Study on special grain boundary distribution of Σ3n in micron selective laser melting of 316L stainless steel during tensile deformation

-

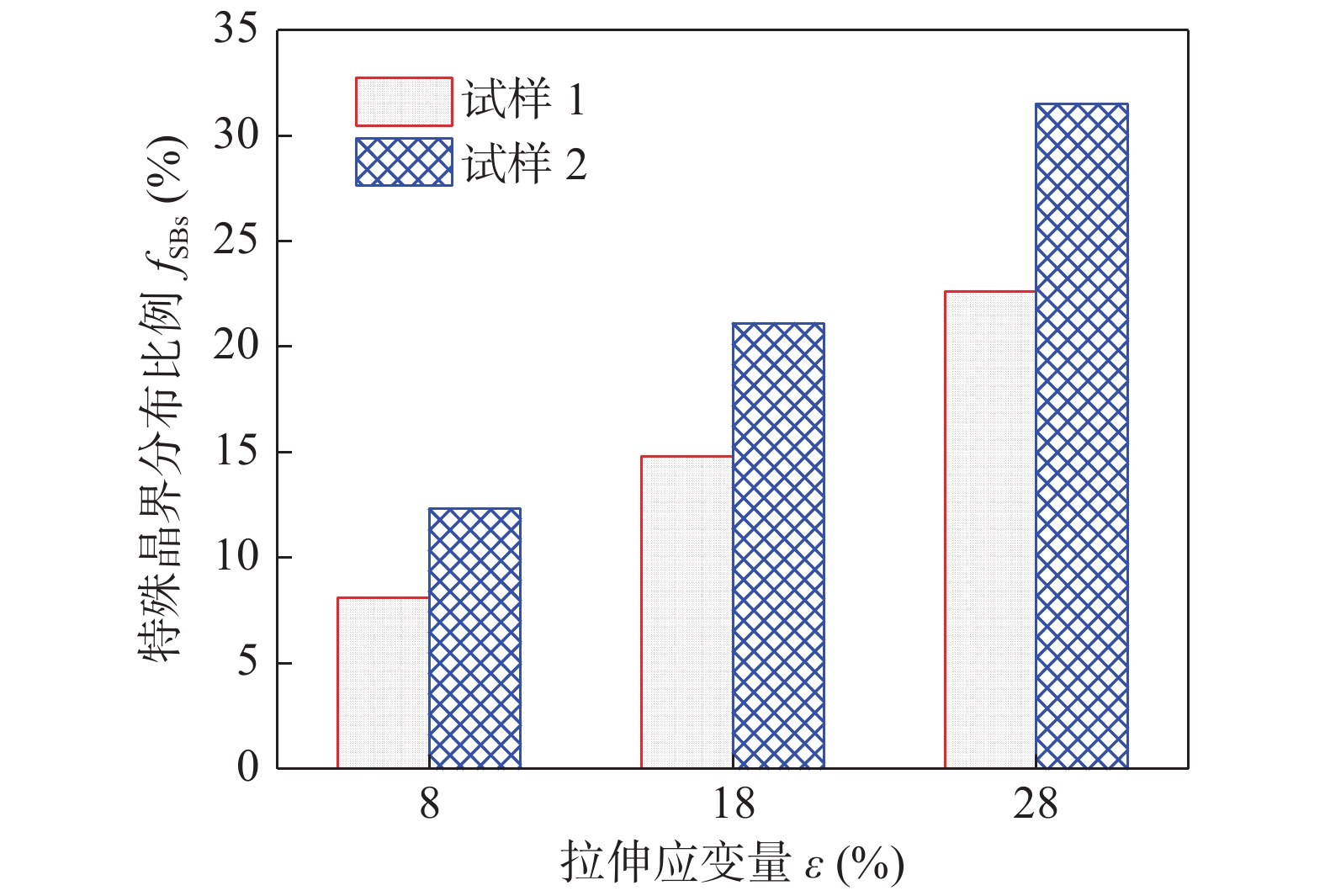

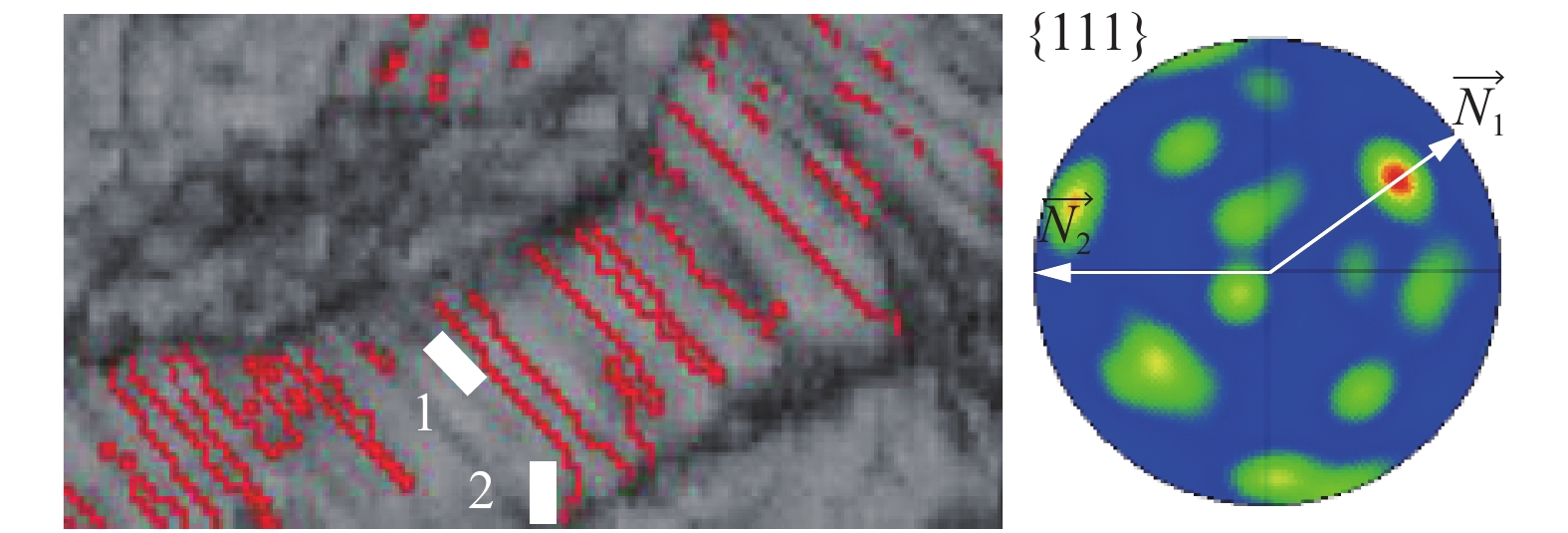

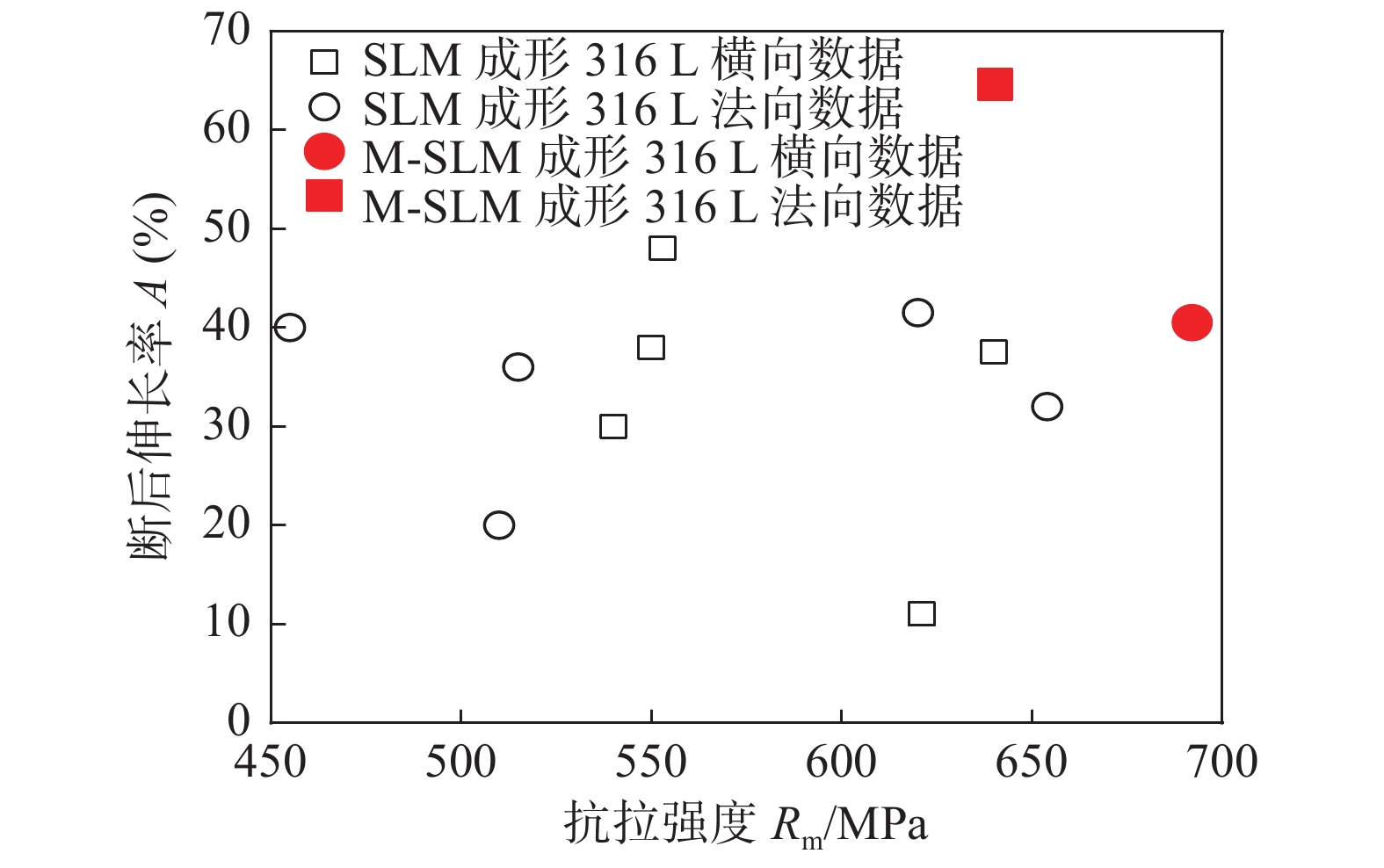

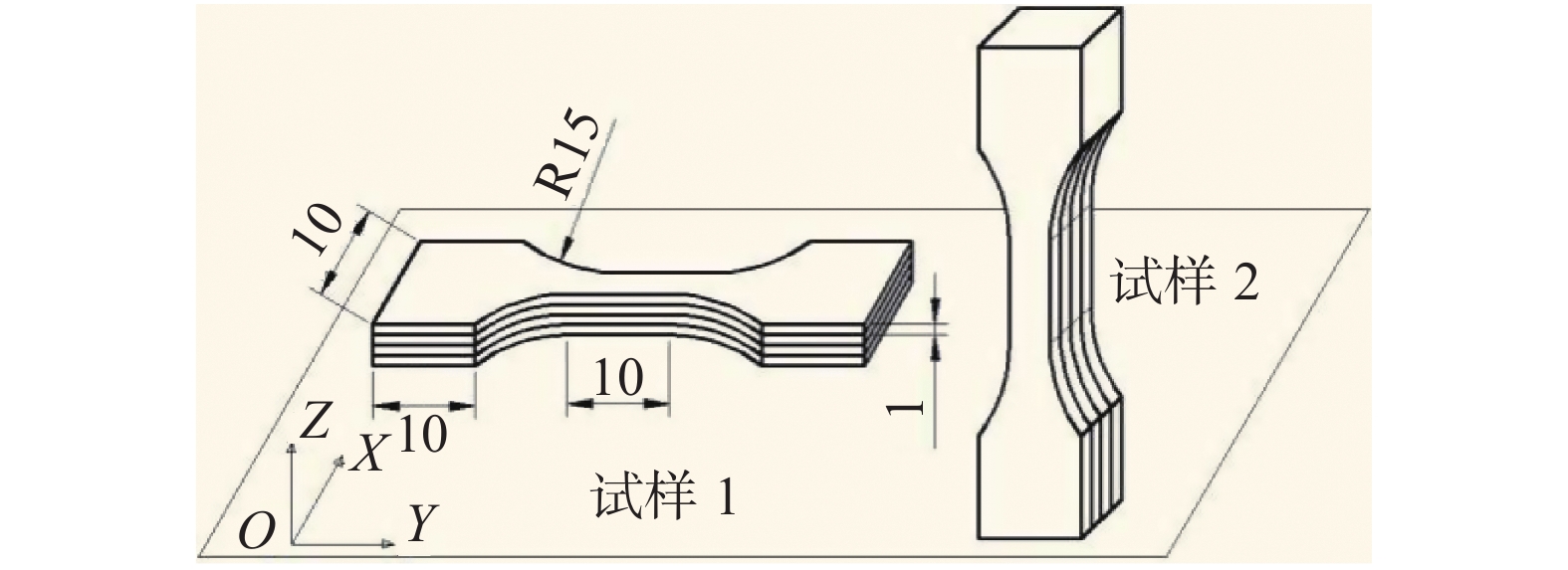

摘要: 利用电子背散射衍射(EBSD)技术研究了微米级选区激光熔化制备316L不锈钢横向拉伸试样和法向拉伸试样在8%、18%和28%拉伸应变下的晶界特征分布. 结果表明,随着拉伸应变的增加,横向试样和法向试样的Σ3晶界比例显著增加,Σ9 + Σ27晶界比例明显降低. Σ3晶界有效隔断了一般大角度晶界的贯通性. 通过微矩形截面法对Σ3特殊晶界的共格/非共格特征进行测定,其中,横向试样在18%拉伸应变下以Σ3IC为主,约占60%,而法向拉伸试样在同样条件下以Σ3C为主,约占73%. 进一步分析指出,非共格Σ3IC晶界的迁移并与Σ9晶界的汇合是促进拉伸应变过程中Σ3特殊晶界比例升高的原因.Abstract: In this paper, electron back scatter diffraction (EBSD) technique was used to study the grain boundary characteristic distribution of 316L stainless steel transverse tensile samples and normal tensile samples prepared by micron selective laser melting under 8%, 18% and 28% tensile strain. The results show that with the increase of tensile strain, the proportion of Σ3 grain boundaries of transverse and normal samples increased significantly, while the proportion of Σ9 and Σ27 grain boundaries decreased significantly. The connectivity of general high angle grain boundary network was effectively interrupted by Σ3 grain boundaries. The coherent/incoherent characteristics of special grain boundaries were measured by micro rectangular section method. When the transverse specimen was under 18% tensile strain, the special grain boundaries were mainly Σ3IC, accounting for about 60%. Under the same conditions, the special grain boundaries of normal tensile specimen were mostly Σ3C, accounting for about 73%. Further analysis pointed out that the migration of incoherent Σ3IC grain boundaries and the interaction with Σ9 grain boundaries were the reasons for the increase of the proportion of Σ3 special grain boundaries during the tensile strain.

-

Keywords:

- selective laser melting /

- 316L /

- plastic deformation /

- Σ3n grain boundary

-

-

表 1 316L不锈钢粉末的化学成分(质量分数, %)

Table 1 Chemical composition of 316L stainless steel powder

C Si Mn S P Cr Ni N O Fe 0.02 0.22 1.58 <0.006 <0.008 18.02 13.82 0.078 <0.015 余量 编号 角度公差θ(°) 晶界特征 编号 角度公差θ(°) 晶界特征 6b-1 + 2 C 6b-16 − 7 IC 6b-2 − 5 IC 6b-17 + 8 IC 6b-3 + 5 IC 6b-18 − 5 IC 6b-4 + 9 IC 6b-19 + 1 C 6b-5 + 1 C 6b-20 + 1 C 6b-6 − 2 C 6b-21 + 5 IC 6b-7 + 5 IC 6b-22 − 4 IC 6b-8 − 6 IC 6b-23 + 7 IC 6b-9 + 4 IC 6b-24 − 6 IC 6b-10 − 2 C 6b-25 − 4 IC 6b-11 0 C 6b-26 + 3 C 6b-12 + 2 C 6b-27 + 1 C 6b-13 − 8 IC 6b-28 − 4 IC 6b-14 + 5 IC 6b-29 0 C 6b-15 − 3 C 6b-30 − 5 IC 编号 角度公差θ(°) 晶界特征 编号 角度公差θ(°) 晶界特征 7b-1 + 2 C 7b-16 0 C 7b-2 − 3 C 7b-17 + 3 C 7b-3 + 1 C 7b-18 − 2 C 7b-4 − 5 IC 7b-19 + 4 IC 7b-5 + 3 C 7b-20 + 4 C 7b-6 − 2 C 7b-21 − 6 IC 7b-7 + 5 IC 7b-22 + 1 C 7b-8 − 3 C 7b-23 + 2 C 7b-9 + 1 C 7b-24 − 2 C 7b-10 + 7 IC 7b-25 − 3 C 7b-11 − 1 C 7b-26 + 1 C 7b-12 0 C 7b-27 + 5 IC 7b-13 + 2 C 7b-28 − 5 IC 7b-14 + 5 IC 7b-29 0 C 7b-15 − 3 C 7b-30 − 1 C -

[1] 兰红波, 李涤尘, 卢秉恒. 微纳尺度3D打印[J]. 中国科学:技术科学, 2015, 45(9): 919 − 940. doi: 10.1360/N092014-00397 Lan Hongbo, Li Dichen, Lu Bingheng. Micro-and nanoscale 3D printing[J]. Scientia Sinica Technologica, 2015, 45(9): 919 − 940. doi: 10.1360/N092014-00397

[2] Liu G, Zhang X F, Chen X L, et al. Additive manufacturing of structural materials[J]. Materials Science and Engineering:R:Reports, 2021, 145: 100596. doi: 10.1016/j.mser.2020.100596

[3] Gunasekaran J, Sevvel P, Solomon I J. Metallic materials fabrication by selective laser melting: A review[J]. Materials Today:Proceedings, 2020, 37: 252 − 256.

[4] 金鑫源, 兰亮, 何博, 等. 选区激光熔化成形金属零件表面粗糙度研究进展[J]. 材料导报, 2021, 35(3): 3168 − 3175. doi: 10.11896/cldb.19100109 Jin Xinyuan, Lan Liang, He Bo, et al. A review on surface roughness of metals parts fabricated by selective laser melting[J]. Materials Reports, 2021, 35(3): 3168 − 3175. doi: 10.11896/cldb.19100109

[5] 张楠, 张海武, 王淼辉. 微米级选区激光熔化316L不锈钢的拉伸力学性能[J]. 金属学报, doi:10.11900/0412.1961.2022.00041 Zhang Nan, Zhang Haiwu, Wang Miaohui. Tensile mechanical properties of micron-selective laser melted 316L stainless steel [J]. Acta Metallurgica Sinica, doi:10.11900/0412.1961.2022.00041

[6] Fu Jin, Qu Shuo, Ding Junhao, et al. Comparison of the microstructure, mechanical properties and distortion of stainless steel 316 L fabricated by micro and conventional laser powder bed fusion[J]. Additive Manufacturing, 2021, 44: 102067. doi: 10.1016/j.addma.2021.102067

[7] 余晨帆, 赵聪聪, 张哲峰, 等. 选区激光熔化316L不锈钢的拉伸性能[J]. 金属学报, 2020, 56(5): 683 − 691. Yu Chenfan, Zhao Congcong, Zhang Zhefeng, et al. Tensile properties of selective laser melted 316L stainless Steel[J]. Acta Metallurgica Sinica, 2020, 56(5): 683 − 691.

[8] Salman O O, Gammer C, Chaubey A K, et al. Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting[J]. Materials Science & Engineering A, 2019, 748: 205 − 212.

[9] Liu L F, Ding Q Q, Zhong Y, et al. Dislocation network in additive manufactured steel breaks strength–ductility trade-off[J]. Materials Today, 2018, 21(4): 354 − 361. doi: 10.1016/j.mattod.2017.11.004

[10] Watanabe T. An approach to grain boundary design of strong and ductile polycrystals[J]. RES Mechanica, 1984, 11(1): 47 − 84.

[11] Shimada M, Kokawa H, Wang Z J, et al. Optimization of grain boundary character distribution for intergranular corrosion resistant 304 stainless steel by twin-induced grain boundary engineering[J]. Acta Materialia, 2002, 50(9): 2331 − 2341. doi: 10.1016/S1359-6454(02)00064-2

[12] Brandon D G. The structure of high-angle grain boundaries[J]. Acta Metallurgica, 1966, 14(11): 1479 − 1484. doi: 10.1016/0001-6160(66)90168-4

[13] 张坤, 王卫国, 方晓英, 等. 不同温度轧制Pb-Ca-Sn-Al合金高温退火后的晶界特征分布[J]. 金属学报, 2008, 44(6): 652 − 658. doi: 10.3321/j.issn:0412-1961.2008.06.003 Zhang Kun, Wang Weiguo, Fang Xiaoying, et al. Grain Boundary character at elevated temperature after rolled at different temperatures[J]. Acta Metallurgica Sinica[J], 2008, 44(6): 652 − 658. doi: 10.3321/j.issn:0412-1961.2008.06.003

[14] 王卫国, 周邦新, 冯柳, 等. 冷轧变形Pb-Ca-Sn-Al合金在回复和再结晶过程中的晶界特征分布[J]. 金属学报, 2006, 42(7): 715 − 721. doi: 10.3321/j.issn:0412-1961.2006.07.008 Wang Weiguo, Zhou Bangxin, Feng Liu, et al. Grain boundary character distributions (GBCD) of cold-rolled Pb-Ca-Sn-Al alloy[J]. Acta Metallurgica Sinica, 2006, 42(7): 715 − 721. doi: 10.3321/j.issn:0412-1961.2006.07.008

[15] Reed B W, Kumar M. Mathematical methods for analyzing highly-twinned grain boundary networks[J]. Scripta Materialia, 2006, 54(06): 1029 − 1033. doi: 10.1016/j.scriptamat.2005.11.045

[16] Kumar M, Schwartz A J, King W E. Microstructural evolution during grain boundary engineering of low to medium stacking fault energy FCC materials[J]. Acta Materialia, 2002, 50(10): 2599 − 2612. doi: 10.1016/S1359-6454(02)00090-3

[17] Randle V, Hu Y. The role of vicinal Σ3 boundaries and Σ9 boundaries in grain boundary engineering[J]. Journal of Materials Science, 2005, 40: 3243 − 3246. doi: 10.1007/s10853-005-2692-2

[18] 方晓英, 王卫国, 郭红, 等. 304不锈钢冷轧退火∑3 n特殊晶界分布研究[J]. 金属学报, 2007, 43(12): 1239 − 1244. Fang Xiaoying, Wang Weiguo, Guo Hong, et al. ∑3n special boundary distributions of the cold-rolled and annealed 304 stainless steel[J]. Acta Metallurgica Sinica, 2007, 43(12): 1239 − 1244.

[19] 祁斌, 刘玉德, 石文天, 等. 脉冲式激光选区熔化成形搭接率的研究[J]. 激光技术, 2018, 42(3): 311 − 317. doi: 10.7510/jgjs.issn.1001-3806.2018.03.005 Qi Bin, Liu Yude, Shi Wentian, et al. Study on overlap ratio of pulse laser selective melting forming[J]. Laser Technology, 2018, 42(3): 311 − 317. doi: 10.7510/jgjs.issn.1001-3806.2018.03.005

[20] 马英怡, 刘玉德, 石文天, 等. 扫描速度对选区激光熔化316L不锈钢粉末成形缺陷及性能的影响[J]. 激光与光电子学进展, 2019, 56(10): 210 − 219. Ma Yingyi, Liu Yude, Shi Wentian, et al. Effect of scanning speed on forming defects and Properties of Selective Laser Melted 316L Stainless Steel Powder[J]. Laser & Optoelectronics Progress, 2019, 56(10): 210 − 219.

[21] 石文天, 王朋, 刘玉德, 等. 选区激光熔化成形316L表面质量及工艺试验研究[J]. 表面技术, 2019, 48(3): 257 − 267. doi: 10.16490/j.cnki.issn.1001-3660.2019.03.035 Shi Wentian, Wang Peng, Liu Yude, et al. Experimental Study on Surface Quality and Process of Selective Laser Melting Forming 316L[J]. Surface Technology, 2019, 48(3): 257 − 267. doi: 10.16490/j.cnki.issn.1001-3660.2019.03.035

[22] Afkhami S, Dabiri M, Piili H, et al. Effects of manufacturing parameters and mechanical post-processing on stainless steel 316L processed by laser powder bed fusion[J]. Materials Science & Engineering A, 2021, 802: 140660.

[23] Kumar P, Jayaraj R, Suryawanshi J, et al. Fatigue strength of additively manufactured 316L austenitic stainless steel[J]. Acta Materialia, 2020, 199: 225 − 239. doi: 10.1016/j.actamat.2020.08.033

-

期刊类型引用(1)

1. 王文安. 铝合金焊接头的软化及改善措施分析. 中国设备工程. 2021(12): 73-74 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: