Microstructure and properties of heat affected zone of high strength steel with rare earth

-

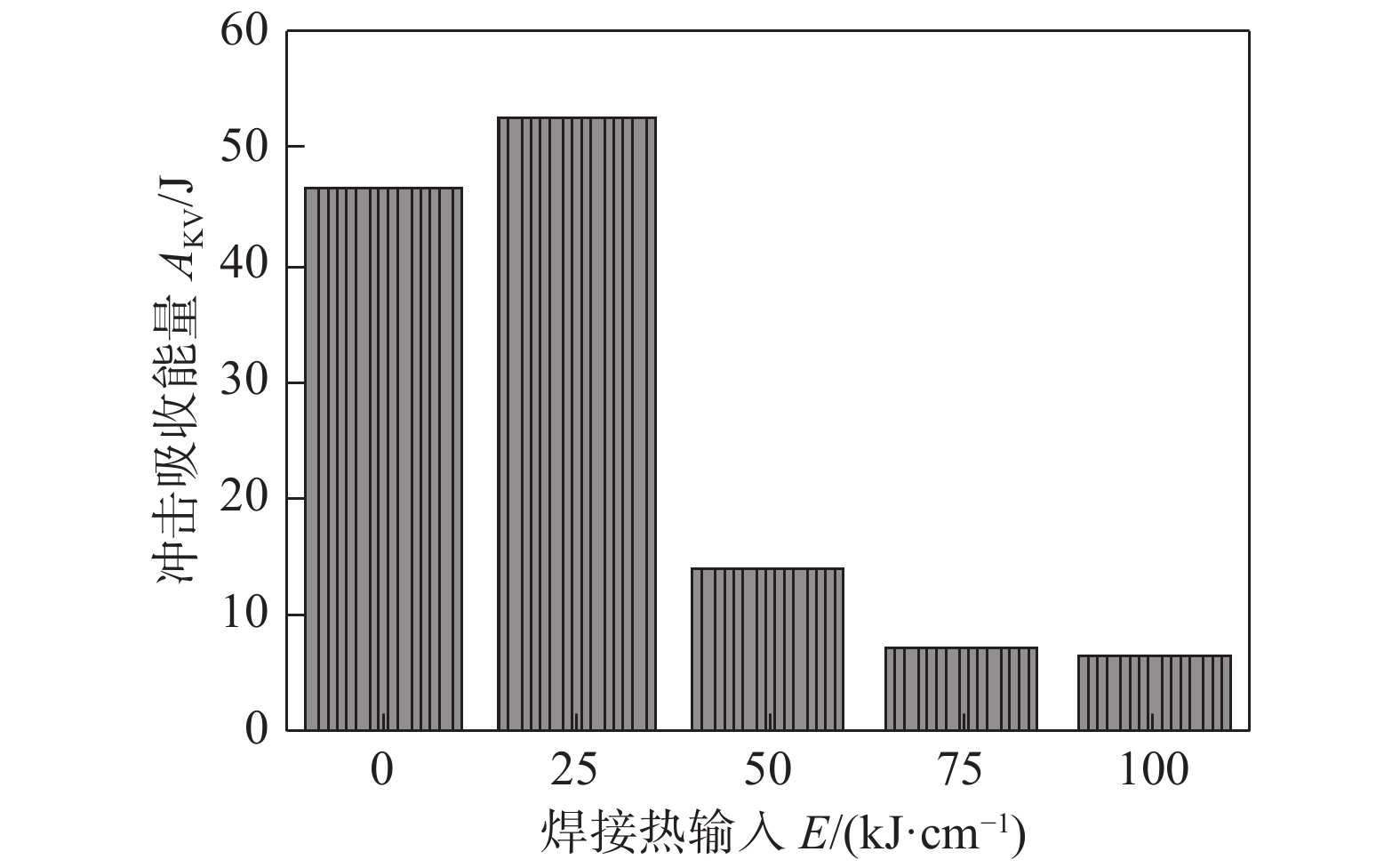

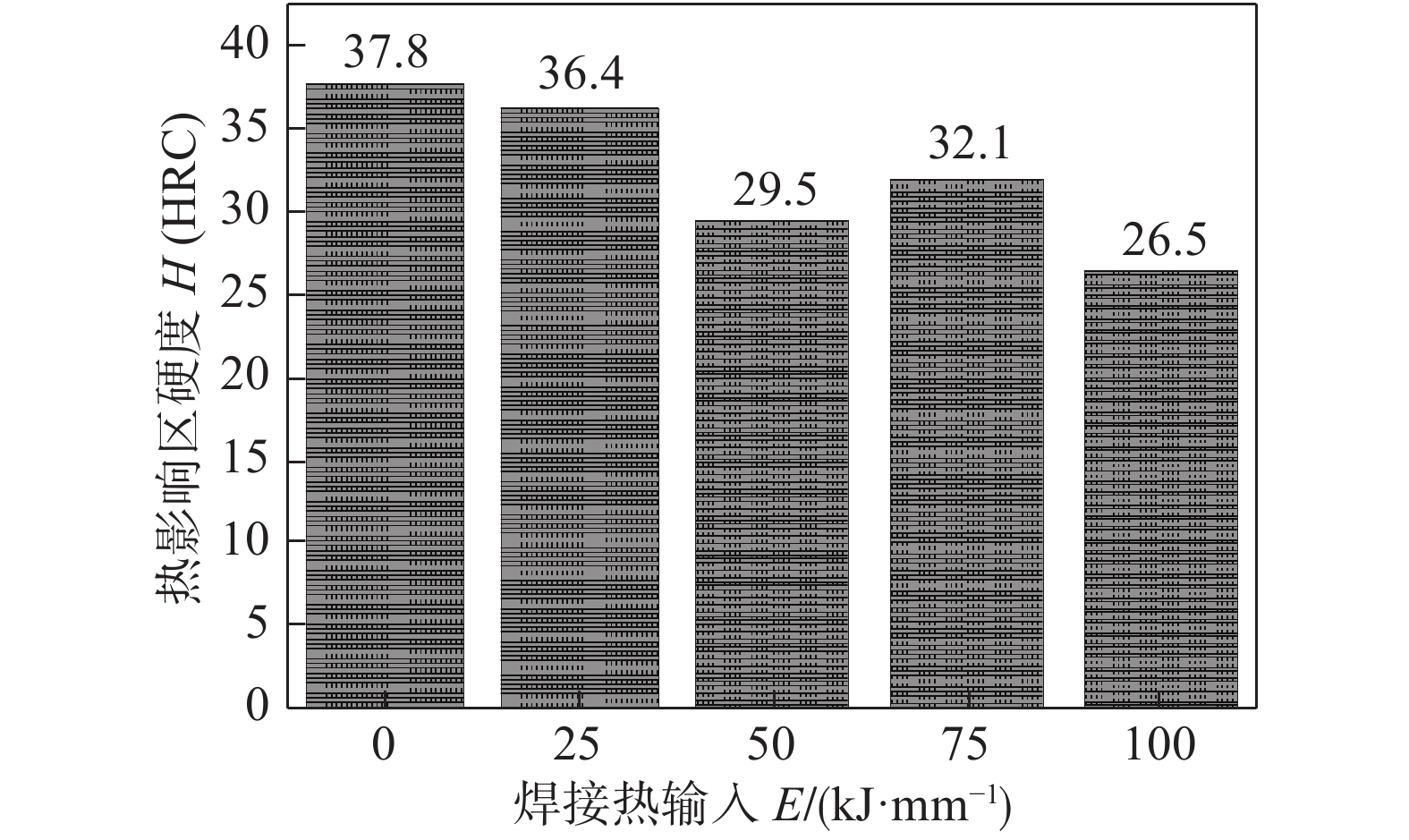

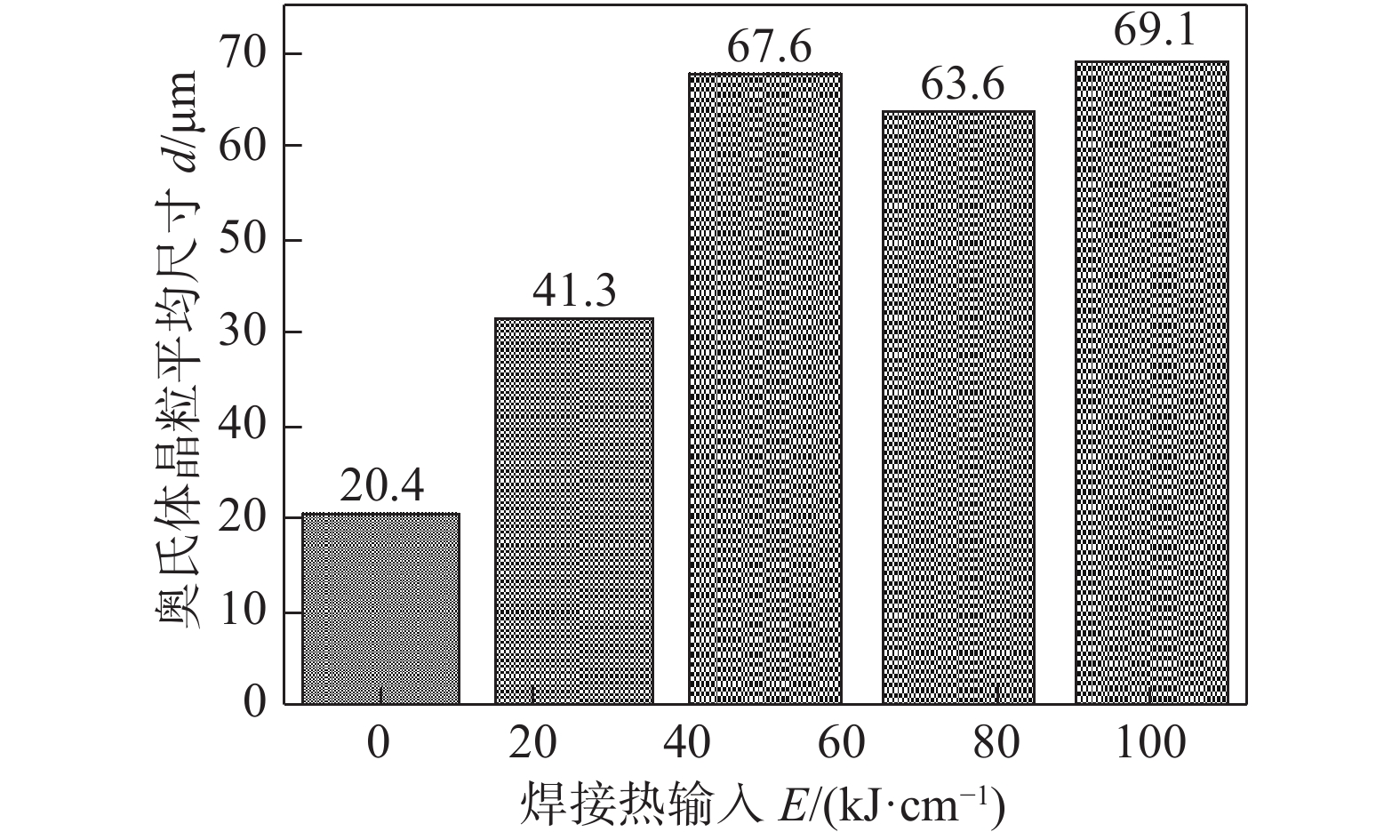

摘要: 机械装备的整体性能和寿命随着高强钢的大量使用而大幅提高,但性能薄弱区仍然是焊接热影响区. 应用恰当的处理技术,能生成形态、尺寸和分布有益的稀土夹杂物,在焊接中抑制原奥氏体晶粒长大改善钢的焊接性能. 试验制备了一种0.18%C的稀土高强钢,采用Gleeble-3500热模拟机模拟4种热输入下的热循环过程,采用光学显微镜观察了试验钢的焊接热影响区显微组织转变,用冲击试验机测试了焊接热影响区的冲击吸收能量,测量了不同冷却速度下的原始奥氏体晶粒尺寸的变化. 结果表明,焊接热输入值为25 kJ/cm时,HAZ组织主要为马氏体,晶粒尺寸细小,这时的冲击韧性和硬度值最高. 当焊接热输入值大于50 kJ/cm以上时,钢中生成了上贝氏体和粒状贝氏体,晶粒也逐渐长大,出现了韧性下降和软化. 试验钢的C含量为0.18%,在热循环中焊缝中出现了粗大的马氏体组织,形成淬硬组织,未生成针状铁素体组织.Abstract: The overall performance and service life of engineering equipment can be greatly improved for the heavy use of high-strength steel, but it does not change the fact that the weak performance area after welding is still the heat affected zone(HAZ). By the proper rare earth treatment technology, not only the rare earth inclusions with beneficial morphology, size and distribution can be formed in the steel, but also the growth of original austenite grain can be restrained during the welding process. It is actually for these reasons that the welding performance of the steel are boosted.In this study, a kind of 0.18% C high-strength steel with rare earth is produced. The thermal cycling processes under 4 kinds of heat input are simulated by the Gleeble-3500 thermal simulator. The microstructure transformation of HAZ is observed by the optical microscope. The impact absorption energy of HAZ is measured by the testing machine. The changes of original austenite grain size under different cooling rates are measured. The results show that when the welding heat input is 25 kJ/cm, the HAZ microstructure is mainly martensite with fine grain size, and then the impact toughness and hardness are the highest level. When the heat input is higher than 50 kJ/cm, the upper bainite and granular bainite are formed, and the grains grow up gradually, resulting in the decrease of both toughness and hardness. The C content of the test steel is 0.18%. During the thermal cycle the coarse martensite structure appears, forming the harden structure without the acicular ferrite structure.

-

Keywords:

- high strength steel /

- rare earth /

- welding heat affected zone /

- microstructure /

- properties

-

0. 序言

焊接生产智能化与自动化是焊接制造领域的技术发展趋势,实现自动焊接的前提是焊缝的自动识别.激光视觉传感技术是将激光投射在焊缝表面形成包含焊缝轮廓信息的焊缝条纹图像,然后进行特征提取,因其具有非接触、高精度等技术优势在焊缝识别领域得到了广泛应用[1].在自动焊接过程中,对焊缝坡口关键位置信息进行准确提取,可明显提升焊接质量[2-3].余佳杰等人[4]利用质心法提取焊缝中心线,通过最小二乘法和k均值聚类提取焊缝特征点,提高了焊缝识别的准确度;Li等人[5]构造焊缝轨迹特征三角形来提取形状特征,并基于欧几里德距离判别焊缝轨迹,提高了焊接效率与稳定性;Zhang等人[6]提出二阶导数算法对特征点进行初始定位,然后进行线性拟合实现精确定位,实现焊缝实时跟踪;Tian等人[7]通过使用自适应生成动态感兴趣区域(region of interest, ROI)并进行迭代操作,设置ROI内的边界条件后,有效提高该算法的焊缝识别精度.

焊接智能化要求焊缝识别算法具有较强的抗干扰能力和适应能力,以适用于不同场景下的焊接要求.传统的图像识别方法需要各种特征提取算法进行焊缝识别,其适应性和抗干扰能力较差,近年来,深度学习方法已在焊接领域得到了广泛应用[8],陈凯等人[9]基于深度学习的方法对焊缝识别定位,先对焊缝类型进行分类,再对焊缝图像进行分割以得到焊缝位置信息,该算法轻量高效并具有较高定位精度;杨国威等人[10]引入先验框定位焊缝特征点区域,并将焊缝的位置与置信度相结合,提取焊缝特征点,抑制了噪声干扰,保证了焊接精度,具有一定的适应性;唐溪等人[11]基于改进的CenterNet网络对焊缝进行定位,加入特征融合和注意力机制,提升了检测精度.深度学习方法不同于传统图像识别,省去了繁琐的特征提取,有效提高了焊缝识别的适应性.

文中采用深度学习方法,对焊缝特征识别技术展开分析,将焊缝特征点识别问题变成关键点检测问题.通过采集不同角度的焊缝图像,选取焊缝特征的关键点作为数据集,将标注好的焊缝数据输入特征提取网络模型中,经过一系列卷积、池化操作提取焊缝特征,进行上采样与深浅层特征融合,输出焊缝特征点热力图.热力图中响应值最大的位置为关键点,获取关键点坐标,并返回其位置.由于是从热力图中提取目标信息,不需要非极大值抑制(non-maximum suppression, NMS)进行筛选,减小了网络参数及计算量,提升了特征提取速度.通过对焊缝特征点的定位结果进行分析,满足自动焊接的定位精度和实时性要求.

1. 焊缝特征提取算法

传统的图像处理算法提取焊缝特征点时,面对不同类型的焊缝坡口图像,需要调整阈值,以便找到焊缝的特征点,因此该方法的泛化能力较差.深度学习[12]方法直接使用图像作为网络的输入,将特征表达融于网络的训练过程中,避免了传统识别算法中复杂繁琐的特征提取和数据重建过程,所以使用适应性强、抗干扰能力强的卷积神经网络进行焊缝特征提取,在不同类型的焊缝坡口图像中提取焊缝特征点也有利于提高焊接效率.

CenterNet,HRNet等关键点检测方法[13-15]广泛应用于2D和3D目标检测、人体姿态检测等领域,具有较高的检测速度与精度.受关键点检测方法的启发[16],并基于在焊接场景下能够准确定位焊缝的坡口位置,获取焊缝特征点位置信息,设计了简单高效的焊缝特征提取网络,如图1所示.

焊缝图像输入尺寸为

$W \times H \times D $ ,式中:$ W $ 为图像宽度;$ H $ 为图像高度;$ D $ 为图像深度.焊缝特征提取网络生成含有焊缝特征点位置的热力图,将热力图进行归一化,其值在0 ~ 1且和为1,操作如下

$$ {Z_{ij}} ={\rm{ Soft}}\max \left( {{{\textit{z}}_{i,j}}} \right) = \frac{{\exp ({{\textit{z}}_{i,j}})}}{{\displaystyle\sum\limits_{i = 1}^w {\displaystyle\sum\limits_{j = 1}^h {\exp ({{\textit{z}}_{i,j}})} } }} $$ (1) 式中:

${Z_{ij}} $ 表示(i, j)点的势力值;i = 1···n;j = 1···h;$\exp ({{\textit{z}}_{i,j}}) $ 为$e ({{\textit{z}}_{i,j}}) $ 生成两个与热力图尺寸一致的矩阵X和Y,具体计算为

$$ \left\{ {\begin{array}{*{20}{c}} {{X_{ij}} = \dfrac{{2j - \left( {w + 1} \right)}}{w}} \\ {{Y_{ij}} = \dfrac{{2i - \left( {h + 1} \right)}}{h}} \end{array}} \right. $$ (2) 从而得到热力图中焊缝特征点的位置坐标

$$ \left( {x,y} \right) = \left[ {{{\left\langle {Z,X} \right\rangle }_F},{{\left\langle {Z,Y} \right\rangle }_F}} \right] $$ (3) 式中:

$ {{\left\langle {Z,X} \right\rangle }_F} $ 表示矩阵Z与矩阵X进行F范数;$ {{\left\langle {Z,Y} \right\rangle }_F} $ 表示矩阵Z与矩阵Y进行F范数,关键点热力图的特征点坐标转换如图2所示.1.1 焊缝特征提取网络

焊缝特征提取网络如图3所示,下采样网络由4个卷积层和3个池化层组成.提取网络将输入焊缝图像进行下采样,每个卷积层含有多个卷积核特征提取器,用于提取输入图像的特征,卷积层提取丰富的焊缝特征信息.池化层对图像进行降维,降低网络模型的复杂度,防止过拟合,提高模型的泛化能力 [17].焊缝特征提取网络进行下采样时,通过卷积和池化操作对焊缝位置信息和边缘特征进行提取,产生了丰富的位置信息.图像经过多次卷积、池化操作,图像的边缘、位置信息会丢失很多,为了将输出的特征映射维度还原为原始图像维度,进行上采样操作.通过上采样恢复图像大小,提高输出图像的分辨率,恢复目标细节并使定位更准确.在网络的上采样过程中,采用的是最邻近上采样,这样可以最大程度保留特征图的语义信息,得到既有良好的空间信息又有较强烈的语义信息的特征图,有利于热力图中心回归预测.

1.2 特征融合

焊缝识别定位的检测需要准确的位置信息,进行下采样操作后会降低图像维度,为减少位置信息的损失,因此加入特征融合机制以提高焊缝定位精度.通过上采样与特征融合,提高输出图像的分辨率,恢复目标细节并使定位更准确.

通过特征融合减少卷积过程的信息损失,增强焊缝检测的鲁棒性,从而提高焊缝的定位精度.如图4所示,深浅层网络特征融合中,1 × 1卷积用于跨通道融合,上采样操作后,利用3 × 3卷积对其进一步融合,消除上采样带来的重叠效应,将相同尺寸但不同语义的特征相融合,最终采用最高分辨率特征图,采用低层与高层信息的特征融合,保留了焊缝像素之间的相对位置,有利于提高焊缝检测的精度与抗干扰性.

1.3 模型训练与数据集

文中采用京航科技公司的JHSM1400相机,采集坡口宽度10 mm,厚度5 mm的焊缝图像,通过采集不同角度和高度的焊缝图像,提高焊缝特征点的检测精度和鲁棒性,以满足焊缝特征点识别的任务需求,将采集到的焊缝数据集分为训练集1 000张,测试集100张.原始图像边缘存在多余的激光条纹,为降低网络模型训练所需的硬件资源与时间成本,将采集的图像尺寸调整为360像素 × 480像素.

为保证焊缝特征点的识别精度,对原始图像进行图像旋转和镜像操作,实现增大数据集的目的,防止因为样本数据较少而出现的欠拟合问题,并提高训练后的网络模型的泛化性能.多种坡口类型的焊缝图像进行处理后,得到3 000张训练集图像,300张测试集图像.

试验中所用的焊缝图像采集好后,对焊缝数据集中的焊缝图像进行标注,标注示意图如图5所示.通过标注在线结构光上的焊缝特征点,将焊缝特征点的位置信息储存在标签文件里,为减小人工标注的误差,多次标注焊缝图像,取多组焊缝数据的平均值作为特征点坐标.

试验使用的计算机配置为16G内存,CPU i5-12500H,GPU GeForce RTX2060,Pytorch 1.6.0.

网络的损失函数Lk选用SmoothL1损失函数

$$ {{{L}}_{{{\rm{k}}}}}(l,t) = \sum\limits_{i \in \left\{ {x,y} \right\}} {{\text{Smoo}}{\rm{t}}{{\rm{h}}_{{\rm{L1}}}}} \left( {{l_i} - {t_i}} \right) $$ (4) 式中:

$ l = \left( {{l_x},{l_y}} \right) $ 表示焊缝特征点的预测位置;$ t = \left( {{t_x},{t_y}} \right) $ 表示真实的焊缝位置信息$$ {\text{Smoo}}{\rm{t}}{{\rm{h}}_{{\rm{L1}}}}\left( x \right) = \left\{ {\begin{array}{*{20}{c}} {0.5{x^2}}, \\ {\left| x \right| - 0.5} , \end{array}} \right.\begin{array}{*{20}{c}} {{\rm{if}}\left| x \right| < 1} \\ {{\rm{otherwise}}} \end{array} $$ (5) 模型训练采用适应性矩估计Adam优化器,学习率设置为0.001,batch bize为4,迭代训练100轮.训练过程中,每30轮循环后更新学习率,学习率衰减为原来的0.1倍,在加载训练数据时,使用实时数据增强,以提高模型的泛化能力.

2. 试验结果与分析

为验证文中算法在焊缝图像特征点上的提取精度,将标注好的焊缝数据输入特征提取网络模型中,输出提取结果的关键点坐标,采用均方根误差(root mean square error, RMSE)来衡量焊缝图像特征点提取精度的评价指标. 图6为不同坡口类型焊缝图像中特征点的提取结果,图中圆圈中心点为SIFT算法提取的焊缝特征点,方框中心点为焊缝特征提取网络预测的焊缝特征点.焊接过程受到噪声干扰时,SIFT算法对提取到的焊缝特征点存在特征点误判情况,反应出了算法具有一定的抗干扰性.对于不同坡口类型的焊缝,所采用的方法均能较准确地检测到焊缝特征点,具有较强的普适性和泛化能力.

为了准确对比特征提取结果精度,将3种坡口类型的焊缝图像,分别做100组试验.将识别的焊缝特征点与人工标注的真实位置的误差进行计算,焊缝特征点的提取精度对比结果见表1.焊缝特征点定位误差曲线图如图7 ~ 图9所示,从试验结果可以看出,3种坡口类型的焊缝图像特征点的识别结果均方根误差为0.187 mm.

表 1 焊缝特征点提取精度对比Table 1. Comparison of weld feature points extraction accuracy算法 均方根误差σRMSE/mm V形 搭接 对接 均值 SIFT 0.258 0.247 0.254 0.253 Ours 0.201 0.173 0.188 0.187 焊缝特征点位置信息的准确提取决定了焊缝定位的精度,为保证定位精度,对焊缝特征点的平均定位误差以及误差分布情况进行评估,如图10所示,大部分焊缝特征点定位误差小于0.2 mm,焊缝特征点检测结果具有很高的精度,满足焊接的要求.

为保证焊接过程中的实时性要求,将各算法在焊缝数据集上的用时进行比较,算法用时见表2.从用时结果来看,文中算法用时32.145 6 ms,略少于SIFT算法用时,满足焊接的实时性要求.综上所述,本文算法用时少,同时提取的焊缝特征点的误差小,可以准确实现焊缝特征点的定位.

表 2 算法用时比较Table 2. Algorithm time comparison算法 时间t/ms V形 搭接 对接 均值 SIFT 40.518 2 39.470 5 40.993 0 40.327 2 Ours 31.626 1 32.907 1 31.903 6 32.145 6 3. 结论

(1)基于关键点检测方法进行焊缝识别,输出焊缝特征点热力图,从热力图中获得焊缝特征位置信息,可实现多坡口类型的焊缝定位.

(2)所提方法具有很高的精度,大部分焊缝特征点定位误差小于0.2mm,满足焊接的要求.

(3)算法用时32.145 6 ms,略少于SIFT算法用时,满足焊接的实时性要求.

-

表 1 焊接热循环试验工艺参数

Table 1 Thermal cycle test parameters for welding

热输入

E/(kJ·cm−1)最高加热温度Tmax/℃ 高温停留时间tH/s 冷却时间t8/5/s 25 1350 1 18 50 1350 1 74 75 1350 1 165 100 1350 1 295 -

[1] 李少峰, 马成勇, 宋志刚, 等. 800 MPa级高强钢焊接接头组织及力学性能[J]. 焊接学报, 2020, 41(5): 91 − 96. Li Shaofeng, Ma Chengyong, Song Zhigang, et al. Study on the welding joint microstructure and mechanical properties of 800 MPa grade high stress steel[J]. Transactions of the China Welding Institution, 2020, 41(5): 91 − 96.

[2] 张洪涛, 桑健, 王琪晨, 等. TATM700钢等离子-MIG复合焊接工艺[J]. 焊接学报, 2019, 40(12): 25 − 30. Zhang Hongtao, Sang Jian, Wang Qichen, et al. Research on plasma-MIG hybrid welding process of TATM700 steel[J]. Transactions of the China Welding Institution, 2019, 40(12): 25 − 30.

[3] Yang L, Jiang X H, Wang X H. Study on welding process performance of HG70D high strength steel plate[J]. China Welding, 2018, 27(3): 59 − 64.

[4] 张元杰, 彭云, 马成勇, 等. Q890 高强钢焊接淬硬倾向和冷裂纹敏感性[J]. 焊接学报, 2013, 34(6): 53 − 56. Zhang Yuanjie, Peng Yun, Ma Chengyong, et al. Harden quenching tendency and cold cracking susceptibility of Q890 steel during welding[J]. Transactions of the China Welding Institution, 2013, 34(6): 53 − 56.

[5] 苏小虎, 栗卓新, 李红, 等. 高强钢金属芯焊丝E120C-K4熔敷金属粗晶区显微组织对冲击韧性的影响[J]. 焊接学报, 2019, 40(10): 48 − 53. Su Xiaohu, Li Zhuoxin, Li Hong, et al. Microstructure to properties of coarse grained heat affected zone in deposited weld metal of metal cored wire E120C-K4 SU[J]. Transactions of the China Welding Institution, 2019, 40(10): 48 − 53.

[6] 张继魁, 辛莹, 张曼曼. 汽车大梁用低合金高强度钢板的性能与发展[J]. 汽车工艺与材料, 2004(6): 42 − 46. doi: 10.3969/j.issn.1003-8817.2004.06.008 Zhang Jikui, Xin Ying, Zhang Manman. Property and development of high strength low alloy hot rolled steel sheet for truck frame use[J]. Automobile Technology & Material, 2004(6): 42 − 46. doi: 10.3969/j.issn.1003-8817.2004.06.008

[7] 陆斌, 陈芙蓉, 智建国, 等. 应用稀土氧化物冶金技术改善高强钢焊接性能[J]. 金属学报, 2020, 56(9): 1206 − 1216. doi: 10.11900/0412.1961.2020.00052 Lu Bin, Chen Furong, Zhi Jianguo, et al. Enhanced welding properties of high strength steel via rare earth oxide metallurgy technology[J]. Acta Metallurgica Sinica, 2020, 56(9): 1206 − 1216. doi: 10.11900/0412.1961.2020.00052

[8] 安同邦, 田志凌, 单际国, 等. 保护气对 1 000 MPa 级熔敷金属组织及力学性能的影响[J]. 金属学报, 2015, 51(12): 1489 − 1499. doi: 10.11900/0412.1961.2015.00294 An Tongbang, Tian Zhiling, Shan Jiguo, et al. Effect of shielding gas on micrpstructure and performance of 1 000 MPa grade deposited metals[J]. Acta Metallurgica Sinica, 2015, 51(12): 1489 − 1499. doi: 10.11900/0412.1961.2015.00294

[9] 陆斌, 张军, 张文博, 等. 稀土耐磨钢绿色产品设计与研发[J]. 包钢科技, 2019, 45(6): 6 − 9, 17. doi: 10.3969/j.issn.1009-5438.2019.06.003 Lu Bin, Zhang Jun, Zhang Wenbo, et al. Design and research for green products of wear-resistant steel with rare earth[J]. Sci. and Tech. of Baotou steel, 2019, 45(6): 6 − 9, 17. doi: 10.3969/j.issn.1009-5438.2019.06.003

[10] 陈付红, 丁伟, 黄威, 等. 国外先进公司工程机械用高强钢发展现状[J]. 上海金属, 2015(1): 47 − 51. doi: 10.3969/j.issn.1001-7208.2015.01.011 Chen Fuhong, Ding Wei, Huang Wei, et al. Developmet status of foreign high strength steel for engineering machinery[J]. Shanghai Metal, 2015(1): 47 − 51. doi: 10.3969/j.issn.1001-7208.2015.01.011

[11] Lan L, Qiu C, Zhao D, et al. Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel[J]. Material Science & Engineering: A, 2011, 529(1): 192 − 200.

[12] 张文博, 樊立峰, 陆斌, 等. 稀土La在包钢CSP无取向电工钢 中的应用研究[J]. 包钢科技, 2019, 45(6): 85 − 90. doi: 10.3969/j.issn.1009-5438.2019.06.021 Zhang Wenbo, Fan Lifeng, Lu Bin, et al. Application research on rare earth La in CSP non-oriented electrical steel of Baotou steel[J]. Science and Technology of Baotou Steel, 2019, 45(6): 85 − 90. doi: 10.3969/j.issn.1009-5438.2019.06.021

[13] Kim S, Kang D, Kim T W, et al. Fatigue crack growth behavior of the simulated HAZ of 800 MPa grade high-performance steel[J]. Material Science & Engineering: A, 2011, 528(6): 2331 − 2338. doi: 10.1016/j.msea.2010.11.089

[14] Lambert-Perlade A, Gourgues A F, Pineau A. Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel[J]. Acta Mater, 2004, 52(8): 2337 − 2348. doi: 10.1016/j.actamat.2004.01.025

[15] Shome M, Gupta O P, Mohanty O N. Effect of simulate thermal cycles on the microstructure of the heat-affected zone in HSAL-80 and HSLA-100 steel plates[J]. Metallurgical and Materials Transactions A, 2004, 35(3): 985 − 996. doi: 10.1007/s11661-004-0025-8

[16] 王龙妹, 稀土在低合金及合金钢中的应用[M].北京: 冶金工业出版社, 2016. Wang Longmei.Applcation of rare earth in low alloy and alloy steel[M]. Beijing: Metallurgical Industry Press, 2016.

[17] 余圣甫, 杨可, 雷毅, 等. 大热输入焊接高强度低合金钢热影响 区的晶粒细化[J]. 焊接学报, 2008, 29(3): 17 − 19. doi: 10.3321/j.issn:0253-360X.2008.03.005 Yu Shengfu, Yang Ke, Lei Yi, et al. Grain refinement of heat affected zone of high strength low alloy steel by large heat input welding[J]. Transactions of the China Welding Institution, 2008, 29(3): 17 − 19. doi: 10.3321/j.issn:0253-360X.2008.03.005

-

期刊类型引用(5)

1. 金东升,曹文田,张英杰. 双目极线约束下的储罐环焊缝定位算法. 机械科学与技术. 2025(01): 1-8 .  百度学术

百度学术

2. 于强,肖澜,郑大伟,彭昭鸿,宋凯宏. 基于计算机视觉的锂电池连接片焊接检测系统. 焊接学报. 2024(10): 38-49 .  本站查看

本站查看

3. 李春凯,潘宇,石玗,王文楷,赵中博. 基于视觉传感的热丝激光金属沉积熔滴—熔池多特征信息同步监测. 焊接学报. 2024(11): 115-120 .  本站查看

本站查看

4. 乐健,李发园,束志恒,曾明如,张华. 基于视觉传感的焊接电流及电压检测控制方法. 焊接学报. 2024(11): 85-89 .  本站查看

本站查看

5. 贾瑞燕,李海超,魏方锴,徐勇,周宇飞. 基于三维点云的磁极焊缝识别及机器人轨迹生成技术. 焊接学报. 2024(11): 50-54 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: