Prediction on thin plate welding buckling of TIG bead welding

-

摘要: 针对TIG堆焊所引起的薄板复杂屈曲变形问题,采用基于热弹塑性理论的有限元法建立薄板焊接变形预测模型,提出了数字图像相关法对预测屈曲模型进行试验验证并设计了薄板焊接变形检测试验装置. 结果表明,基于数字图像相关技术的非接触变形检测方法能够全场动态获取堆焊屈曲变形数据,全面验证了焊接变形有限元预测模型,基于高斯热源模型、非线性瞬态热传导边界条件、材料高温性能参数等的热−力耦合热弹塑性预测模型具有较高的精度.薄板焊接变形冷却后呈马鞍形,结合动态温度场与应力场,对揭示焊接马鞍形屈曲变形机理具有重要的意义.Abstract: In view of the complex deformation of thin plate caused by TIG bead welding, a thermal-elasto-plastic finite element method was used to establish the prediction model of welding deformation. A non-contact detection method based on digital image correlation technology was proposed to verify the prediction model and a thin plate welding deformation test device was designed. The research shows that the non-contact deformation detection method based on digital image correlation technology can dynamically obtain welding deformation data in the whole field, and can fully verify the welding deformation finite element prediction model. The welding deformation prediction thermo-mechanical coupling model has high accuracy based on Gaussian heat source model, nonlinear transient heat conduction boundary conditions, and material high-temperature performance parameters. The welding deformation of thin plates is saddle-shaped after cooling. Combining the dynamic temperature field and stress field, it is great significance in revealing the mechanism of welding saddle-shaped buckling deformation.

-

Keywords:

- bead welding /

- thermal-elasto-plasticity /

- buckling /

- digital image correlation

-

0. 序 言

高效高精度的预测焊接变形是结构设计与矫正工艺的必要前提,焊接变形过程计算是一个复杂、多维、多参数的过程,有限元数值计算能处理焊接过程中的各种非线性问题,而且相对解析法具有更高的过程模拟精度,因此,广泛应用于焊接变形预测研究中.

近几年,科研工作者采用热弹塑性有限元法对薄板焊接变形状态、变形演化规律、变形影响因素等做了深入研究. Deng等人[1-2]采用热–冶金–力三者耦合的三维有限元法研究了在低碳钢和中碳钢中固态相变对焊接残余应力和变形的影响,研究表明固相相变几乎不影响低碳钢的残余应力和变形,可以忽略相变对其影响以使模型简单化并减少计算时间. Fu等人[3]采用与温度相关性质材料的热–力耦合有限元模型研究焊接顺序对T形接头残余应力和变形的影响,研究表明焊接顺序对残余应力和变形的分布和数值均具有较大的影响,双向分段焊接工艺能够产生相对较小的面外变形和残余应力. Tchoumi等人[4]采用3D热弹塑性有限元方法分析了316L钢在TIG焊接及冷却过程中的热力行为,采用了曲面相应法对高斯热源参数进行优化设计,提高了模拟预测模型精度,研究表明焊接速度与热输入直接相关,焊接面外变形形状在很大程度上依赖于薄板宽厚比. Guo等人[5]采用基于热弹塑性理论的有限元法揭示了薄板在不同约束条件下的激光焊接变形规律,研究表明,约束点距离对横向塑性应变数值、残余应力的分布与数值均具有较大的影响,随着约束点距离的增大,横向残余拉应力峰值、角变形量都增大. Tchoumi等人[4]采用了曲面相应法对高斯热源参数进行优化设计提高了模拟预测模型精度,研究了两种焊接速度对焊接变形的影响,研究表明焊接速度与热输入直接相关,焊接面外变形形状在很大程度上依赖于薄板宽厚比. Fu等人[3]采用Faro-Arm测量仪在焊接前后获取关键点的变形位移以计算焊接面内面外变形量,试验结果验证了模拟模型的正确性,研究表明焊接顺序对残余应力和变形的分布和数值均具有较大的影响,双向分段焊接工艺能够产生相对较小的面外变形和残余应力. Ma等人[6]采用基于热弹塑性有限元法量化研究了夹具约束对焊接变形的影响,模拟结果与三坐标测量试验结果有较好的一致性,研究表明,夹具约束使焊接角变形明显减小,而对收缩应力和横向收缩变形影响较小. 叶延洪等人[7]采用热弹塑性有限元法模拟焊接过程中的热–力学耦合行为,当焊接热输入相对较小时,整个薄板形成凹–凸变形;热输入较大时,角变形很小,薄板厚度方向的不均匀纵向收缩力在纵向产生下凹变形,横向产生上凸,最终形成凸–凹面外变形. 肖顺湖[8]建立了一种薄板焊接变形的有限元模型,并采用三种热源模型进行计算焊接温度场,结果表明生死单元模型精度较高.

热弹塑性有限元预测法具有模拟各种试验方案、减少试验时间和经费、在生产制造前预先发现潜在的问题等优势,在焊接等制造领域中具有重要的作用. 但是,受目前检测方法的限制,其焊接过程的精度的试验验证仍然具有局部性,因此,高精度的薄板焊接预测是目前亟待解决的问题. 提出基于数字图像相关技术的非接触检测方法可以全场动态对焊接屈曲变形进行实时检测,全面修正并验证预测模型.

1. 试验方法

1.1 模型建立方案

薄板材料Q235,尺寸300 mm × 200 mm × 3 mm,焊接方式为TIG堆焊,焊接电流150 A,电弧电压17.5 V,速度5 mm/s,钨极直径3.2 mm. 焊接及其冷却过程的变形分析主要涉及热力耦合问题,采用基于热弹塑性理论的有限元法预测整个分析过程的,预测模型方案如图1所示.

进行热分析获得与实际相符的焊接温度场分布,需要建立几何模型、定义单元类型、材料属性等,划分网格时要考虑到结构分析的要求,在应力集中的地方即焊缝处要划分较细的网格;然后施加边界条件并确定载荷步,进行温度场分析;温度场计算结果如果符合实际温度分布,则继续进行应力分析,如果不符合,则重新修改载荷步、材料性能参数等. 计算应力应变场时,需要重新进入前处理器,将热单元转化为相应的结构单元,设置材料属性、读入节点温度,设置参考温度、进行求解;然后,定义边界条件和施加载荷,在实际的焊接过程中,大多是放置在工作台、支撑架、夹具或地面上进行的,在焊接模拟过程中也要考虑支撑架和夹具的约束作用;最后,求得的温度历程作为热载荷加载到薄板结构中进行应力场分析计算,施加载荷时,读入与温度场的节点温度相应的载荷步,即可得到各个载荷步下的应力场分布情况.

1.2 热源模型的建立

在对焊接温度场的计算过程中,焊接热源模型的选择非常重要,因为它会影响到焊接温度场、应力场以及变形场整个计算过程的精确度. TIG焊接时,电弧热源把热能作用于一定面积的金属上,在薄板表面电弧笼罩的区域内,热流密度的分布可以用高斯正态分布函数来描述,对焊接温度场进行薄板堆焊数值模拟时,将高斯热源作为加热热源模型. 根据加热中心距离为r处点A的热流密度可用以下函数表达式来描述

$$ q(r) = {q_m}\exp\left( - \frac{{3{r^2}}}{{{R^2}}}\right) $$ (1) $$ {q_m} = \frac{3}{{P{R^2}}} Q_{{\rm {net}}} $$ (2) $$ Q_{{\rm {net}}} = \eta UI $$ (3) 式中:qm为热源中心最大热流密度(J/m2·s);R为电弧有效加热半径(mm);Qnet为净热输入(J/mm);η为焊接热效率;U为电弧电压(V);I为焊接电流(A).

采用的模型中焊缝方向为x方向,故焊接过程中电弧加热中心O的坐标为(

$v*TIME $ ,0,0),v为焊接速度,TIME为焊接时间. 即由平面内两点间距离公式可知$$ {r^2} = {(x - v*TIME)^2} + {\left( {y - 0} \right)^2} + {(z - 0)^2} $$ (4) 高斯热源是通过施加函数型载荷实现的,最终定义的热源函数为

$$ q\left( r \right) = {q_m}* \exp \left(\frac{{ - 3({{(x - v*TIME)}^2} + \left( {y - 0{)^2}} \right)}}{{{R^2}}}\right) $$ (5) 将高斯热源作为载荷施加至焊缝单元,在实际计算中,随着时间的变化热源实现匀速移动.

1.3 温度场与应力场预测

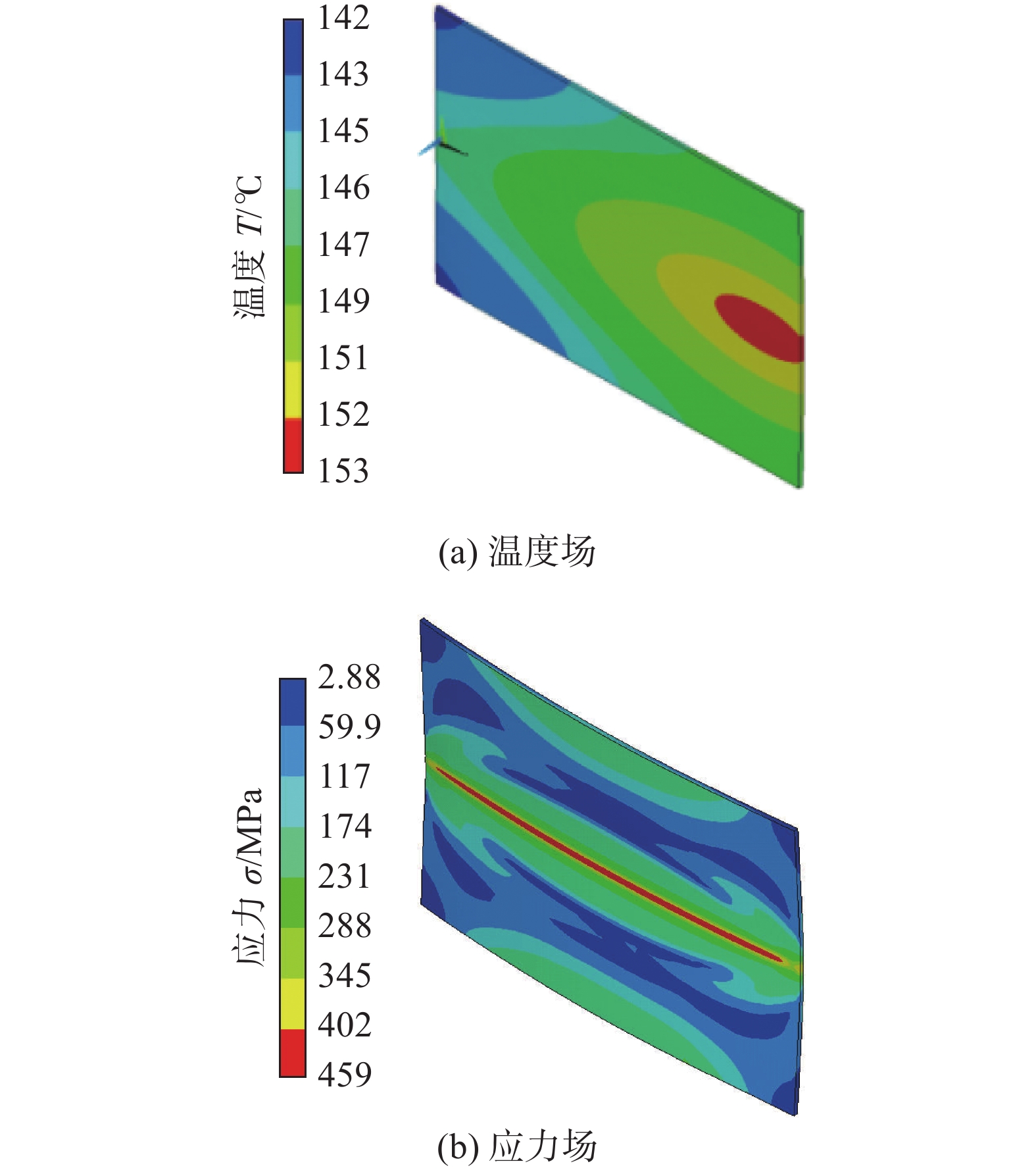

随着焊接热源的移动,整个焊件特别是焊缝区的温度随时间急剧变化,温度场梯度较大. 由于材料的热物理机械性能随温度剧烈变化,相变潜热对温度场具有一定的影响,但对于所采用的低碳钢材料,焊接区组织的转变对焊接应力场的影响较小而忽略不计. 因此,焊接温度场分析属于典型的非线性瞬态热传导问题. 另外,热辐射产生的热量相对较小,有限元模拟时也忽略热辐射对预测模型的影响. 计算应力场及变形场时,考虑到变形检测试验中薄板放置于焊台上四周均无约束,因此在薄板网格模型上依次对四个点采用x,y,z方向位移约束,x,y方向位移约束,z方向位移约束以及无约束. 冷却结束后薄板的温度场和应力场如图2所示. 从温度场分布可以看出,热源传热结束,由于薄板与周围空气之间的传热占了主导地位,薄板不断向周围空气散热,传热能力下降的同时温度场阶梯趋于均匀. 从应力场中可以看出,薄板冷却后整个焊缝都发生收缩现象,由于焊缝区和热影响区在焊接过程中产生较大的温度梯度,塑性变形也较大,因此冷却后残余应力也较大. 另外,材料Q235的屈服应力是单轴拉伸下的检测值,而焊接计算时采用的屈服应力模型是三轴应力,其真实屈服应力应大于235 MPa,因此,对于有限元模拟的焊接残余应力值会大于传统检测的屈服应力值.

2. 试验结果与分析

2.1 检测方案

采用基于数字图像相关技术的非接触检测装置对薄板进行TIG堆焊屈曲变形检测,通过对焊接冷却后的全场静态与焊接过程中的单点动态比对验证预测模型精度. 为了更加真实模拟焊接工况下的薄板变形,采用基于正弦条纹投影的三维结构光面扫描技术对焊接薄板实际轮廓数据进行精确获取,将带有初始变形的薄板模型导入有限元分析软件中进行屈曲变形预测.

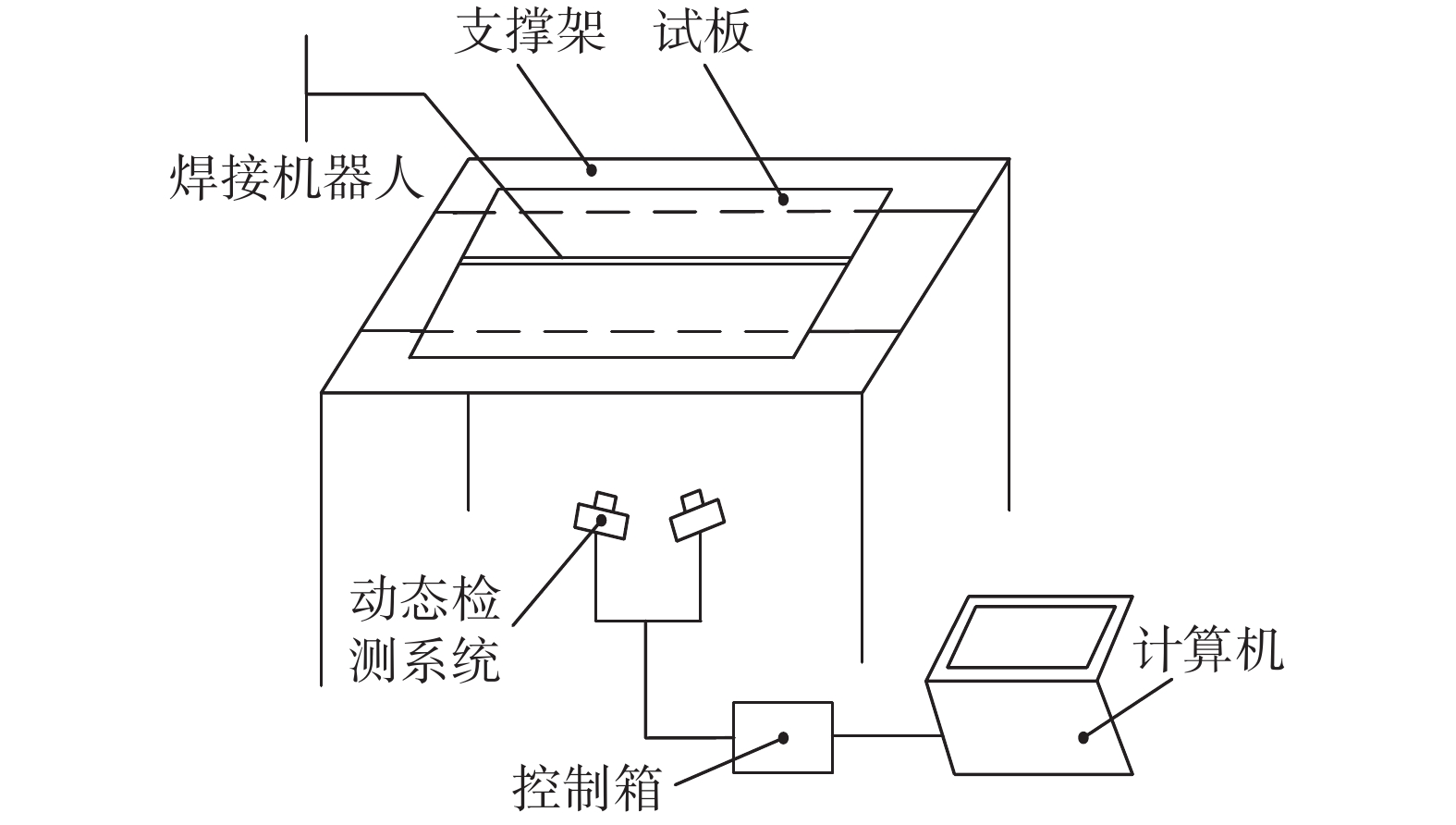

对于薄板焊接变形全场动态数据的获取,变形检测试验装置示意图如图3所示,焊接薄板检测面喷涂高温散斑(高温散斑用高温漆制成,先喷涂一层白色,待晾干后喷涂黑色小斑点,可采用漏板模式喷涂),平放在焊台支撑架上,由于焊接时会产生强光烟雾等,而且实验板比较薄,因此变形检测系统与焊接机器人分置于薄板两侧,采用薄板上端焊接,下端检测的试验方案,两个检测相机正对于薄板已喷涂散斑的面,用于实时记录散斑变形状态,待相机标定与焊接机器人路径程序设定后,焊接与检测同时进行作业. 焊接验证试验参数与模拟预测参数一致,测量装置动态采集速率为2帧/秒,相机型号Aca1600-20 gm、分辨率1 626 pix × 1 236 pix,像素大小为4.4 μm × 4.4 μm,幅面为400 mm × 300 mm,设置面格大小为30 pix × 30 pix,步长为15 pix × 15 pix,焊接时间为60 s,冷却时间为360 s.

2.2 验证结果分析

图4为试验实际焊缝区形貌和有限元预测的对比,从图中可以看出,熔池中心温度远高于1 500 ℃(材料熔点温度),将1 500 ℃以上温度视为融化区域,有限元预测温度轮廓与实际焊缝形貌较为接近.

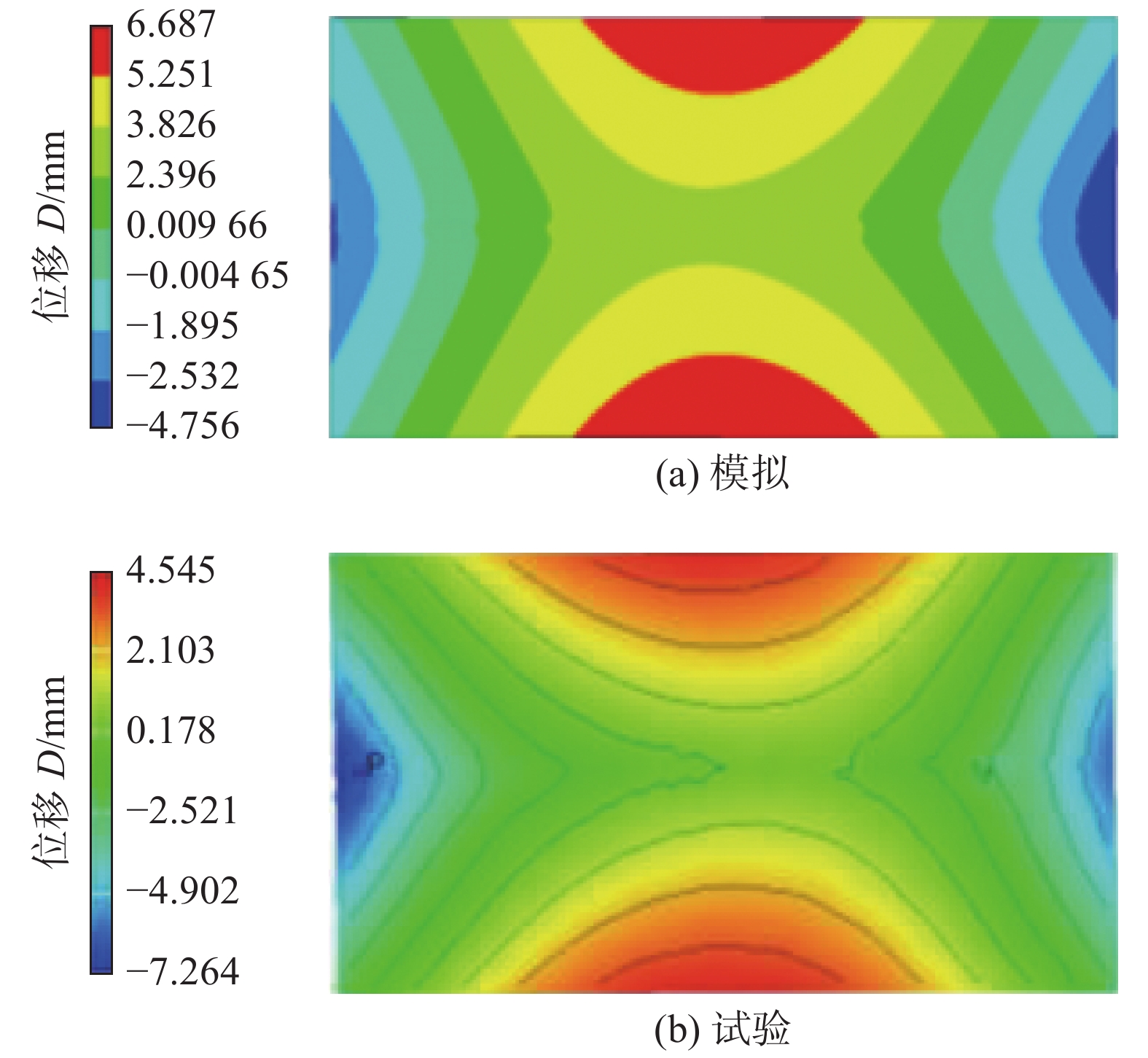

焊接冷却完成后,有限元模拟与试验检测的薄板面外全场变形如5所示,由于试验中焊台遮挡薄板宽度边缘18 mm,为有效对比全场静态结果,模拟变形截取与试验检测相同的区域. 从图中可以看出,预测和试验结果表明薄板焊接冷却后都发生了马鞍形屈曲变形,其面外变形总位移分别为11.443 mm和11.809 mm. 对于模拟与试验结果中最大值/最小值相差较大,是由于试验时的焊台支撑约束与模拟中的三点约束是不完全相同的,因此,从静态全场面外变形的分布和总变形值表明有限元预测的精度比较高.

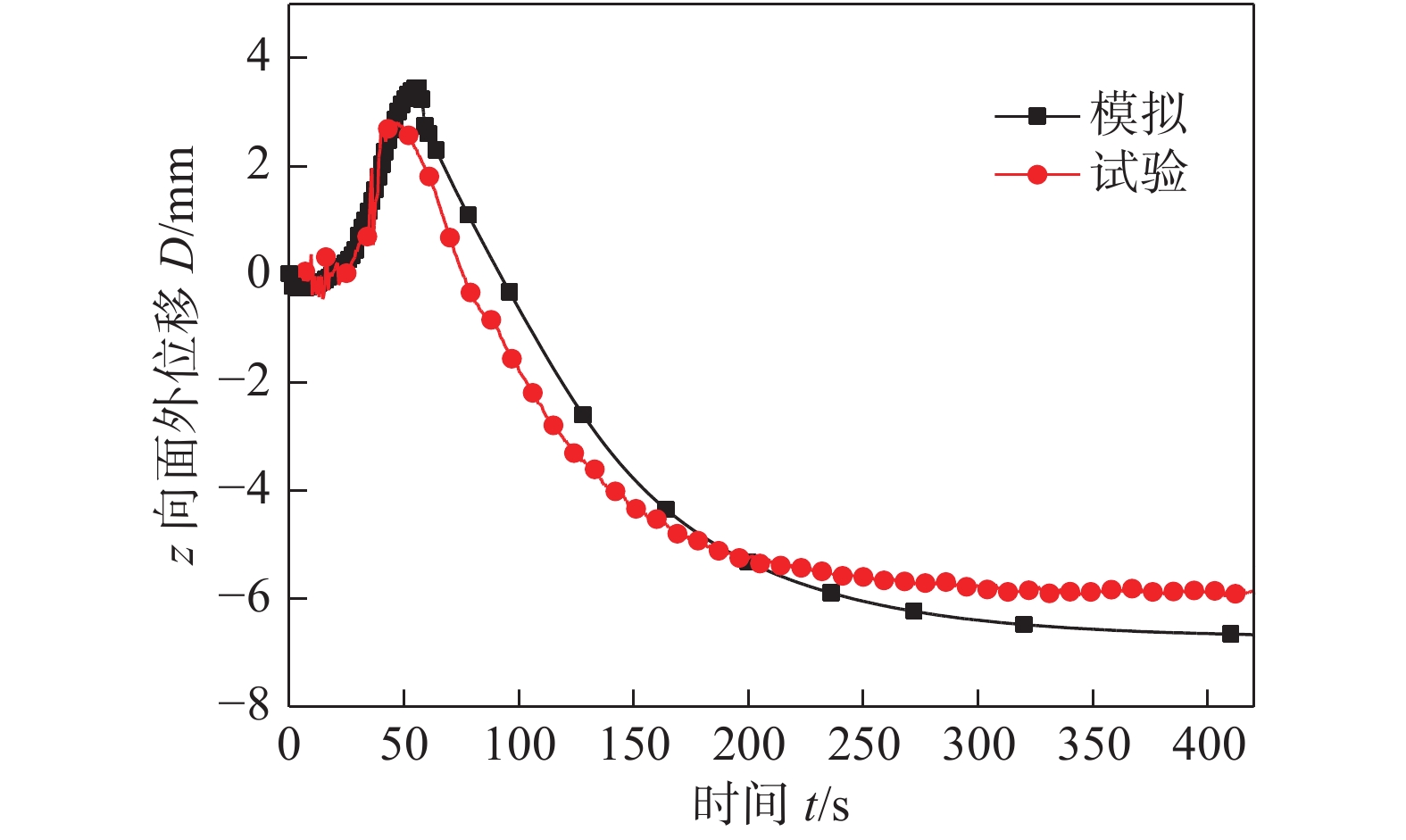

对于模拟预测模型的验证,除了全场变形的验证,还需要对关键点的动态变形精度进行验证,由于模拟与试验的薄板约束条件不能保证完全一致,关键点P如图5b所示,其z向面外动态位移取与薄板中心点的差值. 预测与试验的关键点动态面外变形比较如6所示,在整个焊接与冷却过程中,由于P点在薄板焊缝偏焊接起始端的位置,因此,在前60 s热源在薄板上时,位移均经历先正向迅速增大,热源撤出后薄板迅速冷却,开始经历收缩阶段,因此曲线快速下降,越过基准零位移位置后继续向负向增大,冷却逐渐变缓,位移曲线也下降缓慢直到稳定,预测动态变形曲线真实表现了薄板焊接屈曲变形过程. 模拟值与试验值比较吻合,预测焊接变形模型具有较高的精度,可以用来对焊接变形规律及机理的研究,对焊接结构的设计制造重要的意义.

3. 结 论

(1)基于数字图像相关技术的非接触变形检测方法能够全场动态获取焊接变形数据,能够全面验证焊接变形有限元预测模型.

(2)基于高斯热源模型、非线性瞬态热传导边界条件、材料高温性能参数等的焊接变形预测热力耦合模型具有较高的精度.

(3)薄板焊接变形冷却后呈马鞍形,结合有限元预测获得的动态温度场与应力场,可以揭示焊接马鞍形屈曲变形机理.

-

-

[1] Deng D. FEM prediction of welding residual stress and distortion in carbon steel considering phase transformation effects[J]. Materials and Design, 2009, 30: 359 − 366. doi: 10.1016/j.matdes.2008.04.052

[2] 孙加民, 朱家勇, 夏林印, 等. 电渣焊接头焊接残余应力与变形的数值模拟[J]. 焊接学报, 2016, 37(5): 23 − 27. Sun Jiamin, Zhu Jiayong, Xia Linyin, et al. Numerical simulation of welding residual stress and deformation induced by electro slag welding[J]. Transactions of the China Welding Institution, 2016, 37(5): 23 − 27.

[3] Fu G, Lourenco M, Duan M, et al. Influence of the welding sequence on residual stress and distortion of fillet welded structures[J]. Marine Structures, 2016, 46: 30 − 55. doi: 10.1016/j.marstruc.2015.12.001

[4] Tchoumi T, Peyraut F, Bolot R. Influence of the welding speed on the distortion of thin stainless steel plate-Numerical and experimental investigation in the framework of the food industry machines[J]. Journal of Materials Processing Technology, 2016, 229: 216 − 229. doi: 10.1016/j.jmatprotec.2015.07.021

[5] Guo Y, Wu D, Ma G, et al. Numerical simulation and experimental investigation of residual stress and distortions in pulsed laser welding of hastelloy C-276 thin sheets[J]. Rare Metal Materials and Engineering, 2014, 43(11): 2663 − 2668. doi: 10.1016/S1875-5372(15)60022-4

[6] Ma N, Huang H, Murakawa H. Effect of jig constraint position and pitch on welding deformation[J]. Journal of Materials Processing Technology, 2015, 221: 154 − 162. doi: 10.1016/j.jmatprotec.2015.02.022

[7] 叶延洪, 何 静, 蔡建鹏, 等. 6061-T651铝合金薄板接头的焊接变形[J]. 中国有色金属学报, 2014, 24(10): 2435 − 2442. Ye Yanhong, He Jing, Cai Jianpeng, et al. Welding deformations of 6061-T651 Al alloy thin-plate joints[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2435 − 2442.

[8] 肖顺湖. 薄板焊接过程数值模拟与试验研究[D]. 广西: 广西大学, 2005. -

期刊类型引用(3)

1. 刘健欣. 体操器械支撑座感知判断的变形预测研究. 机械设计与制造. 2022(05): 119-122 .  百度学术

百度学术

2. 郭文举,郭楠,马喜强,杨芳. 热输入与薄板材TIG焊接面内外变形关系研究. 安徽工程大学学报. 2022(06): 25-30+50 .  百度学术

百度学术

3. 范成磊,陈超,林三宝,杨春利,狄忠举. TIG焊接参数对全息干涉条纹的影响. 焊接学报. 2020(02): 1-5+97 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: