Effect of long term high temperature aging on CGHAZ microstructure of T23 water wall welded joint

-

摘要:

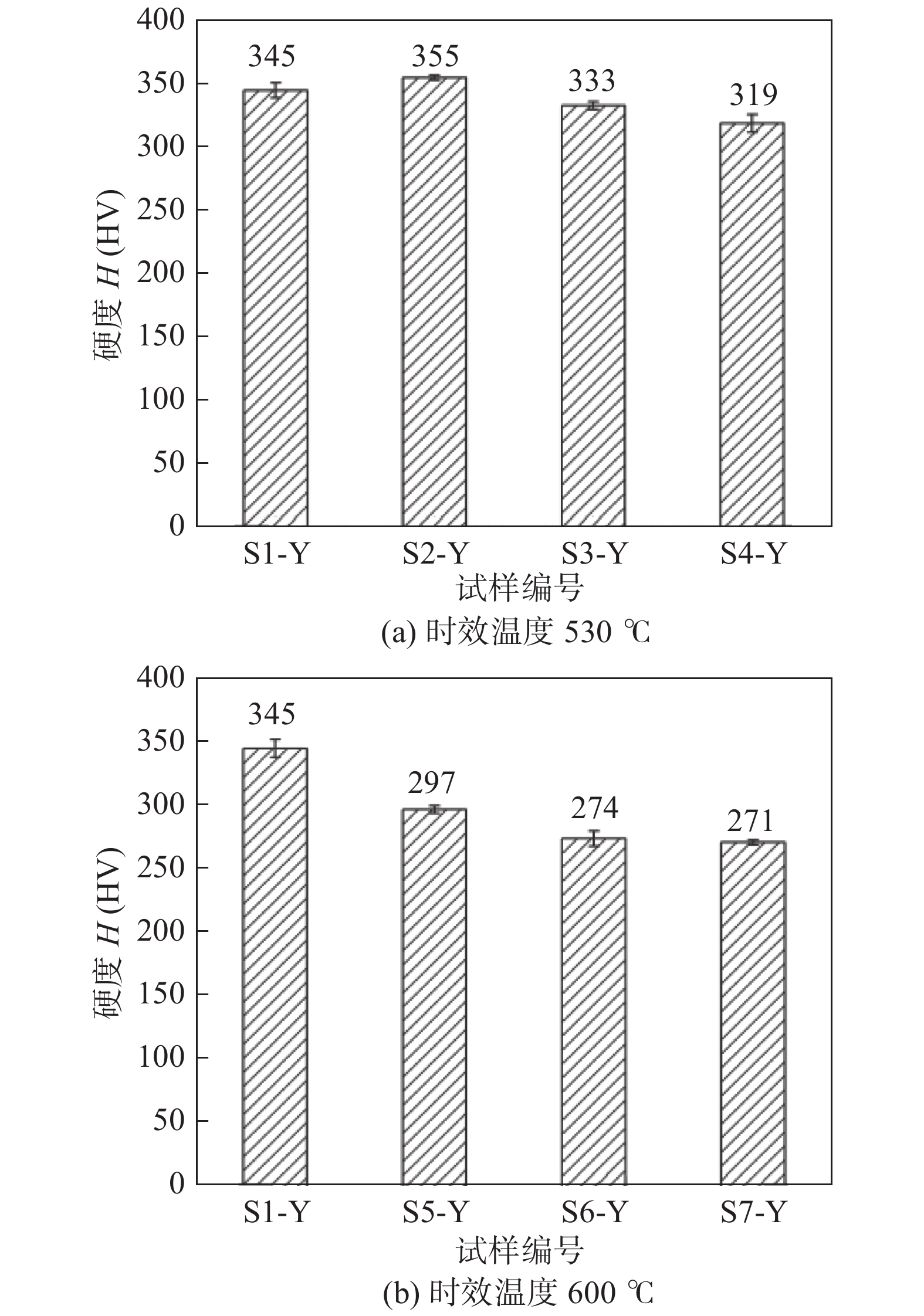

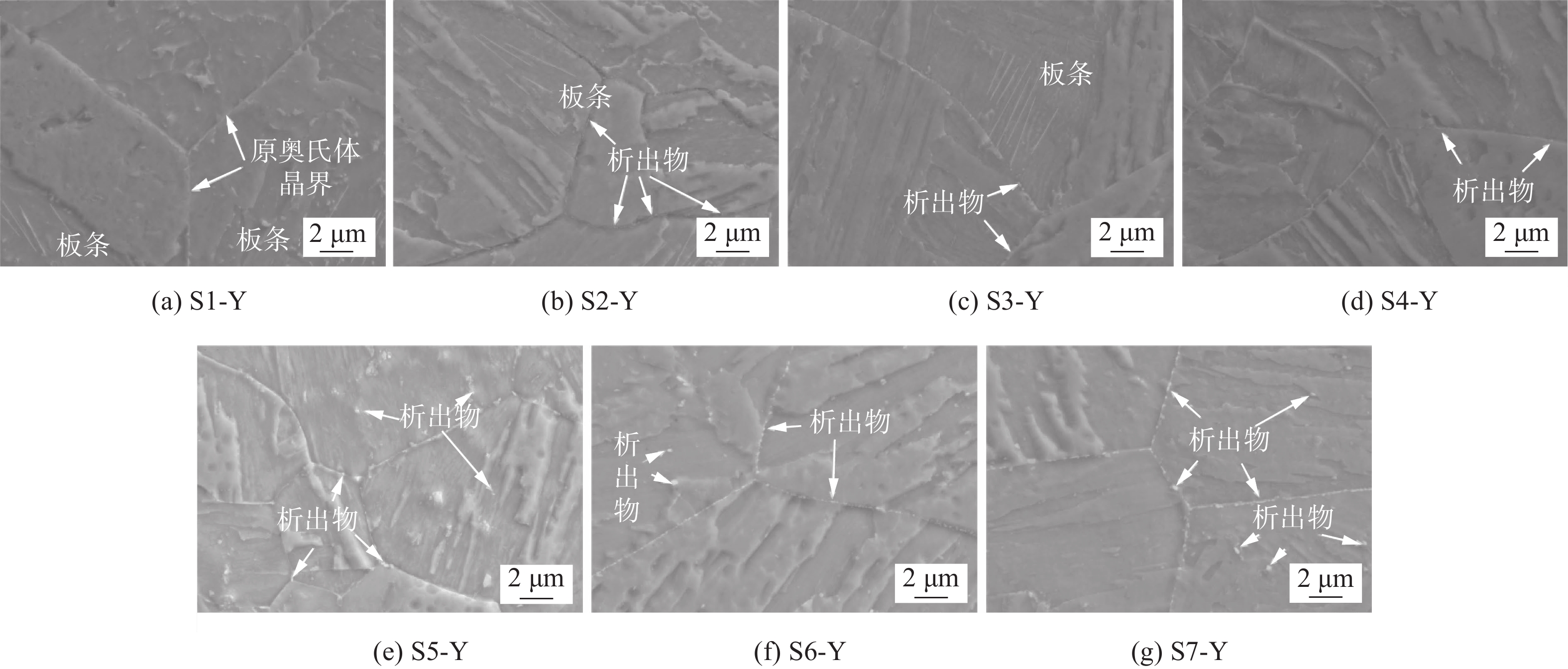

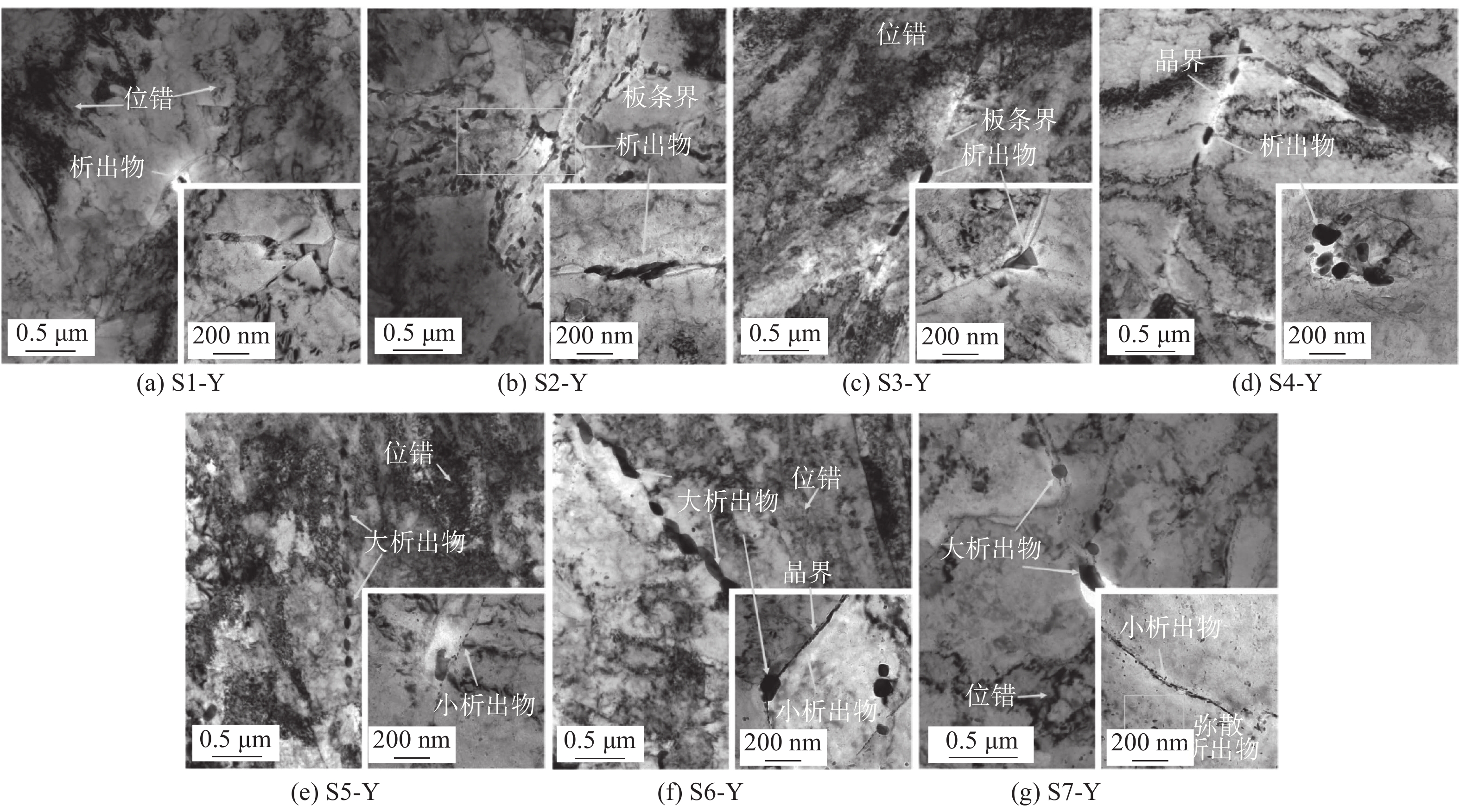

通过高温时效方法分析了焊后未热处理T23水冷壁管焊接接头粗晶热影响区(coarse grained heat affected zone,CGHAZ)在服役过程中形成再热裂纹的微观机理,揭示了工程中未热处理T23水冷壁接头在机组启机后,短期运行容易发生开裂泄漏的内在原因. 采用材料表征手段对未时效和高温时效处理后的水冷壁焊接接头CGHAZ硬度、微观组织、析出物物相等进行系统分析. 结果表明,在530 ℃时效100 h后,CGHAZ硬度出现由晶内弥散强化导致的二次硬化现象,随着时效(运行)时间增加,CGHAZ硬度逐渐降低,但时效1000 h后,CGHAZ硬度仍有319 HV高于标准要求;在600 ℃温度下,随着时效时间的增加,CGHAZ硬度随之降低,组织回复、再结晶、马氏体板条宽化、位错密度降低、C元素及合金元素从基体析出等因素导致的CGHAZ硬度降低作用高于MX碳化物在晶内弥散析出导致的硬度升高,M23C6型碳(氮)化物在晶界、亚晶界逐渐析出和长大.

Abstract:The micro-mechanism of reheat crack formation in coarse grain heat affected zone (CGHAZ) of welded joint of T23 water wall tube without heat treatment after welding was analyzed by high temperature aging method.It reveals the internal reason that T23 water wall joint without heat treatment is easy to crack and leak in short-term operation after unit startup.The hardness, microstructure and precipitates of welded joints of water wall after unaged and high temperature aging treatment were systematically analyzed by means of material characterization.The results show that after aging at 530 ℃ for 100 h, the hardness of CGHAZ appears secondary hardening caused by intragranular dispersion strengthening. With the increase of aging (running) time, the hardness of CGHAZ gradually decreases, but after aging for 1000 h, the hardness of CGHAZ is still 319 HV, which is higher than the standard requirement.After aging at 600 ℃, the hardness of CGHAZ decreases with the increase of aging time. The hardness of CGHAZ decreased due to the recovery of microstructure,recrystallization, broadening of martensite lath, reduction of dislocation density, and precipitation of C and alloy elements from the matrix, which is higher than the hardness increased due to dispersion and precipitation of MX carbide in the grain. M23C6 carbide gradually precipitates and grows at grain boundaries and subgrain boundaries.

-

Keywords:

- high temperature aging /

- T23 steel /

- water cooling wall /

- CGHAZ /

- reheat crack

-

-

表 1 焊接工艺参数

Table 1 Welding parameters

预热温度

T1/℃层间温度

T2/℃焊接电流

I/A电弧电压

U/V150 ℃ 200 ~ 300 100 ~130 10 ~14 -

[1] 周任远, 朱丽慧, 李世贤, 等. T23钢再热裂纹敏感性的改善及其组织[J]. 钢铁, 2020, 55(3): 80 − 86. Zhou Renyuan, Zhu Lihui, Li Shixian, et al. Improvement of reheat crack sensitivity and microstructure of T23 steel[J]. Iron and Steel, 2020, 55(3): 80 − 86.

[2] Li Y, Wang X, Wang J Q, et al. Stress-relief cracking mechanism in simulated coarse-grained heat-affected zone of T23 steel[J]. Journal of Materials Processing Technology, 2019, 266: 73 − 81.

[3] 牛锐锋, 曹怡姗, 朱一乔, 等. 国产T23钢再热裂纹敏感性试验研究[J]. 兵器材料科学与工程, 2014, 37(5): 36 − 39. Niu Ruifeng, Cao Yishan, Zhu Yiqiao, et al. Experimental study on reheat crack sensitivity of domestic T23 steel[J]. Ordnance Material Science and Engineering, 2014, 37(5): 36 − 39.

[4] 于在松, 聂铭, 侯淑芳, 等. HCM2S(T23)钢中的碳化物及其演化规律[J]. 热力发电, 2012, 41(9): 1 − 6. Yu Zaisong, Nie Ming, Hou Shufang, et al. Carbides in HCM2S(T23) steel and its evolution law[J]. Thermal Power Generation, 2012, 41(9): 1 − 6.

[5] Zieliński A, Golański G, Sroka M, et al. Microstructure and mechanical properties of the T23 steel after long-term ageing at elevated temperature[J]. Materials at High Temperatures, 2016, 33: 154 − 163. doi: 10.1080/09603409.2016.1139306

[6] Miyata K, Igarashi M, Sawaragi Y. Effect of trace elements on creep properties of 0.06C-2.25Cr-1.6W-0.1Mo-0.25V-0.05Nb Steel[J]. ISIJ International, 1999, 39(9): 947 − 954. doi: 10.2355/isijinternational.39.947

[7] Morito S, Yoshida H, Maki T, et al. Effect of block size on the strength of lath martensite in low carbon steels[J]. Materials Science & Engineering, A, 2006, 438: 237 − 240.

[8] 李世贤, 朱丽慧, 周任远, 等. T23低合金耐热钢再热裂纹敏感性研究[J]. 上海金属, 2020, 42(3): 7 − 11. Li Shixian, Zhu Lihui, Zhou Renyuan et al. Study on reheat crack sensitivity of T23 low alloy heat resistant steel[J]. Shanghai Metal, 2020, 42(3): 7 − 11.

[9] 周任远, 朱丽慧, 柯志刚, 等. 回火温度对改进型T23钢冲击吸收功的影响[J]. 钢铁, 2021, 56(3): 51 − 57. Zhou Renyuan, Zhu Lihui, Ke Zhigang et al. Influence of tempering temperature on impact absorption energy of improved T23 steel[J]. Iron and Steel, 2021, 56(3): 51 − 57.

[10] 王学, 李勇, 王家庆, 等. 高温时效对T23钢粗晶热影响区显微组织及再热裂纹敏感性的影响[J]. 金属学报, 2021, 57(6): 736 − 748. Wang Xue, Li Yong, Wang Jiaqing, et al. Effect of high temperature aging on the microstructure and reheat crack susceptibility of T23 steel coarse-grained heat-affected zone[J]. Acta Metallurgica Sinica, 2021, 57(6): 736 − 748.

[11] 金玉静. T23钢粗晶热影响区再热裂纹敏感性研究[D]. 上海: 上海交通大学, 2015. Jin Yujing. Study on reheat crack sensitivity of T23 steel coarse grain heat affected zone [D]. Shanghai: Shanghai Jiaotong University, 2015.

[12] 金玉静, 周巍. 改良型T23钢CGHAZ再热裂纹开裂特征[J]. 金属热处理, 2017, 42(11): 191 − 197. Jin Yujing, Zhou Wei. CGHAZ reheat cracking characteristics of improved T23 steel[J]. Metal Heat Treatment, 2017, 42(11): 191 − 197.

[13] 周任远, 朱丽慧, 李世贤, 等. 改进型T23钢的再热裂纹敏感性[J]. 金属热处理, 2020, 45(1): 20 − 25. Zhou Renyuan, Zhu Lihui, Li Shixian. et al. Reheat crack susceptibility of improved T23 steel[J]. Metal Heat Treatment, 2020, 45(1): 20 − 25.

[14] 柯志刚, 朱丽慧, 周任远, 等. 改进型T23钢冲击韧度的改善[J]. 上海金属, 2022, 44(4): 49 − 54. Ke Zhigang, Zhu Lihui, Zhou Renyuan, et al. Improvement of impact toughness of improved T23 steel[J]. Shanghai Metal, 2022, 44(4): 49 − 54.

下载:

下载: