"Γ" shaped arc and its promotion method in Tri-Arc dual wire welding

-

摘要:

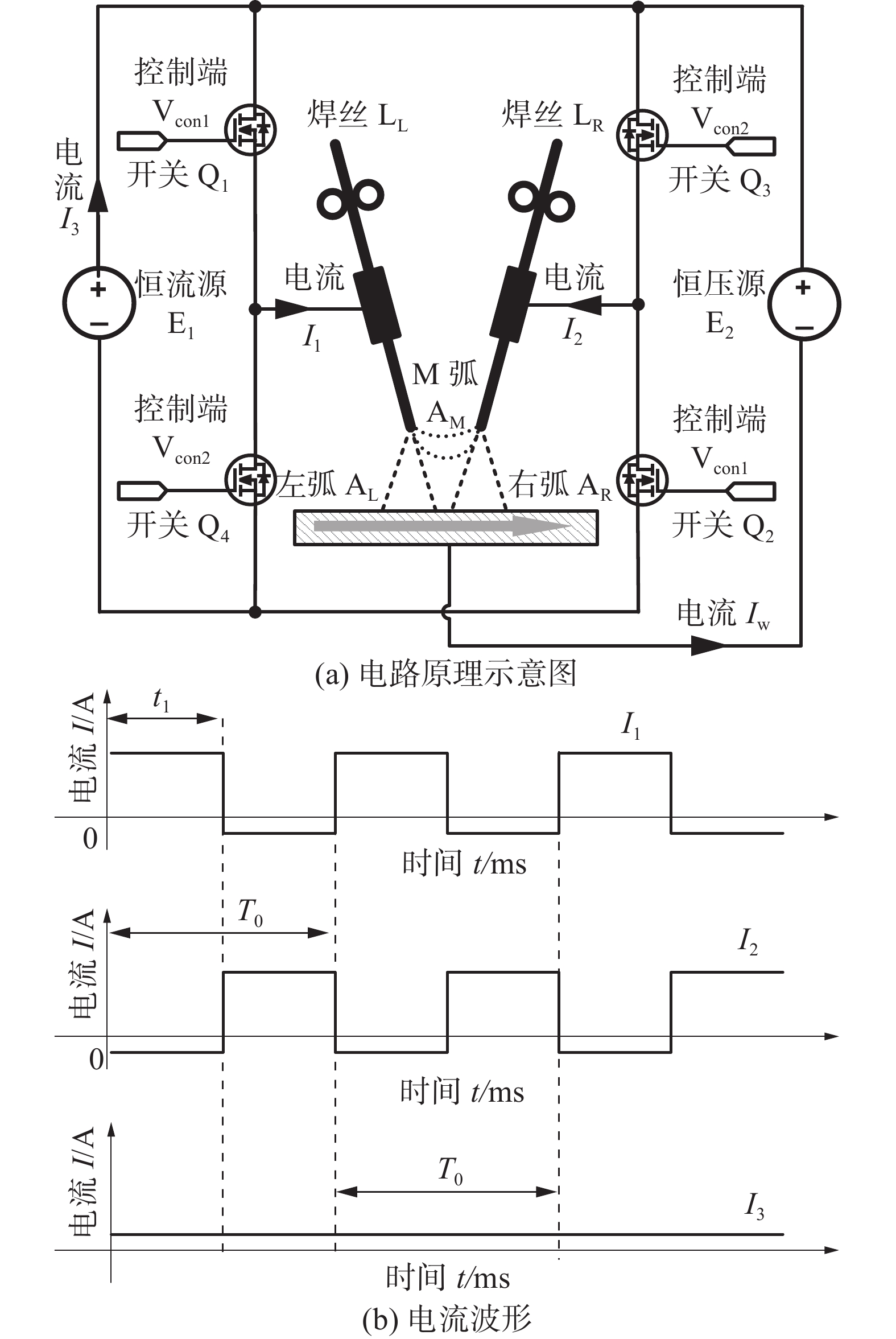

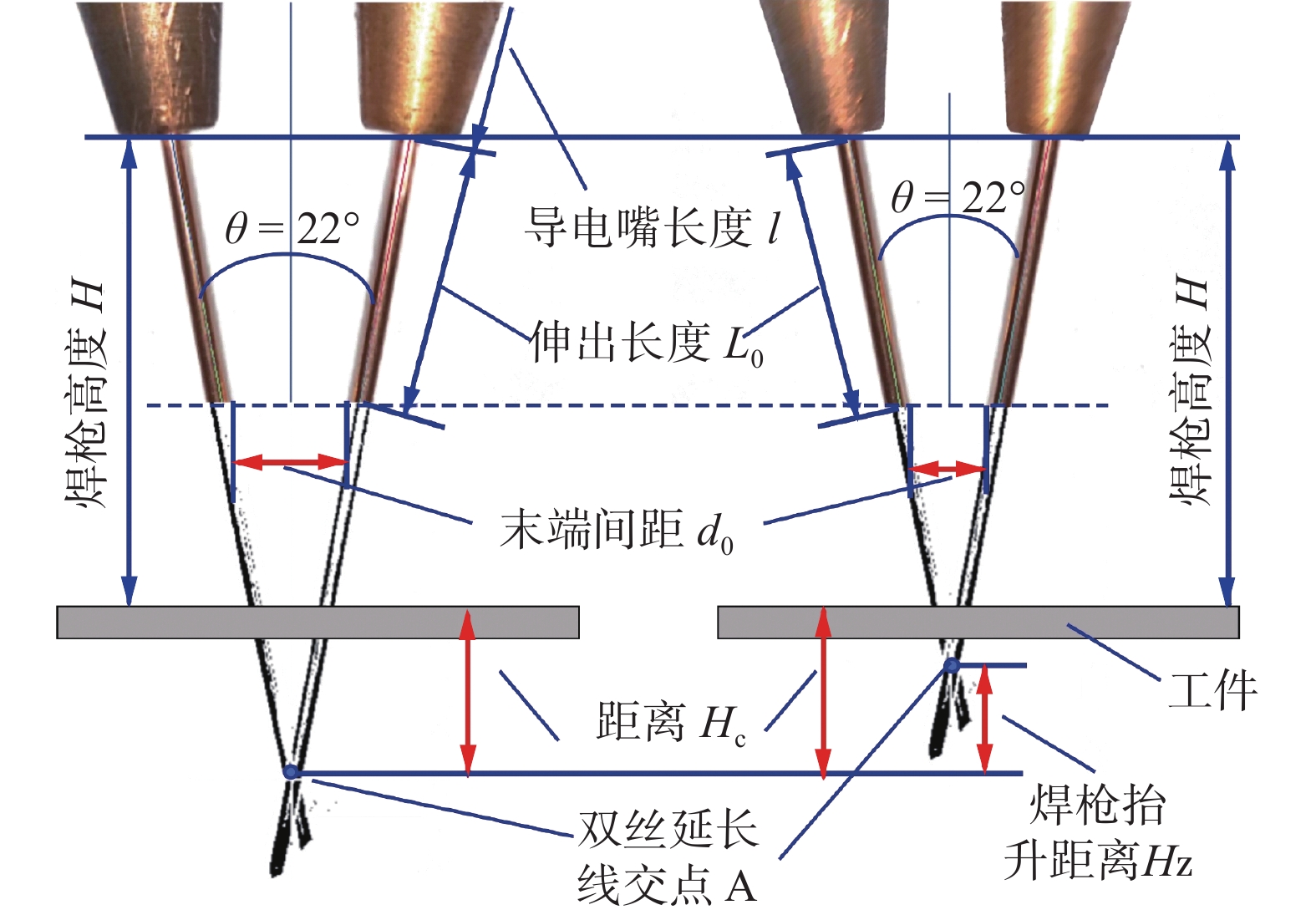

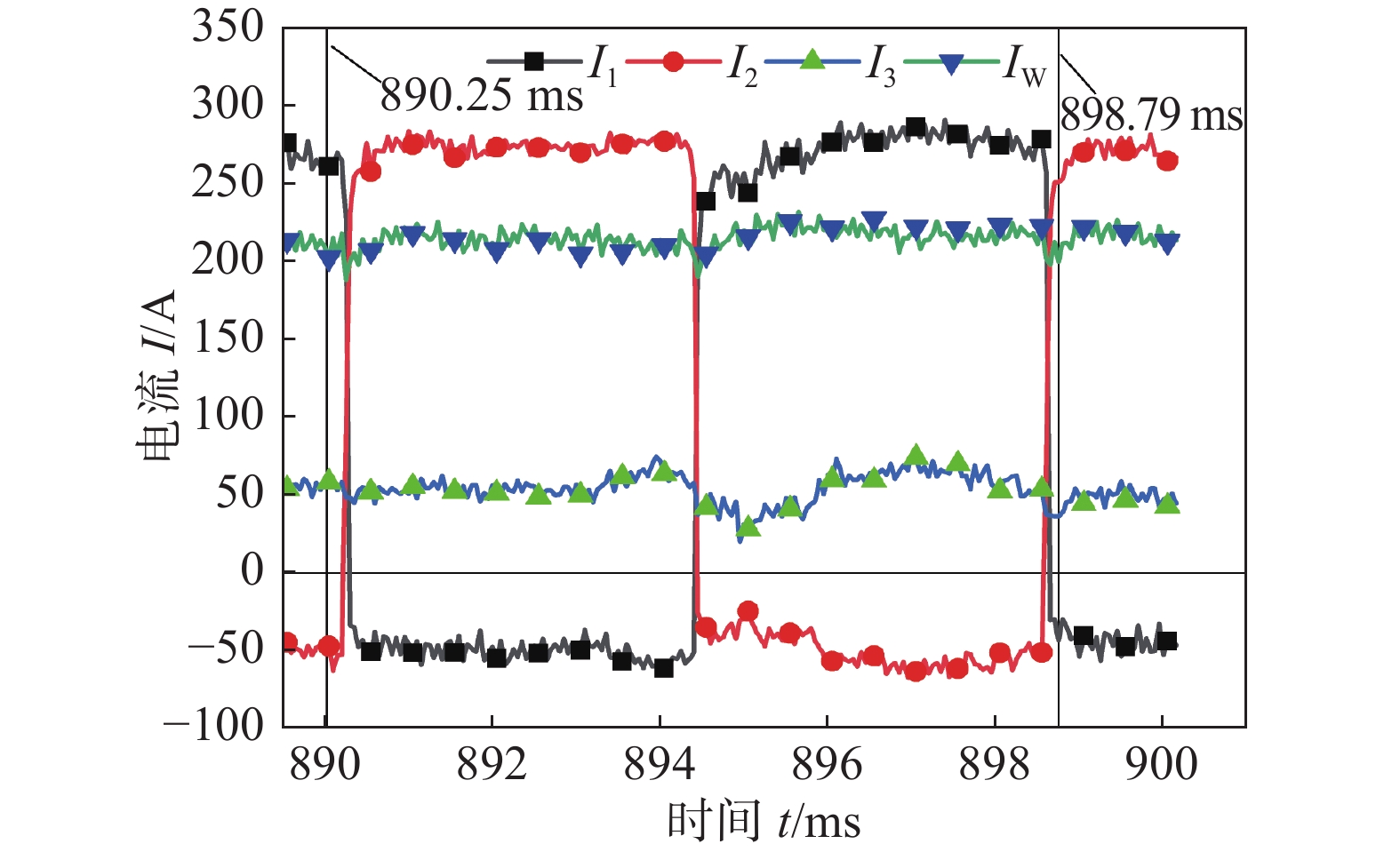

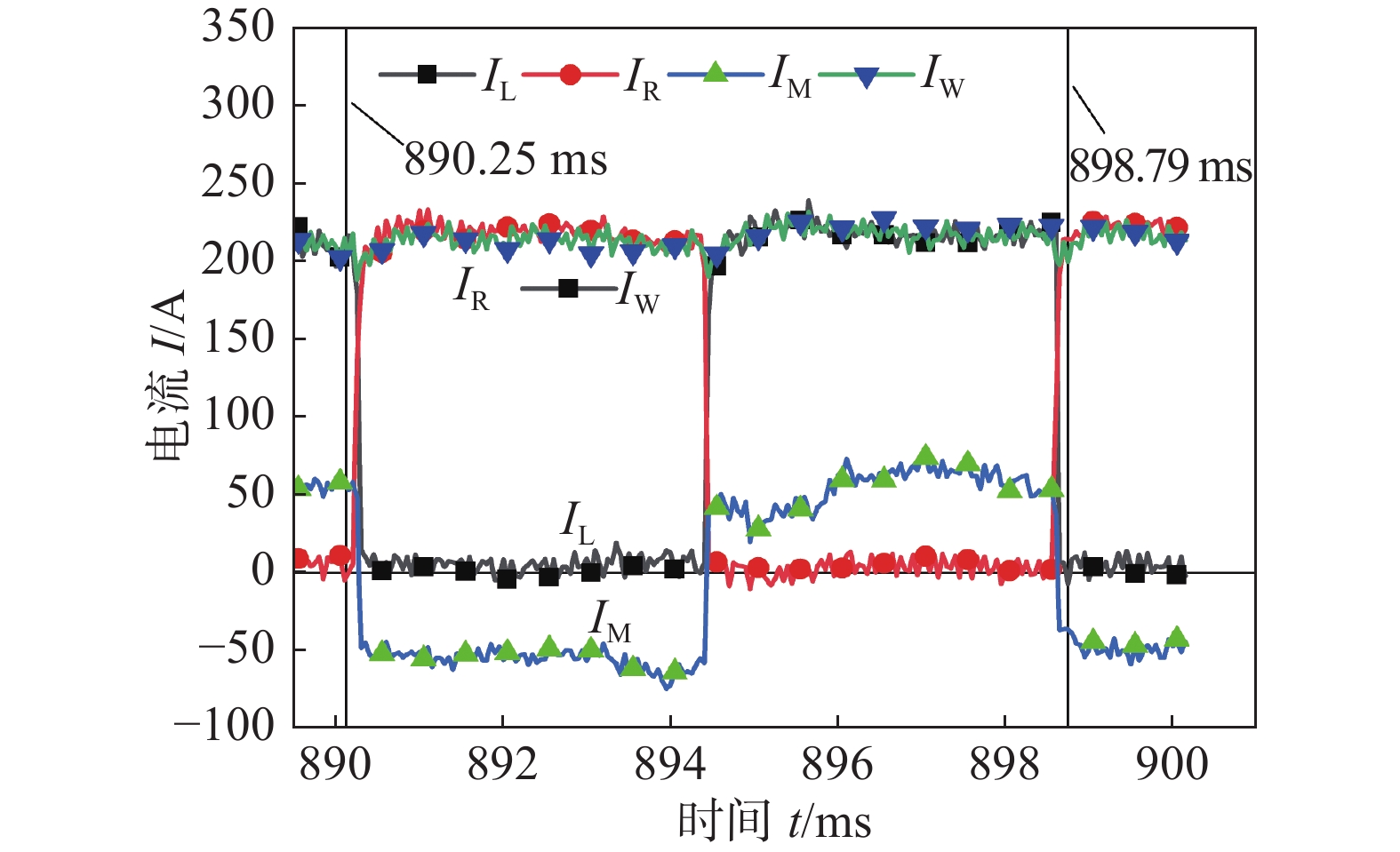

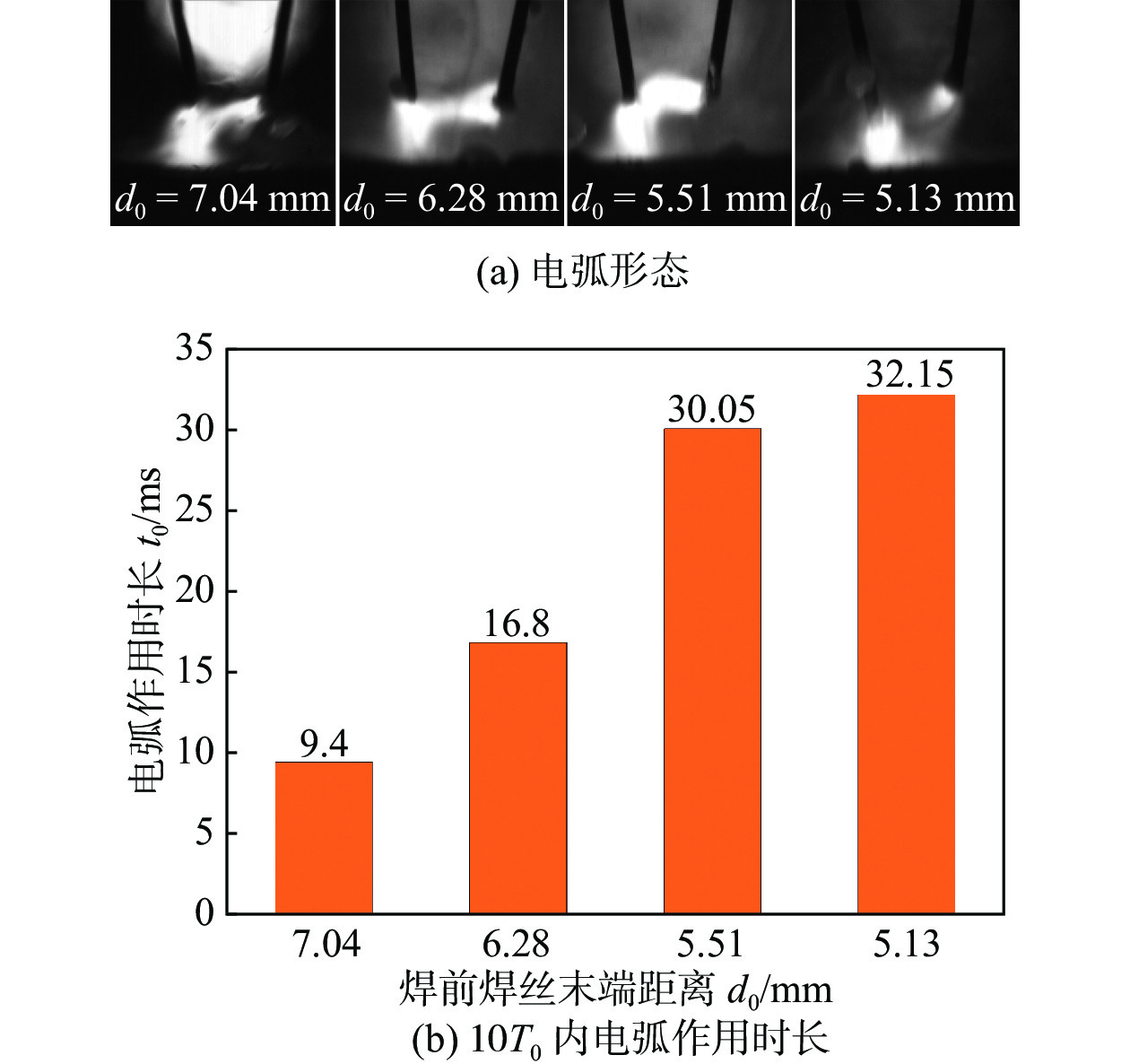

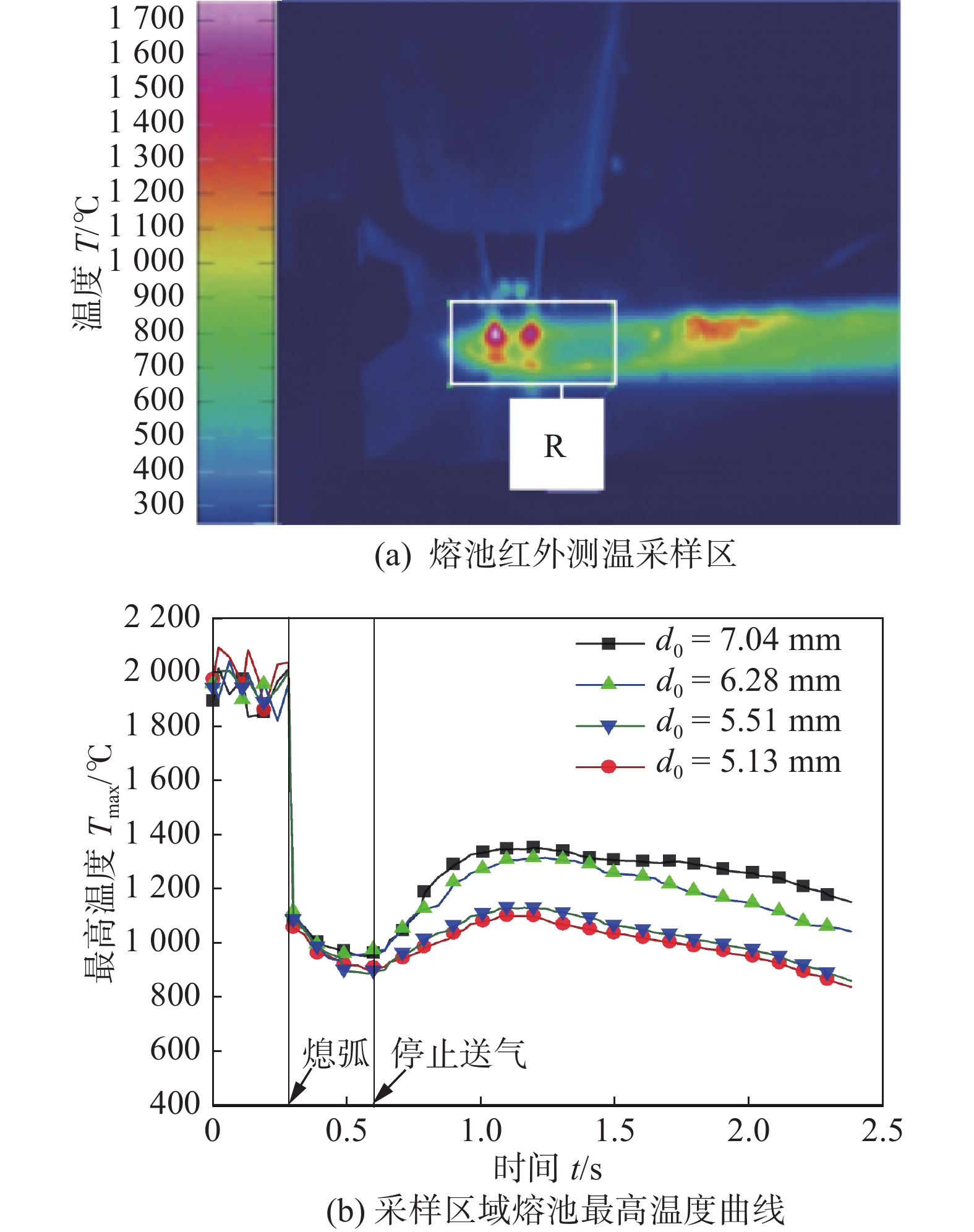

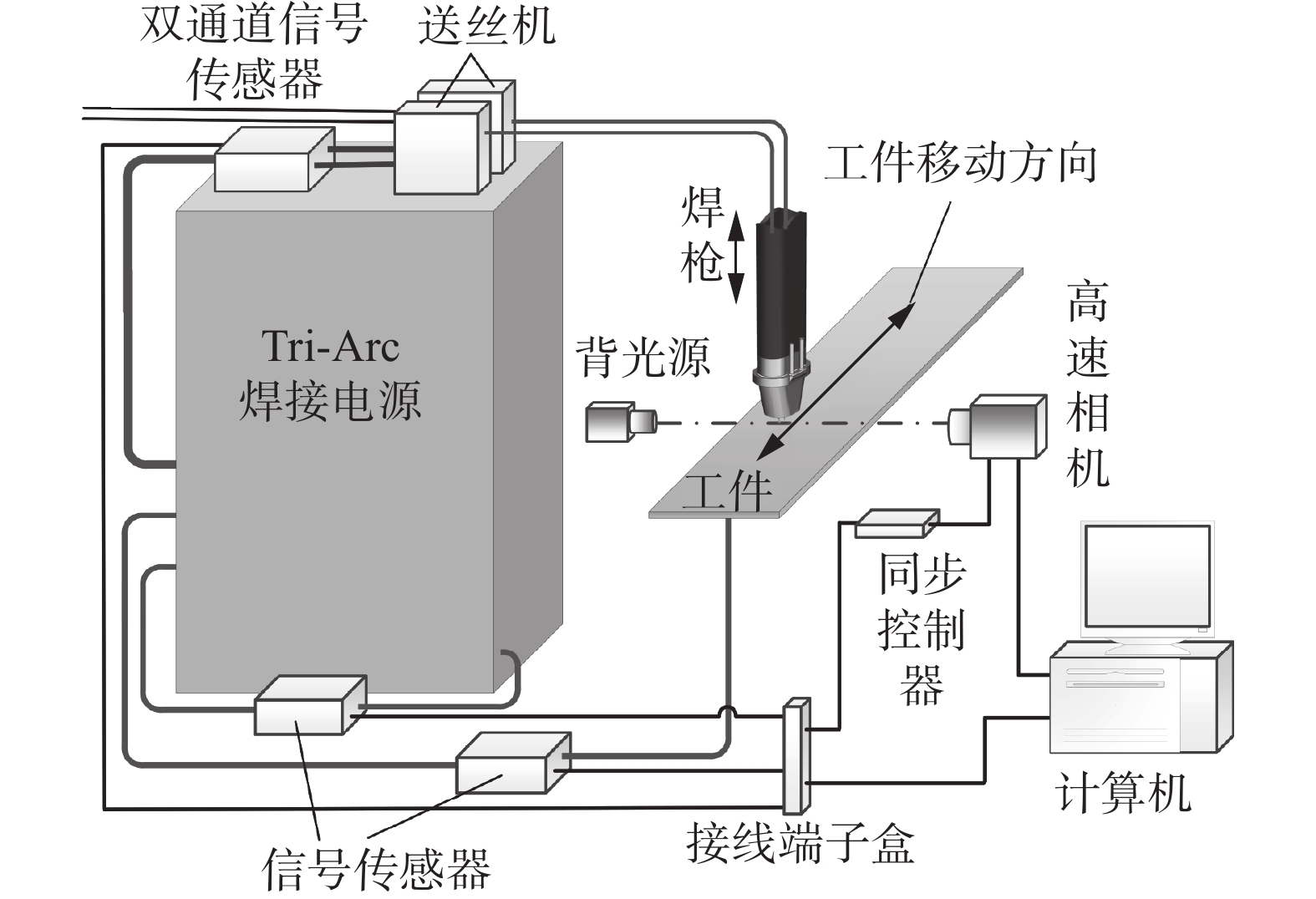

Tri-Arc双丝三电弧焊通过中间第3弧的M弧重新分配焊接热输入,实现高熔覆率低热输入焊接. M弧与主电弧耦合,在整个动态周期表现为“Γ”形和“μ”形及其镜像形态. 该文研究“Γ”形电弧的形成机理和热输入调控机制,结果表明,“Γ”形态由“μ”形态转变而来,熔滴振荡引起焊丝末端间距的变化,从而促进耦合电弧“Γ”形态的形成,此时M弧不作用于母材,比“μ”形电弧焊接热输入更低. 为提高Tri-Arc双丝焊接低热输入效果,在维持导电嘴末端到工件距离不变的前提下,提高焊枪枪体抬升距离从而改变焊丝末端间距. 当导电嘴长度由30 mm增加至35 mm时,随着焊枪抬升,“Γ”形电弧作用时间逐渐增加,能更好地促进电弧热分配,降低Tri-Arc双丝焊接热输入,从而降低熔池最高温度,获得更小宽高比和更小熔深的焊缝.

Abstract:The Tri-Arc dual wire welding achieves a high deposition rate and low heat input by redistributing the heat input through an intermediate third arc called M-Arc. The M-arc is coupled to the main arc and exhibits "Γ" and "μ" shapes and their mirror images throughout the dynamic cycle. In this paper, the formation mechanism of the "Γ"-shaped arc and the heat input regulation mechanism are investigated first. The results indicate that the "Γ" shape evolves from the "μ" shape, the oscillation of adhered molten droplets induces a variation in the distance between two wire ends, thereby facilitating the formation of "Γ" shape in the coupled arc. In this case, the M-arc does not touch the workpiece, rendering a lower heat input during welding than the "μ"-shaped arc. In order to enhance the low heat input effectiveness of the Tri-Arc dual wire welding, the alteration of the distance at two wire ends is achieved by elevating the welding torch. Simultaneously, the length of the conductive nozzle should be increased to maintaining a constant distance between the tip of the conductive nozzle and the workpiece. When the length of the conductive nozzle is increased from 30 mm to 35 mm, as the welding torch is elevated, the duration of the "Γ" shaped arc phase gradually extends. This extended duration effectively facilitates arc thermal distribution, consequently reducing the heat input during Tri-Arc dual wire welding. As a result, peak value of the highest temperature within the molten pool diminishes, thereby reduced the weld bead width-to-height ratios and weld penetration.

-

Keywords:

- tri-arc dual wire welding /

- coupled arc /

- arc shape /

- arc thermal distribution /

- weld thermal input

-

-

表 1 焊接试验工艺参数

Table 1 Parameters of welding test

主弧电压

U / VM弧电流

I / A送丝速度

vf / (m·min−1)焊接速度

v / (mm·s−1)32 60 6 14 脉冲频率

f / Hz占空比

k(%)焊枪高度

H / mm导电嘴长度

l / mm120 50 18 30 表 2 焊前焊丝末端距离变化

Table 2 Changes in wire end distance before welding

试验组 导电嘴长度

l/mm焊枪抬升距离

Hz/mm焊前末端距离

d0/mm0 30 0 7.04 1 32 1.96 6.28 2 34 3.93 5.51 3 35 4.91 5.13 4 30 0 5.13 表 3 不同形态下的电弧电流值

Table 3 Arc current for different arc shapes

电弧形态 L弧电流IL/A R弧电流IR/A M弧电流IM/A “μ”形 I1 I2(I3) — “Γ”形 I1−I3 — I3 镜像“μ”形 I1(I3) I2 — 镜像“Γ”形 — I2−I3 I3 -

[1] Xue P S, Jian K H, Ding F. Review of functionally graded materials processed by additive manufacturing[J]. China Welding, 2023, 32(3): 41 − 50.

[2] Liu G Q, Tang X H, Han S Y, et al. Influence of interwire distance and arc length on welding process and defect formation mechanism in double-wire pulsed narrow-gap gas metal arc welding[J]. Journal of Materials Engineering and Performance, 2021, 30(10): 7622 − 7635. doi: 10.1007/s11665-021-05888-w

[3] 钟蒲, 李亮玉, 柴俊逸. 双丝焊接技术及双丝三电弧焊接稳定性研究进展[J]. 焊接, 2020(6): 38 − 46. Zhong Pu, Li Liangyu, Chai Junyi. Research progress of double wire welding technology and double wire tri-arc welding stability[J]. Welding & Joining, 2020(6): 38 − 46.

[4] 吴开源, 陈梓威, 黄浩, 等. 低频相位对双丝双脉冲GMAW熔滴过渡和焊缝成形的影响[J]. 焊接学报, 2022, 43(7): 43 − 48. Wu Kaiyuan, Chen Ziwei, Huang Hao, et al. Effect of low frequency phase on droplet transfer and weld formation of twin wire double-pulse GMAW[J]. Transactions of the China Welding Institution, 2022, 43(7): 43 − 48.

[5] Laukik P R, Ravindra V T. Wire arc additive manufacturing: a comprehensive review and research directions[J]. Journal of Materials Engineering and Performance, 2021, 30(7): 4768 − 4791. doi: 10.1007/s11665-021-05871-5

[6] Lu Y, Chen S J, Shi Y, et al. Double-electrode arc welding process: principle, variants, control and developments[J]. Journal of Manufacturing Processes, 2014, 16(1): 93 − 108. doi: 10.1016/j.jmapro.2013.08.003

[7] 耿正. 双丝动态三电弧焊接方法: 201010601796.8[P]. 2011-05-25. Geng Zheng. The dual wire dynamic three arc welding method: CN201010601796.8[P]. 2011-05-25.

[8] 邱光, 耿正, 王巍, 等. 实现双丝三电弧焊接的电源装置: 201420356537. 7[P]. 2014-11-05. Qiu Guang, Geng Zheng, Wang Wei, et al. Power supply for realizing dual wire three arc welding: CN201410305559.5[P]. 2014-11-05.

[9] 朱浩天. 双丝三电弧焊接工艺研究[D]. 镇江: 江苏科技大学, 2016 Zhu Haotian, The Research of Double wire and three arc welding technology[D]. Zhenjiang: Jiangsu University of Science and Technology, 2016.

[10] 杨俊. 基于双丝三电弧的堆焊工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2015 Yang Jun. Study on cladding welding process based on Tri-Arc double electrode[D]. Harbin: Harbin Institute of Technology, 2015.

[11] Zheng J, Wang T Q, Zhong P, et al. Effect of pulse M-arc frequency on tri-arc DE droplet transfer and weld forming[J]. China Welding, 2019, 28(1): 1 − 5.

[12] 郑佳, 李亮玉, 钟蒲, 等. 双丝三电弧焊中熔滴过渡及焊缝成形机理[J]. 焊接学报, 2019, 40(7): 31 − 36. Zheng Jia, Li Liangyu, Zhong Pu, et al. Droplet transfer and weld forming of tri-arc DE welding[J]. Transactions of the China Welding Institution, 2019, 40(7): 31 − 36.

[13] Ma Z, Zhuang M H, Li M Q. Effect of main arc voltage on arc behavior and droplet transfer in tri-arc twin wire welding[J]. Journal of Materials Research and Technology, 2020, 9(3): 4876 − 7883. doi: 10.1016/j.jmrt.2020.03.007

[14] 马振, 庄明辉, 牟立婷, 等. M弧电流对tri-arc双丝电弧焊熔滴过渡形态影响[J]. 焊接学报, 2017, 38(11): 57 − 60. Ma Zhen, Zhuang Minghui, Mou Liting, et al. Effects of M Arc current on tri-arc double wire welding droplet transfer modes[J]. Transactions of the China Welding Institution, 2017, 38(11): 57 − 60.

[15] 刘丹, 常云龙. 双丝三电弧铝合金熔丝电弧行为[J]. 焊接, 2018(5): 16 − 20. Liu Dan, Chang Yunlong. Arc behavior of aluminum alloy fusion of tri-arc double wires[J]. Welding& Joining, 2018(5): 16 − 20.

[16] Zhong P, Li L Y, Liu H H, et al. Arc shape and dynamic behavior of the tri-arc twin-wire GMAW process[J]. The International Journal of Advanced Manufacturing Technology, 2023, 125(3/4): 1633 − 1643.

-

期刊类型引用(4)

1. 周金旭,王东辉,叶树茂,刘迪,金鑫,恒俊楠. 铝合金薄板脉冲激光焊接工艺及接头组织特征研究. 有色金属加工. 2025(02): 34-40 .  百度学术

百度学术

2. 苗晓军,韩丽娟,李凯,王磊,姜来合格,廖伟,高明. 铝合金高频振荡扫描激光-电弧复合焊缝成形规律与预测. 焊接学报. 2024(07): 83-91 .  本站查看

本站查看

3. 陈健豪,何志强,蒯夕伟,孟燕菲,邓礼兵. 储能电池用铝合金环形激光焊接特性研究. 机电工程技术. 2024(09): 135-139 .  百度学术

百度学术

4. 郭克星. 铝合金激光焊接技术研究进展. 热处理. 2024(06): 1-7 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: