Progress on the control of intermetallic compounds in aluminum/steel friction stir welding

-

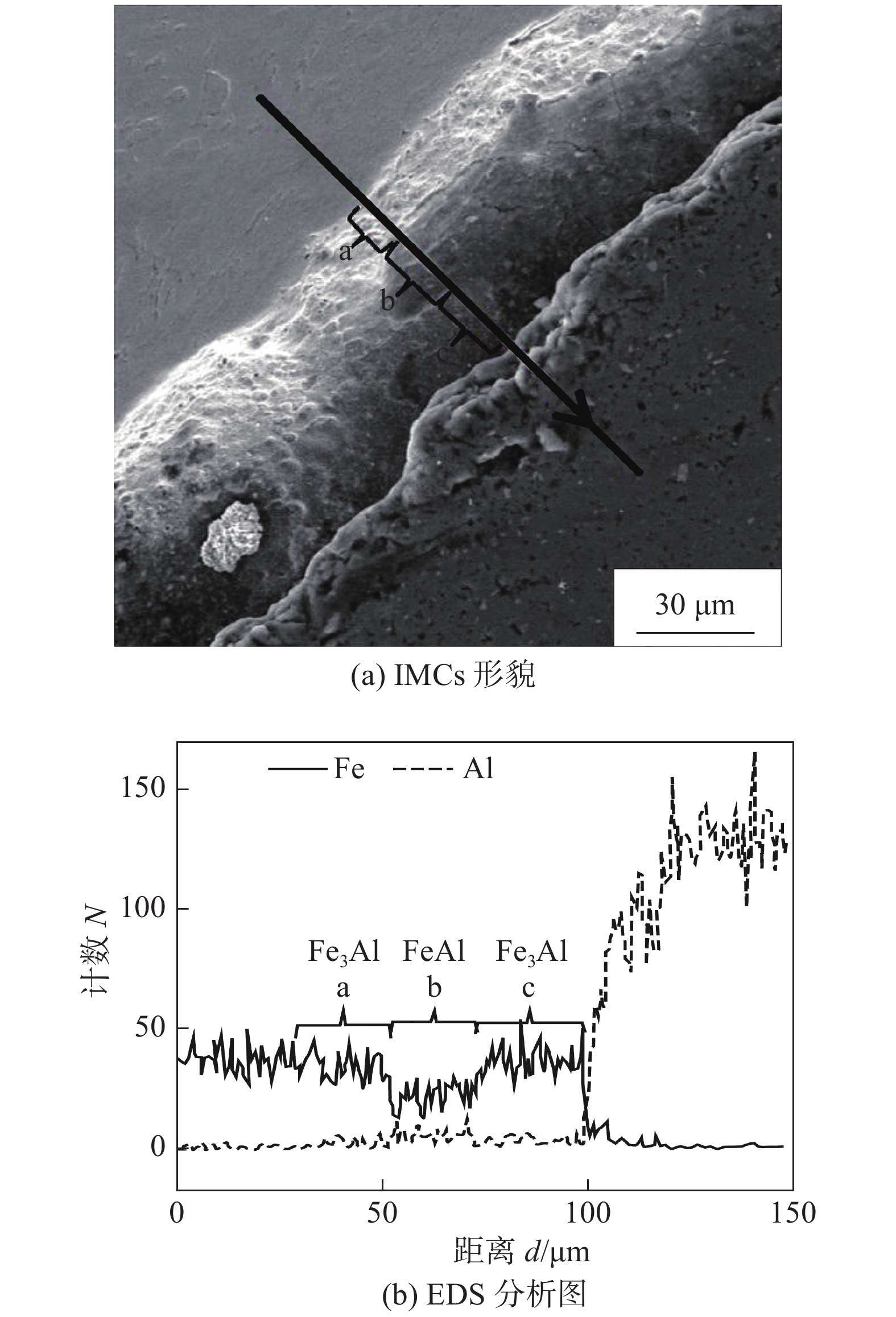

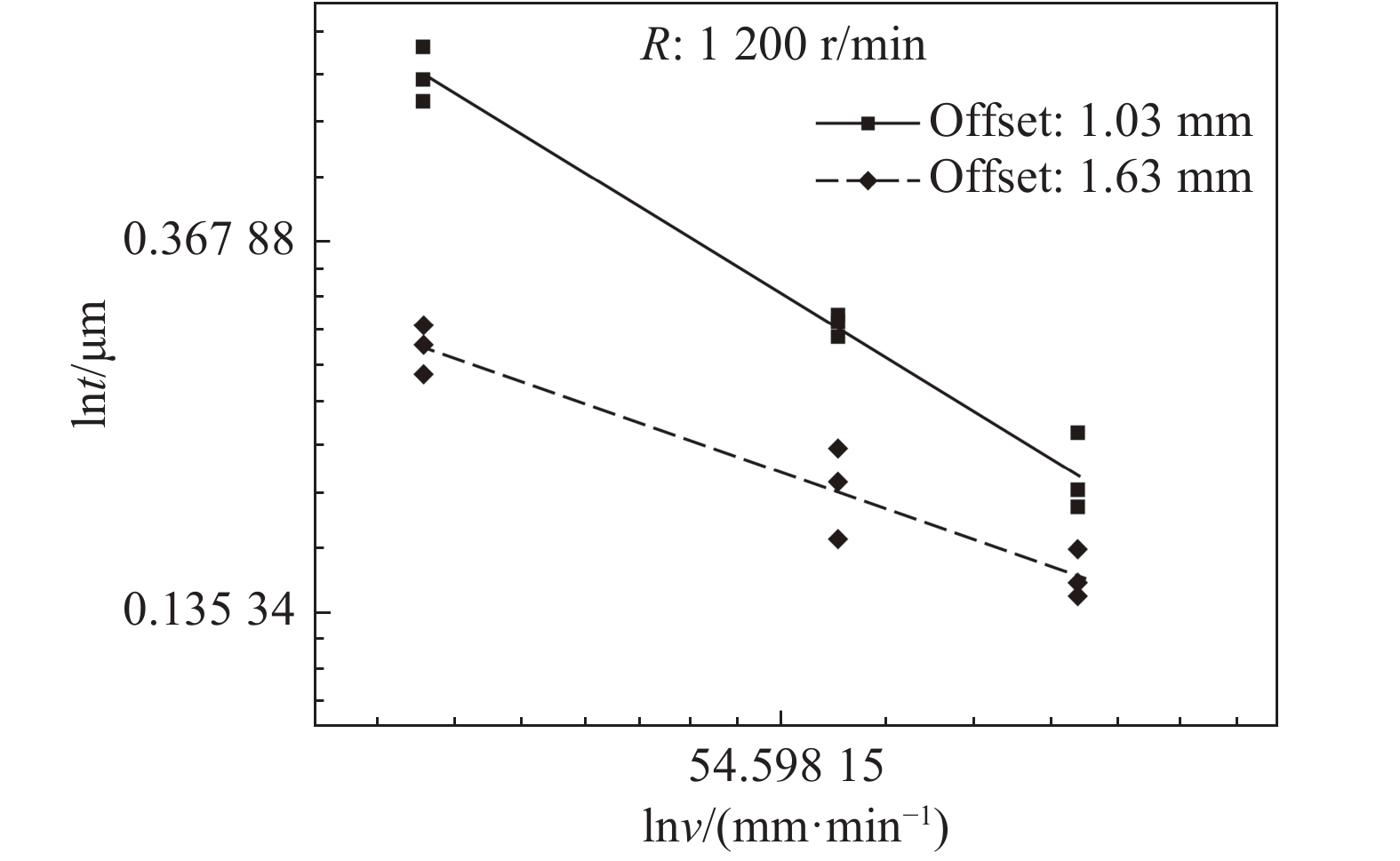

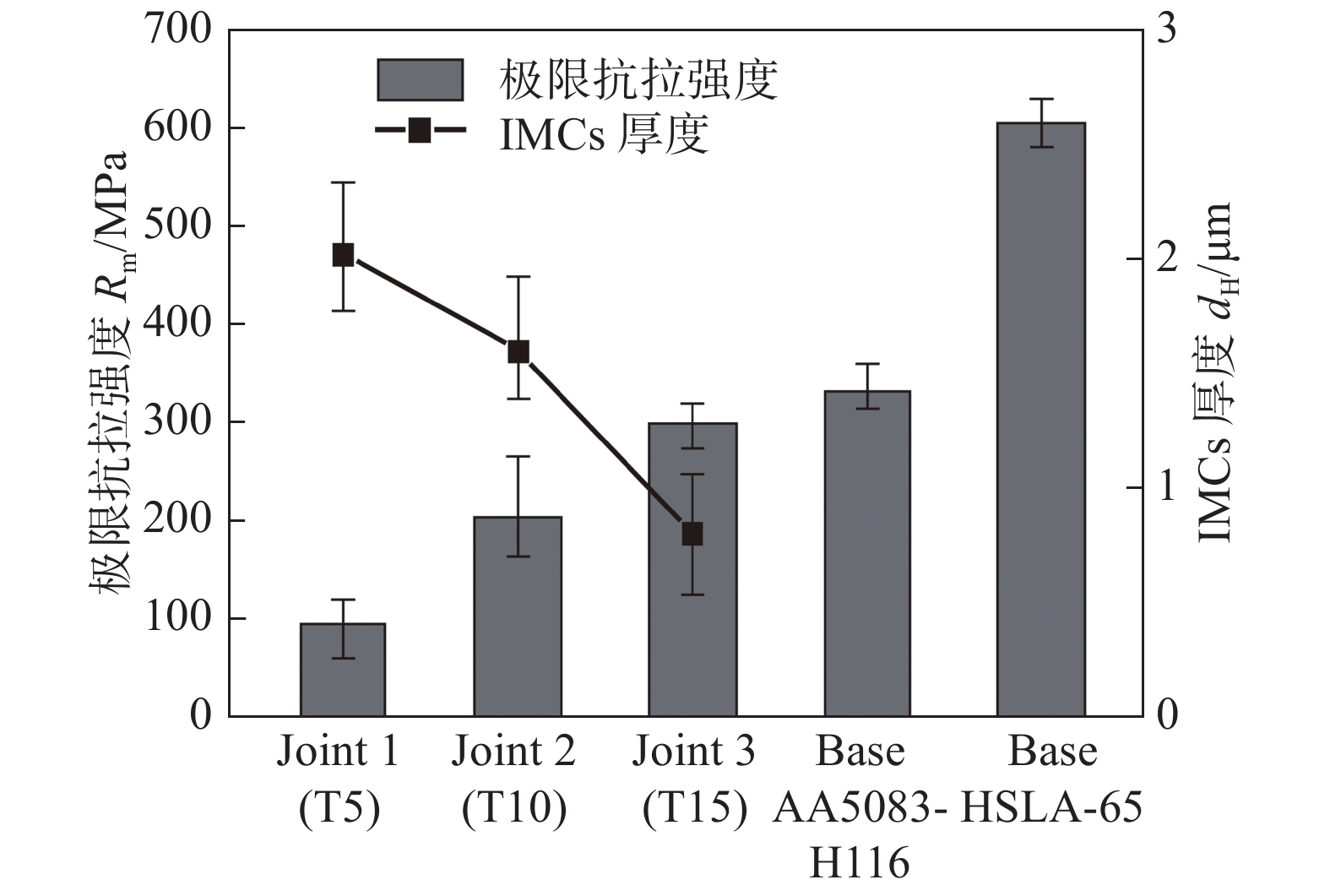

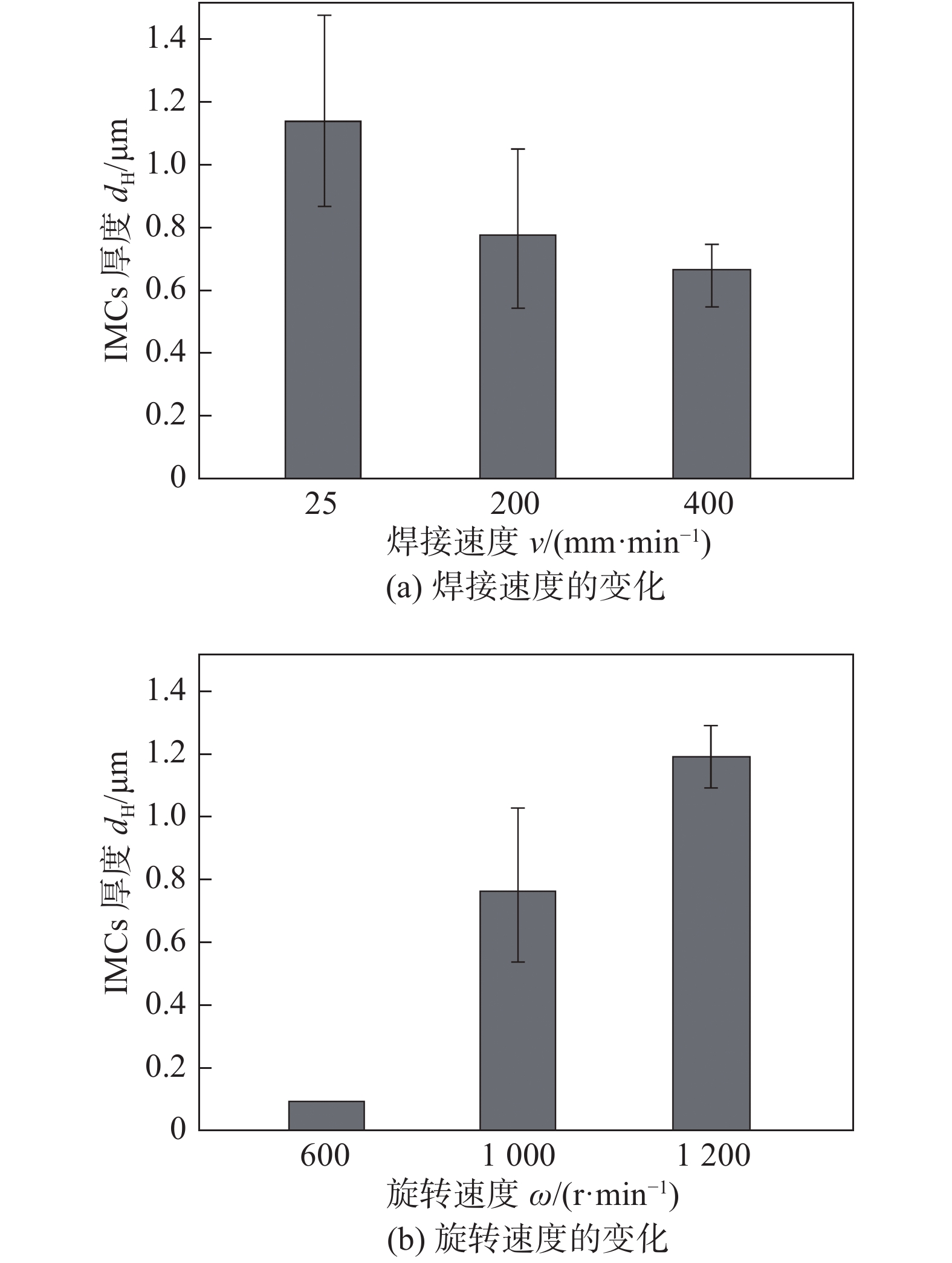

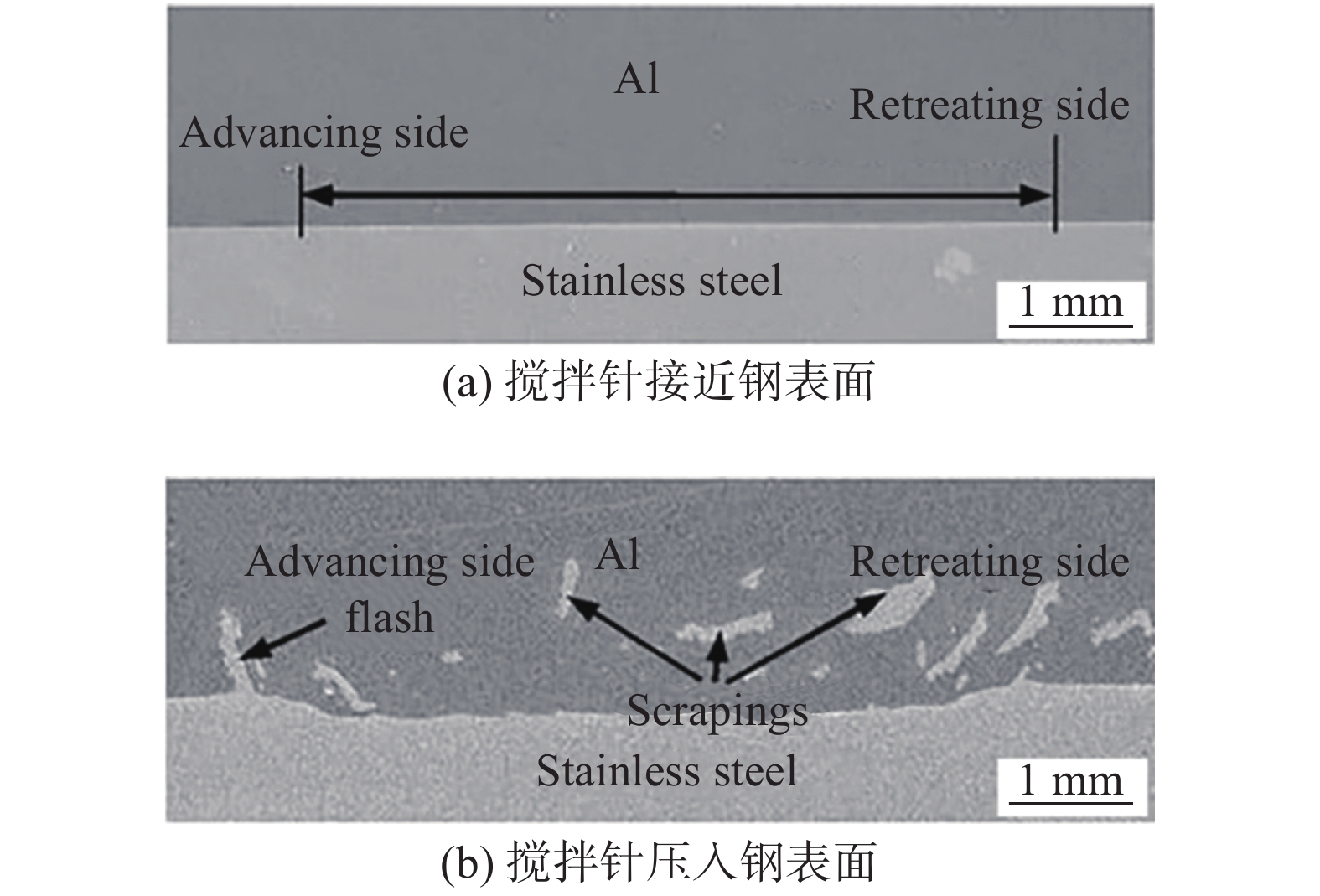

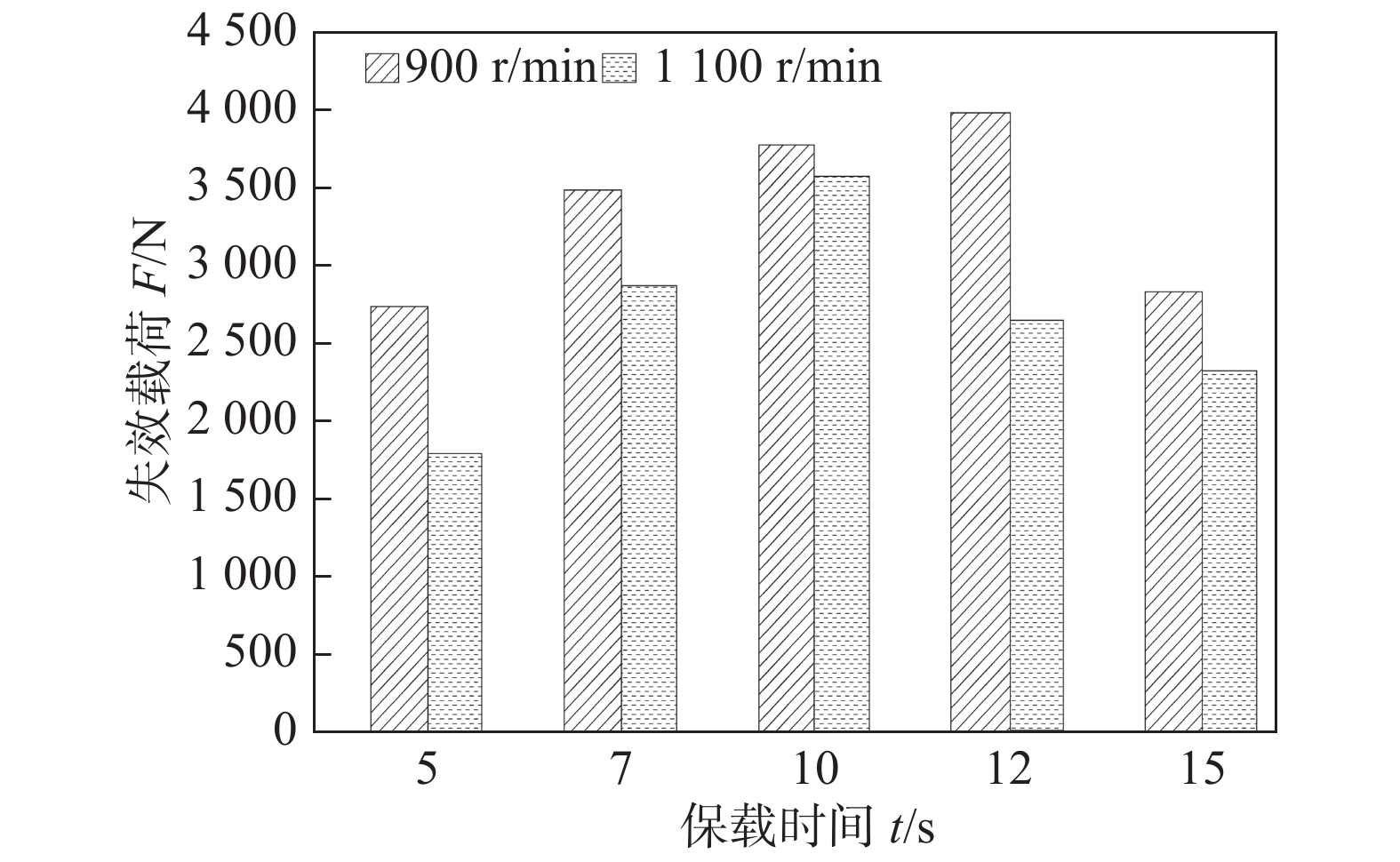

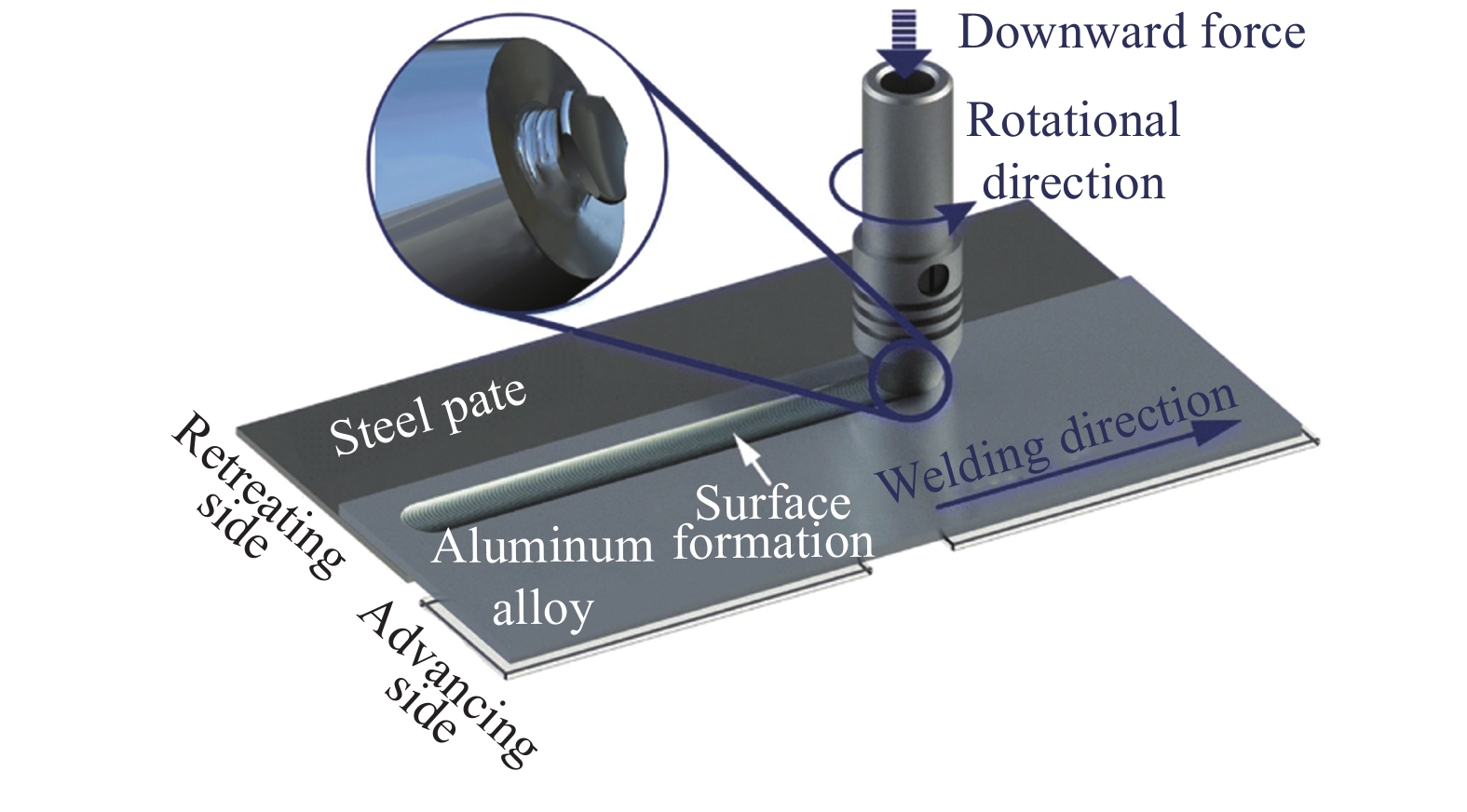

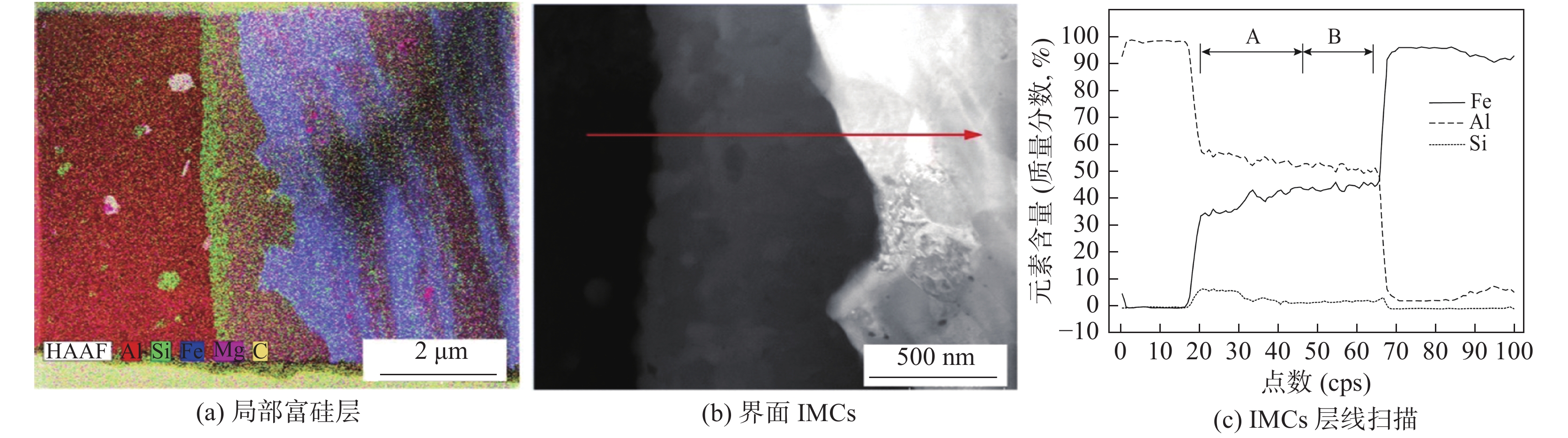

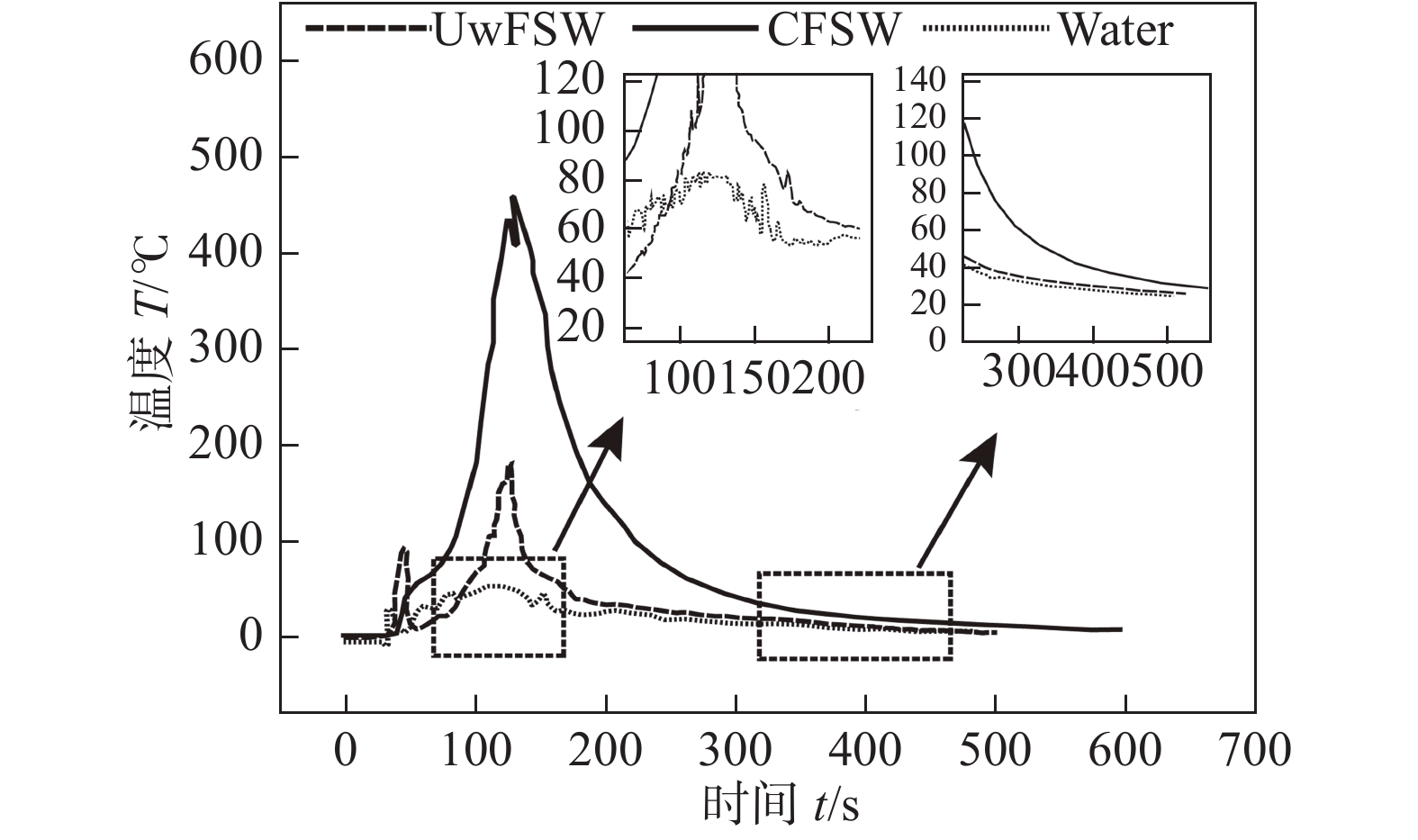

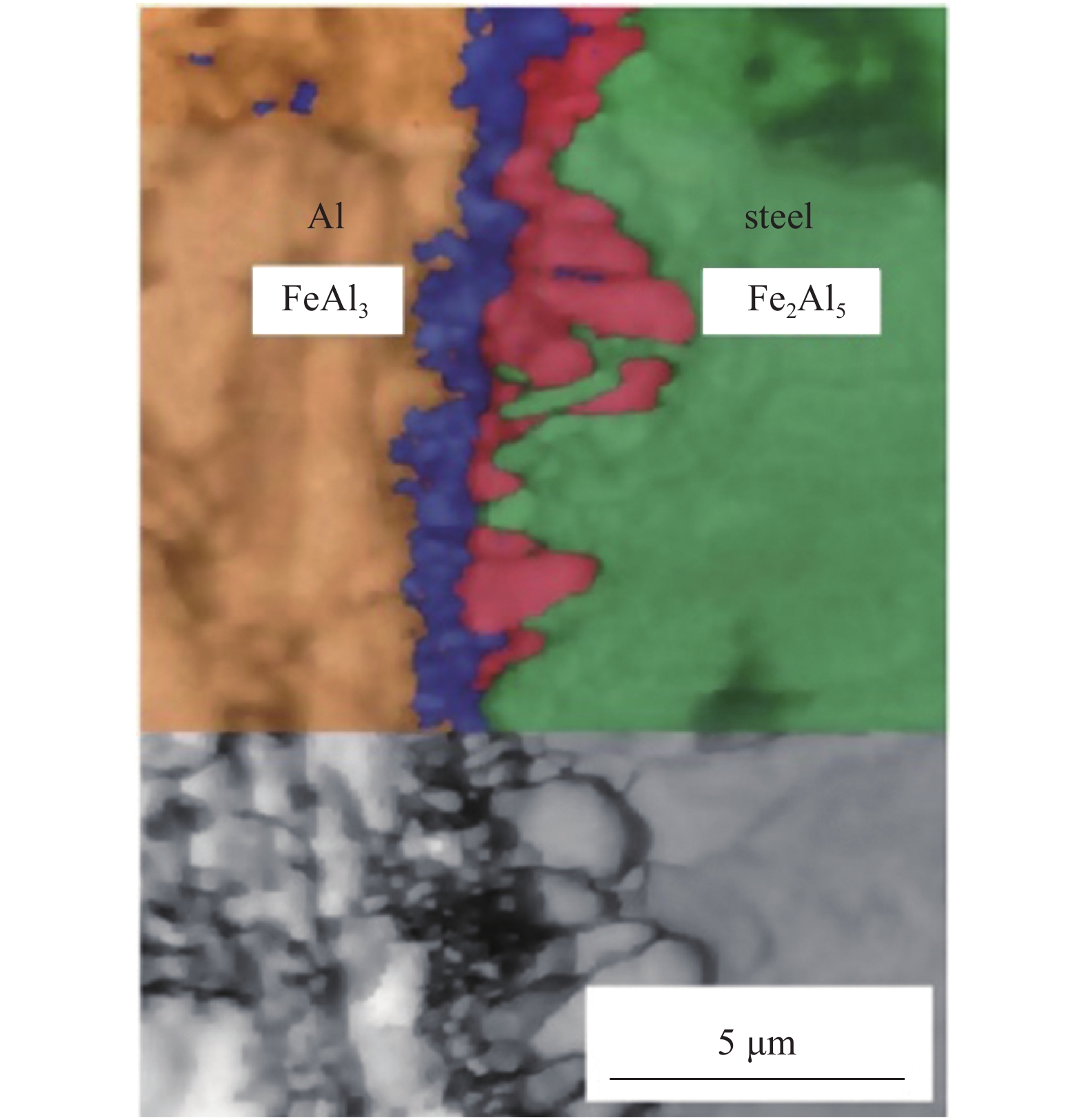

摘要: 铝/钢异种金属的可靠连接是汽车行业实现轻质节能设计的重要途径. 铝和钢的热物理性能和化学性能差异大,采用固相焊方法连接较为适宜. 搅拌摩擦焊(friction stir welding, FSW)具有热输入低、高温停留时间短和焊接变形小等特点,在连接铝/钢异种金属上具有较大的优势和潜力. 铝/钢异种金属FSW高质量的核心技术之一为界面金属间化合物的调控. 基于铝/钢FSW固相连接机制,文中从焊接参数(焊接速度、焊具转速、偏移量、倾斜角和下压量)、焊具结构(搅拌针形貌、螺纹及锥角)和中间层(铝和锌等)设计等方面对界面金属间化合物调控的研究现状进行了综述,并围绕接头承载能力的提升总结了铝/钢FSW新技术(匙孔填充、自铆接及外源辅助FSW),并进一步展望了铝/钢FSW的发展趋势.Abstract: The reliable joining of aluminum/steel dissimilar metals is an important way to realize lightweight and energy-saving design in the automobile industry. Solid-state welding for dissimilar aluminum/steel was more applicable due to their great differences in thermal physical and chemical properties. Friction stir welding (FSW) has great advantages and potentials in joining aluminum/steel dissimilar metals because of its low heat input, short holding time at elevated temperature and low welding distortion. One of the core technologies for high-quality aluminum/steel dissimilar FSW joints could be attributed to the control of intermetallic compounds. Based on the solid-state joining mechanism of aluminum/steel during FSW, the current progress on the regulation of interfacial intermetallic compounds was reviewed from the aspects of welding parameters (including welding speed, rotational velocity, tool offset, tilting angle and plunging depth), tool structures (pin profile, thread and taper angle) and interlayer design (Al and Zn, etc.). Based on the enhancement of joint bearing capacity, new techniques about the FSW of aluminum/steel were summarized, such as keyhole refilling, self-riveting and external assisted FSW. Furthermore, the development trends on FSW of aluminum/steel were prospected.

-

-

-

[1] Meng Xiangchen, Huang Yongxian, Cao Jian, et al. Recent progress on control strategies for inherent issues in friction stir welding[J]. Progress in Materials Science, 2020, 115: 100706.

[2] 万龙. 铝/钢搅拌摩擦搭接强流变作用下界面行为及力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2015. Wan Long. Influence of severe plastic deformation on interfacial behavior and mechanical properties of Al/steel friction stir lap joint[D]. Harbin:Harbin Institute of Technology, 2015.

[3] Coelho R S, Kostka A, Sheikhi S, et al. Microstructure and mechanical properties of an AA6181-T4 aluminium alloy to HC340LA high strength steel friction stir overlap weld[J]. Advanced Engineering Materials, 2008, 10(10): 961 − 972. doi: 10.1002/adem.200800028

[4] Massalski T B. Binary alloy phase diagrams[M]. New York: ASM International, 1990.

[5] 李国伟, 王楠楠, 邱然锋, 等. 铝合金/不锈钢电阻点焊工艺与接头性能研究[J]. 轻合金加工技术, 2015, 43(6): 62 − 66. Li Guowei, Wang Nannan, Qiu Ranfeng, et al. Study on resistance spot welding and performances of the joint between aluminum alloy and stainless[J]. Light Alloy Fabrication Technology, 2015, 43(6): 62 − 66.

[6] 张明军, 陈根余, 李时春, 等. 车用铝合金与镀锌钢光纤激光搭接焊试验研究[J]. 中国激光, 2011, 38(6): 134 − 139. Zhang Mingjun, Chen Genyu, Li Shichun, et al. Experimental investigation on fiber laser overlap welding of automotive aluminum to galvanized steel[J]. Chinese Journal of Lasers, 2011, 38(6): 134 − 139.

[7] 张满, 张军, 蒋腾, 等. Fe-Al金属间化合物对铝/钢钎焊接头力学性能的影响[J]. 焊接学报, 2018, 39(1): 61 − 64. Zhang Man, Zhang Jun, Jiang Teng, et al. Effect of Fe-Al intermetallic compound on mechanical property of aluminum/steel brazed joint[J]. Transactions of the China Welding Institution, 2018, 39(1): 61 − 64.

[8] Ma Yunwu, Lou Ming, Li Yongbing, et al. Effect of rivet and die on self-piercing rivetability of AA6061-T6 and mild steel CR4 of different gauges[J]. Journal of Materials Processing Technology, 2018, 251: 282 − 294. doi: 10.1016/j.jmatprotec.2017.08.020

[9] 王希靖, 邓向斌, 王磊. Q235钢板与6082铝合金搅拌摩擦焊工艺[J]. 焊接学报, 2016, 27(1): 99 − 102. Wang Xijing, Deng Xiangbin, Wang Lei. Parametric study on friction stir welding of Q235 steel with 6082 aluminum alloy[J]. Transactions of the China Welding Institution, 2016, 27(1): 99 − 102.

[10] Masaki K, Sato Y S, Maeda M, et al. Experimental simulation of recrystallized microstructure in friction stir welded Al alloy using a plane-strain compression test[J]. Scripta Materialia, 2008, 58(5): 355 − 360. doi: 10.1016/j.scriptamat.2007.09.056

[11] Wu X L, Tao N R, Wei Q M, et al. Microstructural evolution and formation of nanocrystalline intermetallic compound during surface mechanical attrition treatment of cobalt[J]. Acta Materialia, 2007, 55(17): 5768 − 5779. doi: 10.1016/j.actamat.2007.06.030

[12] Ma Z Y, Pilchak A L, Juhas M C, et al. Microstructural refinement and property enhancement of cast light alloys via friction stir processing[J]. Scripta Materialia, 2008, 58(5): 361 − 366. doi: 10.1016/j.scriptamat.2007.09.062

[13] Rest C V D, Jacques P J, Simar A. On the joining of steel and aluminium by means of a new friction melt bonding process[J]. Scripta Materialia, 2014, 77: 25 − 28. doi: 10.1016/j.scriptamat.2014.01.008

[14] 万龙, 黄永宪, 刘鑫, 等. 铝/钢异质金属搅拌摩擦焊技术研究进展[J]. 焊接, 2018(1): 12 − 19, 24. Wan Long, Huang Yongxian, Liu Xin, et al. Study progress on friction stir welding of aluminum / steel dissimilar materials[J]. Welding & Joining, 2018(1): 12 − 19, 24.

[15] Movahedi M, Kokabi A H, Reihani S M S, et al. Effect of tool travel and rotation speeds on weld zone defects and joint strength of aluminium steel lap joints made by friction stir welding[J]. Science and Technology of Welding and Joining, 2012, 17(2): 162 − 167. doi: 10.1179/1362171811Y.0000000092

[16] Bozzi S, Helbert-Etter A L, Baudin T, et al. Intermetallic compounds in Al 6016/IF-steel friction stir spot welds[J]. Materials Science and Engineering, 2010, 527(16-17): 4505 − 4509. doi: 10.1016/j.msea.2010.03.097

[17] 王希靖, 邓向斌, 王磊, 等. 铝/钢搅拌摩擦焊对接焊缝组织及机理研究[J]. 材料科学与工艺, 2015, 23(5): 77 − 81. Wang Xijing, Deng Xiangbin, Wang Lei, et al. Microstructure and joining mechanism of aluminium-steel friction stir butt welding[J]. Materials Science and Technology, 2015, 23(5): 77 − 81.

[18] Hsieh M J, Lee R T, Chiou Y C. Friction stir spot fusion welding of low-carbon steel to aluminum alloy[J]. Journal of Materials Processing Technology, 2016, 240: 118 − 125.

[19] Dehghani M, Amadeh A, Mousavi S A A A. Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel[J]. Materials and design, 2013, 49: 433 − 441. doi: 10.1016/j.matdes.2013.01.013

[20] Pourali M, Abdollah-zadeh A, Saeid T, et al. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds[J]. Journal of Alloys and Compounds, 2017, 715: 1 − 8. doi: 10.1016/j.jallcom.2017.04.272

[21] 张桂源, 郄新哲, 宫文彪, 等. 钢铝异种材料搅拌摩擦焊界面组织及性能[J]. 材料热处理学报, 2018, 39(5): 159 − 164. Zhang Guiyuan, Qie Xinzhe, Gong Wenbiao, et al. Microstructure and properties of friction stir welding interface of steel and aluminum dissimilar materials[J]. Transactions of Materials and Heat Treatment, 2018, 39(5): 159 − 164.

[22] Haghshenas M, Abdel-Gwad A, Omran A M, et al. Friction stir weld assisted diffusion bonding of 5754 aluminum alloy to coated high strength steels[J]. Materials and Design, 2014, 55: 442 − 449. doi: 10.1016/j.matdes.2013.10.013

[23] Liu X, Lan S H, Ni J. Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel[J]. Materials and Design, 2014, 59: 50 − 62. doi: 10.1016/j.matdes.2014.02.003

[24] Wang Tianhao, Komarasamy M, Liu Kaimiao, et al. Friction stir butt welding of strain-hardened aluminum alloy with high strength steel[J]. Materials science and Engineering, 2018, 737(8): 85 − 89.

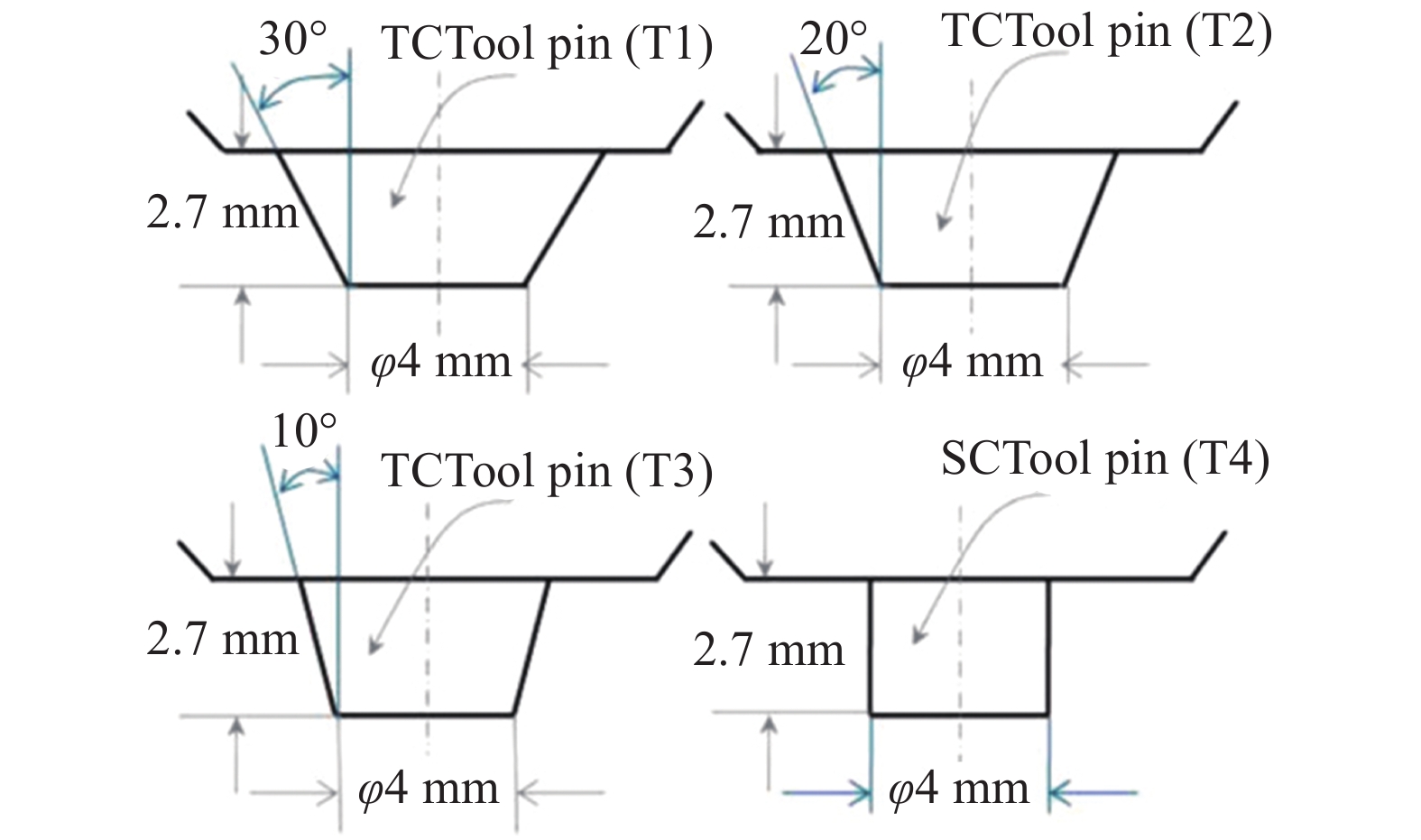

[25] Ramachandran K K, Murugan N, Kumar S S. Effect of tool axis offset and geometry of tool pin profile on the characteristics of friction stir welded dissimilar joints of aluminum alloy AA5052 and HSLA steel[J]. Materials Science and Engineering, 2015, 639(15): 219 − 233.

[26] Wan Long, Huang Yongxian. Microstructure and mechanical properties of Al/steel friction stir lap weld[J]. Metals, 2017, 7(12): 542. doi: 10.3390/met7120542

[27] Wei Y, Li J, Xiong J T, et al. Effect of tool pin insertion depth on friction stir lap welding of aluminum to stainless steel[J]. Journal of Materials Engineering and Performance, 2013, 22(10): 3005 − 3013. doi: 10.1007/s11665-013-0595-y

[28] 邢丽, 柯黎明, 黄春平. 铝合金与钢的搅拌摩擦焊焊缝成形及接头性能[J]. 焊接学报, 2007, 28(1): 29 − 32. Xing Li, Ke Liming, Huang Chunping. Weld appearances and mechanical properties of friction stir welded joint of Al alloy and mild steel[J]. Transactions of the China Welding Institution, 2007, 28(1): 29 − 32.

[29] Elrefaey A, Gouda M, Takahashi M, et al. Characterization of aluminum/steel lap joint by friction stir welding[J]. Journal of Materials Engineering and Performance, 2005, 14(1): 10 − 17. doi: 10.1361/10599490522310

[30] Fereiduni E, Movahedi M, Kokabi A H. Aluminum/steel joints made by an alternative friction stir spot welding process[J]. Journal of Materials Processing Technology, 2015, 224: 1 − 10. doi: 10.1016/j.jmatprotec.2015.04.028

[31] 张昭, 刘会杰. 搅拌头形状对搅拌摩擦焊材料变形和温度场的影响[J]. 焊接学报, 2011, 32(3): 5 − 8. Zhang Zhao, Liu Huijie. Effect of pin shapes on material deformation and temperature filed in friction stir welding[J]. Transactions of the China Welding Institution, 2011, 32(3): 5 − 8.

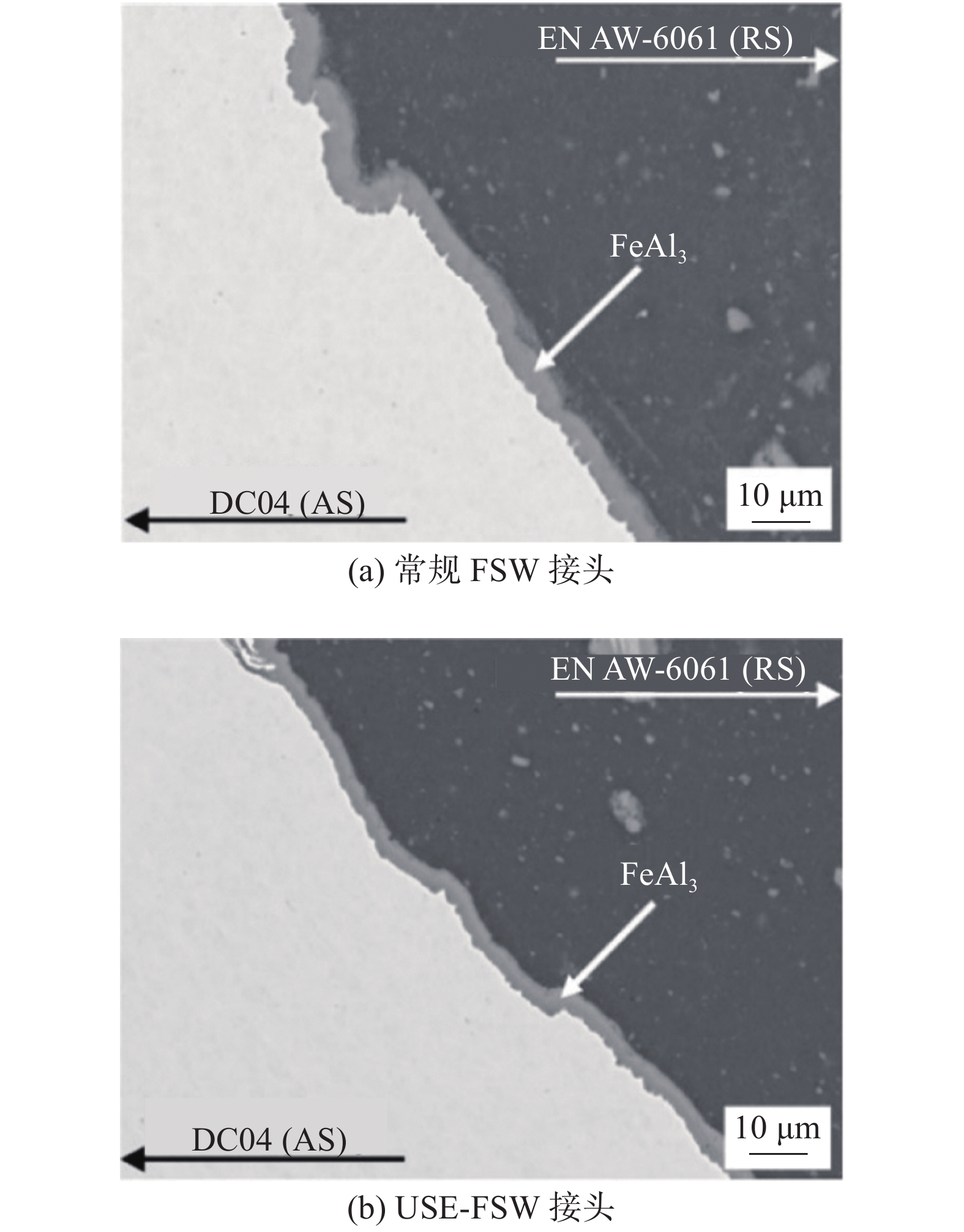

[32] Huang Yongxian, Wan Long, Si Xiaoqing, et al. Achieving high-quality Al/Steel joint with ultrastrong interface[J]. Metallurgical and Materials Transactions A, 2019, 50: 295 − 299. doi: 10.1007/s11661-018-5006-4

[33] Xiong J T, Li J L, Qian J W, et al. High strength lap joint of aluminium and stainless steels fabricated by friction stir welding with cutting pin[J]. Science and Technology of Welding and Joining, 2012, 17(3): 196 − 201. doi: 10.1179/1362171811Y.0000000093

[34] 姬书得, 孟庆国, 史清宇, 等. 搅拌针形状影响搅拌摩擦焊过程金属塑性流动规律的数值模拟[J]. 焊接学报, 2013, 24(2): 97 − 100. Ji Shude, Meng Guoqing, Shi Qingyu, et al. Numerical simulation of metal plastic flow in friction stir welding affected by pin shape[J]. Transactions of the China Welding Institute, 2013, 24(2): 97 − 100.

[35] 王大勇, 冯吉才, 王攀峰. 搅拌摩擦焊焊热输入数值模型[J]. 焊接学报, 2005, 26(3): 25 − 29. Wang Dayong, Feng Jicai, Wang Panfeng. Numerical model of heat input from rotational tool during friction stir welding[J]. Transactions of the China Welding Institution, 2005, 26(3): 25 − 29.

[36] Li Shuhan, Chen Yuhua, Kang Jidong, et al. Friction stir lap welding of aluminum alloy to advanced high strength steel using a cold-spray deposition as an interlayer[J]. Materials Letters, 2019, 239: 212 − 215. doi: 10.1016/j.matlet.2018.12.060

[37] Zhou Li, Yu Mingrun, Liu Baiyang, et al. Microstructure and mechanical properties of Al/steel dissimilar welds fabricated by friction surfacing assisted friction stir lap welding[J]. Journal of Materials Research and Technology, 2020, 9(1): 212 − 221. doi: 10.1016/j.jmrt.2019.10.046

[38] Niu Shiyu, Ji Shude, Yan Dejun, et al. AZ31B/7075-T6 alloys friction stir lap welding with a zinc interlayer[J]. Journal of Materials Processing Technology, 2019, 263: 82 − 90. doi: 10.1016/j.jmatprotec.2018.08.009

[39] 高鹏宇, 许惠斌, 李添翼, 等. 镀锌钢板与6061铝合金搭接搅拌摩擦钎焊[J]. 精密成形工程, 2018, 10(2): 113 − 116. Gao Pengyu, Xu Huibin, Li Tianyi, et al. Lap friction stir brazing of galvanized steel sheet and 6061 aluminum alloy[J]. Journal of Netshape Forming Engineering, 2018, 10(2): 113 − 116.

[40] 高鹏宇, 许惠斌, 李默阳, 等. Zn中间层下钢与铝基复合材料的搅拌摩擦焊研究[J]. 热加工工艺, 2019, 48(3): 73 − 76. Gao Pengyu, Xu Huibin, Li Moyang, et al. Study on friction stir welding of steel and aluminum matrix composite with Zn intermediate layer[J]. Hot Working Technology, 2019, 48(3): 73 − 76.

[41] Zheng Qixian, Feng Xiaomei, Shen Yifu, et al. Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal[J]. Journal of Alloys and Compounds, 2016, 686: 693 − 701. doi: 10.1016/j.jallcom.2016.06.092

[42] Chen Y C, Komazaki T, Tsumura T, et al. Role of zinc coat in friction stir lap welding Al and zinc coated steel[J]. Materials Science and Technology, 2008, 24(1): 33 − 39. doi: 10.1179/174328407X248505

[43] Ratanathavorn W, Melander A. Influence of zinc on intermetallic compounds formed in friction stir welding of AA5754 aluminium alloy to galvanised ultra-high strength steel[J]. Science and Technology of Welding and Joining, 2017, 22(8): 673 − 680. doi: 10.1080/13621718.2017.1302553

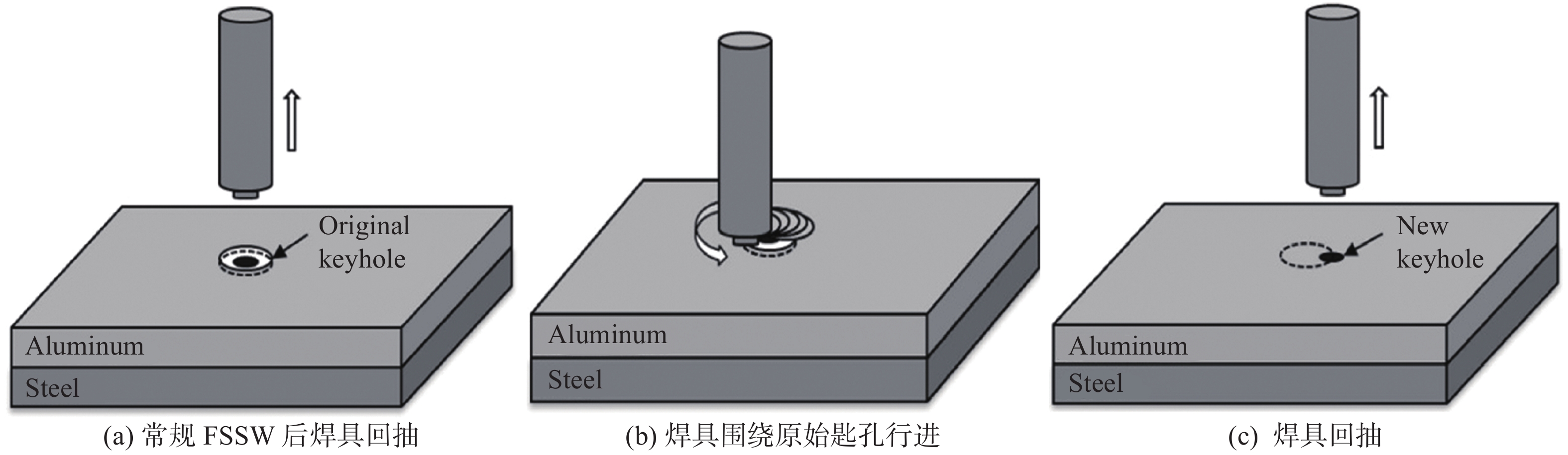

[44] Chen Kai, Liu Xun, Ni Jun. Keyhole refilled friction stir spot welding of aluminum alloy to advanced high strength steel[J]. Journal of Materials Processing Technology, 2017, 249: 452 − 462. doi: 10.1016/j.jmatprotec.2017.06.039

[45] 姬书得, 卓彬, 马琳, 等. 回填式搅拌摩擦点焊过程的材料流动规律模拟[J]. 焊接学报, 2016, 37(4): 39 − 42. Ji Shude, Zhuo Bin, Ma Lin, et al. Simulation of material flow behavior during refill friction stir spot welding process[J]. Transactions of the China Welding Institution, 2016, 37(4): 39 − 42.

[46] Li Peng, Chen Su, Dong Honggang, et al. Interfacial microstructure and mechanical properties of dissimilar aluminum/steel joint fabricated via refilled friction stir spot welding[J]. Journal of Manufacturing Processes, 2020, 49: 385 − 396. doi: 10.1016/j.jmapro.2019.09.047

[47] 王希靖, 张亚州, 张忠科, 等. 铝/钢无匙孔搅拌摩擦点焊焊接性分析[J]. 焊接学报, 2015, 36(1): 1 − 4. Wang Xijing, Zhang Yazhaou, Zhang Zhongke, et al. Welding analyses of friction stir spot welding without keyhole between aluminum alloy and zinc-coated steel[J]. Transactions of the China Welding Institution, 2015, 36(1): 1 − 4.

[48] Huang Yongxian, Huang Tifang, Wan Long, et al. Material flow and mechanical properties of aluminum-to-steel self-riveting friction stir lap joints[J]. Journal of Materials Processing Technology, 2019, 263: 129 − 137. doi: 10.1016/j.jmatprotec.2018.08.011

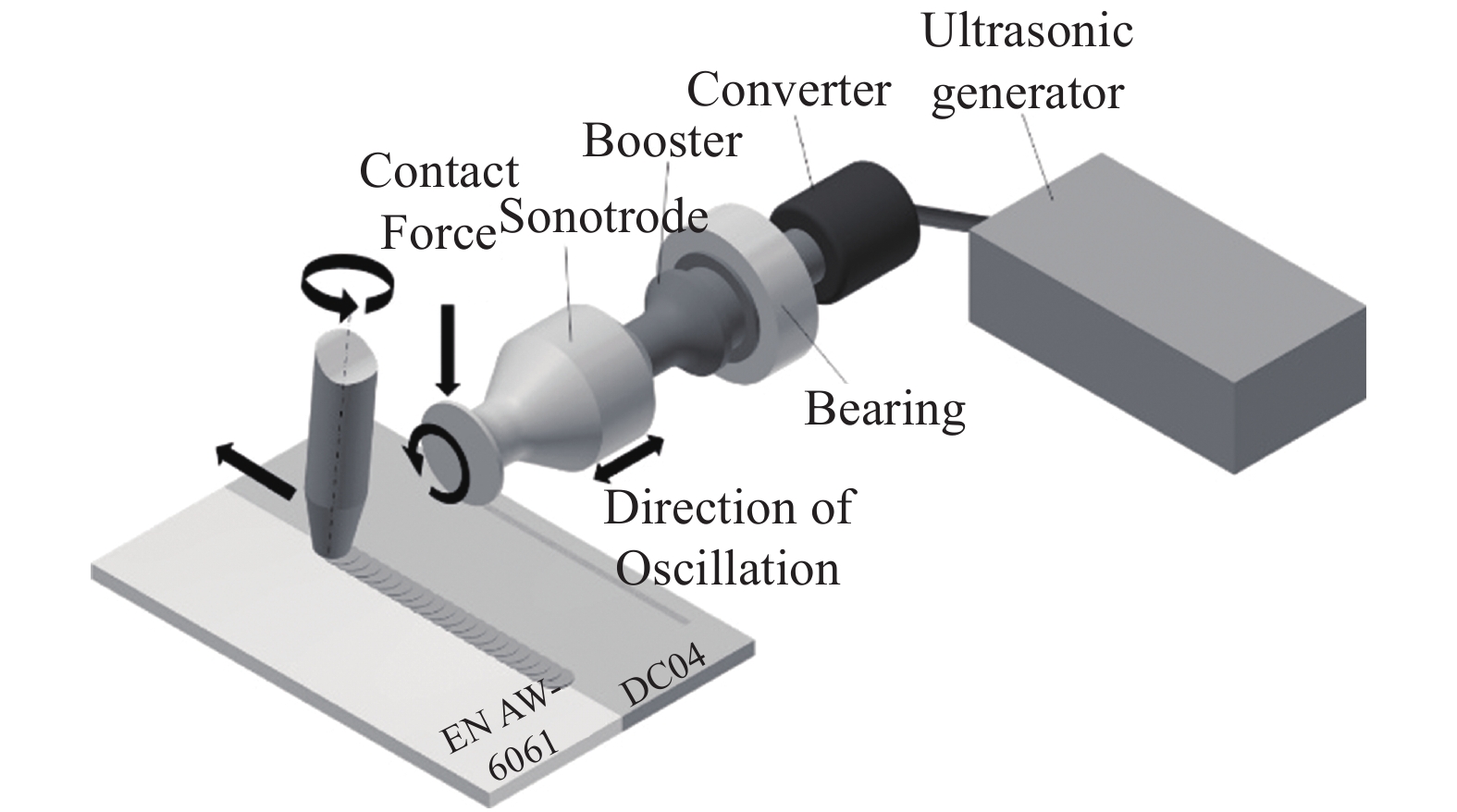

[49] Marco Thomä, Wagner G, Benjamin Straß, et al. Ultrasound enhanced friction stir welding of aluminum and steel: Process and properties of EN AW 6061/DC04-Joints[J]. Journal of Materials Science and Technology, 2018, 34(1): 163 − 172. doi: 10.1016/j.jmst.2017.10.022

[50] Patel V, Badheka V, Li W Y, et al. Hybrid friction stir processing with active cooling approach to enhance superplastic behavior of AA7075 aluminum alloy[J]. Archives of Civil and Mechanical Engineering, 2019, 19(4): 1368 − 1380. doi: 10.1016/j.acme.2019.08.007

[51] Mahto R P, Gupta C, Kinjawadekar M, et al. Weldability of AA6061-T6 and AISI 304 by underwater friction stir welding[J]. Journal of Manufacturing Processes, 2019, 38: 370 − 386. doi: 10.1016/j.jmapro.2019.01.028

[52] Derazkola H A, Khodabakhshi F. Underwater submerged dissimilar friction-stir welding of AA5083 aluminum alloy and A441 AISI steel[J]. International Journal of Advanced Manufacturing Technology, 2019, 102: 4383 − 4395. doi: 10.1007/s00170-019-03544-1

[53] Patel V, Li W Y, Liu X C, et al. Tailoring grain refinement through thickness in magnesium alloy via stationary shoulder friction stir processing and copper backing plate[J]. Materials Science and Engineering A, 2020, 784: 139322. doi: 10.1016/j.msea.2020.139322

-

期刊类型引用(1)

1. 王文安. 铝合金焊接头的软化及改善措施分析. 中国设备工程. 2021(12): 73-74 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: