, et al. Hybrid laser-arc welding of X90 pipeline steel: Effect of laser power on microstructure and mechanical properties[J]. Transactions of the Indian Institute of Metals, 2018, 71(10): 2487 − 2496. doi: 10.1007/s12666-018-1379-8

[7] Huang H, Zhang P, Yan H, et al. Research on weld formation mechanism of laser-MIG arc hybrid welding with butt gap[J]. Optics & Laser Technology, 2021, 133: 1 − 13.

[8] 严春妍, 张浩, 朱子江, 等. X80管线钢多道激光-MIG复合焊残余应力分析[J]. 焊接学报, 2021, 42(9): 28 − 34. Yan Chunyan, Zhang Hao, Zhu Zijiang, et al. Residual stress analysis of X80 pipeline steel by multi pass laser MIG hybrid welding[J]. Transactions of the China Welding Institution, 2021, 42(9): 28 − 34.

[9] Ivan B, Jan F, Akselsen O M, et al. The penetration efficiency of thick plate laser-arc hybrid welding[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97: 2907 − 2919. doi: 10.1007/s00170-018-2103-x

[10] 黄瑞生, 杨义成, 蒋宝, 等. 超高功率激光-电弧复合焊接特性分析[J]. 焊接学报, 2019, 40(12): 73 − 77. Huang Ruisheng, Yang Yicheng, Jiang Bao, et al. Characteristic analysis of ultra high power laser arc hybrid welding[J]. Transactions of the China Welding Institution, 2019, 40(12): 73 − 77.

[11] 石庭深, 朱加雷, 焦向东, 等. X80管线钢激光-电弧复合焊接工艺[J]. 电焊机, 2015, 45(5): 69 − 72. Shi Tingshen, Zhu Jialei, Jiao Xiangdong, et al. Laser arc hybrid welding process of X80 pipeline steel[J]. Electric Welding Machine, 2015, 45(5): 69 − 72.

[12] Yin L, Wang J, Chen X, et al. Microstructures and their distribution within HAZ of X80 pipeline steel welded using hybrid laser-MIG welding[J]. Welding in the World, 2018, 62: 721 − 727. doi: 10.1007/s40194-018-0582-x

[13] 刘博, 王媛媛, 李彬. X120管线钢激光-电弧复合焊接头组织及硬度分析[J]. 焊管, 2021, 44(10): 19 − 23. Liu Bo, Wang Yuanyuan, Li Bin. Microstructure and hardness analysis of laser arc composite welded joint of X120 pipeline steel[J]. Welded Pipe and Tube, 2021, 44(10): 19 − 23.

[14] 王小朋. 不锈钢纯Ar保护激光扫描-CMT复合焊接研究[D]. 北京: 机械科学研究总院, 2012. Wang Xiaopeng. Study on laser scanning CMT hybrid welding of stainless steel with pure Ar protection[D]. Beijing: General Institute of Mechanical Sciences, 2012.

[15] Müller A, Goecke S F, Rethmeier M. Laser beam oscillation welding for automotive applications[J]. Welding in the World, 2018, 62: 1039 − 1047. doi: 10.1007/s40194-018-0625-3

[16] 许飞, 何恩光, 陈俐, 等. 钛合金扫描振镜激光-TIG复合焊接工艺研究[J]. 应用激光, 2020(5): 855 − 859. Xu Fei, He Enguang, Chen Li, et al. Study on laser TIG hybrid welding process of titanium alloy scanning galvanometer[J]. Applied Laser, 2020(5): 855 − 859.

[17] Fetzer F, Sommer M, Weber R, et al. Reduction of pores by means of laser beam oscillation during remote welding of AlMgSi[J]. Optics and Lasers in Engineering, 2018, 108: 68 − 77. doi: 10.1016/j.optlaseng.2018.04.012

[18] Cai C, Li L, Tao W, et al. Effects of weaving laser on scanning laser-MAG hybrid welding characteristics of high-strength steel[J]. Science and Technology of Welding and Joining, 2017, 22(2): 104 − 109. doi: 10.1080/13621718.2016.1199126

[19] 陈新亚. 激光-MAG复合摆动焊的焊接特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. Chen Xinya. Study on welding characteristics of laser MAG hybrid swing welding[D]. Harbin: Harbin Institute of Technology, 2014.

[20] Wang X N, Sun Q, Zheng Z, et al. Microstructure and fracture behavior of laser welded joints of DP steels with different heat inputs[J]. Materials Science & Engineering A, 2017, 699: 18 − 25.

[21] 王进. X80高强钢组织及焊接工艺研究[D]. 成都: 西南石油大学, 2014. Wang Jin. Study on microstructure and welding process of X80 high strength steel[D]. Chengdu: Southwest Petroleum University, 2014.

-

期刊类型引用(10)

1. 文学,汪宏辉,李熙岩,钱建康,毕思源,雷正龙. X80M钢管道全自动焊接接头裂纹尖端张开位移差异性. 焊接学报. 2024(02): 98-104+134-135 .  本站查看

本站查看

2. 肖友福,刘永贞,孙有辉,闫玉升,徐连勇,韩永典. 预充氢对SCR焊接接头应力腐蚀敏感性影响. 焊接学报. 2024(10): 19-27 .  本站查看

本站查看

3. 陈自振,李天伟,任建志,韩卫亮,范伟. 油气管道激光电弧焊工艺安全条件研究与应用. 安全、健康和环境. 2023(02): 22-27 .  百度学术

百度学术

4. 夏佩云,封小松,王春明,徐程,黄珲,何建利. 激光摆动焊接工艺参数对不锈钢焊缝成形与气孔率的影响. 焊接学报. 2023(04): 39-44+131 .  本站查看

本站查看

5. 付超,刘阳,王勇,李学达,曲畅. 大壁厚X80钢焊接HAZ沿壁厚方向的低温韧性. 焊接. 2023(06): 9-17 .  百度学术

百度学术

6. 王鹏宇,闫臣. 从油气管道工程建设的发展看焊接技术的进步. 焊接. 2023(06): 44-51+64 .  百度学术

百度学术

7. 周斌,陈捷狮,张杨,张文帅,杨尚磊,陆皓. 激光螺旋点焊和电阻点焊DC06镀锌钢接头组织和性能. 焊接学报. 2023(06): 41-49+131-132 .  本站查看

本站查看

8. 廖宁宁,王艳淼,周永东,林敏,张弛. Q355E圆锥管激光-MAG复合焊可行性应用研究. 金属加工(热加工). 2023(08): 65-69 .  百度学术

百度学术

9. 胡美娟,田野,慕进良,胡旭,宁杰,张林杰. CMT增材X80钢组织和性能与韧性调控措施. 焊接. 2022(07): 6-13 .  百度学术

百度学术

10. 汪宏辉,王鹏宇. 水网地区铜衬垫外根焊全自动焊接技术适应性. 焊接. 2022(07): 60-64 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: