Study on microstructure and comprehensive properties of SAF2205 duplex stainless steel multilayer and multipass welded joint

-

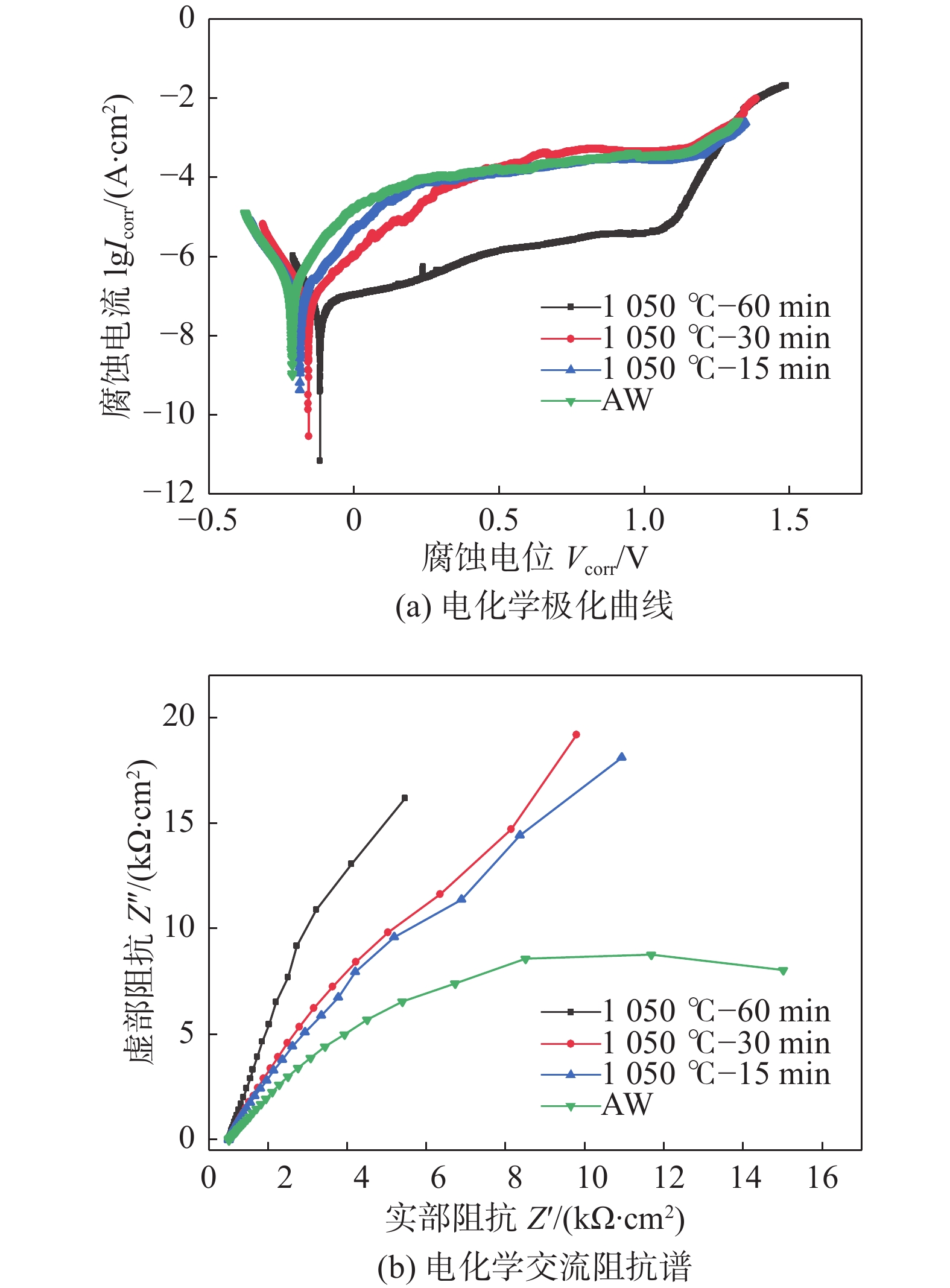

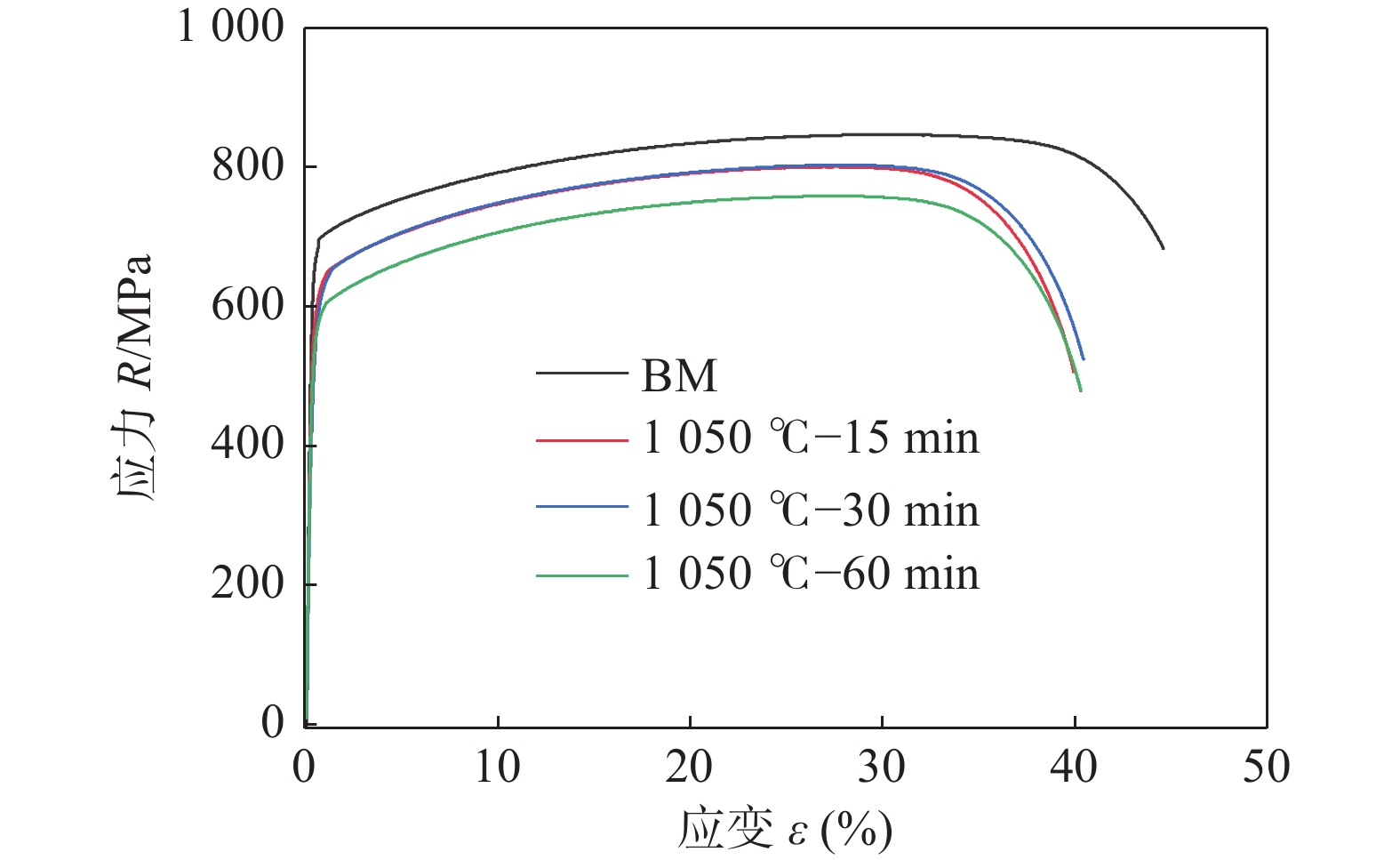

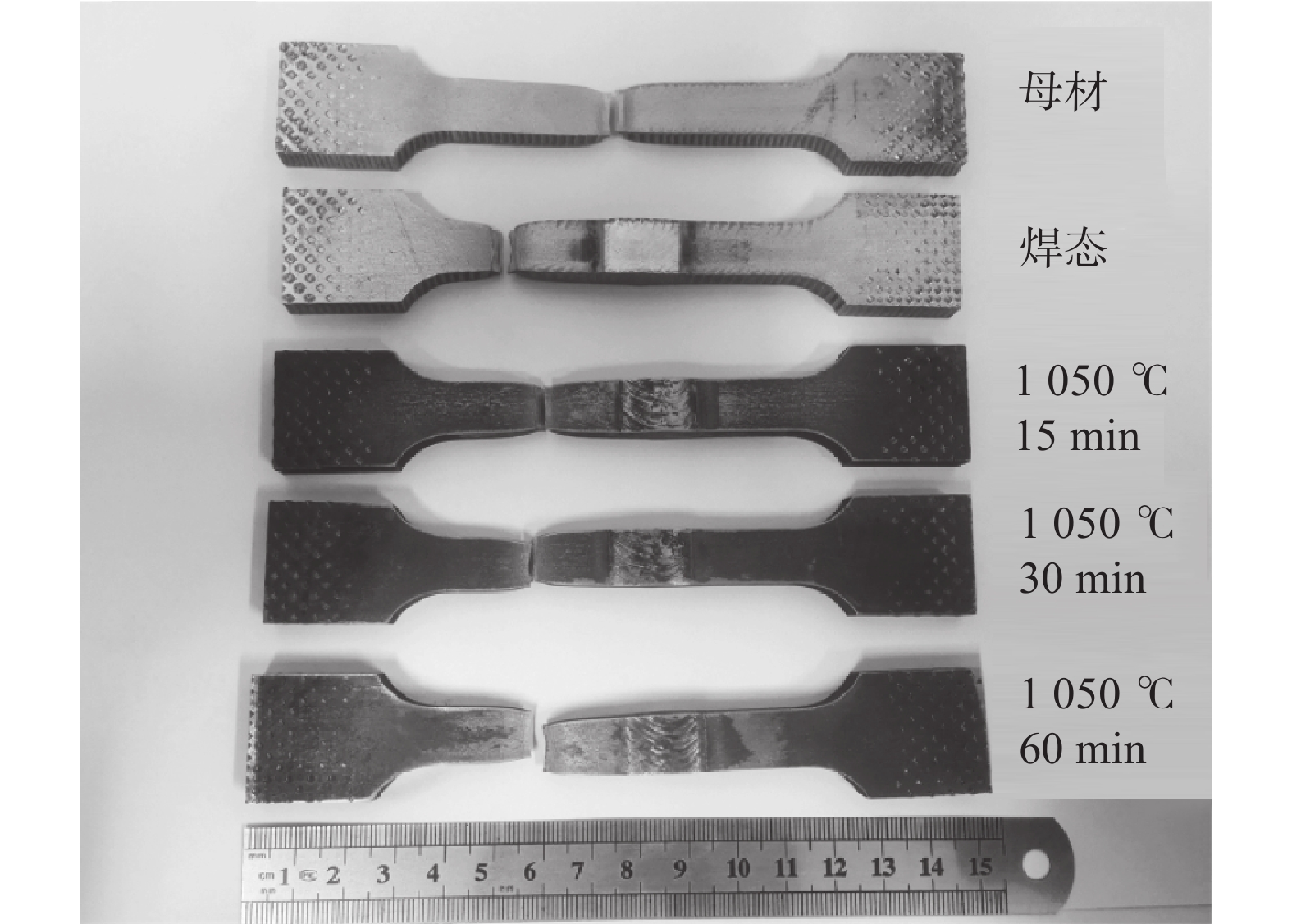

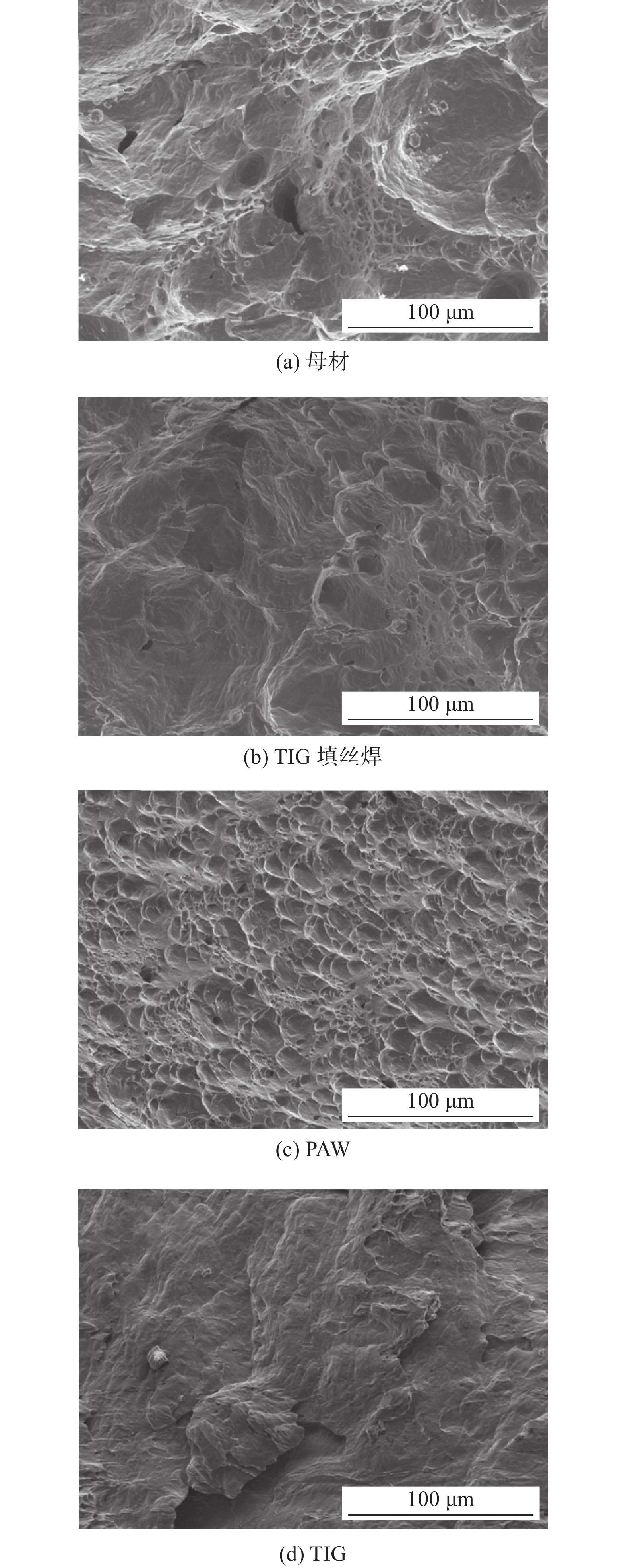

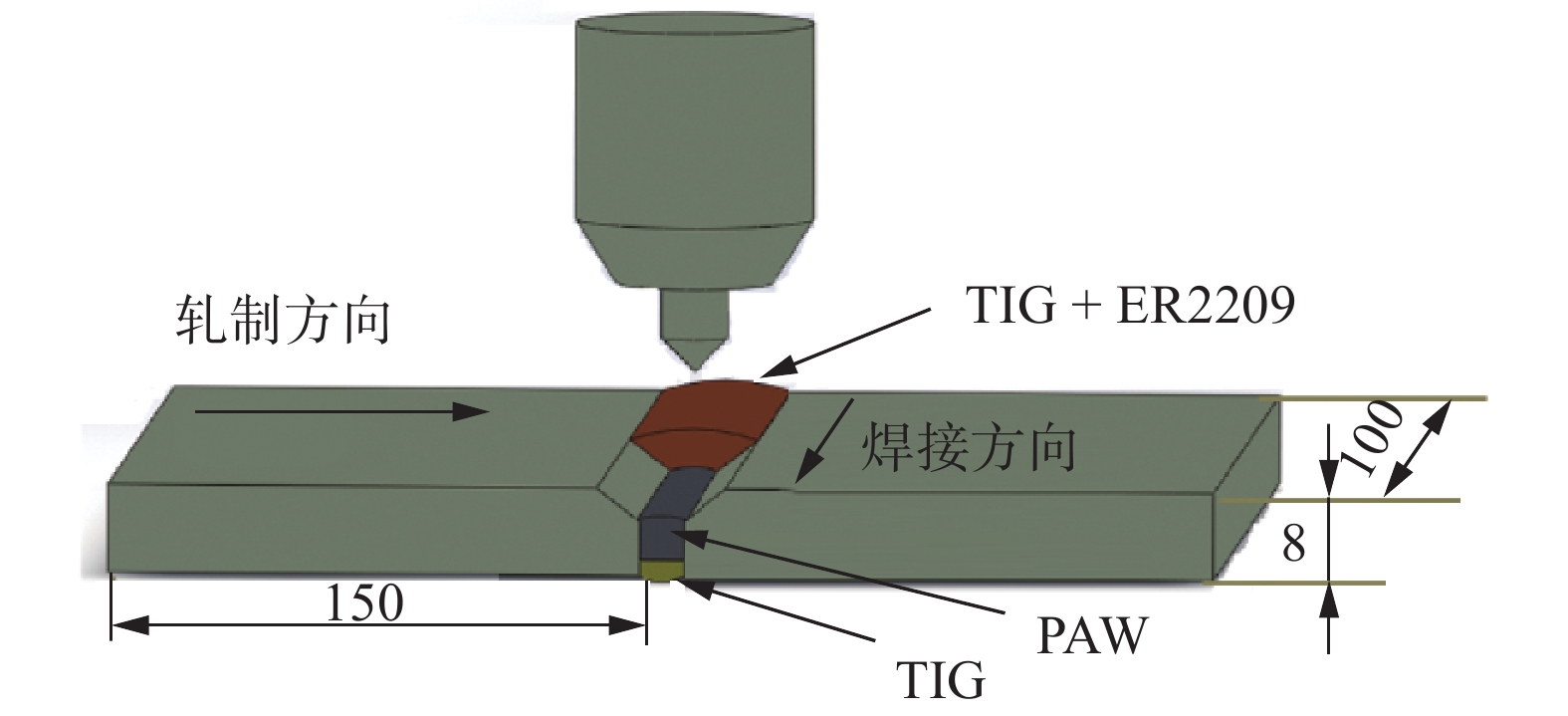

摘要: 采用TIG/PAW复合焊接对SAF2205双相不锈钢进行多层多道焊接,并进行固溶处理,利用OM、SEM、EBSD等设备,通过电化学腐蚀、拉伸、冲击等试验研究焊缝组织演变与综合性能的关系. 结果表明:TIG填丝盖面焊接处的焊缝铁素体含量为70.5%,由于添加焊丝的原因,焊缝奥氏体晶粒最大为177 μm2,大于母材142 μm2;PAW焊缝铁素体含量为65.4%,因为焊接顺序的不同,后续焊接对焊缝有加热作用,导致铁素体含量最少;在TIG焊缝中,热输入较大,导致铁素体晶粒粗化最大为8 147 μm2,大于母材264 μm2,导致奥氏体形核位置减少,奥氏体仅为3.96%. 在1 050 ℃固溶处理60 min后焊缝两相接近1∶1,并且奥氏体趋于均匀化,随固溶时间的延长耐腐蚀性增强. 焊态焊缝抗拉强度大于846 MPa,拉伸断裂均在母材. 焊缝冲击吸收能量为144 J,小于母材(156 J),焊缝表现为复合断裂.

-

关键词:

- SAF2205双相不锈钢 /

- 复合焊接TIG/PAW /

- 微观组织 /

- 固溶处理 /

- 综合性能

Abstract: TIG/PAW composite welding was used to weld SAF2205 duplex stainless steel with three layers and three channels, and solution treatment was carried out. OM, SEM, EBSD and electrochemical corrosion, tensile, impact and other experiments were used to study the relationship between the microstructure evolution of the weld and mechanical properties, corrosion resistance. The results show that the ferrite content of TIG filler wire weld is 70.5%, and the austenite grain of TIG filler wire weld is the largest (177 μm2), which is larger than that of base metal (142 μm2) due to the addition of welding wire. The ferrite content of PAW weld is 65.4%. Due to the different welding sequence, subsequent welding has a heating effect on the weld, resulting in the least ferrite content. In TIG weld, the large heat input results in the coarsening of ferrite grain (8 147 μm2), which is larger than the base metal (264 μm2), resulting in the reduction of austenite core location and only 3.96% austenite. Due to the difference of deformation mechanism and stacking fault energy between austenite and ferrite, the number of ferrite sub-grains is larger than that of austenite, while the number of recrystallized grains and high-angle grain boundary is smaller than that of austenite. After solution treatment at 1 050 ℃ for 60 min, the two phases of the weld are close to 1∶1, and the austenite tends to homogenize, and the corrosion resistance increases with the extension of solution time. The tensile fractures were all in the base metal, and the tensile strength of the weld were greater than 846 MPa. The weld impact energy is 144 J, less than the base metal (156 J), and the weld shows composite fracture. -

-

图 5 焊缝局部微观组织特征

Figure 5. Microstructure characteristics of the weld. (a) the OM morphologie of TIG filler wire welding seam; (b) the OM morphologie of PAW welding seam; (c) the OM morphologie of TIG welding seam; (d) the IPF diagram of TIG filler wire welding seam; (e) the IPF diagram of PAW welding seam; (f) the IPF diagram of TIG welding seam; (g) the two-phase distribution diagram of TIG filler wire welding seam; (h) the two-phase distribution diagram of PAW welding seam; (i) the two-phase distribution diagram of TIG welding seam

图 6 SAF2205双相不锈钢1 050 ℃固溶处理后焊缝微观形貌

Figure 6. Microstructure of welding seam after solution treatment at 1 050 ℃ of SAF2205 duplex stainless steel. (a) TIG filler wire welding seam after solution treatment for 15 min; (b) PAW welding seam after solution treatment for 15 min; (c) TIG welding seam after solution treatment for 15 min; (d) TIG filler wire welding seam after solution treatment for 30 min; (e) PAW welding seam after solution treatment for 30 min; (f) TIG welding seam after solution treatment for 30 min; (g) TIG filler wire welding seam after solution treatment for 60 min; (h) PAW welding seam after solution treatment for 60 min; (i) TIG welding seam after solution treatment for 60 min

表 1 SAF2205化学成分(质量分数,%)

Table 1 Chemical constituents of SAF2205

C Mn Si Mo Cr Ni N S P Fe 0.016 0.82 0.36 3.12 22.48 5.46 0.16 0.001 0.024 余量 表 2 1 050 ℃固溶处理后焊缝两相比例(γ∶α)

Table 2 Two-phase ratio of solid solution treated welds at 1 050 ℃

固溶处理时间t/min TIG + ER PAW TIG 15 30.20∶69.80 34.25∶65.25 19.02∶80.98 30 38.66∶61.34 41.11∶58.59 31.75∶68.25 60 47.08∶52.92 52.42∶47.58 40.98∶59.02 表 3 SAF2205双相不锈钢电化学腐蚀参数

Table 3 Electrochemical corrosion parameters of SAF2205 duplex stainless steel

固溶处理时间

t/min腐蚀速度

vcorr /(g∙m−2∙h−1)腐蚀电流

Icorr /(1 × 10−5 A∙cm2)腐蚀电位

Vcorr /V15 1.015 462 2.871 −0.1163 30 3.045 871 4.684 −0.1567 60 3.658 807 4.628 −0.1868 焊态 4.794 887 9.967 −0.2124 表 4 SAF2205双相不锈钢焊缝和母材的拉伸性能

Table 4 Tensile properties of SAF2205 duplex stainless steel weld and base metal

固溶处理时间t/min 屈服强度ReL/MPa 抗拉强度Rm/MPa 断后伸长率

A/(%)母材 685 846 44.40 15 639 800 39.82 30 644 803 40.44 60 598 758 40.00 -

[1] Moteshakker A, Danaee I. Microstructure and corrosion resistance of dissimilar weld-joints between duplex stainless steel 2205 and austenitic stainless steel 316L[J]. Journal of Materials Science & Technology, 2016, 32(6): 282 − 290.

[2] Satyanarayana V V, Reddy G M, Mohandas T. Dissimilar metal friction welding of austenitic-ferritic stainless steels[J]. Journal of Materials Processing Technology, 2005, 160(2): 128 − 137. doi: 10.1016/j.jmatprotec.2004.05.017

[3] Verma j, Taiwade R V. Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review[J]. Journal of Manufacturing Processes, 2017, 25: 134 − 152. doi: 10.1016/j.jmapro.2016.11.003

[4] Badji R, Bouabdallah M, Bacroix B. Phasetransformation and mechanical behavior in annealed 2205 duplex stainless steelwelds[J]. Materials Characterization, 2008, 59: 447 − 453. doi: 10.1016/j.matchar.2007.03.004

[5] Kim D C, Ogura T, Yamashita S. Computer prediction of α/γ phase fraction in multi-pass weld of duplex stainless steel and microstructural improvement welding process[J]. Materials and Design, 2020, 196: 109154. doi: 10.1016/j.matdes.2020.109154

[6] Woo W, An G B, Kingston E J. Through-thickness distributions of residual stresses in two extreme heat-input thick welds: A neutron diffraction, contour method and deep hole drilling study[J]. Acta Materialia, 2013, 61(10): 3564 − 3574. doi: 10.1016/j.actamat.2013.02.034

[7] Gao S, Geng S, Jiang P. Numerical analysis of the deformation behavior of 2205 duplex stainless steel TIG weld joint based on the microstructure and micro-mechanical properties[J]. Materials Science & Engineering A, 2021, 815: 141303.

[8] Shen J L, Wei Z J, Zhu X R. Microstructure evolution and mechanical properties of flash butt-welded Inconel 718 joints[J]. Materials Science & Engineering A, 2018, 718: 34 − 42.

[9] Cui S W, Shi Y H, Sun K. Microstructure evolution and mechanical properties of keyhole deep penetration TIG welds of S32101 duplex stainless steel[J]. Materials Science & Engineering A, 2018, 709(2): 214 − 222.

[10] Toth T, Krasnorutskyi S, Hensel J. Electron beam welding of 2205 duplex stainless steel using pre-placed nickel-based filler material[J]. International Journal of Pressure Vessels and Piping, 2021, 191: 104354. doi: 10.1016/j.ijpvp.2021.104354

[11] Lai R, Cai Y, Wu Y. Influence of absorbed nitrogen on microstructure and corrosion resistance of 2205 duplex stainless steel joint processed by fiber laser welding[J]. Journal of Materials Processing Technology, 2016, 231: 397 − 405. doi: 10.1016/j.jmatprotec.2016.01.016

[12] Zhang Z Q, Jing H Y, Xua L Y. Effect of post-weld heat treatment on microstructure evolution and pitting corrosion resistance of electron beam-welded duplex stainless steel[J]. Corrosion Science, 2018, 141(15): 30 − 45.

[13] Yang Y Z, Wang Z Y, Tan H. Effect of a brief post-weld heat treatment on the microstructure evolution and pitting corrosion of laser beam welded UNS S31803 duplex stainless steel[J]. Corrosion Science, 2012, 65: 472 − 480. doi: 10.1016/j.corsci.2012.08.054

[14] Jastej S, Shahi A S. Metallurgical and corrosion characterization of electron beam welded duplex stainless steel joints[J]. Journal of Manufacturing Processes, 2020, 50: 581 − 595. doi: 10.1016/j.jmapro.2020.01.009

[15] Ku J S, Ho N J, Tjong S C. Properties of electron beam welded SAF 2205 duplex stainless steel[J]. Journal of Manufacturing Processing Technology, 1997, 63(1-3): 770 − 775. doi: 10.1016/S0924-0136(96)02721-5

[16] Sieurin H, Sandström R. Austenite reformation in the heat-affected zone of duplex stainless steel 2205[J]. Materials Science & Engineering A, 2006, 418(1-2): 250 − 256. doi: 10.1016/j.msea.2005.11.025

[17] Mourad A H I, Khourshid A, Sharef T. Gas tungsten arc and laser beam welding processes effects on duplex stainless steel 2205 properties[J]. Materials Science & Engineering A, 2012, 549(15): 105 − 113.

[18] Saravanan S, Raghukandan K, Sivagurumanikandan N. Pulsed Nd: YAG laser welding and subsequent post-weld heat treatment on super duplex stainless steel[J]. Journal of Manufacturing Processes, 2017, 25: 284 − 289. doi: 10.1016/j.jmapro.2016.12.015

[19] Zhang Z Q, Jing, H Y, Xu L Y. The impact of annealing temperature on improving microstructure and toughness of electron beam welded duplex stainless steel[J]. Journal of Manufacturing Processes, 2018, 31: 568 − 582. doi: 10.1016/j.jmapro.2017.12.018

-

期刊类型引用(1)

1. 孟美情,韩俭,朱瀚钊,梁哲滔,蔡养川,张欣,田银宝. 基于多丝电弧增材制造研究现状. 材料工程. 2025(05): 46-62 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: