Microstructure and toughness of heat-affected zone in girth welding of X80 steel pipe with different Nb content

-

摘要:

为研究Nb含量对焊接热影响区微观组织和性能的影响,采用熔化极气体保护焊(gas metal arc welding,GMAW)和手工焊条电弧焊(shielded metal arc welding,SMAW)对0.055%Nb和0.075%Nb含量的X80钢管进行环焊. 采用夏比冲击试验和金相分析方法,研究热影响区的微观组织差异和夏比冲击韧性. 并借助扫描电镜和超高温激光共聚焦显微镜分析不同Nb含量X80管体的微观组织对热影响区性能的影响. 结果表明,在0 ℃和−20 ℃时,0.075%Nb和0.055%Nb的X80钢管GMAW环焊接头热影响区均具有较高的冲击韧性,其平均冲击吸收能量均高于150 J. 其中0.055%Nb略高于0.075%Nb的GMAW环焊接头热影响区夏比冲击吸收能量;焊接热输入较低时,0.055%Nb低于0.075%Nb的X80环焊接头粗晶区的韧脆转变温度,具有更好的低温韧性. 焊接热输入较高时,0.075%Nb的X80环焊接头粗晶区具有更高的上平台冲击吸收能量,且上平台温度和韧脆转变温度也更低,其低温韧性也更优异;还发现了X80环焊接头热影响区的冲击韧性不仅与热输入量和热影响区马氏体−奥氏体组织(M-A)的形状、大小、分布有关,而且还受管体中Nb含量、原始的强度与韧性、微观组织状态的遗传影响.

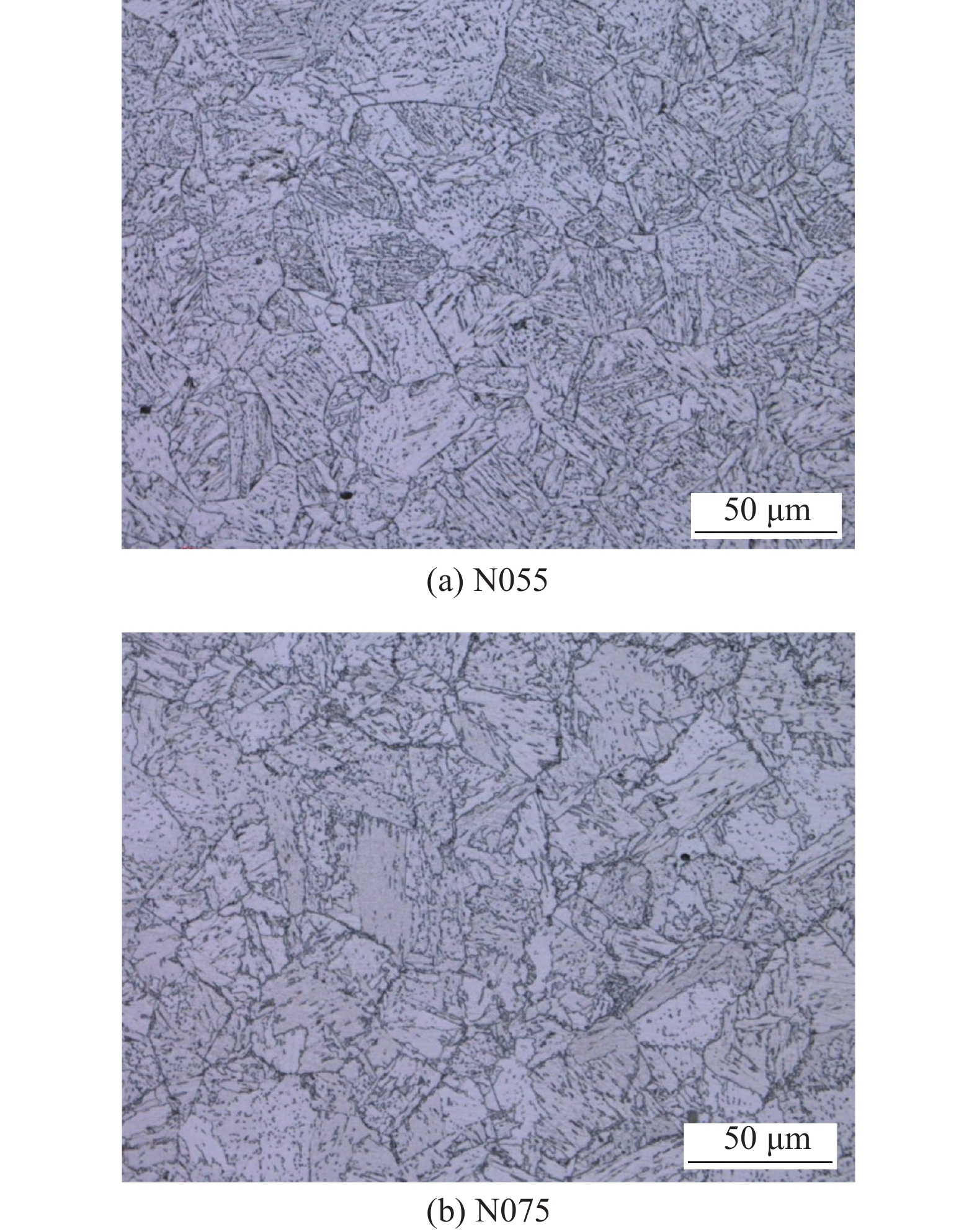

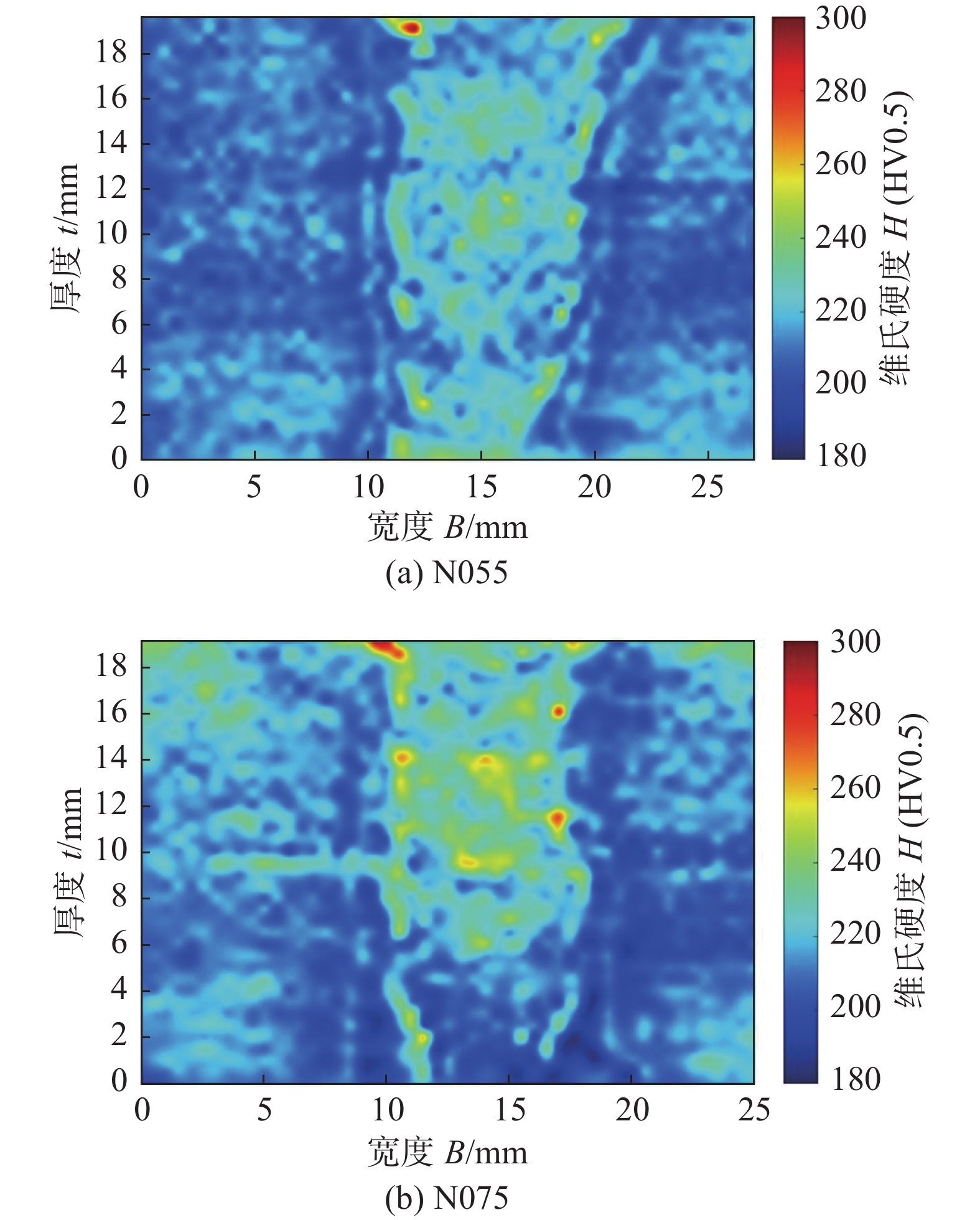

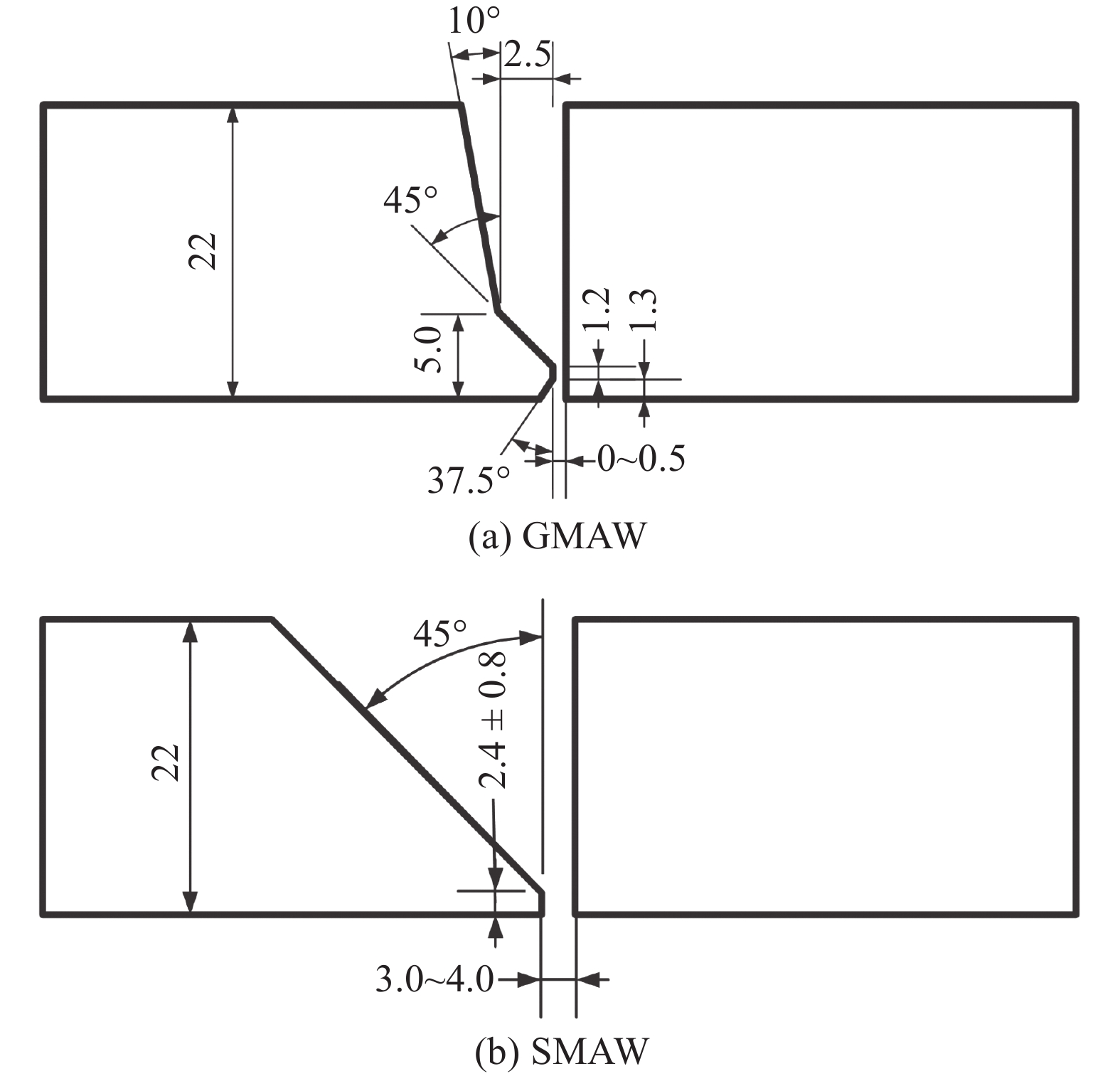

Abstract:In order to study the effect of Nb content on the microstructure and properties of heat affected zone (HAZ), the 0.055%Nb and 0.075%Nb content X80 steel pipes were girth welded by Gas metal arc welding (GMAW) and shielded metal arc welding (SMAW). Charpy impact test and metallographic analysis were used to study the impact toughness and microstructure differences in the HAZ. The effects of the microstructure of X80 pipe body with different Nb content on the properties of the heat-affected zone were analyzed by scanning electron microscope and confocal laser microscope with high temperature. The results show that at 0 ℃ and −20 ℃, 0.075%Nb and 0.055%Nb X80 steel pipes have high impact toughness in the HAZ of GMAW girth welded joints, and their average impact absorbed energy are higher than 150J. However, the Charpy impact absorbed energy in the HAZ of GMAW girth welded joint of X80 steel pipe with 0.055% Nb is higher than that of X80 steel pipe with 0.075%Nb. When GMAW is used, the ductile-brittle transition temperature (DBTT) of X80 girth welded joint with 0.055%Nb is lower than that of X80 with 0.075%Nb because of the low welding heat input. When SMAW is used, due to higher heat input, the coarse grain heat affected zone (CGHAZ) of X80 girth welding joint with 0.075%Nb has higher impact absorbed energy on the upper-shelf and lower temperature of upper-shelf zone and DBTT, and its low temperature toughness is better. It is also discussed that the impact toughness of the HAZ of X80 girth welded joint is not only related to the heat input and the shape, size and distribution of M-A, but also genetically influenced by the content of Nb in the pipe body and the original strength, toughness and microstructure state.

-

Keywords:

- X80 steel pipe containing niobium /

- girth welded joint /

- HAZ /

- impact toughness /

- M-A

-

-

表 1 试验钢管的化学成分(质量分数,%)

Table 1 Chemical compositions of steel pipes

编号 C Mn Si P S Cr Mo Ni Nb V Ti Cu B Al N Fe CEPcm N055 0.049 1.74 0.15 0.010 0.0025 0.25 0.093 0.16 0.058 0.0043 0.011 0.022 0.0003 0.027 0.0031 余量 0.165 N075 0.051 1.72 0.16 0.013 0.0026 0.26 0.088 0.16 0.082 0.0045 0.012 0.026 0.0003 0.025 0.0033 余量 0.167 表 2 单侧双V形坡口GMAW焊接工艺参数

Table 2 Welding process parameters of single side double V-groove GMAW girth welding

焊接层 焊接电流

I/A电弧电压

U/V送丝速度

vf/(m·min−1)焊接速度

vw/(mm·min−1)保护气体 平均热输入

$ \overline Q $/(kJ·mm−1)混合比例(Ar : CO2) 流量Q/(L·min−1) 根焊 150 ~ 200 22 ~ 26 8.13 ~ 9.65 460 ~ 660 4∶1 20 ~ 25 0.48 热焊 180 ~ 240 24 ~ 27 11.43 ~ 12.92 560 ~ 760 4∶1 30 ~ 35 0.52 填充焊 160 ~ 220 24 ~ 26 8.13 ~ 10.92 330 ~ 460 4∶1 25 ~ 35 0.75 盖面焊 150 ~ 200 22 ~ 26 7.62 ~ 9.14 330 ~ 460 4∶1 20 ~ 30 0.65 表 3 单侧V形坡口SMAW焊接工艺参数

Table 3 Welding process parameters of single side V-groove GMAW girth welding

焊接

层数焊接电流I/A 电弧电压U/V 焊接速度vw/(mm·min−1) 平均热输入$ \overline Q $/(kJ·mm−1) 根焊 130 ~ 150 24 ~ 27 90 ~ 100 2.10 热焊 130 ~ 150 24 ~ 27 100 ~ 120 1.91 填充焊 170 ~ 210 24 ~ 27 90 ~ 120 2.84 盖面焊 170 ~ 200 24 ~ 27 90 ~ 120 2.70 -

[1] Morrison W B. Microalloy steels - the beginning[J]. Materials Science and Technology, 2009, 25(9): 1066 − 1073. doi: 10.1179/174328409X453299

[2] Deardo A, Hua M, Cho K, et al. On strength of microalloyed steels: an interpretive Review[J]. Materials Science and Technology, 2009, 25(9): 1074 − 1082. doi: 10.1179/174328409X455233

[3] Fateh F, Matthias M. Effect of Nb on austenite formation and decomposition in an X80 linepipe steel[J]. Journal of Iron and Steel Research International, 2011, 18: 658 − 663.

[4] 缪成亮, 尚成嘉, 王学敏, 等. 高Nb X80管线钢焊接热影响区显微组织与韧性[J]. 金属学报, 2010, 46(5): 541 − 546. doi: 10.3724/SP.J.1037.2009.00803 Miao Chengliang, Shang Chengjia, Wang Xuemin, et al. Microstructure and toughness of HAZ in X80 pipeline steel with high Nb content[J]. Acta Metallurgica Sinica, 2010, 46(5): 541 − 546. doi: 10.3724/SP.J.1037.2009.00803

[5] Teixeira P, Loureiro A, Rodrigues D, et al. Effect of the HAZ microstructural gradient on the unstable fracture behaviour of welds in a high strength steel[J]. Materials Science Forum, 2006, 514-516(5): 539 − 543.

[6] 徐杰, 卓小敏, 李朋朋. 温度对X80管线钢韧/脆转变区断裂韧性的影响[J]. 工程力学, 2016, 33(S): 56 − 61. Xu Jie, Zhuo Xiaomin, Li Pengpeng. Effect of temperature on the fracture toughness of X80 pipeline steel in ductile-to-brittle transition region[J]. Engineering Mechanics, 2016, 33(S): 56 − 61.

[7] 袁军军, 禅志善, 曹睿, 等. 多层多道平焊接头冲击性能不稳定的原因分析[J]. 焊接学报, 2017, 38(5): 100 − 103. Yuan Junjun, Chan Zhishan, Cao Rui, et al. Analysis of impact toughness variation for flat position multi-pass weld joint[J]. Transactions of the China Welding Institution, 2017, 38(5): 100 − 103.

[8] Mohammadijoo M, Collins L, Rashid M F, et al. Influence of steel chemistry and field girth welding procedure on performance of API X70 line pipe steels[C]//International Pipeline Conference. ASME, Virtual, Online, 2020.

[9] Wang H, Wang J, Tong Z, et al. Characterization of Nb interface segregation during welding thermal cycle in microalloyed steel by atom probe tomography[J]. Metallurgical and Materials Transactions A, 2018(12): 6224 − 6230.

[10] 赵建平, 张秀敏, 沈士明. 材料韧脆转变温度数据处理方法探讨[J]. 石油化工设备, 2004, 33(4): 29 − 32. Zhao Jianping, Zhang Xiumin, Shen Shiming. On the method of data processing for ductile-brittle transition temperature[J]. Petro-chemical Equipment, 2004, 33(4): 29 − 32.

[11] 周昌玉, 夏翔鸣. CrMo钢材料韧脆转变温度曲线的回归分析[J]. 压力容器, 2003, 20(6): 13 − 18. Zhou Changyu, Xia Xiangming. Regression analysis of ductile- brittle transition temperature curve for CrMo steel[J]. Pressure Vessel Technology, 2003, 20(6): 13 − 18.

[12] 周腾飞, 关凯书. 不同缺口形式小冲杆试样测试3Cr1MoV钢韧脆转变温度的对比[J]. 机械工程材料, 2018, 42(12): 21 − 26. Zhou Tengfei, Guan Kaishu. Comparison of ductile-brittle transition temperature testing of 3CrlMoV steel with small punch specimens of different notch forms[J]. Materials for Mechanical Engineering, 2018, 42(12): 21 − 26.

[13] 李学达, 尚诚嘉, 韩昌柴, 等. X100 管线钢焊接热影响区中链状M-A组元对冲击韧性和断裂机制的影响[J]. 金属学报, 2016, 52(9): 1025 − 1035. Li Xueda, Shang Chengjia, Han Changchai, et al. Influence of necklace-type M-A constituent on impact toughness and fracture mechanism in the heat affected zone of X100 pipeline steel[J]. Acta Metallurgica Sinica, 2016, 52(9): 1025 − 1035.

[14] 李学达, 李春雨, 曹宁, 等. 高强管线钢焊接临界再热粗晶区中逆转奥氏体的逆相变晶体学[J]. 金属学报, 2021, 57(8): 967 − 976. Li Xueda, Li Chunyu, Cao Ning, et al. Crystallography of reverted austenite in the intercritically reheated coarse-grained heat-affected zone of high strength pipeline steel[J]. Acta Metallurgica Sinica, 2021, 57(8): 967 − 976.

[15] Qi Xiaonan, Huan Pengcheng, Wang Xiaonan, et al. Effect of root welding heat input on microstructure evolution and fracture mechanism in intercritically reheat-coarse grained heat-affected zone of X80 pipeline steel[J]. Materials Today Communications, 2022, 31: 1 − 9.

[16] 王学林, 李学达, 尚成嘉. 高强度管线钢焊接热影响区显微组织精细表征[J]. 焊管, 2019, 42(7): 27 − 37. Wang Xuelin, Li Xueda, Shang Chengjia. Fine characterization of high strength pipeline steel welding HAZ microstructure[J]. Weld Pipe and Tube, 2019, 42(7): 27 − 37.

下载:

下载: