Process and mechanism of low power laser-double arc welding of titanium alloy plate

-

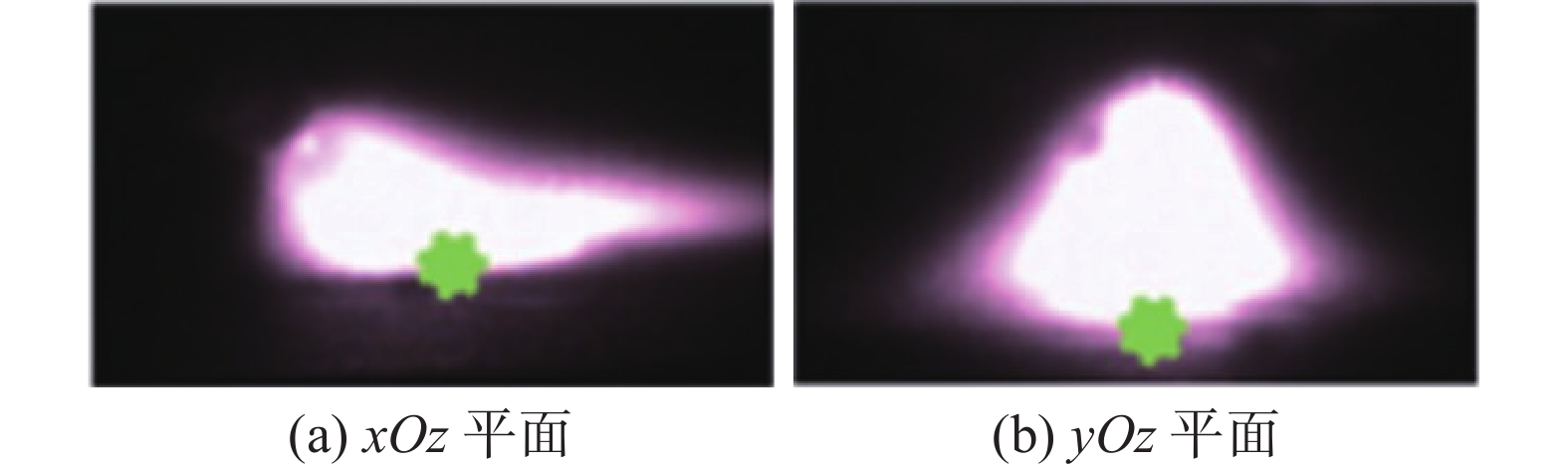

摘要: 采用单钨极惰性气体保护焊(single tungsten inert gas welding,STIG焊)、双钨极惰性气体保护焊(double tungsten inert gas welding,DTIG焊)、激光-STIG电弧(L-STIG)复合焊和激光-DTIG电弧(L-DTIG)复合焊4种方式对6 mm 厚TA2钛合金进行对接焊试验,实现单面焊双面成形. 结果表明,L-DTIG复合焊的电弧能量更为集中,焊接速度可达680 mm/min. L-DTIG复合焊的热输入为605.5 J/mm,仅是DTIG焊的35.5%和L-STIG复合焊的59.0%. L-DTIG复合焊接头的焊缝区晶粒细小,显微硬度可达229.5 HV. 拉伸试样在母材处断裂,接头抗拉强度优于母材. 加入激光后,L-DTIG复合焊的电弧等离子体中心导电区在xOz和yOz平面电弧分别收缩51.0%,45.5%,电弧根部收缩75.0%. 测得L-DTIG复合焊热源在工件上的电弧压力为3 465 Pa,分别是DTIG焊和L-STIG复合焊的4.17和2.25倍. 较高的电弧收缩比和电弧压力可显著提高焊接效率,降低焊接热输入.

-

关键词:

- 钛合金 /

- 中厚板 /

- 热输入 /

- 激光诱导双电弧复合热源 /

- 等离子体

Abstract: Single tungsten inert gas welding (STIG), double tungsten inert gas welding (DTIG), laser-single TIG arc hybrid welding (L-STIG) and laser-double TIG arc hybrid welding (L-DTIG) were used to weld TA2 titanium alloy butt joints with 6 mm thickness , and one-side welding with back formation were achieved. The results show that the arc energy of L-DTIG hybrid welding is more concentrated, and the welding speed can reach 680 mm/min. The heat input of L-DTIG hybrid welding is 605.5 J/mm, which is only 35.5% of DTIG and 59.0% of L-STIG. The grain size of L-DTIG weld zone is fine, and the microhardness can reach 229.5 HV. Tensile specimens fracture at the base material and the joint strength is better than that of the base material. After the addition of laser, the arc plasma central conductive zone of L-DTIG shrinks by 51.0% and 45.5% in the xOy and yOz planes, respectively, and the arc root shrinks by 75.0%. The measured arc pressure of the L-DTIG composite welding heat source on the workpiece was 3 465 Pa, which was 4.17 and 2.25 times higher than that of DTIG and L-STIG composite welding, respectively. The higher arc shrinkage ratio and arc pressure can significantly improve the welding efficiency and reduce the welding heat input. -

0. 序言

钛合金具有耐腐蚀性强、密度低、比强度高等特点[1],在航空航天、船舶制造、化工机械、生物医疗、能源工业等领域中得到了广泛的应用. 由于钛合金中厚板焊接时熔池较大,而熔融的钛合金具有活性强、表面张力小、导热性差、热量集中等特点. 因此,热输入的控制对钛合金中厚板焊接接头的性能具有十分重要的影响.

目前,钛合金中厚板常用焊接方法主要有钨极惰性气体保护电弧焊(tungsten inert gas arc welding,TIG焊)、激光焊(laser beam welding,LBW)、激光-电弧复合焊等. TIG焊具有间隙容忍度高、热输入大等特点,导致焊接效率低、能量消耗严重,钛合金受热面积增大,焊缝及热影响区变宽,使得焊接接头的整体连接强度较低[2]. 牟刚等人[3]使用手工TIG多层多道填丝焊方法,对厚度为8 mm的Ti6Al4V(TC4)钛合金进行对接焊试验. 结果表明,在焊接速度为150 mm/min时,可获得了良好的焊缝成形. 激光焊具有热输入小、能量密度高、焊接速度快、可达性好等特点[4-5],且焊接过程中不需要真空,易实现自动化生产[6]. 由于激光器的光-电转化效率低,导致焊接能耗较高,且激光焊对工件的装备精度要求较高. Tian等人[7]使用12 kW大功率连续激光器对厚度为8 mm的TC4钛合金进行对接焊试验,结果表明,随着焊接速度由1.2 m/min降低到0.8 m/min,焊缝中气孔的孔径有增大的趋势. 激光-电弧复合焊结合了激光的高能量密度和电弧的高间隙容忍度等优势,弥补了两者的缺点,与激光焊相比,激光-电弧复合焊具有良好的电弧桥接能力和间隙容忍度;与电弧焊相比,激光-电弧复合焊具有熔深大、变形小等特点[8-9],可大幅度提高焊接效率,降低焊接能耗[10],消除咬边、驼峰等缺陷,是应用广泛的先进连接技术. Turichin等人[11]使用5 kW大功率连续激光与TIG电弧形成复合热源,对5 mm厚TC4钛合金进行填丝焊,研究了电极高度、焊接速度对板材熔透稳定性的影响.

为节约能源、提高焊接效率,提出低功率脉冲激光-双电弧复合焊技术. 通过在传统的激光-电弧复合焊方法中引入一个新的电弧,增强了激光对电弧等离子体的诱导效果,提升了对中厚板的焊接能力. 对比研究单钨极惰性气体保护焊(single tungsten inert gas welding,STIG焊)、双钨极惰性气体保护焊(double tungsten inert gas welding,DTIG焊)、激光-STIG电弧(L-STIG)复合焊和激光-DTIG电弧(L-DTIG)复合焊4种方式对6 mm厚TA2钛合金进行无坡口、不填丝对接焊试验. 通过分析电弧等离子体和电弧压力的变化规律,研究了焊接过程中低功率脉冲激光对电弧等离子体的影响,突出低功率脉冲激光-双电弧复合焊接技术低热输入、高焊接效率的本质特征,对中厚板的焊接具有重要意义.

1. 试验方法

试验材料为TA2钛合金,尺寸为200 mm × 100 mm × 6 mm. 母材化学成分如表1所示. 焊前使用砂纸去除母材表面的氧化膜,并用丙酮清除板材表面的油污和灰尘,保证焊前母材的洁净.

表 1 TA2钛合金化学成分(质量分数,%)Table 1. Chemical compositions of TA2 titanium alloyFe N C O H Ti ≤0.3 ≤0.05 ≤0.10 ≤0.20 ≤0.10 余量 分别使用4种焊接方式进行对接焊试验,试验装置如图1所示. 复合热源采用激光在前电弧在后的旁轴复合的方式,由低功率脉冲式TruPulse 556激光器和松下YC300WX焊机组成. 激光平均功率可通过激光器的峰值功率、脉冲频率、脉冲宽度进行调节,电弧功率可通过氩弧焊机的焊接电流进行调节. 焊接过程中,复合热源位置固定不动,板材进行移动. 试验采用自制气体保护罩安装在TIG焊枪尾部和焊缝背部,紧贴焊缝. 在焊接过程中,向保护罩内充入氩气,防止焊缝表面氧化. 保护气罩和焊枪使用的保护气体均为99.99%的高纯氩气,焊接工艺参数如表2所示.

表 2 主要焊接工艺参数Table 2. Main welding parameters序号 焊接方法 焊接电流I/A 电弧电压U/V 激光功率P/W 焊接速度v/(mm·min−1) 1 STIG焊 400 14.9 — 170 2 DTIG焊 260 + 260 14.3 — 210 3 L-STIG

复合焊400 15.2 500 300 4 L-DTIG

复合焊260 + 260 15.9 500 680 为了获得电弧等离子体的侧面和正面的轮廓,使用拍摄频率为2000帧/s的高速摄像机分别沿垂直、平行于焊接方向放置. 在高速摄像机前端安装一个中心波长为809.5 nm、半波长为9.2 nm的窄带滤光片,采集Ar电弧等离子体实时信息,电弧等离子体图像及电弧压力采集位置如图2所示.

焊接完成后,沿垂直焊缝方向截取试样,获得焊缝的横截面,并进行打磨、抛光,使用自配的腐蚀溶液(3%HF + 6%HNO3 + 91%H2O) 腐蚀后,在MEF-3型金相显微镜下观察焊接接头横截面形貌及其微观组织;沿垂直于焊缝方向截取硬度和静拉伸标准试样. 使用硬度仪在4.9 N压头载荷下,以0.2 mm的步长对焊缝进行硬度测试. 按照标准 GB/T 228—2002《金属材料 室温拉伸试验方法》制备拉伸试样,并使用DNS300型万能试验机在室温下以1 mm/min的拉伸速率进行拉伸试验. 每个参数重复进行3次,通过计算获得试样抗拉强度和断后伸长率,并求平均值. 金相采集位置分别为母材与热影响区界面处(A区域)、焊缝区上部(B区域)和焊缝区下部(C区域). A,B,C 区域及硬度打点位置如图3所示.

2. 结果与讨论

2.1 焊缝截面形貌与热输入对比分析

使用4种焊接方式以表2的工艺参数对厚度为6 mm的TA2钛合金进行对接焊试验,获得的焊缝截面形貌如图4所示. 通过计算,对比不同焊接方式对热源能量的利用效果.

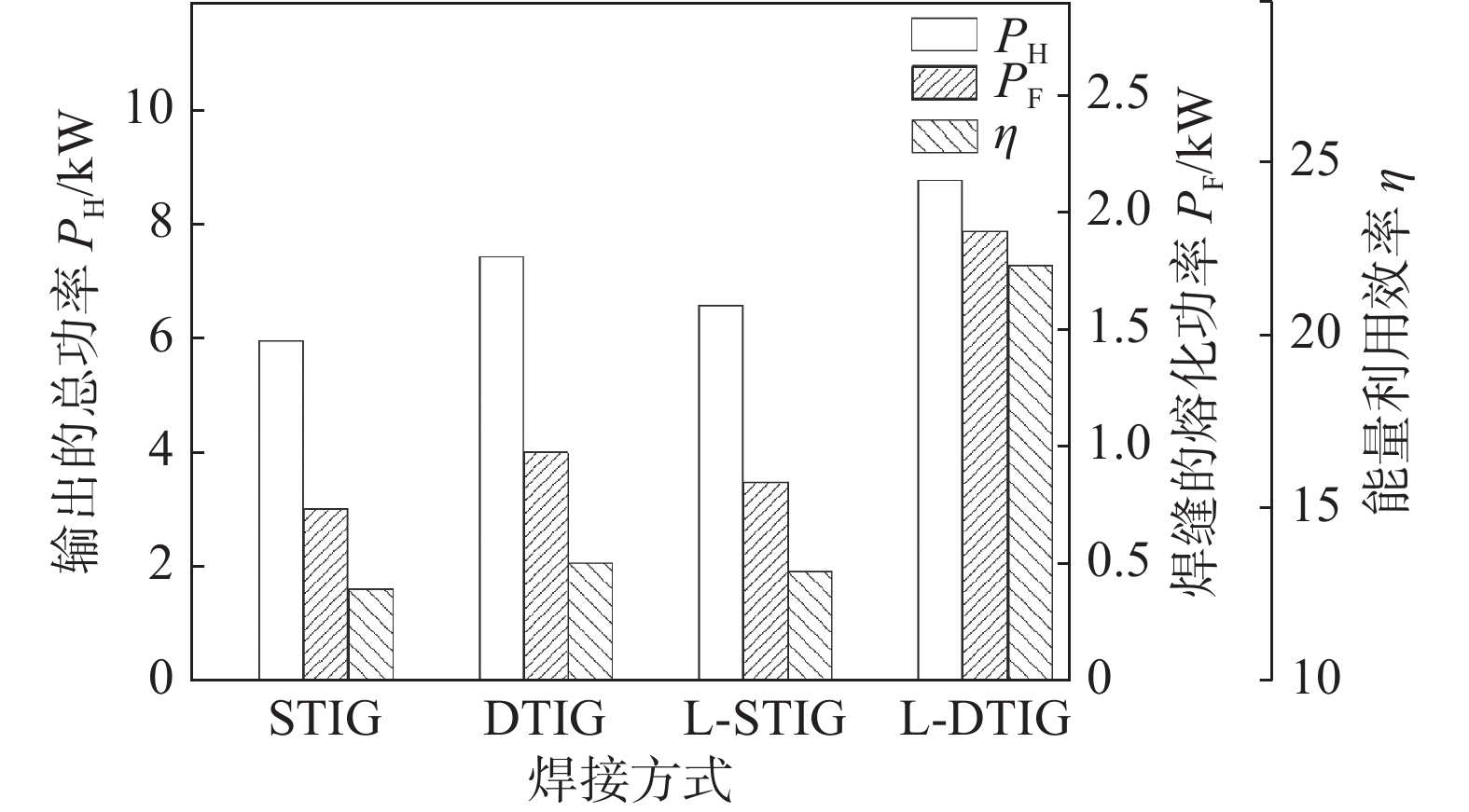

考虑电弧与激光的热传导、热对流、反射、辐射等能量消耗等因素. 能量利用效率可以反映出焊接热源能量的综合利用效果.

$$ \eta=P_{\rm{F}} / P_{\rm{H}} $$ (1) 式中:η为能量利用效率;PF为焊缝的熔化功率;PH为输出的总功率.

焊接过程中输出的总功率为

$$ {P}_{\mathrm{H}}={P}_{\mathrm{T}}+{P}_{\mathrm{L}}={U}_{\mathrm{T}} {I}_{\mathrm{T}}+{P}_{\mathrm{L}} $$ (2) 式中:PT为TIG焊机输出功率;PL为激光器输出功率;UT,IT分别为TIG焊机输出的电压和电流.

焊缝的熔化功率为焊缝熔化所需的热力学功率[12],其计算方法为

$$ {P}_{\mathrm{F}}=\rho \left[{C}_{\mathrm{A}} \left({T}_{\mathrm{M}}-{T}_0\right)+{H}_{\mathrm{F}}\right] {V}_{\mathrm{m}}={K}_{\mathrm{M}} {V}_{\mathrm{m}} $$ (3) 式中:PF为焊缝熔化所需的热力学功率;ρ为材料的密度;CA为比热容;TM和T0分别为熔化温度和初始温度;HF为熔化潜热;Vm为单位时间焊缝熔化的体积;KM为计算所得常数.

由式(3)可知,PF与KM,单位时间焊缝熔化的体积Vm成正比.由表3中TA2的物理性质参数可以算出,KM为5.81 J/mm3;单位时间焊缝熔化的体积为

表 3 TA2 钛合金物理性质参数Table 3. Physical properties of TA2 titanium alloy密度

ρ/ (kg·m−3)比热容

CA / (kJ·kg−1·K−1)初始温度

T0 / ℃熔化温度

TM / ℃熔化潜热

HF /( kJ·kg−1)4 510 0.55 15 1 610 410 $$ V_{\mathrm{m}}={S} _{\mathrm{A}} v $$ (4) 式中:Vm为单位时间焊缝熔化的体积;SA为单位时间焊缝区面积;v为焊接速度.

能量利用效率η和焊缝的熔化功率PF可以直观地反映热源的能量利用效果. 由图5可知,加入激光后,L-STIG复合焊与STIG焊相比,η值稍有提升;但L-DTIG复合焊与DTIG焊相比,η值由13.07%升至21.86%,提升显著. 且L-DTIG复合焊的能量利用效率分别是DTIG焊和L-STIG复合焊的1.67和1.71倍.

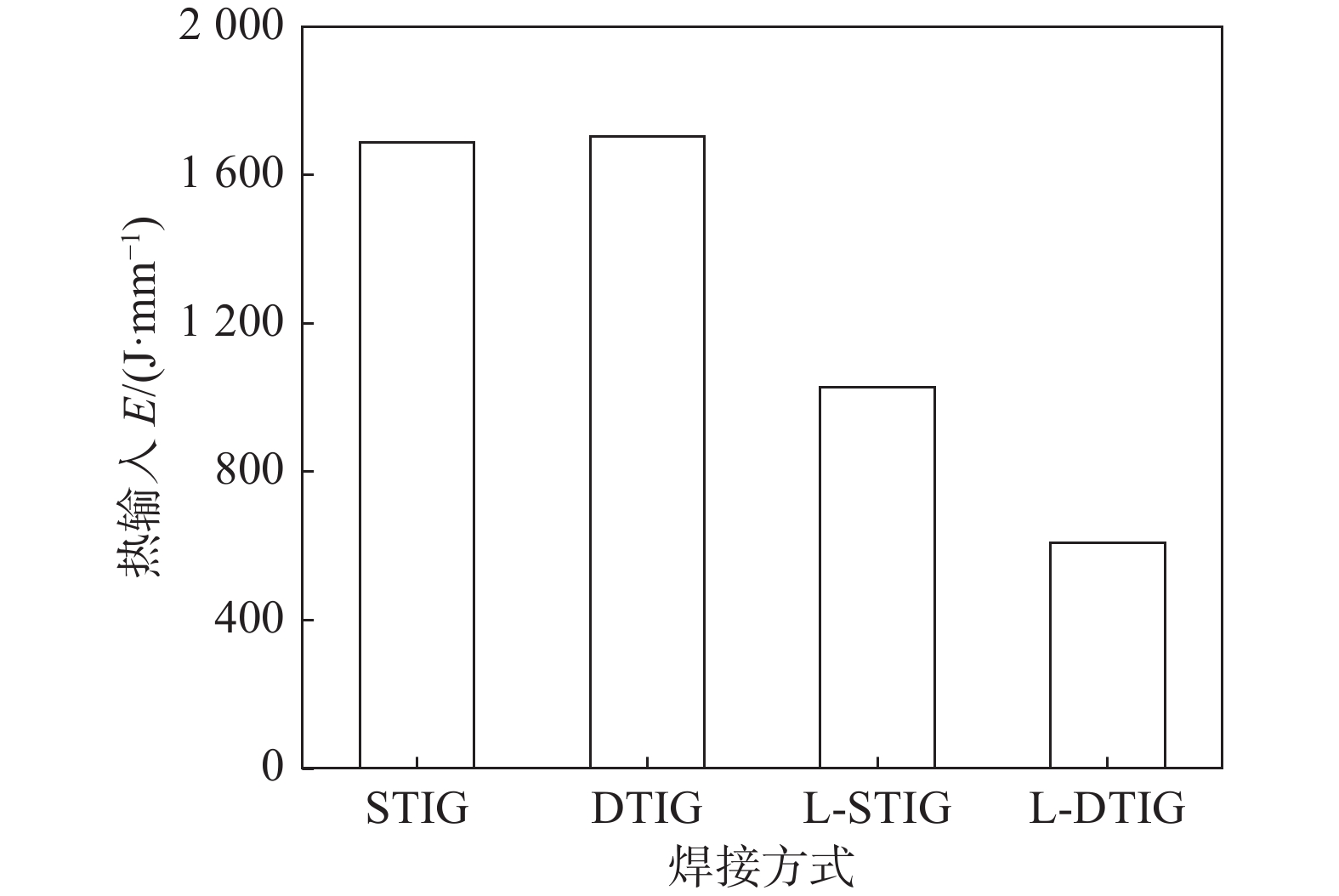

使用表2的工艺参数对4种焊接方式的热输入进行了计算,即

$$ {{{E}}}=\frac{\eta_{\mathrm{T}} {E}_{\mathrm{T}}+\eta_{\mathrm{L}} {E}_{\mathrm{L}}}{{v}}=\frac{\eta_{\mathrm{T}} {U} {I}+\eta_{\mathrm{L}} {P}_{\mathrm{L}}}{{v}} $$ (5) 式中:E为焊接热输入;ηT和ηL分别为TIG电弧和激光的热效率系数;ET和EL分别为TIG焊机和激光器的输出功率;U和I分别为TIG焊的电弧电压和焊接电流;v为焊接速度. 其中TIG热效率系数ηT约为0.8,激光作用于熔化的金属时,液态金属对激光的吸收率约为50%,所以激光的热效率系数ηL取值为0.5[13]. 将试验参数代入式(5)计算可得4种焊接方式热输入如图6所示.

由表2和图6可知,加入激光后,焊接速度明显提高,热输入显著降低. L-STIG复合焊的焊接速度为STIG焊的1.76倍,热输入为STIG焊的60.7%;L-DTIG复合焊的焊接速度为DTIG焊的3.24倍,为L-STIG复合焊的2.27倍. L-DTIG复合焊的热输入仅为605.5 J/mm,是DTIG焊的35.5%,是L-STIG复合焊的59.0%.

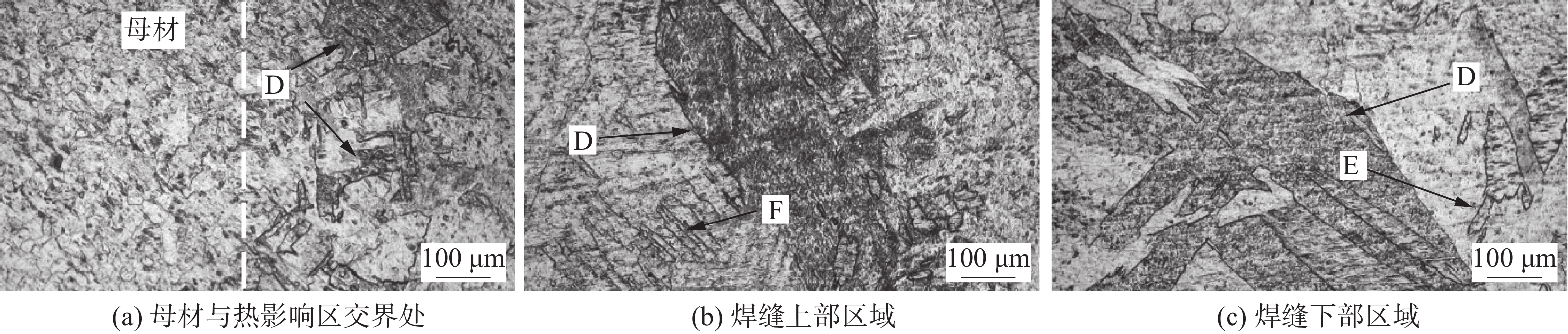

2.2 组织与性能分析

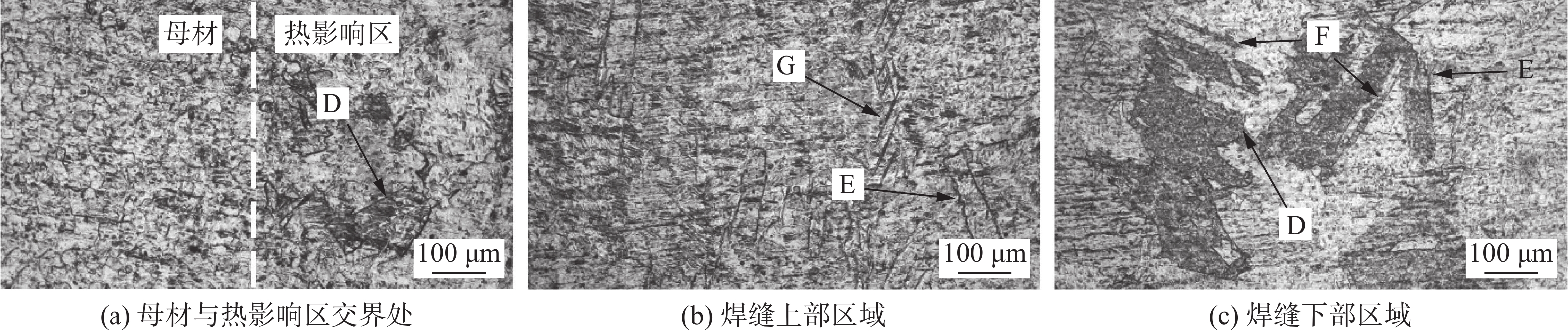

由于4种焊接方式的热输入不同,所以接头的组织性能也有较大的差别. 对焊接接头不同区域的金相组织进行采集,如图3中的A,B,C区域所示. 其中A区域为母材与热影响区界面处,B和C区域分别为焊缝的上部和下部,4种焊接方式接头的微观组织如图7 ~ 图10所示. 由图7 ~ 图10可知,母材由均匀的等轴α晶粒组成,热影响区与母材界面明显,热影响区主要结构为不规则的锯齿状α晶粒(D). STIG和DTIG焊接头中焊缝主要由粗大不规则的锯齿状α晶粒(D)、柱状α晶粒(E)以及少量的针状α晶粒(F)组成. L-STIG和L-DTIG复合焊接头的焊缝区除了存在锯齿状α晶粒、柱状α晶粒,针状α晶粒外还存在部分α孪晶(G). 整体而言,STIG和DTIG焊接头中的晶粒尺寸均大于L-STIG和L-DTIG复合焊接头中的晶粒尺寸. 对比焊缝上部和下部的微观组织可以看出,下部的晶粒尺寸较上部稍有减小,且L-STIG,L-DTIG复合焊接头焊缝组织中细小的α孪晶主要存在于上部区域.

对4种焊接试样进行了硬度测试,硬度分布云如图11所示. 从图11可以看出,从焊缝中心到母材,硬度呈下降趋势. STIG,DTIG焊接头的焊缝区和热影响区硬度分布均匀,焊缝区的平均硬度为202.3,203.1 HV,热影响区的平均硬度为180.2 ,181.7 HV. 加入激光后,L-STIG,L-DTIG复合焊接头的硬度稍有提升,焊缝区的平均硬度为207.1,208.3 HV,热影响区平均硬度为186.5,186.8 HV. 分布于焊缝上部区域细小的针状α晶粒和α孪晶导致该区域硬度明显增加,其最大硬度分别为224.3,229.5 HV.

图12为4种焊接接头的拉伸性能. 从图12可以看出,母材的抗拉强度和断后伸长率分别为436 MPa和32.5%. STIG,DTIG焊接头试样均断裂于焊缝区,抗拉强度分别为381,396 MPa,约为母材的87.4%和90.8%;其断后伸长率分别为19.0%,20.5%,约为母材的58.5%和63.1%. L-STIG,L-DTIG复合焊接头试样均在母材处断裂,断裂处呈现明显的颈缩,其抗拉强度和断后伸长率与母材相当. 由此可见,使用L-DTIG复合焊方法可获得力学性能优良的TA2钛合金焊接接头.

2.3 电弧等离子体形貌及电弧压力分析

使用高速摄像机对xOz和yOz平面的电弧等离子体信息进行采集. 使用压力传感器对电弧等离子体底部中心位置的电弧压力进行测量. 对采集数据进行分析,研究激光-电弧复合热源低热输入、高焊接效率的本质特征.

图13为4种焊接方式的Ar电弧等离子体的形貌. 由图13可知,当有激光作用时,电弧等离子体发生明显的收缩,中心导电通道面积减小. 这是由于Ti原子的电离能(6.81 eV)明显小于Ar原子(15.76 eV)[14],在焊接过程中,Ti原子被优先电离,形成的Ti等离子体取代导电通道中部分Ar等离子体进行导电. 定义电弧等离子体中的关键参数,定量的分析激光对电弧等离子体的诱导、压缩作用. 电弧根部在板材表面的形状类似于椭圆形,电弧根部面积可以用式(6)表示.

$$ S = \frac{{{\text{π }} d_{\rm{t}} d_{\rm{w }}}}{{\text{4}}} $$ (6) 式中:S为电弧根部面积;dt和dw分别为xOz和yOz平面电弧根部长度,如图14所示.

激光作用时,电弧中心导电区的收缩比和根部面积的收缩比例可以反映激光对电弧的诱导效果,可以表示为

$$ C_{\mathrm{T}}=\frac{{T}_{\text {(STIG/DTIG) }}-{T}_{\text {(L-STIG } / \text{L-DTIG})}}{{T}_{\text {(STIG/DTIG) }}} $$ (7) $$ \begin{aligned} &C_{\rm{R}}=\frac{{S}_{(\rm{STIG} / \rm{DTIG})}-{S}_{(\text{L-STIG} / \text{L-DTIG})}}{{S}_{(\rm{STIG} / \rm{DTIG})}}=\\ &{1}-\frac{{d}_{\rm{t}(\text { L-STIG/L-DTIG) }} {d}_{\rm{w}(\text { L-STIG/L-DTIG })}}{{d}_{\rm{t}(\text { STIG/DTIG) }} {d}_{\rm{w}(\text { STIG/DTIG })}} \end{aligned} $$ (8) 式中:CT为电弧中心导电区的收缩比;T为电弧中心导电区的面积;CR为根部面积的收缩比例;S为电弧根部面积;dt为xOz 平面电弧根部长度;dw为yOz平面电弧根部长度;下角标括号中的STIG/DTIG为STIG焊或DTIG焊方法;下角标括号中的L-STIG/L-DTIG为L-STIG复合焊或L-DTIG复合焊方法.

从表4可以看出,在xOz和yOz平面,L-STIG和L-DTIG复合焊电弧中心导电区均有收缩,且L-DTIG复合焊电弧收缩更为明显. L-DTIG复合焊电弧在xOz和yOz平面的收缩比分别是L-STIG复合焊电弧的1.51和1.52倍. 表4中的电弧根部面积的收缩比例(CR)值越大,代表激光对电弧的诱导能力越强. L-DTIG复合焊电弧根部作用面积收缩比例是L-STIG复合焊电弧的1.38倍. 结果表明,激光对双电弧等离子体的诱导能力更强,电弧能量更为集中,使焊接效率提高,热输入降低.

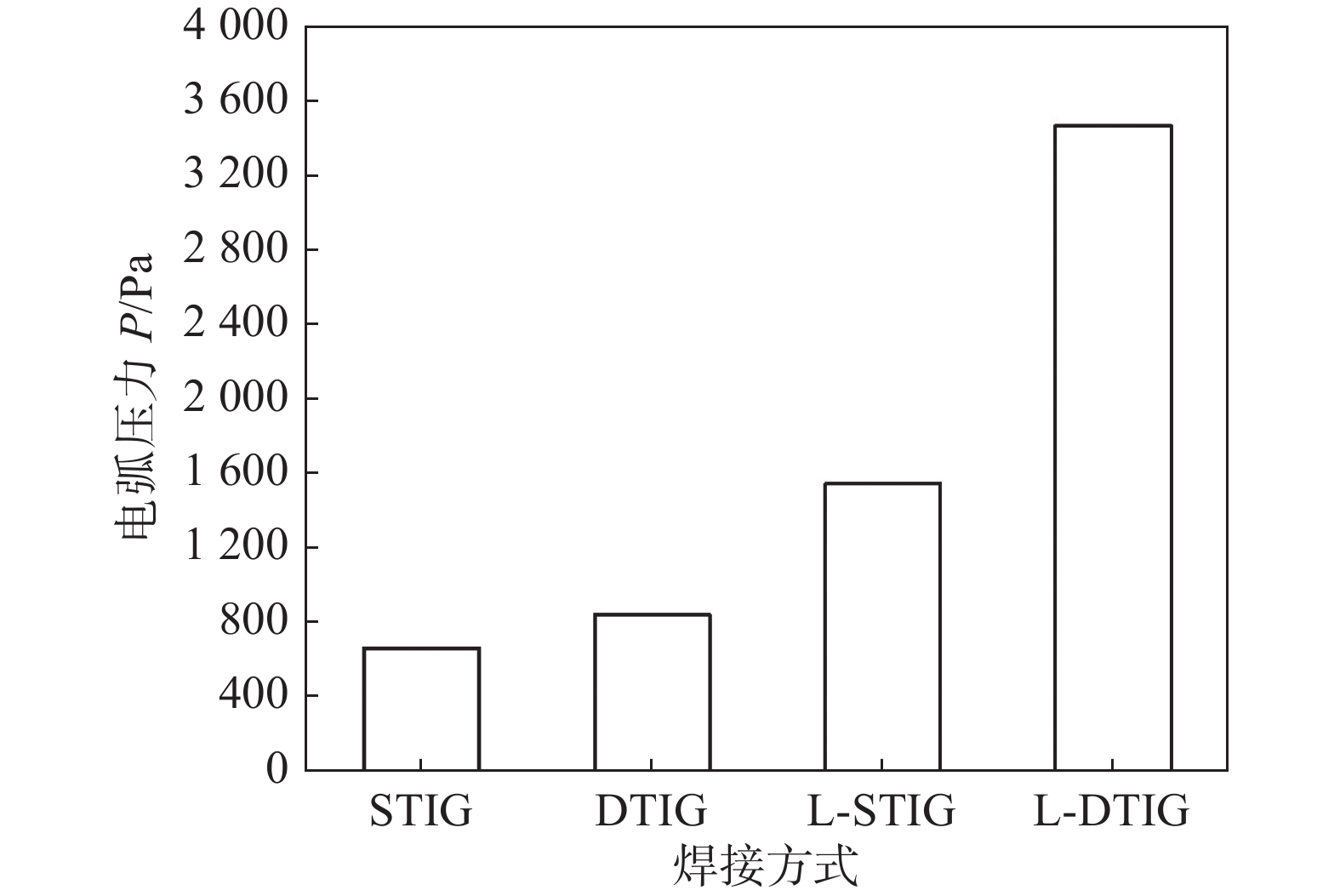

表 4 加入激光后单、双电弧中心导电区和根部面积收缩比(%)Table 4. Shrinkage ratio of single and double arc center conductive area and the root area after adding laser焊接方法 中心导电区收缩比CT 电弧根部面积的收缩比CR xOz平面 yOz平面 L-STIG复合焊 33.7 29.9 54.4 L-DTIG复合焊 51.0 45.5 75.0 对4种焊接方式电弧根部中心位置的电弧压力进行测量,其结果如图15所示. 加入激光后,电弧压力显著提高. L-DTIG复合焊电弧压力为3 465 Pa,是DTIG焊的4.17倍,是L-STIG复合焊的2.25倍.

电弧压力是高速运动的等离子体射流撞击阳极板材所产生的力. 假设电弧等离子体射流撞击阳极板材后,运动速度变为0,根据动能守恒定律,电弧根部中心处的电弧压力为[15]

$$ P_{{\rm{arc}}} = \frac{{{{\rho }}{v^2}}}{{\text{2}}} $$ (9) 式中:Parc为电弧压力;ρ为电弧等离子体密度;v为等离子运动速度.

由式(9)可知,电弧压力与电弧等离子体密度和等离子体流速成正相关. 假设等离子体在无粘流、不可压缩的条件下进行运动,等离子体的运动速度可表示为[14]

$$ {v}=\sqrt{\frac{\mu_0 {I J}}{2 {\text{π}} \rho}} $$ (10) 式中:v为等离子运动速度;μ0为自由空间磁导率;I和J分别为电弧中心的电流强度和电流密度;ρ为电弧等离子体密度.

电弧等离子体的电流密度为[16]

$$ {J}=\frac{{H} {e}^2 {n}_{\mathrm{e}} {\lambda}_{\mathrm{e}}}{\sqrt{8 {{{k}}{ {{m}}_{\rm{e}}} }{T}_{\mathrm{e}} /{\text{π}}}} $$ (11) 式中:H为电弧等离子体电场强度;e为电子电荷;ne,λe分别为电子密度和电子平均自由程;k为玻尔兹曼常数;me为电子质量;Te为电子温度.

将式(10) ~ 式(11)代入式(9)中,得到电弧压力的具体计算式,即

$$ P_{{\rm{arc}}} = \frac{{{{\rm{\mu }}_{\rm{0}}}{{{e}}^2} \lambda _{\rm{e}} IH n_{\rm{e }}}}{{{\rm{20}}\sqrt {{{k}}{ {{m}}_{\rm{e}}} T_{\rm{e}} } }} $$ (12) 由式(12)可知,Parc与Te成弱相关,与I,H,ne的相关性较强.

当激光作用时,电弧等离子体明显收缩,导电通道直径减小,按照最小电压原理,电弧电压增加. 由于钨极高度保持一致,电弧电压增加导致电场强度(E)增强. 电弧等离子体受到电场和洛伦兹力共同影响,使电子获得大量能量,加剧了高能电子与Ar粒子的碰撞,促进了粒子的电离,电弧等离子体中电子密度(ne)明显增加. 所以L-STIG,L-DTIG复合焊电弧压力明显高于STIG和DTIG焊,且L-DTIG复合焊高于L-STIG复合焊,计算结果与试验测得数据一致. 这是由于与L-STIG复合焊相比,L-DTIG复合焊单个电极焊接电流(260 A)较小,由于电弧挺度与电极电流成正相关. 在激光作用时,激光更容易克服电弧挺度,L-DTIG复合焊电弧等离子体的收缩程度大于L-STIG复合焊,电场强度更大;且L-DTIG复合焊的总焊接电流(520 A)大于L-STIG复合焊(400 A),导致L-DTIG复合焊的电流强度更大;在两者共同作用下,使得L-DTIG复合焊电弧压力明显高于L-STIG复合焊. 电弧等离子体作用于板材,电弧压力的增大,更有利于在板材表面形成更大的熔深. 即在获得相同熔深的前提下,增大电弧压力,可提升焊接效率、降低焊接的热输入.

综上所述,由于STIG焊和DTIG焊的电弧放电面积大,电弧压力较小,能量密度较低,熔透6 mm钛合金时需要更大的热输入,使熔池冷却速度慢,高温停留时间长,导致焊缝及热影响区晶粒粗大,硬度相对较低,焊缝的结合强度相对较弱. 激光作用时,L-DTIG复合焊的变化最为显著. 在L-DTIG焊过程中,脉冲激光作用于熔池促进了熔池内液态金属的相互扰动,破碎枝晶,同时激光的诱导放电效应使双电弧等离子体大幅收缩,电弧压力增大,能量密度升高,焊接效率提高. 较低的热输入使熔池冷却加快,晶粒来不及长大,形成细小的α晶粒,提高了焊接接头的力学性能.

3. 结论

(1)在6 mm厚TA2钛合金焊接中,L-DTIG复合焊具有焊接速度快、热输入小、能量利用效率高等优势. L-DTIG热输入仅为605.5 J/mm,为DTIG焊的35.5%,为L-STIG复合焊的59.0%;能量利用效率分别是DTIG焊和L-STIG复合焊的1.67倍和1.71倍.

(2)加入激光后,L-DTIG复合焊热输入显著降低,且脉冲激光搅拌熔池,细化了焊缝及热影响区的晶粒. 从焊缝区到母材硬度呈下降趋势,焊缝区硬度最高为229.5 HV. 拉伸试样断裂位置为母材,抗拉强度与母材相当.

(3)激光作用时,电弧能量更加集中. L-DTIG复合焊电弧等离子体的中心导电区在xOz和yOz平面电弧分别收缩51.0%和45.5%,电弧根部作用面积收缩75.0%. L-DTIG复合焊热源在工件上的电弧压力为3 465 Pa,分别是DTIG焊和L-STIG复合焊的4.17和2.25倍. 较高的电弧收缩比和电弧压力可显著提高焊接效率,降低焊接热输入.

-

表 1 TA2钛合金化学成分(质量分数,%)

Table 1 Chemical compositions of TA2 titanium alloy

Fe N C O H Ti ≤0.3 ≤0.05 ≤0.10 ≤0.20 ≤0.10 余量 表 2 主要焊接工艺参数

Table 2 Main welding parameters

序号 焊接方法 焊接电流I/A 电弧电压U/V 激光功率P/W 焊接速度v/(mm·min−1) 1 STIG焊 400 14.9 — 170 2 DTIG焊 260 + 260 14.3 — 210 3 L-STIG

复合焊400 15.2 500 300 4 L-DTIG

复合焊260 + 260 15.9 500 680 表 3 TA2 钛合金物理性质参数

Table 3 Physical properties of TA2 titanium alloy

密度

ρ/ (kg·m−3)比热容

CA / (kJ·kg−1·K−1)初始温度

T0 / ℃熔化温度

TM / ℃熔化潜热

HF /( kJ·kg−1)4 510 0.55 15 1 610 410 表 4 加入激光后单、双电弧中心导电区和根部面积收缩比(%)

Table 4 Shrinkage ratio of single and double arc center conductive area and the root area after adding laser

焊接方法 中心导电区收缩比CT 电弧根部面积的收缩比CR xOz平面 yOz平面 L-STIG复合焊 33.7 29.9 54.4 L-DTIG复合焊 51.0 45.5 75.0 -

[1] 陈曦, 姜楠, 毕江, 等. 钛/铝激光熔钎焊接头原位TEM拉伸断裂行为[J]. 焊接学报, 2021, 42(11): 22 − 28, 98. doi: 10.12073/j.hjxb.20210420001 Chen Xi, Jiang Nan, Bi Jiang, et al. In-situ TEM tensile fracture behavior of titanium/aluminum laser brazing joint[J]. Transactions of the China Welding Institution, 2021, 42(11): 22 − 28, 98. doi: 10.12073/j.hjxb.20210420001

[2] Tricarico L, Brandizzi M, Satriano A A. CO2 laser-MIG hybrid welding of titanium alloy[C]//AMPT 2009-Advances in Material Processing Technoligies. Kuala Lumpur, Malaysia, 2009.

[3] 牟刚, 华学明, 徐小波, 等. 8 mm厚TC4钛合金TIG、MIG焊接工艺及性能对比研究[J]. 电焊机, 2020, 50(4): 70 − 74. Mou Gang, Hua Xueming, Xu Xiaobo, et al. Comparative study on welding process and performance of 8 mm thick TC4 titanium alloy TIG and MIG[J]. Electric Welding Machine, 2020, 50(4): 70 − 74.

[4] Chen Y, Zhang K, Xue H, et al. Study on laser welding of a Ti-22Al-25Nb alloy: microstructural evolution and high temperature brittle behavior[J]. Journal of Alloys & Compounds, 2016, 681: 175 − 185.

[5] Zhang M, Tang K, Zhang J, et al. Effects of processing parameters on underfill defects in deep penetration laser welding of thick plates[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96: 491 − 501. doi: 10.1007/s00170-018-1613-x

[6] 牛小男, 崔丽, 王鹏, 等. 镍铝青铜过渡层对钛合金/不锈钢异种材料激光焊接头组织与力学性能的影响[J]. 焊接学报, 2022, 43(1): 42 − 47. Niu Xiaonan, Cui Li, Wang Peng, et al. Effect of nickel aluminum bronze transition layer on microstructure and mechanical properties of laser welded titanium alloy/stainless steel joint[J]. Transactions of the China Welding Institution, 2022, 43(1): 42 − 47.

[7] Tian D, Gao Z, Wang F, et al. The porosity formation mechanism in the laser-welded butt joint of 8 mm thickness Ti-6Al-4V alloy: Effect of welding speed on the metallurgical pore formation[J]. Modern Physics Letters B, 2020, 34(4): 566 − 578.

[8] 黄瑞生, 杨义成, 蒋宝, 等. 超高功率激光-电弧复合焊接特性分析[J]. 焊接学报, 2019, 40(12): 73 − 77,96. Huang Ruisheng, Yang Yicheng, Jiang Bao, et al. Analysis of welding characteristics of ultra-high power laser-arc hybrid welding[J]. Transactions of the China Welding Institution, 2019, 40(12): 73 − 77,96.

[9] Zeng Huilin, Xu Yuanbin, Wang Changjiang, et al. Research on laser-arc hybrid welding technology for long-distance pipeline construction[J]. China Welding, 2018, 27(3): 53 − 58.

[10] Liu L, Li C, Shi J. Analysis of energy utilisation efficiency in laser-GTA hybrid welding process[J]. Science & Technology of Welding & Joining, 2014, 19(7): 541 − 546.

[11] Turichin G, Tsibulsky I, Somonov V, et al. Laser-TIG welding of titanium alloys[J]. IOP Conference Series: Materials Science and Engineering, 2016, 142(1): 1757 − 1765.

[12] 史吉鹏, 王红阳, 杨林波, 等. 钛合金激光-TIG复合焊接保护状态对焊缝成形及性能影响[J]. 焊接学报, 2017, 38(2): 61 − 65. Shi Jipeng, Wang Hongyang, Yang Linbo, et al. Effect of protection state of titanium alloy laser-TIG hybrid welding on weld formation and properties[J]. Transactions of the China Welding Institution, 2017, 38(2): 61 − 65.

[13] Brandizzi M, Mezzacappa C, Tricarico L, et al. Optimization of Ti6Al4V titanium alloy laser-arc hybrid weld parameters[J]. Welding International, 2011, 26(12): 1 − 9.

[14] 史吉鹏. 钛合金低功率脉冲激光调控电弧焊接物理机制及工艺研究[D]. 大连: 大连理工大学, 2019. Shi Jipeng. Study on physical mechanism and process of low power pulsed laser regulated arc welding for titanium alloy[D]. Dalian: Dalian University of Technology, 2019.

[15] Leng X, Zhang G, Wu L. The characteristic of twin-electrode TIG coupling arc pressure[J]. Journal of Physics D Applied Physics, 2006, 39(6): 1120 − 1126. doi: 10.1088/0022-3727/39/6/017

[16] 安藤弘平, 长谷川光雄. 焊接电弧现象[M]. 施雨湘, 译. 北京: 机械工业出版社, 1985. Ando K, Hasegawa M. Welding arc phenomenon[M]. Shi Yuxiang, trans. Beijing: China Mechine Press, 1985.

-

期刊类型引用(7)

1. 徐连勇,龙志平,赵雷,韩永典,彭晨涛. EH36钢焊接接头焊趾处应力集中对高低周复合疲劳的影响. 焊接学报. 2024(07): 1-9 .  本站查看

本站查看

2. 李季涛,兆文忠,田长亮. 焊后热处理退火工艺对十字接头疲劳寿命的影响. 金属热处理. 2020(09): 86-90 .  百度学术

百度学术

3. 崔向阳,洪克城. 一种考虑非比例附加损伤的多轴低周疲劳模型. 力学学报. 2019(03): 863-872 .  百度学术

百度学术

4. 李万润,刘宇飞,方钊,李爱群,王辉,杜永峰. 考虑残余应力的高层钢框架梁柱节点焊缝风致疲劳评估. 东南大学学报(自然科学版). 2019(04): 672-678 .  百度学术

百度学术

5. 卢耀辉,张德文,赵智堂,刘俊杰,卢川. 焊接残余应力对动车组铝合金车体疲劳强度的影响. 交通运输工程学报. 2019(04): 94-103 .  百度学术

百度学术

6. 苟磊,马玉娥,杜永,刘磊,郭超,李钢. 7050凹槽铝板激光冲击强化残余应力分布与疲劳寿命. 航空学报. 2019(12): 244-254 .  百度学术

百度学术

7. 袁喆,任建亭. 鱼脊焊缝极限承载能力评估技术研究. 热加工工艺. 2018(21): 199-202 .  百度学术

百度学术

其他类型引用(7)

下载:

下载: