Mechanism of heat treatment temperature on microstructure and properties in deposited metal of 1000 MPa grade high strength steel

-

摘要:

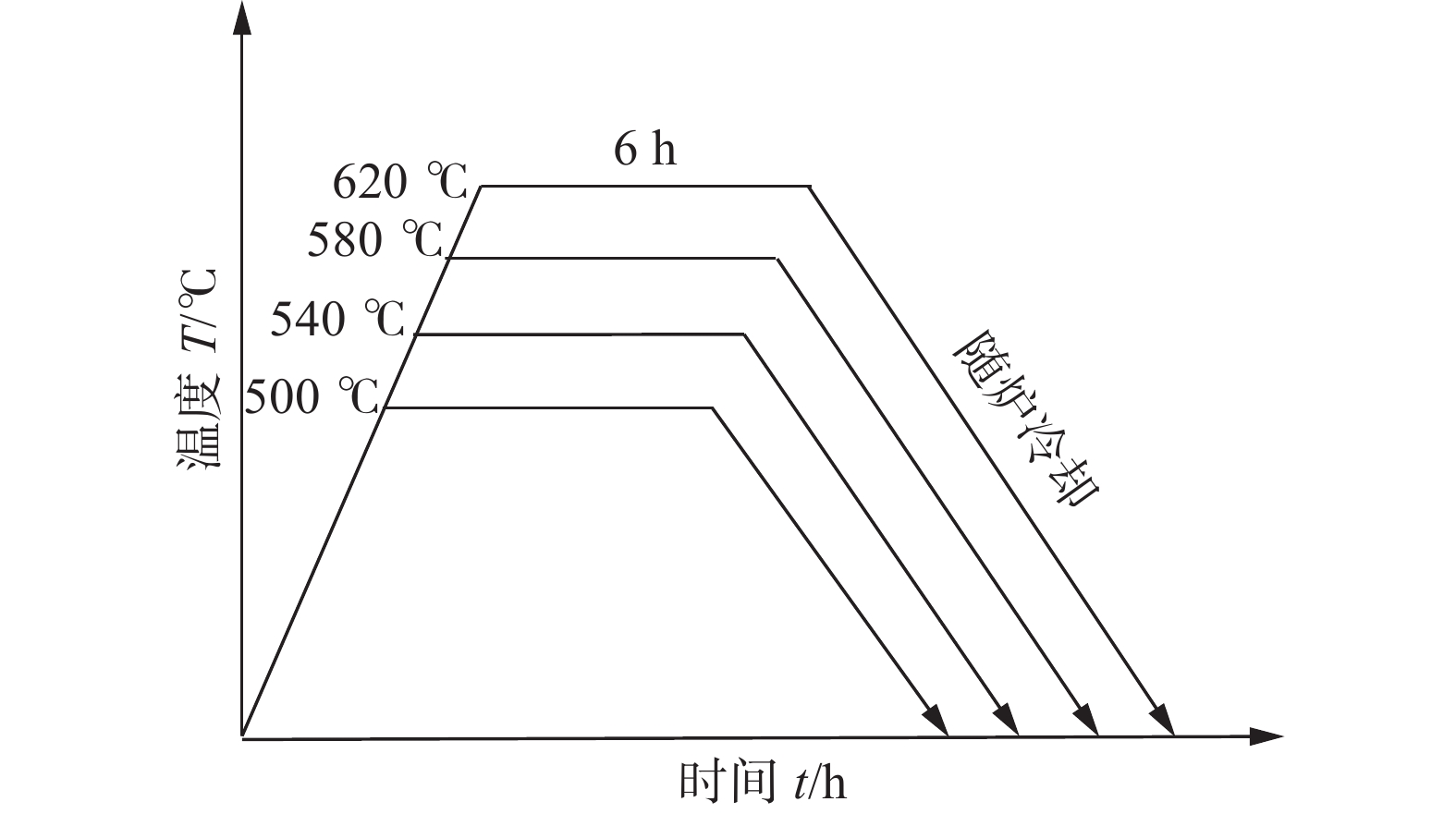

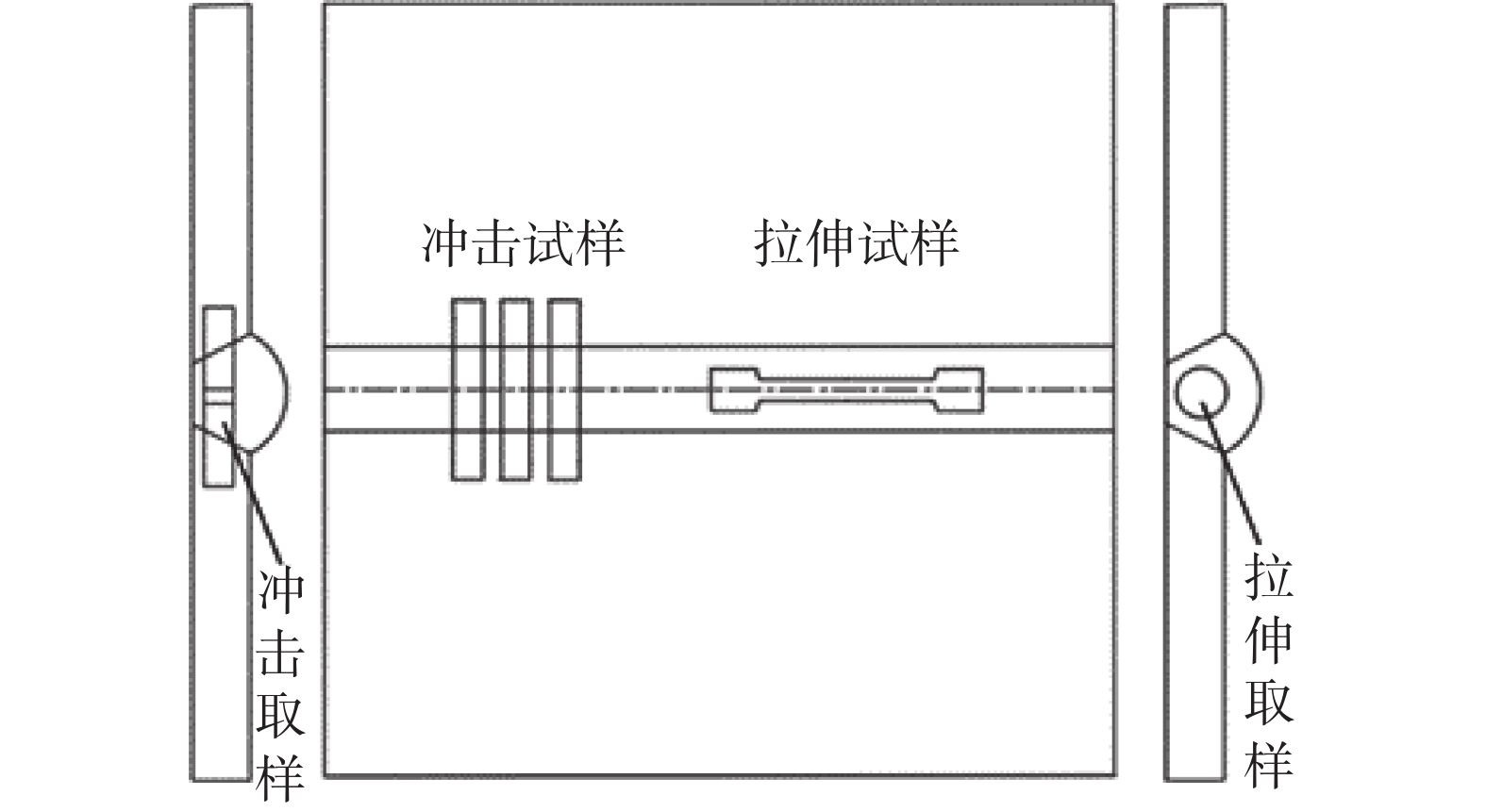

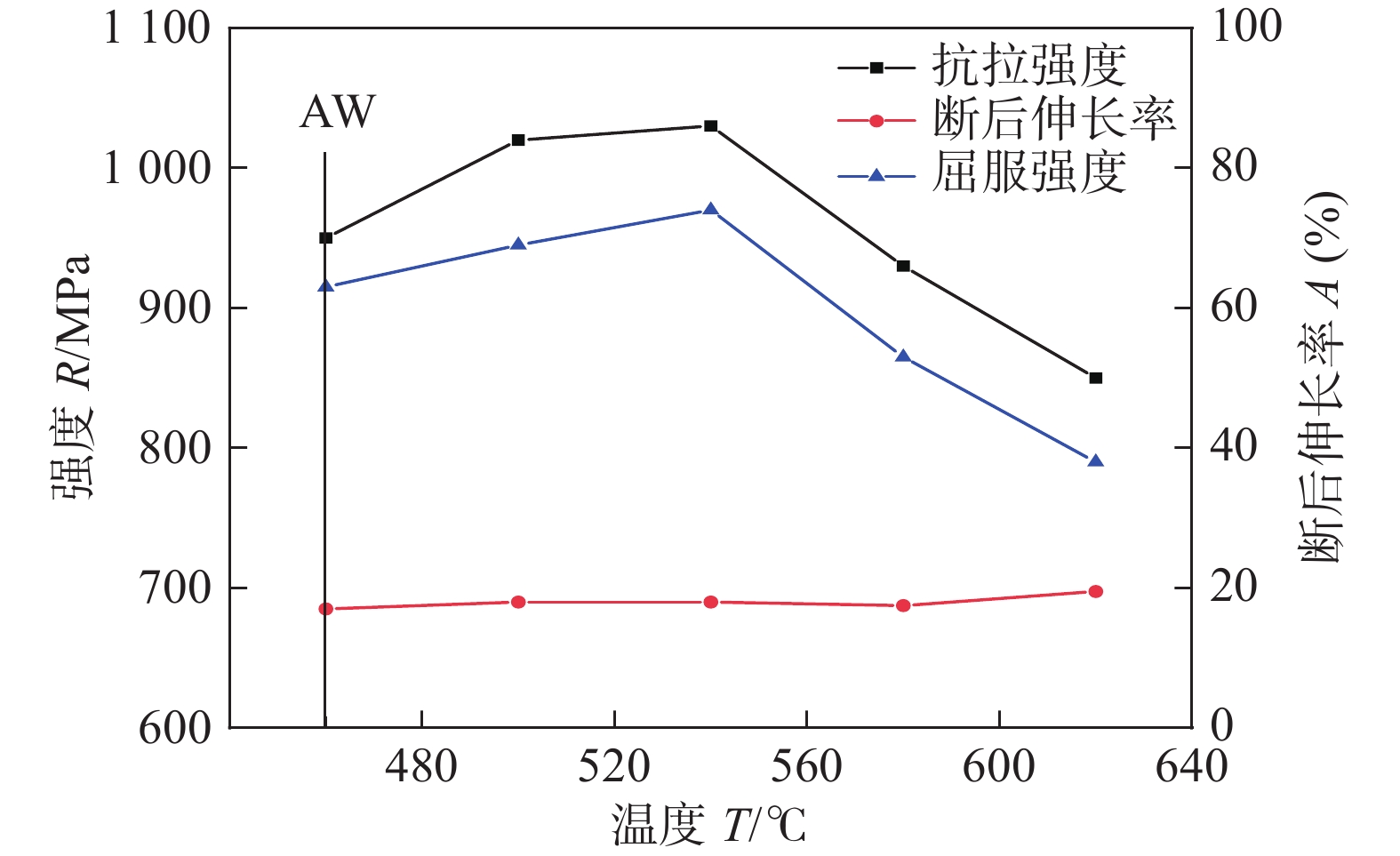

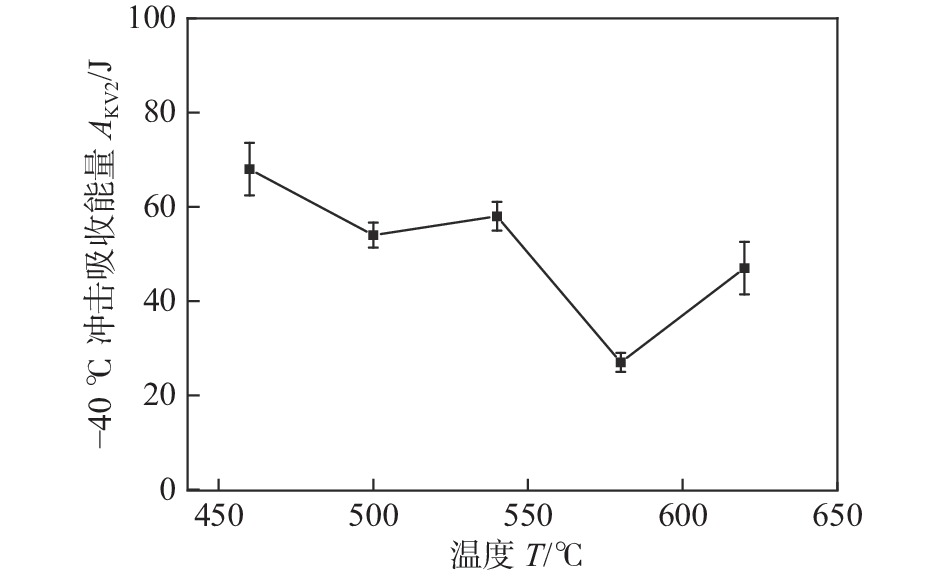

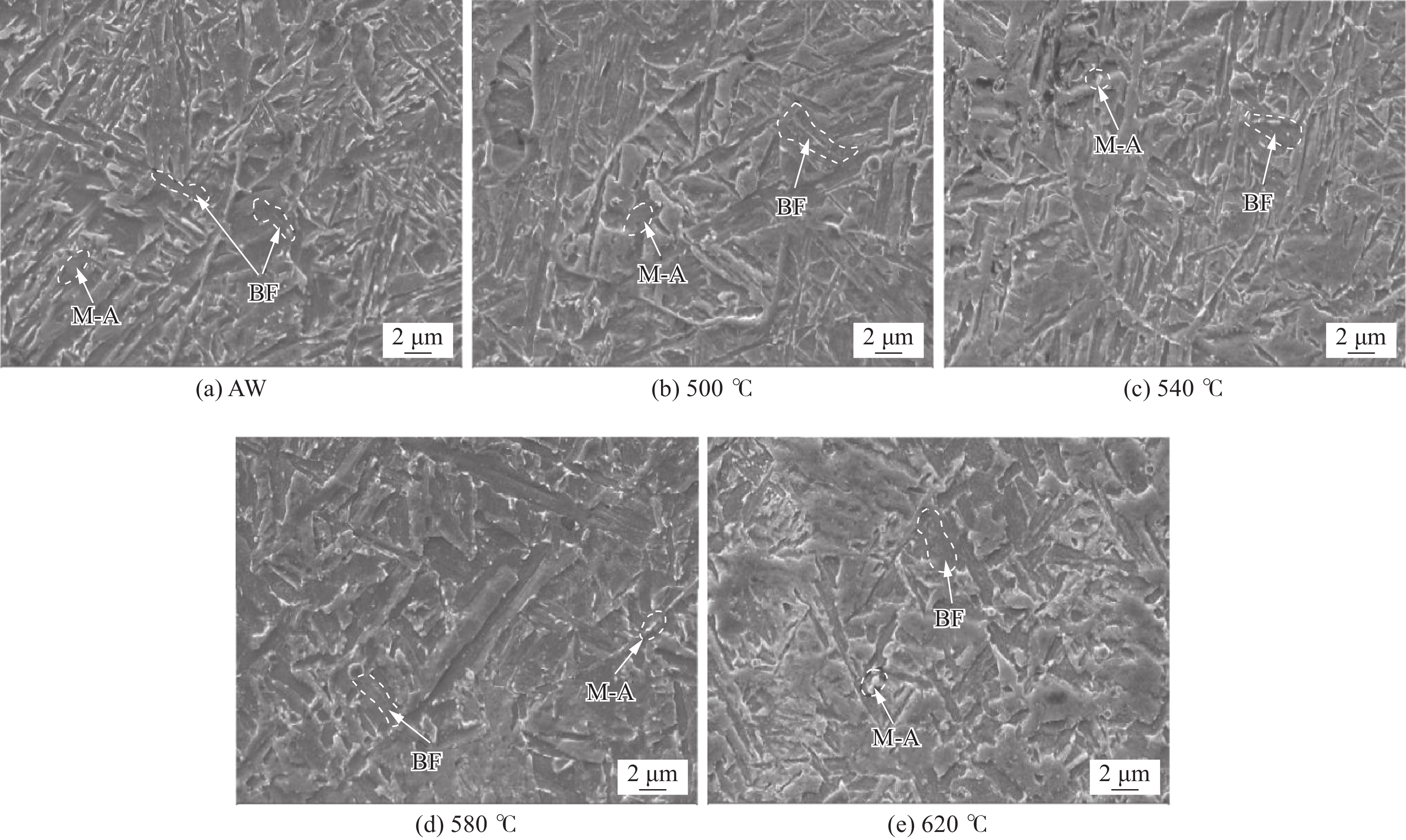

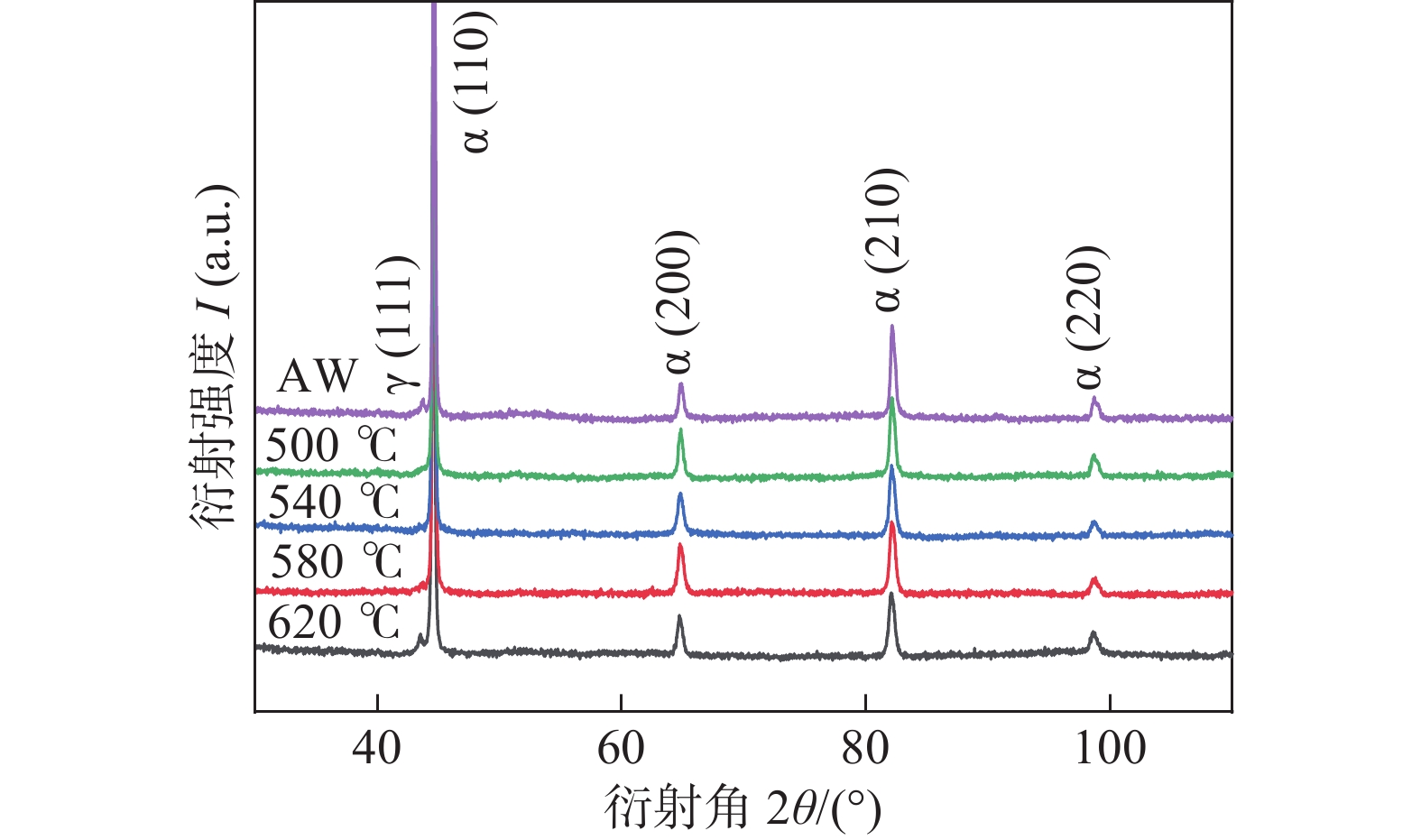

采用丝级埋弧焊方法制备

1000 MPa级高强钢熔敷金属,利用SEM、EBSD、XRD和TEM等微观分析方法研究了焊后热处理温度(500 ~ 620 ℃)对1000 MPa级高强钢熔敷金属组织演变的影响,并通过拉伸和冲击试验评估其力学性能. 结果表明,随着热处理温度升高,1000 MPa级高强钢熔敷金属抗拉强度和屈服强度对比焊态(as welded,AW)先升高后降低,熔敷金属热处理后比AW韧性降低.1000 MPa级高强钢熔敷金属在540 ℃热处理时获得较好强韧匹配效果,抗拉强度1030 MPa,屈服强度970 MPa,−40 ℃冲击韧性58 J.1000 MPa级高强钢熔敷金属在500 ~ 620 ℃热处理过程中M/A组元中的A逐渐分解为碳化物和铁素体,M在620 ℃热处理时生成逆转变奥氏体并保留至室温. 碳化物对于位错具有钉扎作用,但随热处理温度升高碳化物对位错的钉扎作用减弱,位错通过滑移和攀移不断减少. 熔敷金属析出的碳化物对位错的钉扎作用强于位错滑移的软化作用时,熔敷金属强度提高,碳化物对位错的钉扎作用弱于位错滑移的软化作用时基体组织软化,熔敷金属强度降低. 析出的碳化物导致位错塞积,产生的应力集中区域成为裂纹源,使热处理态熔敷金属韧性低于AW.-

关键词:

-

1000 MPa级高强钢 / - 熔敷金属 /

- 焊后热处理 /

- 埋弧焊 /

- 碳化物

Abstract:1000 MPa high strength steel deposited metal is prepared by wire submerged arc welding. The effect of post-weld heat treatment temperature (500 ~ 620 ℃) on the microstructural evolution in deposited metal of1000 MPa grade high strength steels has been investigated using microanalytical methods such as SEM, EBSD, XRD and TEM. Evaluate their mechanical properties by tensile and impact tests. The results show that with the increase of heat treatment temperature, 1000MPa grade high-strength steel deposited metal tensile strength and yield strength of heat-treated state than the AW first increase and then reduce. The heat-treated state deposited metal toughness is lower than the AW. The strength and toughness matching effect of1000 MPa grade high strength steel deposited metal is good at 540 ℃ heat treatment, the tensile strength is1030 MPa, the yield strength is 970 MPa, and the impact toughness is 58 J at −40 ℃.1000 MPa grade high strength steel fused metal in 500 ~ 620 ℃ heat treatment process in the M/A group element A gradually decomposed into carbides and ferrite. During heat treatment at 620 ℃, reverse austenite is generated and retained to room temperature. Carbide for dislocations has a pinning effect, but with the increase of heat treatment temperature carbide on the dislocation of the pinning effect is weakened, dislocations through the slip and climb constantly reduced. Deposited metal precipitation of carbide on the dislocation pinning effect is stronger than the softening effect of dislocation slip, the deposited metal strength, carbides on the dislocation pinning effect is weaker than the softening effect of dislocation slip when the matrix microstructure softens, the deposited metal strength is reduced. The precipitated carbide leads to dislocation plugging, and the stress concentration area becomes the crack source, which makes the toughness of the heat-treated deposited metal lower than the AW. -

-

0. 序言

超窄间隙激光填丝焊具有施焊可达性好,热输入小,焊接效率高的特点,适用于高强钢厚板的焊接[1-3]. 通过Ultra-NGLW不仅可以解决复杂焊接结构施焊可达性问题,同时对控制焊接接头的热输入,降低接头的残余应力应变都有着极大帮助[4-5],但是,影响Ultra-NGLW接头疲劳性能的因素,以及接头疲劳断裂的形式还需要进一步研究. 在有关学者的研究中提到,由于激光填丝焊接头的微观组织复杂,且易产生脆硬性的马氏体组织,不利于激光填丝焊接头的疲劳性能[6],也有学者指出,机械振动可以改善激光填丝焊接头焊缝中的柱状晶,增加树枝晶和等轴晶,提高焊缝硬度,从而提高接头的疲劳性能[7]. 石向阳[8]在激光填丝焊接头疲劳性能的研究结果中指出,激光填丝焊接头疲劳试验时应力会在气孔处集中,裂纹更加容易萌生,形成了疲劳断裂的裂纹源;郭紫威等人[9]为了优化高强钢激光填丝焊,利用高速摄像研究了激光功率,送丝速度和离焦量等工艺参数对焊接过程稳定性的影响,通过减小激光功率或增加送丝速度使焊缝气孔率降低,并调节熔滴过渡模式为液桥过渡,使激光填丝焊的稳定性得到改善,得到气孔率低、接头性能优异的激光填丝焊接接头. Gadallah等人[10]发现当考虑焊接残余应力时,厚度对裂纹扩展速率和疲劳寿命有显著影响,与在焊根处产生的裂纹扩展相比,在焊缝表面及其附近获得了较大的裂纹驱动作用力,随着厚度的增加,沿着裂纹尖端形成了可变的分布.

B950CF贝氏体钢主要用于水轮机、压力容器等,其服役条件会长时间经历疲劳载荷,有必要对其焊接接头的疲劳性能进行掌握和分析. 文中针对B950CF贝氏体高强钢超窄间隙激光焊接头,对比不同填丝深度接头的S-N曲线,并研究失效疲劳断口和断口处的金相组织,结合B950CF贝氏体高强钢超窄间隙激光焊工艺特点,指出Ultra-NGLW接头疲劳断裂主要原因,并分析影响疲劳性能的关键因素.

1. 试验方法

B950CF是一种贝氏体高强钢,主要用于水轮机、压力容器等,焊丝为专门匹配B950CF高强钢的XY-ER100实芯焊丝,直径为1.2 mm[11],B950CF贝氏体钢和XY-ER100实芯焊丝的化学成分见表1,基本力学性能见表2.

表 1 母材和焊丝的主要化学成分(质量分数,%)Table 1. Elements of experimental material and wire材料 C Si Mn Cr Ni Cu Ti Al B950CF 0.128 0.055 1.06 0.523 1.88 0.296 0.008 0.047 XY-ER100 0.107 0.500 1.95 0.584 2.99 0.006 0.088 0.012 表 2 母材及焊丝熔敷金属拉伸性能Table 2. Tensile properties of the base metals and welding wire材料 屈服强度

ReL/MPa抗拉强度

Rm/MPa断后延伸率

A(%)B950CF 934 975 18 XY-ER100 912 1 050 16 Ultra-NGLW疲劳试验件的焊接采用Trump-10002的10 kW激光器和Fronius自动送丝机组成的自动激光焊接系统完成,保护气为80%Ar + 20%CO2的混合气,焊前90 ℃ 预热的连续施焊工艺,工艺参数见表3.

表 3 超窄间隙激光填丝焊接工艺参数Table 3. Parameter of the Ultra-NGLW焊接层道 激光功率

P/kW焊接速度

v/(m·min−1)送丝速度

vf /(m·min−1)离焦量

H/mm单激光打底 3.0 ~ 6.5 0.72 — 0 激光填丝盖面 4.0 0.36 4.2 15 通过激光打底焊接和连续激光填丝焊接,得到优质的B950CF高强钢超窄间隙激光填丝焊接接头,如图1所示. 图1(a)为接头的纵剖面,可以看出在焊接过程中,每道焊缝的熔深稳定,焊道间的重熔部分没有出现较大波动,焊缝表面成形良好见图1(b),最终焊成的接头焊缝没有出现明显的缺陷见图1(c).

采用高频疲劳试验机对4种10 mm厚度不同激光打底深度的高强钢超窄间隙激光填丝焊接头做室温(20 ℃)高频疲劳试验,应力循环比R = 0.1的拉-拉疲劳试验. 不同钝边的高强钢激光填丝焊接头激光填丝深度-激光打底厚度分别为8 mm-2 mm,5 mm-5 mm,3 mm-7 mm,0 mm-10 mm,各式疲劳试样的坡口如图2所示.

采用升降法确定试件的疲劳极限,在试件经历过1 × 107次循环后,如果试件未有裂纹和失效,则视为试件在该应力级下通过试验,并在下一组试验时应力级增加15 MPa,反之则表示试样未通过试验,下一组试验应力级则减少15 MPa,直到确定试样的疲劳极限为止.

同时,通过高应力级的接头疲劳性能试验,按20 MPa的应力级递减,确定高应力级状态下各式接头的疲劳循环周次,结合由升降法得到的疲劳极限,绘制各式接头的S-N曲线图.

2. 疲劳试验结果

2.1 单激光焊接头S-N曲线

采用超窄间隙激光填丝焊的激光打底焊工艺,焊接厚度为10 mm的单激光焊接接头,用以制成疲劳试件. 通过升降法可以确定试样的疲劳极限,结合接头试样高应力级的疲劳试验数据,绘制接头的S-N曲线.

将疲劳试验数据制成疲劳试验升降图,如图3所示. 图中的“○”符号表示在该应力级的条件下,疲劳试件做满1 × 107循环次数而试件没有出现裂纹和发生断裂,图中的“ × ”符号表示在该应力级条件下的疲劳试件,未能做满1 × 107循环次数就发生了断裂.

根据升降图,将相邻应力水平的数据点配成对子,取试件的子样平均疲劳应力级σri作为疲劳中值的估计量,疲劳强度等于以ni为权的σri加权平均值. 在计算得到了激光焊接接头的疲劳强度后,通过计算标准差S可以计算求得变异系数cv,用以验证疲劳强度的置信度和误差范围见表4.

表 4 置信度r = 95%和误差δmax = 5%时的最少观察个数Table 4. Minimum observation numbers of Confidence 95% and Error 5%变异系数cv范围 最少试验观测值个数 <0.020 1 3 0.020 1 ~ 0.031 4 4 0.031 4 ~ 0.040 3 5 0.040 3 ~ 0.047 6 6 0.047 6 ~ 0.054 1 7 0.054 1 ~ 0.059 8 8 0.059 8 ~ 0.065 0 9 0.065 0 ~ 0.069 9 10 0.069 9 ~ 0.074 4 11 …… …… $$ {\sigma _{\mathrm{r}}} = \frac{1}{{{n_{\mathrm{p}}}}}\sum {{\sigma _{{\mathrm{ri}}}}{n_{\mathrm{i}}}} $$ (1) $$ S = \sqrt {\frac{1}{{{n_{\mathrm{p}}} - 1}}\sum {\left[ {{{\left( {{\sigma _{{\mathrm{ri}}}} - {\sigma _{\mathrm{r}}}} \right)}^2}{n_{\mathrm{i}}}} \right]} } $$ (2) $$ {c_v} = \frac{S}{{{\sigma _{\mathrm{r}}}}} $$ (3) 式中:σr为试件疲劳强度;np为升降应力配对对子总数. 通过计算得到激光焊接接头的σr疲劳强度为337.5 MPa,标准差S为8.66 MPa,变异系数cv为0.025 7.

由表4可知,当cv为0.025 7时,最少试验观察个数为4,因此试验观察数满足置信度r = 95%,且误差δmax = 5%,即B950CF高强钢在该工艺下10 mm板激光焊接头疲劳极限强度在置信度95%,为337.5 ± 16.875 MPa. 将数据进行拟合,可得到B950CF高强钢10 mm厚度激光焊接接头疲劳均值S-N曲线,如图4所示.

2.2 不同激光填丝深度接头S-N曲线

通过超窄间隙激光填丝焊的焊接工艺,焊接厚度为10 mm的3种不同填丝深度焊接接头制成疲劳试件,比较不同填丝深度对Ultra-NGLW接头疲劳性能的影响,如图5所示,对应S-N曲线,如图6所示.

2.2.1 3 mm填充层-7 mm激光打底层Ultra-NGLW接头

将疲劳试验结果制成试件的疲劳升降图见图5(a),试件1所在的320 MPa应力级试验点并没有处于该接头疲劳试件的数据点的波动范围,因此可以将该点舍去不用. 当疲劳试件的强度在仅有两个应力级来回波动的情况下,可以直接使用试件子样平均疲劳应力级σri作为试件的疲劳强度.

通过计算可以得到,B950CF高强钢3 mm填充层-7 mm激光打底层Ultra-NGLW接头疲劳极限强度在置信度95%,为297.5 ± 14.875 MPa,再将图6(a)中的数据点进行曲线拟合,就可以得到3 mm填充层Ultra-NGLW接头疲劳均值S-N曲线见图6(a).

2.2.2 5 mm填充层-5 mm激光打底层的Ultra-NGLW接头

根据5 mm填充层-5 mm激光打底层Ultra-NGLW接头试件疲劳升降图见图5(b),将相邻应力水平的数据点配成对子. 通过计算,可以得到5 mm填充层-5 mm激光打底层Ultra-NGLW接头的σr疲劳强度为273.5 MPa,标准差S为8.22 MPa,变异系数cv为0.030 1. 将数据点进行曲线拟合,可得到5 mm填充层Ultra-NGLW接头疲劳均值S-N曲线见图6(b). B950CF高强钢5 mm填充层-5 mm激光打底层Ultra-NGLW接头疲劳极限强度在置信度95%情况下,为273.5 ± 13.675 MPa.

2.2.3 8 mm填充层-2 mm激光打底层的Ultra-NGLW接头

通过计算可以得到,8 mm填充层-2 mm激光打底层的Ultra-NGLW接头的σr疲劳强度为279.5 MPa,标准差S为6.71 MPa,变异系数cv为0.024 0. 在满足置信度r = 95%,误差δmax = 5%,B950CF高强钢8 mm填充层-2 mm激光打底层Ultra-NGLW接头试件疲劳极限强度为279.5 ± 13.975 MPa. 将各个试件的疲劳数据点进行曲线拟合,可以得到B950CF高强钢的8 mm填充层焊接接头的疲劳均值S-N曲线图见图6(c).

2.3 激光填丝焊接头疲劳性能比较

通过高频疲劳试验,得到了4种不同填丝深度的B950CF高强钢10 mm厚Ultra-NGLW接头疲劳性能如图7所示. 当激光填丝深度为0 mm时,接头疲劳极限为337.5 MPa;当填丝深度为3 mm时,疲劳性能大幅度下降,接头疲劳强度为297.5 MPa;当填丝深度为5 mm和8 mm时,疲劳强度分别为273.5 MPa和279.5 MPa. 在接头的S-N曲线的比较中可以看出,当接头没有填丝焊接时,接头的疲劳强度较高,S-N曲线斜率较大;随着接头开始有激光填丝部分,接头的疲劳强度和S-N曲线斜率开始下降,并且疲劳强度随填丝深度的增而降低. 试验结果证明,超窄间隙激光填丝焊接头的疲劳强度远不如单激光焊,并且疲劳试验的应力级越大,接头的疲劳性能大幅下降.

5 mm填丝深度接头和8 mm填丝深度接头的疲劳强度已经相差不太大,S-N曲线的斜率也趋于相同,这说明10 mm厚度的B950CF高强钢激光填丝焊接头在激光填丝层的深度到达5 mm以后,填丝深度对疲劳性能的影响减小,接头的疲劳性能也逐渐趋于平稳,其疲劳强度稳定在约270 MPa.

3. 试验结果与分析

3.1 典型疲劳断口分析

选取Ultra-NGLW接头疲劳试样的典型断口如图8所示,裂纹均从焊缝中的缺陷处开始,断口的疲劳裂纹区呈放射状平稳扩展,可看到疲劳的贝壳状纹路. 由图8(a)可以看出,3 mm填丝深度接头试样(1号试件)的主要疲劳源为填丝区底部的气孔,并伴有多个裂纹源;8 mm填丝深度的接头(2号试件主裂纹)主要疲劳裂纹源为焊缝中的夹杂,疲劳裂纹呈放射状平稳扩展.

对Ultra-NGLW接头各应力级下失效的疲劳试样断口进行观察后发现,几乎所有的失效试样疲劳源均源自焊缝中的夹杂和气孔缺陷,填丝区中的气孔明显多于激光打底区的气孔,如图9所示. 有研究表明,高强钢疲劳断裂绝大多数是由内部缺陷特别是夹杂物引起的[12]. 王习术等人[13]采用扫描电镜原位观测和有限元法得到了超高强度钢低周疲劳下夹杂物对疲劳萌生及扩展的关键尺寸是10 ~ 20 μm,当夹杂物尺寸(特别是长轴)大于10 μm时,夹杂物对超高强钢疲劳裂纹萌生的影响较大. 因此通过各接头S-N曲线(图7)可以推断,随着填丝深度的增加,接头疲劳性能下降的原因是因为随着填丝深度的增加,焊缝中的气孔和夹杂的缺陷也随之增多,这些夹杂可能形成一个或多个疲劳裂纹源. 疲劳裂纹在疲劳源附近比较粗糙见图9(b),随裂纹扩展,断口逐渐变得平坦见图9(c),在疲劳裂纹的扩展区域可以看到密集的疲劳辉纹见图9(d).

3.2 微观组织对接头疲劳的影响

3 mm填丝层-7 mm激光打底层的Ultra-NGLW接头疲劳失效试件的金相组织中,如图10所示,可以看到疲劳裂纹沿焊缝熔合线断裂见图10(b),进一步的显微观察发现断裂处的微观组织为熔合区的板条马氏体,并且在失效疲劳试件的焊缝热影响区粗晶区见图10(c)和细晶区见图10(d)均存在有微裂纹.

Ultra-NGLW接头的填丝区熔合区和粗晶区有脆硬的板条马氏体组织,由于其较差的韧性,该组织在一般的认知中是不利于接头疲劳性能的[14-15]. 这是因为马氏体屈服强度高、塑性差,在一般应力水平下晶内难于产生滑移;但晶界状态比较复杂且各种夹杂物或第二相质点沉淀及偏聚,因而晶界结合强度较低. 在交变应力作用下,塑性应变和不可逆滑移在缺陷较多的晶界附近发生,从而形成扩展裂纹[16]. Huang等人[17]也认为,接头的非均匀微观结构可能会影响其疲劳裂纹扩展行为,在激光焊接头熔合区硬度较高,而热影响区则出现软化,激光焊引起的焊缝过匹配效应会阻碍疲劳裂纹的扩展,因此在填丝区域融合线出现裂纹,而在激光焊接区域表现为疲劳塑性变形见图10(a).

Ultra-NGLW接头的疲劳性能较低且在填丝区呈现出沿熔合区断裂,是接头缺陷和不利微观组织共同作用下导致的. 但激光焊接头也存在马氏体,疲劳性能远却高于有激光填丝的焊接接头,因此可以推断,Ultra-NGLW接头的疲劳裂纹多源于Ultra-NGLW接头中易形成气孔和夹杂等缺陷的熔合区和粗晶区,并且由于马氏体等不利于疲劳性能的脆硬组织的存在,在循环载荷作用下粗晶区形成较多的微裂纹,加速疲劳裂纹的扩展.

4. 结论

(1) 通过对不同填丝深度的10 mm厚B950CF钢Ultra-NGLW接头疲劳性能对比分析,揭示了Ultra-NGLW接头的疲劳强度远不如单激光焊接头,并且疲劳试验的应力级越大,接头的疲劳性能大幅下降.

(2) 在激光填丝层的深度到达5 mm以后,填丝深度对疲劳性能的影响减小,接头的疲劳性能也逐渐趋于平稳,其疲劳强度稳定在约270 MPa.

(3) Ultra-NGLW接头的疲劳裂纹多源于Ultra-NGLW接头中易形成气孔和夹杂等缺陷的熔合区和粗晶区,并且由于马氏体等不利于疲劳性能的脆硬组织的存在,在循环载荷作用下粗晶区形成较多的微裂纹,加速疲劳裂纹的扩展.

-

图 8 AW和不同热处理温度

1000 MPa级高强钢熔敷金属TEM像和SAED花样Figure 8. TEM images and SAED patterns of deposited metal with

1000 MPa grade high strength steel in AW and different heat treatment temperatures. (a) TEM image of deposited metal AW; (b) TEM image of deposited metal at 540 °C heat-treated; (c) TEM image of deposited metal at 620 °C heat-treated; (d) TEM and SAED patterns of austenite in heat-treated deposited metal at 620 ℃表 1 熔敷金属的化学成分 (质量分数,%)

Table 1 Chemical compositions of deposited metal

C Si Mn P S Cr Ni Mo Fe 0.08 0.15 1.6 0.008 0.005 0.7 2.8 1.0 余量 -

[1] Xie H, Du L X, Hu J, et al. Microstructure and mechanical properties of a novel

1000 MPa grade TMCP low carbon microalloyed steel with combination of high strength and excellent toughness[J]. Materials Science and Engineering A, 2014, 612: 123 − 130. doi: 10.1016/j.msea.2014.06.033[2] Tumer M, Schneider-Broskamp C, Enzinger N. Fusion welding of ultra-high strength structural steels-a review[J]. Journal of Manufacturing Processes, 2022, 82: 203 − 229. doi: 10.1016/j.jmapro.2022.07.049

[3] Li K, Yang T B, Gong N, et al. Additive manufacturing of ultra-high strength steels: a review[J]. Journal of Alloys and Compounds, 2023, 965: 171390. doi: 10.1016/j.jallcom.2023.171390

[4] 曹志龙, 朱浩, 安同邦, 等. 1 000 MPa级高强钢熔敷金属强韧化机理分析[J]. 焊接学报, 2023, 44(7): 116 − 122. doi: 10.12073/j.hjxb.20220609002 Cao Zhilong, Zhu Hao, An Tongbang, et al. Analysis of the strengthening and toughening mechanism of deposited metal of 1000 MPa grade high strength steel[J]. Transactions of the China Welding Institution, 2023, 44(7): 116 − 122. doi: 10.12073/j.hjxb.20220609002

[5] Schnitzer R, Zuegner D, Haslberger P, et al. Influence of alloying elements on the mechanical properties of high-strength weld metal[J]. Science and Technology of Welding and Joining, 2017, 22(6): 536 − 543. doi: 10.1080/13621718.2016.1274095

[6] 张成竹, 陈辉. B950CF高强钢超窄间隙激光焊接头组织对残余应力的影响[J]. 中国激光, 2021, 48(6): 43 − 54. Zhang Chengzhu, Chen Hui. Effect of microstructures of ultranarrow gap laser welded B950CF steel joints on residual stress distribution[J]. Chinese Journal of Lasers, 2021, 48(6): 43 − 54.

[7] Gomes A J, Jorge J C, Souza L F, et al. Influence of chemical composition and post welding heat treatment on the microstructure and mechanical properties of high strength steel weld metals[J]. Materials Science Forum, 2013, 758: 21 − 32. doi: 10.4028/www.scientific.net/MSF.758.21

[8] Mao G J, Cao R, Yang J, et al. Effect of nickel contents on the microstructure and mechanical properties for low-carbon bainitic weld metals[J]. Journal of Materials Engineering and Performance, 2017, 26(5): 2057 − 2071. doi: 10.1007/s11665-017-2638-2

[9] Jorge J C, Monteiro J L, Gomes A J, et al. Influence of welding procedure and PWHT on HSLA steel weld metals[J]. Journal of Materials Research and Technology, 2019, 8(1): 561 − 571. doi: 10.1016/j.jmrt.2018.05.007

[10] Lee S, Kim S, Hwang B, et al. Effect of carbide distribution on the fracture toughness in the transition temperature region of an SA 508 steel[J]. Acta Materialia, 2002, 50(19): 4755 − 4762. doi: 10.1016/S1359-6454(02)00313-0

[11] 蒋中华, 杜军毅, 王培, 等. M-A岛高温回火转变产物对核电SA508-3钢冲击韧性影响机制[J]. 金属学报, 2021, 57(7): 891 − 902. Jiang Zhonghua, Du Junyi, Wang Pei, et al. Mechanism of improving the impact toughness of SA508-3 steel used for nuclear power by pre-transformation of M-A islands[J]. Acta Metallurgica Sinica, 2021, 57(7): 891 − 902.

[12] 李学达, 尚成嘉, 韩昌柴, 等. X100管线钢焊接热影响区中链状M-A组元对冲击韧性和断裂机制的影响[J]. 金属学报, 2016, 52(9): 1025 − 1035. doi: 10.11900/0412.1961.2015.00610 Li Xueda, Shang Chengjia, Han Changchai, et al. Influence of necklace-type M-A constituent on impact toughness and fracture mechanism in the heat affected zone of X100 pipeline steel[J]. Acta Metallurgica Sinica, 2016, 52(9): 1025 − 1035. doi: 10.11900/0412.1961.2015.00610

[13] 温涛, 胡小锋, 宋元元, 等. 回火温度对一种Fe-Cr-Ni-Mo高强钢碳化物及其力学性能的影响[J]. 金属学报, 2014, 50(4): 447 − 453. Wen Tao, Hu Xiaofeng, Song Yuanyuan, et al. Effect of tempering tempurature on carbide and mechanical properties in a Fe-Cr-Ni-Mo high-strength steel[J]. Acta Metallurgica Sinica, 2014, 50(4): 447 − 453.

[14] 屈岳波, 黄欣泉, 曹彬, 等. 残余奥氏体对2.25Cr-1Mo钢焊缝冲击性能的影响[J]. 机械工程学报, 2011, 47(14): 44 − 48. doi: 10.3901/JME.2011.14.044 Qu Yuebo, Huang Xinquan, Cao Bin, et al. Effect of residual austenite content on impact toughness of the filler metal of 2.25Cr-1Mo steel[J]. Journal of Mechanical Engineering, 2011, 47(14): 44 − 48. doi: 10.3901/JME.2011.14.044

[15] 周成, 赵坦, 叶其斌, 等. 回火温度对1000 MPa级NiCrMoV低碳合金钢微观组织和低温韧性的影响[J]. 金属学报, 2022, 58(12): 1557 − 1569. Zhou Cheng, Zhao Tan, Ye Qibin, et al. Effects of tempering temperature on microstructure and low-temperature toughness of 1000 MPa grade NiCrMoV low carbon alloyed steel[J]. Acta Metallurgica Sinica, 2022, 58(12): 1557 − 1569.

[16] Luo Y, Peng J M, Wang H B, et al. Effect of tempering on microstructure and mechanical properties of a non-quenched bainitic steel[J]. Materials Science and Engineering A, 2010, 527(15): 3433 − 3437. doi: 10.1016/j.msea.2010.02.010

[17] Kuzmina M, Ponge D, Raabe D. Grain boundary segregation engineering and austenite reversion turn embrittlement into toughness: example of a 9 wt. % medium Mn steel[J]. Acta Materialia, 2015, 86: 182 − 192. doi: 10.1016/j.actamat.2014.12.021

[18] 孙树文, 茅建富, 雷廷权, 等. 低合金Cr-Mo-V钢中VC沉淀相的精细结构[J]. 金属学报, 2000, 36(10): 1009 − 1014. doi: 10.3321/j.issn:0412-1961.2000.10.001 Sun Shuwen, Mao Jianfu, Lei Tingquan, et al. Microstructural characterization of VC precipitates in a low alloy Cr-Mo-V steel[J]. Acta Metallurgica Sinica, 2000, 36(10): 1009 − 1014. doi: 10.3321/j.issn:0412-1961.2000.10.001

[19] 蒋中华, 王培, 李殿中, 等. 回火温度对2.25Cr-1Mo-0.25V钢粒状贝氏体显微组织和力学性能的影响[J]. 金属学报, 2015, 51(8): 925 − 934. Jiang Zhonghua, Wang Pei, Li Dianzhong, et al. Effects of tempering temperature on the microstructure and mechanical properties of granular bainite in 2.25Cr-1Mo-0.25V steel[J]. Acta Metallurgica Sinica, 2015, 51(8): 925 − 934.

[20] 刘政军, 裘荣鹏, 武丹, 等. 960 MPa高强钢金属粉芯型药芯焊丝焊缝金属韧化机理[J]. 焊接学报, 2018, 39(1): 102 − 106. doi: 10.12073/j.hjxb.2018390023 Liu Zhengjun, Qiu Rongpeng, Wu Dan, et al. Research on toughening mechanism of weld metal with metal powder flux-cored wire for 960 MPa high strength steel[J]. Transactions of the China Welding Institution, 2018, 39(1): 102 − 106. doi: 10.12073/j.hjxb.2018390023

[21] Srivatsa K, Srinivas P, Balachandran G, et al. Room temperature microstructure and property evaluation of a heat treated fully bainitic 20CrMoVTiB410 steel[J]. Journal of the Minerals, Metals & Materals Society, 2016, 68(10): 2704 − 2712. doi: 10.1007/s11837-016-2063-2

[22] Soleimani M, Kalhor A, Mirzadeh H. Transformation-induced plasticity (TRIP) in advanced steels: a review[J]. Materials Science and Engineering A, 2020, 795: 140023. doi: 10.1016/j.msea.2020.140023

[23] Lambert A, Drillet J, et al. Microstructure of martensite–austenite constituents in heat affected zones of high strength low alloy steel welds in relation to toughness properties[J]. Science and Technology of Welding and Joining, 2000, 5(3): 168 − 173. doi: 10.1179/136217100101538164

[24] 陈剑虹, 曹睿. 焊缝金属解理断裂微观机理[J]. 金属学报, 2017, 53(11): 1427 − 1444. doi: 10.11900/0412.1961.2017.00145 Chen Jianhong, Cao Rui. Micromechanism of cleavage fracture of weld metals[J]. Acta Metallurgica Sinica, 2017, 53(11): 1427 − 1444. doi: 10.11900/0412.1961.2017.00145

-

期刊类型引用(1)

1. 王晓飞,田峻. 压力容器焊接工艺对疲劳强度的影响分析. 中国机械. 2025(08): 50-53 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: