Dilution rate monitoring of DED based on a spectral physical feature perception network

-

摘要:

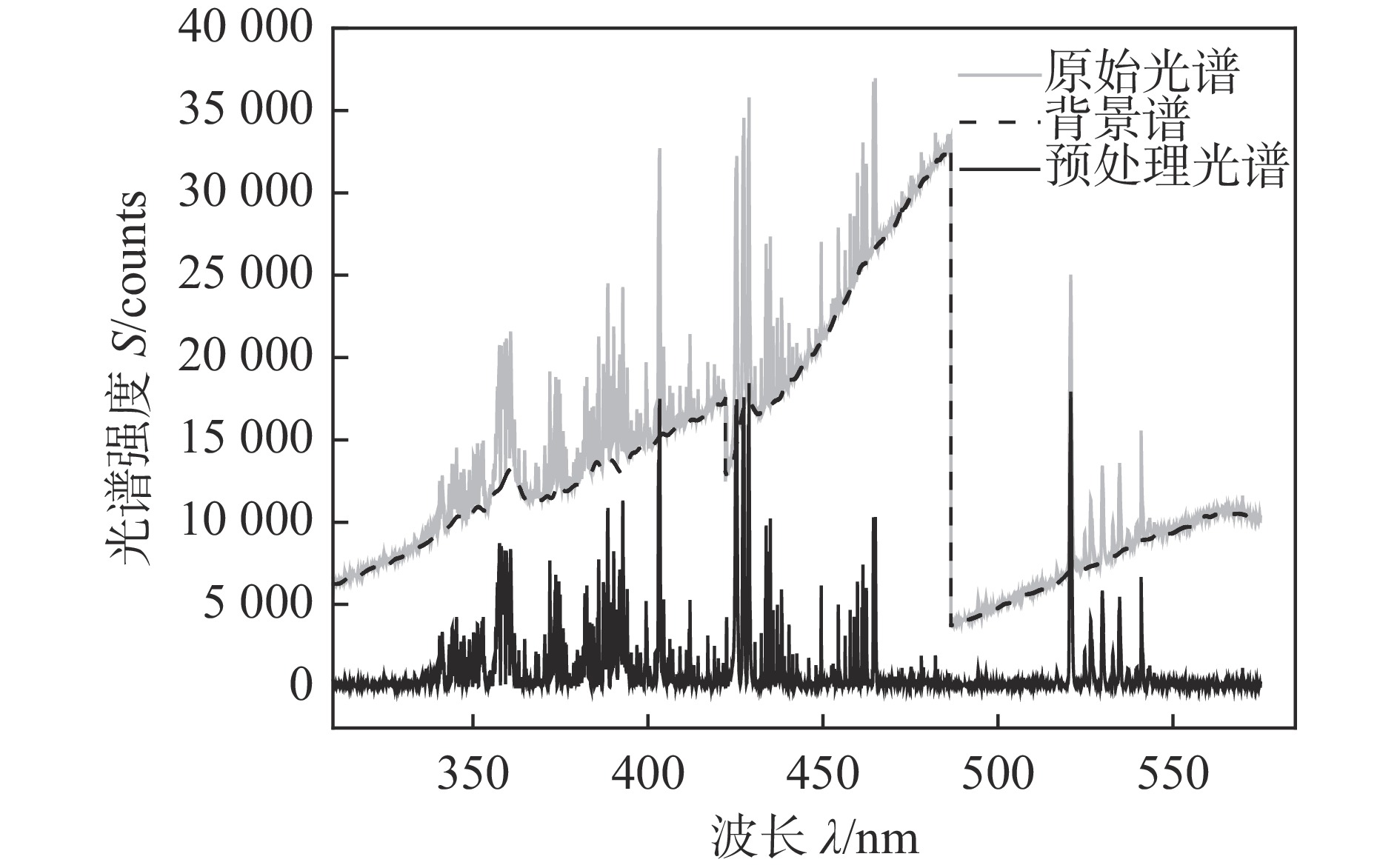

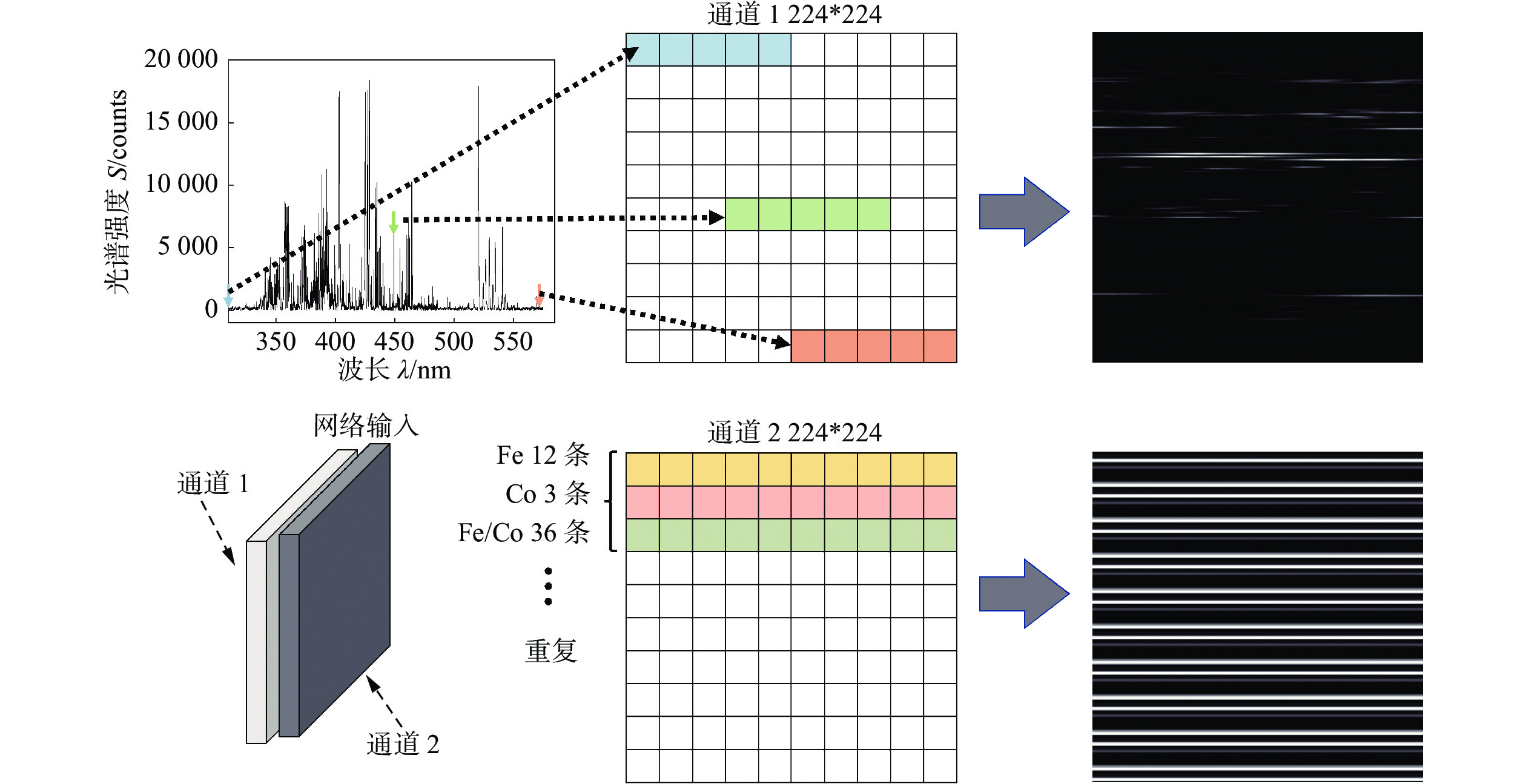

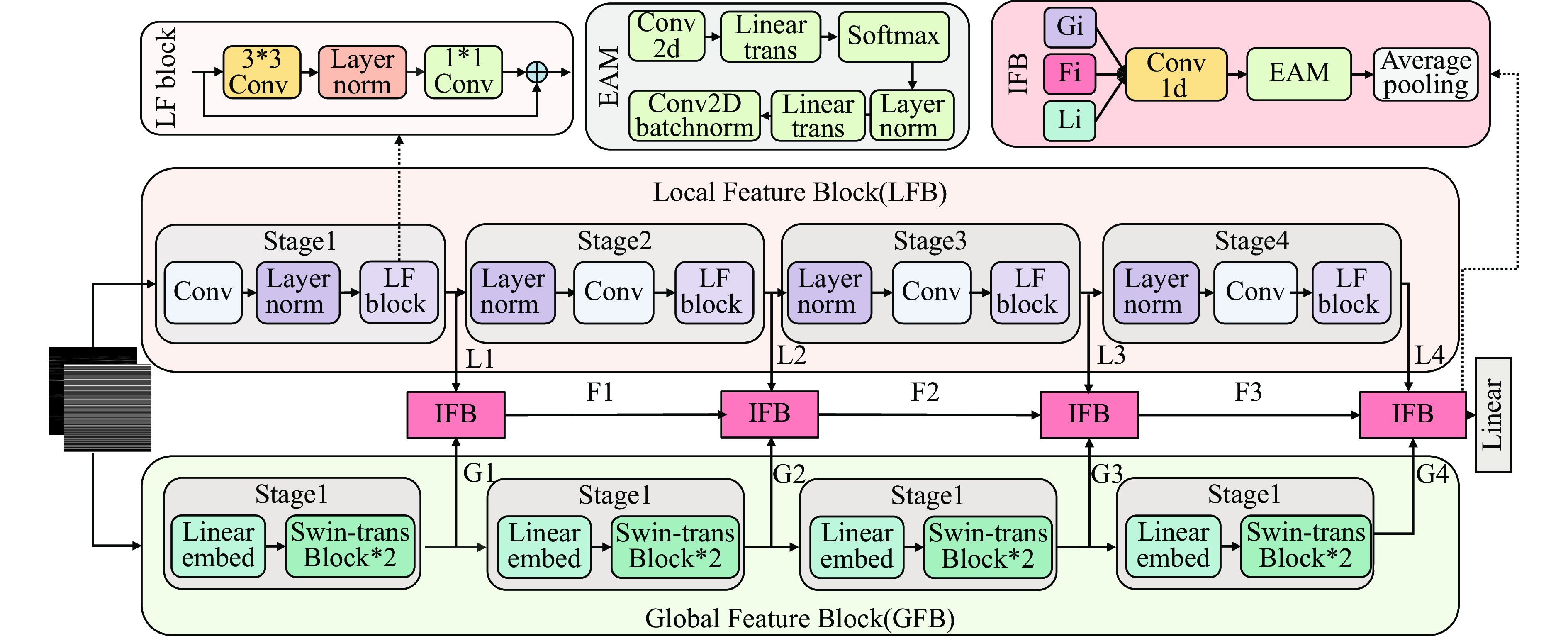

稀释率对激光能量沉积基体和熔覆层之间的冶金结合强度和成形精度至关重要.论文搭建了一套基于y-双通道光纤的DED过程稀释率实时监测系统.基于所采集等离子体光谱信号,提取基板和粉末关键代表元素谱线比表征稀释率变化.搭建光谱物理特征感知网络(Pi-LGNet),以光谱预处理信号和所提元素谱线等光谱物理特征作为双通道输入,实现了DED过程中稀释率的分类识别.结果表明,所提关键代表元素谱线比与稀释率具有强相关关系,所提Pi-LGNet网络模型准确率可达91.8%,消融试验和对比试验验证了该网络对光谱信号识别的优越性.

Abstract:The dilution rate is crucial for the metallurgical bonding strength and forming precision between the substrate and the cladding layer in laser energy deposition. However, existing monitoring methods find it challenging to perform online quality monitoring. Therefore, a real-time dilution rate monitoring system based on a Y-dual-channel fiber in the DED process was developed. This system collects plasma spectral signals and extracts the key representative elemental line ratios of the substrate and powder to characterize the dilution rate variation. The Pi-LGNet, a spectral physical feature perception network, was established, using preprocessed spectral signals and extracted elemental line ratios as dual-channel inputs, achieving classification and identification of the dilution rate during the DED process. The results show that the extracted key representative elemental line ratios have a strong correlation with the dilution rate, and the proposed Pi-LGNet network model achieves an accuracy of 91.8%. Ablation and comparative experiments confirm the superiority of this network in spectral signal recognition.

-

-

表 1 消融试验结果(%)

Table 1 Spectral data classification label

网络 训练集 验证集 测试集 Pi-LFB 99.4 85.7 85.1 Pi-GFB 91.7 90.7 90.4 LGNet 95.4 90.3 89.6 No EAM 98.1 89.0 87.1 Pi-LGNet 94.3 92.3 91.8 -

[1] Gibson I, Rosen D W, Stucker B, et al., Additive manufacturing technologies[M]. USA: Springer, 2021.

[2] Armstrong M, Mehrabi H, Naveed N. An overview of modern metal additive manufacturing technology[J]. Journal of Manufacturing Processes, 2022, 84: 1001 − 1029. doi: 10.1016/j.jmapro.2022.10.060

[3] Taminger K M, Domack C S. Challenges in metal additive manufacturing for large-scale aerospace applications[J]. Women in Aerospace Materials: Advancements and Perspectives of Emerging Technologies, 2020, 105-124.

[4] Kawalkar R, Dubey H K, Lokhande S P. A review for advancements in standardization for additive manufacturing[J]. Materials Today: Proceeding, 2021, 50: 1983 − 1990.

[5] Kladovasilakis N, Charalampous P, Kostavelis I, et al. Impact of metal additive manufacturing parameters on the powder bed fusion and direct energy deposition processes: a comprehensive review[J]. Progress in Additive Manufacturing, 2021, 6: 349 − 365. doi: 10.1007/s40964-021-00180-8

[6] Wang D, Liu L Q, Deng G W, et al. , Recent progress on additive manufacturing of multi-material structures with laser powder bed fusion[J]. Virtual and Physical Prototyping, 2022, 17: 329 − 365. doi: 10.1080/17452759.2022.2028343

[7] Kotadia H, Gibbons G, Das A, et al, A review of laser powder bed fusion additive manufacturing of aluminium alloys: Microstructure and properties[J]. Additive Manufacturing, 2021, 46, 102155.

[8] Blakey-Milner B, Gradl P, Snedden G, et al. Metal additive manufacturing in aerospace: A review[J]. Materials & Design, 2021, 209: 110008.

[9] Mehdiyev Z, Felho C. Metal additive manufacturing in automotive industry: A review of applications, advantages, and limitations[J]. Materials Science Forum, 2023, 1103: 49 − 62. doi: 10.4028/p-bg0niN

[10] Tom T, Sreenilayam S P, Brabazon D, et al. Additive manufacturing in the biomedical field-recent research developments[J]. Results in Engineering, 2022, 16: 100661.

[11] Sawant M S, Jain N K and Nikam S H. Theoretical modeling and finite element simulation of dilution in micro-plasma transferred arc additive manufacturing of metallic materials[J]. International Journal of Mechanical Sciences, 2019, 164: 105166.

[12] Schmidt M, Partes K, Rajput R, et al. Monitoring the degree of dilution during directed energy deposition of aluminum bronze and H13 tool steel using optical emission spectroscopy[J]. Journal of Laser Applications, 2023, 35: 042058.

[13] 余焕伟, 叶震, 张志芬, 等. Al-Mg合金钨极气体保护焊接电弧的光谱特征提取方法[J]. 上海交通大学学报, 2013, 47: 1655 − 1660. Yu Hanwei, Ye Zhen, Zhang Zhifen, et al. Spectral feature extraction method for tungsten gas shielded welding arc of Al-Mg alloy[J]. Journal of Shanghai Jiao Tong University, 2013, 47: 1655 − 1660.

[14] 白子键, 李治文, 张志芬, 等. 基于电弧光谱的核电堵管TIG焊接质量在线监测[J]. 焊接学报, 2019, 45(5): 8 − 19. Bai Zijain, Li Zhiwen, Zhang Zhifen, et al. On-line monitoring of TIG welding quality of nuclear power tube plug based on arc spectrum[J]. Acta Weldologica Sinica, 2019, 45(5): 8 − 19.

下载:

下载: