Effect of wire current on microstructure and properties of 7075-T6 aluminum alloy joint welded by double-wire pulsed cold metal transition method

-

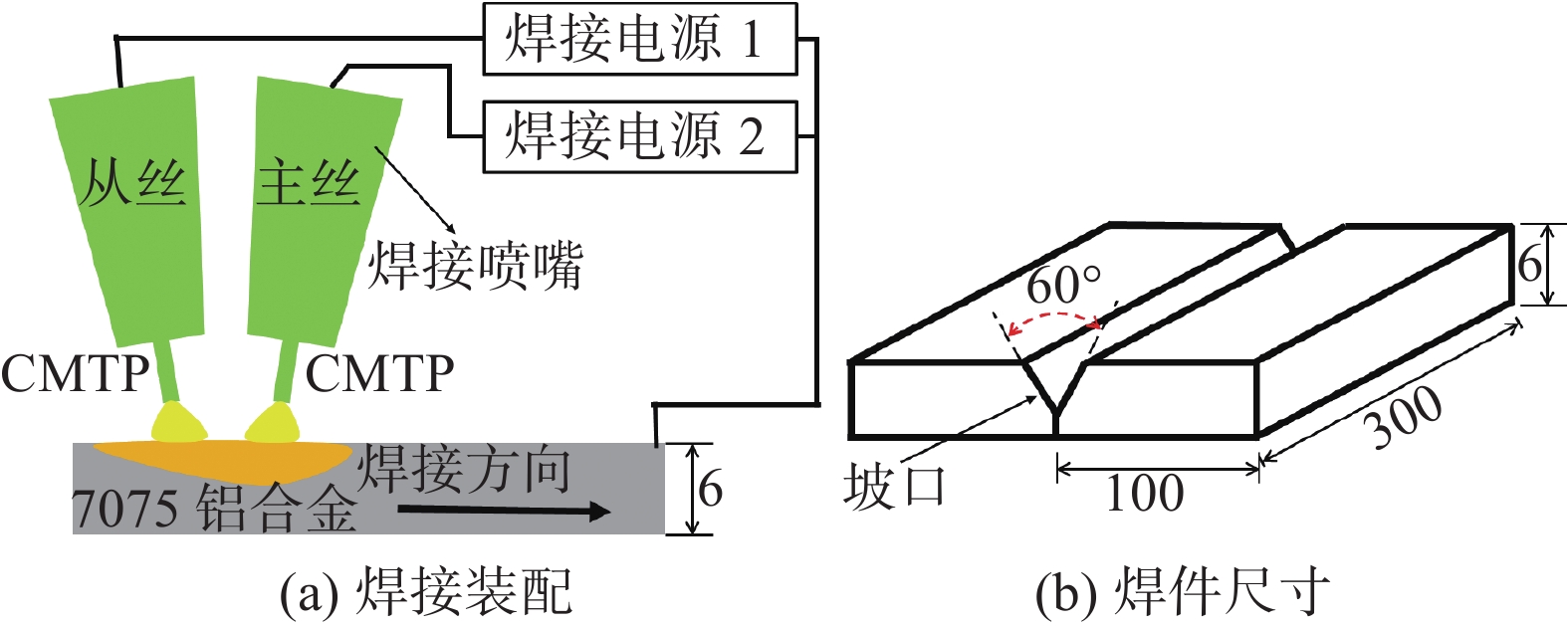

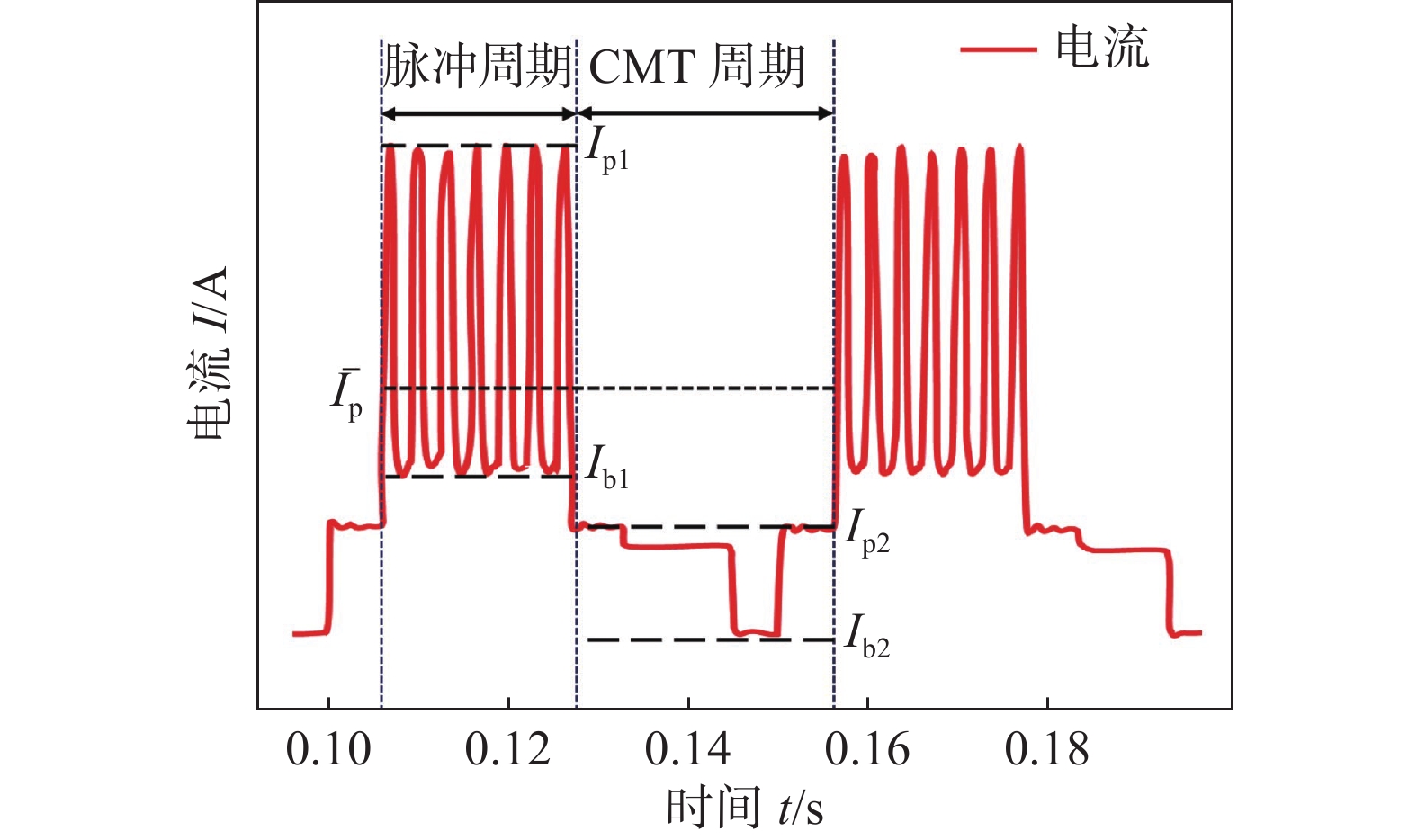

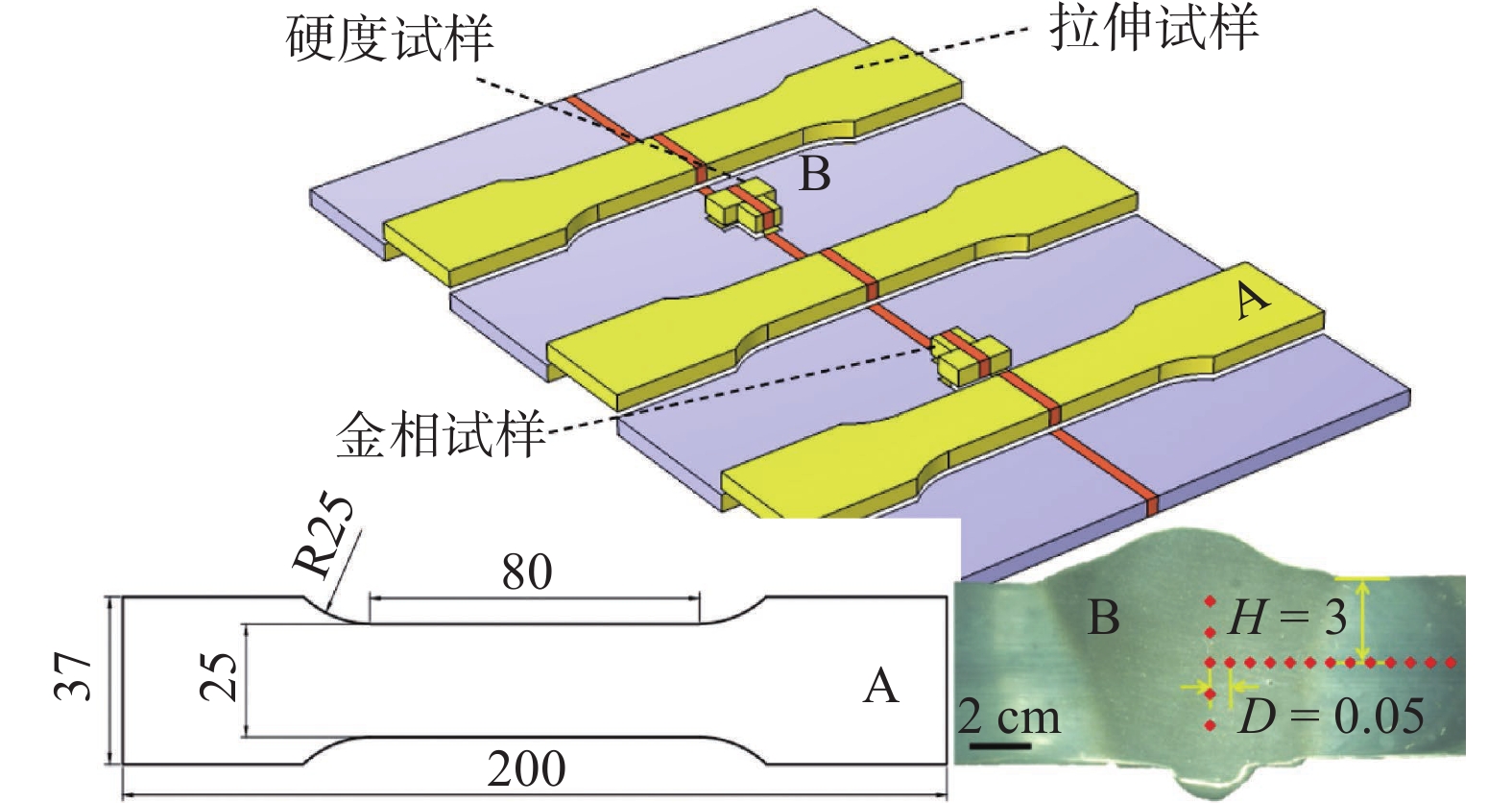

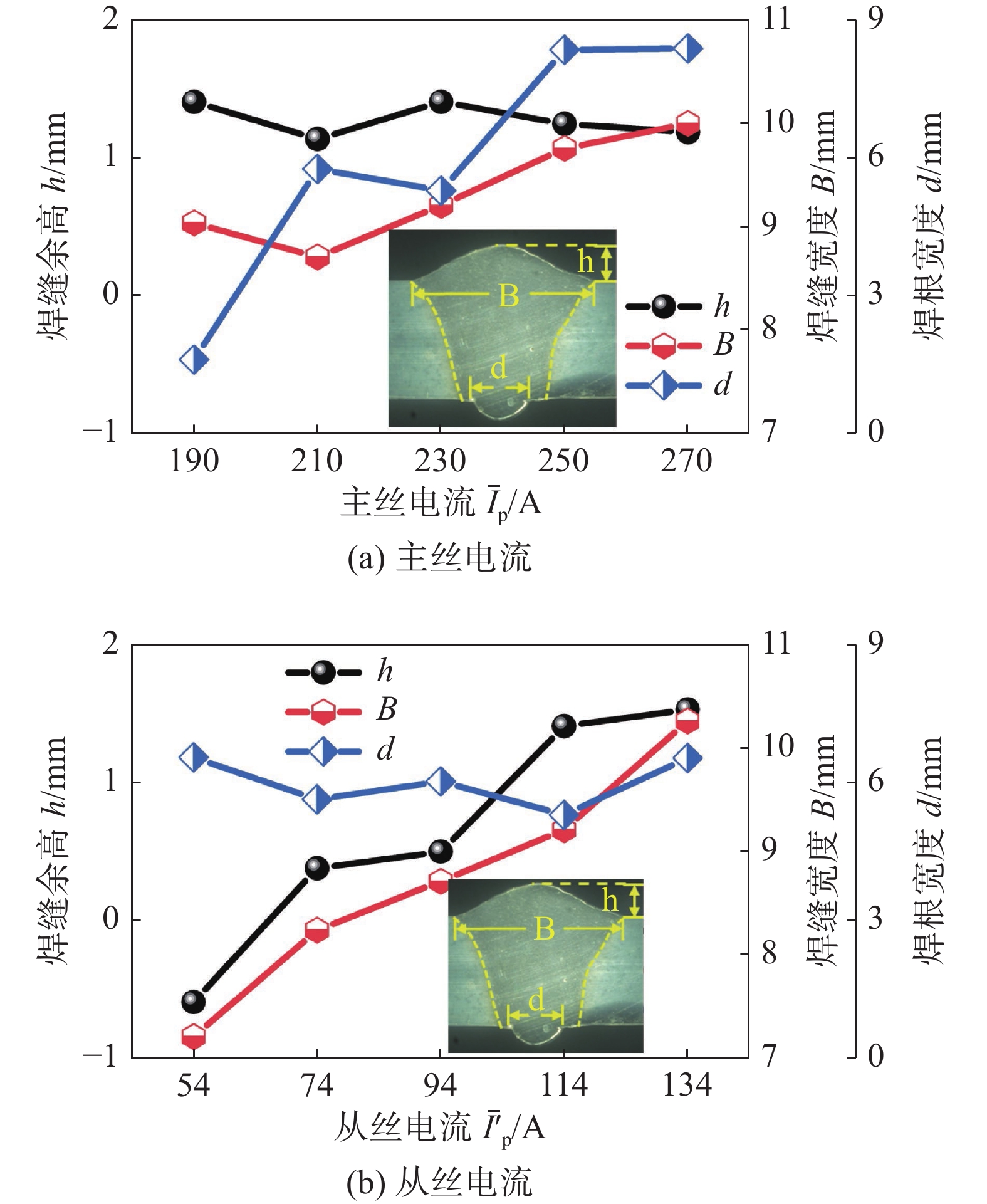

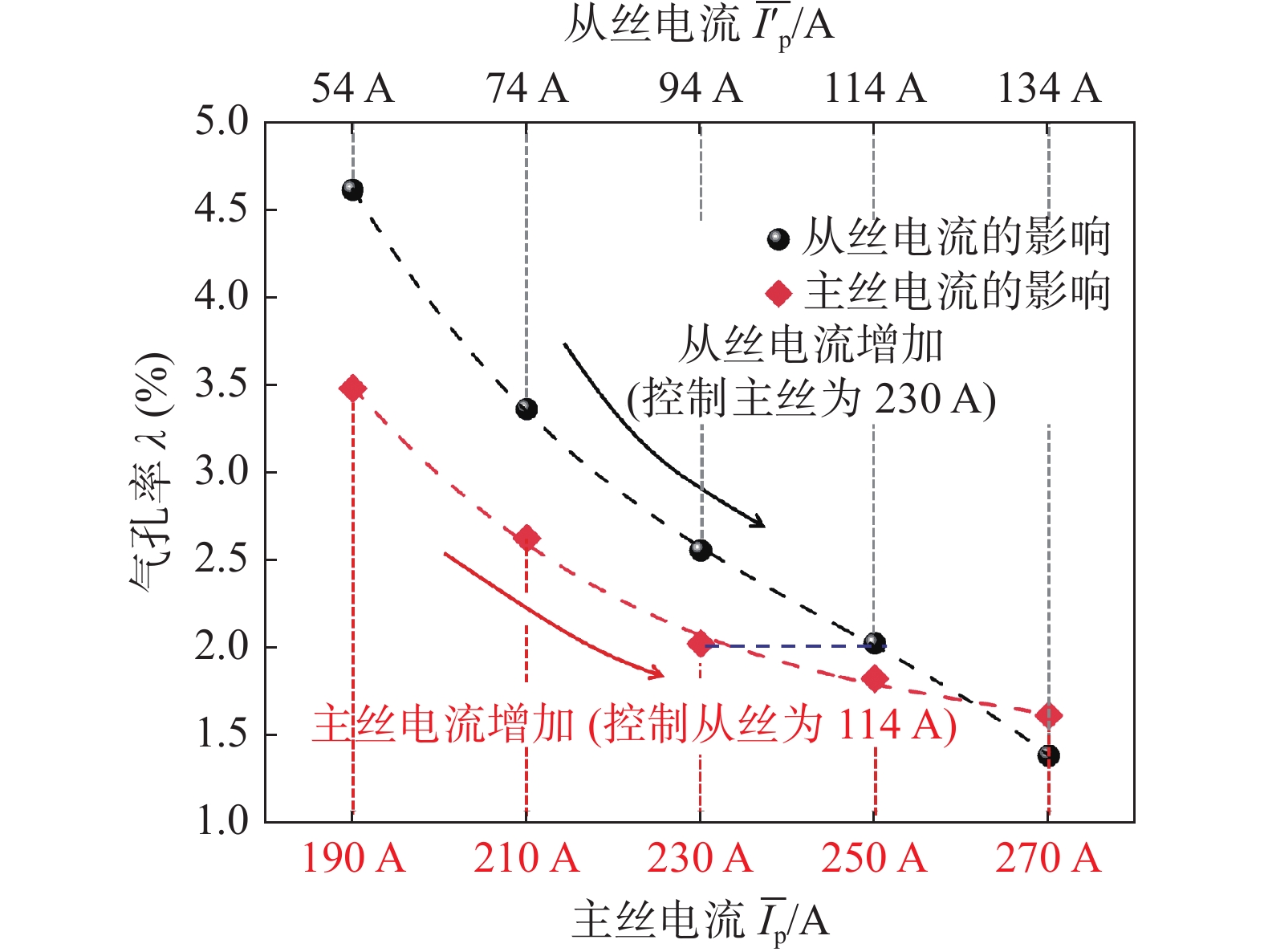

摘要: 为提高7075-T6铝合金熔化焊接接头性能,提出了一种双丝脉冲冷金属过渡(DW-CMTP)焊接方法,并研究了双丝平均电流大小对6 mm厚7075-T6铝合金对接接头组织和力学性能的影响. 结果表明,通过调控主、从丝电流可实现DW-CMTP焊接过程无明显飞溅且焊后接头成形效果良好;增加主、从丝平均电流分别能够促进熔深和熔宽;提高主丝平均电流可增大气泡上浮力,提高从丝平均电流则可加强熔池流动,以致均促进了焊缝中气体逸出,且从丝平均电流的增大对气孔降低效果更为显著;接头强度随主丝平均电流增大呈现先增加后降低的趋势,随从丝平均电流的增大则呈现先降低后增加的趋势,焊接接头最大强度达到389 MPa,为母材强度的70.8%.

-

关键词:

- 7075铝合金 /

- 双丝脉冲冷金属过渡焊 /

- 显微组织 /

- 力学性能 /

- 气孔

Abstract: In order to improve the performance of the fusion welded joint of 7075-T6 aluminum alloy, a double-wire pulsed cold metal transition (DW-CMTP) welding method was proposed. The effects of the average currents of double wires on the microstructure and mechanical properties of the butt joints of 7075-T6 aluminum alloy plates in 6mm thickness were studied. The results showed that in the DW-CMTP process no obvious spattering appeared and the joint was shaped very well by adjusting the leading and trailing wire currents. Both the weld penetration depth and the weld width enlarged with the increases of the average leading and trailing wire currents respectively. Increasing either the average leading or trailing wire current enlarged the bubble’s buoyant force and fostered the flow of the molten pool. The trailing wire current had a more significant effect on the reduction of porosity in the weld seam. The tensile strength of the joint increased first and then decreased with the average leading wire current increasing, while the strength decreased first and then increased with the average trailing wire current. The maximum joint strength reached 389 MPa, which was 70.8% of that of the base metal. -

0. 序言

随着核电汽轮机功率的不断增加,汽轮机转子的尺寸也随之加大,早期的整体锻造技术和套装转子已不能满足所要求的相应性能,而在结构和性能上更有优势的焊接转子技术,逐渐用于大尺寸汽轮机转子的制造[1-3]. 由于焊接温度的梯度变化,使汽轮机焊接转子接头区域由焊缝区、热影响区和母材区组成,不同区域的化学成分、组织和晶体结构等存在差异,导致汽轮机焊接转子接头在一定的腐蚀环境中存在电偶腐蚀效应[4-5]和力学性能差异. 对于异种金属焊接结构,Wang等人[6]发现A508钢与52M合金异种焊接接头中,两种材料存在的电势差使A508钢优先发生均匀腐蚀,而52M合金则被保护. 对于NiCrMoV钢同种金属焊接结构,在180 ℃,3.5% NaCl溶液中浸泡的U形试样表面发现靠近熔合线的焊缝区优先产生了大量点蚀坑[7]. 此外,核电汽轮机焊接转子在实际运转中受应力与环境的交互作用,存在发生应力腐蚀开裂(SCC)的可能[8-9],而热影响区和焊缝区成为发生SCC的敏感区域[10-12].

汽轮机在启停或变负荷等非稳定工况时,由于热应力和离心应力的作用使核电汽轮机焊接转子产生一定的疲劳损伤[13-14]. 一方面,在核电汽轮机的启动和停机过程中,由于核电汽轮机转子沿半径方向的温度分布不均匀产生较大的热应力,根据弹性应力的计算方法得出的热应力可能超过材料的屈服极限[15],同时考虑热应力与离心应力的共同作用,有可能使核电汽轮机焊接转子产生一定的低周疲劳损伤. 另一方面,在核电汽轮机稳态运行的过程中,由于叶片与核电汽轮机焊接转子的重力载荷、离心力等载荷作用使核电汽轮机焊接转子产生一定的高周疲劳损伤. 研究表明,疲劳后金属材料的微观组织与力学性能发生了显著变化,位错密度发生了降低[16-18]. 对于核电汽轮机焊接转子,疲劳后发生了不同程度的软化现象[19-22]. 循环软化不仅使材料的力学性能发生变化,还导致了微观结构的改变[18],同时疲劳也使转子接头各区域的电化学性能随之改变,母材和焊缝区之间的腐蚀电位差变大,增大了电偶腐蚀敏感性[23]. 核电汽轮机焊接转子的破坏主要受载荷(疲劳和蠕变)和环境因素(腐蚀、应力腐蚀、腐蚀疲劳)的影响. 根据上述介绍可以发现,对于核电汽轮机焊接转子的疲劳、腐蚀及应力腐蚀性能已做了广泛的研究. 但是,对于核电汽轮机焊接转子承受一定疲劳损伤后的应力腐蚀问题鲜有研究.

研究预先对核电汽轮机转子钢焊接接头进行不同循环周次的疲劳试验,随后通过慢应变速率拉伸试验(SSRT)研究其应力腐蚀开裂敏感性,进一步采用光学显微镜(OM)、显微硬度仪和扫描电子显微镜(SEM),研究了疲劳损伤对核电汽轮机焊接转子接头应力腐蚀开裂敏感性的影响及断裂机理.

1. 试验方法

试验所用的母材为25Cr2NiMoV核电汽轮机低压转子用钢(简称为25Cr2Ni2MoV钢),母材(BM)和焊缝(WM)的化学成分如表1所示,室温下,25Cr2Ni2MoV钢的屈服强度为700 MPa,抗拉强度为800 MPa. 接头通过窄间隙焊进行焊接,其中分别采用自动氩弧焊(automatic argon-welding, AMAW)和埋弧焊(submerged arc welding, SAW)进行打底和填充焊接.

表 1 25Cr2Ni2MoV钢焊接接头母材和焊缝的化学成分(质量分数,%)Table 1. Chemical compositions of 25Cr2Ni2MoV welded joint base metal and weld材料 C Si Mn P S Cr Ni Mo V BM 0.23 0.10 0.18 0.005 0.005 2.33 2.21 0.75 0.1 WM 0.12 0.20 1.48 0.005 0.005 0.57 2.18 0.51 — 为了研究疲劳损伤对核电汽轮机焊接转子接头应力腐蚀敏感性的影响,首先对材料进行一系列疲劳中断试验. 疲劳试验的试样为跨焊接接头试样,如图1所示. 焊缝位于试样中间,具体尺寸如图1a所示,试样中间部分为焊缝. 试验采用应力控制,应力范围为7.6 ~ 760 MPa,载荷谱为正弦波,应变比为0.1,频率为0.5 Hz,中断试验的循环周次分别为2 500,5 000,9 000和15 000周次.

以热影响区(heat affected zone, HAZ)为中心,在不同循环周次的疲劳试样上的焊接接头取样,试样尺寸为10 mm × 10 mm × 2 mm. 利用蔡司光镜,在50倍和500倍下观察焊接接头母材区、焊缝区和热影响区的微观组织. 观察前,试样表面依次用180,400,800,1200和2000目的金刚石砂纸打磨、抛光,最后使用4%硝酸酒精溶液对表面进行化学腐蚀.

显微硬度的测量采用和微观观察相同的试样,在未经疲劳的原始试样上进行,测量的区域以熔合线为中心线及其两侧各5 mm的区域;试验采用维氏硬度仪,加载压力为1.96 N,保载时间为15 s.

SSRT试验试样均由经过不同循环周次的疲劳试样加工而成,取样如图1a中虚线所示,其尺寸如图1b所示,熔合线在试样标距段的中央,标距段上包含WM,HAZ和BM 3个区域. 为了对比疲劳损伤对汽轮机焊接转子应力腐蚀敏感性的影响,同时进行了未疲劳接头的拉伸试验.

为了评定材料的应力腐蚀开裂敏感性,分别在180 ℃、空气和180 ℃、3.5 % NaCl(质量分数)溶液中进行SSRT,应变速率为1 × 10−6 s−1. 试验采用CORTEST高温高压慢应变速率应力腐蚀试验机. 试验前将试样依次使用去离子水和无水乙醇超声清洗5 min后吹干,装入反应釜内的夹具上,釜内温度达到180 ℃后开始试验,由试验机的位移传感器和力传感器记录力与位移曲线,直到试样断裂后停止试验. 待反应釜冷却后取出断裂试样,将试样依次使用去离子水和无水乙醇超声清洗5 min后吹干,测量断面收缩率,并使用扫描电镜观察断口形貌.

2. 试验结果与讨论

2.1 微观组织与显微硬度

图2为未疲劳焊接接头的微观显微组织. BM由板条状回火马氏体组成;WM由马氏体基体、条状贝氏体和少量铁素体组成;HAZ晶粒大小由于焊接时温度的梯度变化,从熔合线向母材不断减少,分为粗晶区和细晶区,粗晶区微观组织由回火马氏体和板条状贝氏体组成,细晶区微观组织由颗粒状的回火马氏体组成. 图2e为未疲劳焊接接头整体显微组织形貌,显微组织从左到右分别为WM,HAZ和BM. 对比了疲劳前后的微观组织,由于组织未发生变化,故文中未提供疲劳焊接接头的微观组织. 图3为未疲劳焊接接头的显微硬度的变化和分布. 从图3可以看出,焊接接头中熔合线处的硬度最高,3个区域中HAZ的硬度最高,BM和WM处的硬度相差不大.

2.2 SSRT试验结果

经不同疲劳损伤的试样分别在180 ℃、空气和180 ℃、3.5% NaCl溶液中进行SSRT得到的载荷与位移曲线如图4所示. 从图4可以看出,无论是空气还是3.5% NaCl溶液中,疲劳后试样的屈服强度与抗拉强度均比未疲劳试样高,这表明经疲劳后试样的强度得到了提高,这是应变强化的结果. 对比空气中和腐蚀环境下拉伸试样的断面收缩率和断后伸长率可以发现,疲劳损伤对接头的断面收缩率和断后伸长率影响较小,而在3.5% NaCl溶液中,经不同循环周次后的疲劳接头断面收缩率和断后伸长率与未疲劳接头相比都发生了一定程度的下降. 但是,从表2可以看出,拉伸试验所获的屈服强度与抗拉强度并没有随着循环周次的增加而增大,断面收缩率和断后伸长率也未能发现明确的变化规律. 利用断面收缩率和断后伸长率计算得到不同循环周次下的应力腐蚀开裂敏感性系数I1和I2列于表2中,所用公式如下.

表 2 SSRT试验参数与应力腐蚀开裂敏感性指标Table 2. SSRT experimental parameters and stress corrosion cracking sensitivity indexes疲劳寿命C(周次) 环境 屈服强度ReL/MPa 强度极限RTS/MPa 断后伸长率A(%) 断面收缩率Z(%) 敏感性参数(%) I1 I2 0 空气 647 708 13.5 59.5 — — 腐蚀 602 666 7.0 29.5 51.85 49.58 2 500 空气 710 738 15.0 66.0 — — 腐蚀 665 724 5.5 12.0 36.67 18.18 5 000 空气 688 763 15.0 62.0 — — 腐蚀 681 742 5.0 17.5 33.33 28.23 9 000 空气 705 759 14.5 64.5 — — 腐蚀 679 726 4.5 12.5 31.03 19.38 15 000 空气 707 751 14.0 63.0 — — 腐蚀 675 717 6.0 16.0 42.86 25.40 $$ I = \left( {{\delta _{\rm{s}}}/{\delta _0}} \right) \times 100\% $$ (1) 式中:

$\delta _{\rm{s}} $ 和$\delta _0 $ 分别代表180 °C下3.5% NaCl溶液和空气环境中的SSRT试验参数. I的值越小,说明材料的应力腐蚀开裂敏感性越大. 计算所得的应力腐蚀开裂敏感性系数如表2所示,从表2可以看出经过疲劳后,开裂不论采用断后伸长率还是断面收缩率计算获得的应力腐蚀开裂敏感性参数均发生了下降,这说明了疲劳损伤增强了焊接接头的应力腐蚀开裂敏感性.焊接接头SSRT试样的断裂位置如图5所示. 值得注意的是,空气中拉伸试样的断裂位置均在WZ. 但是,在腐蚀环境下,焊接接头的断裂位置出现了明显的变化,对于0周次和15 000周次的试样,其断裂位置仍在WZ,然而对于2 500,5 000及9 000周次的试样,其断裂位置却变为靠近熔合线的HAZ. 这是由于疲劳损伤加大了焊接接头不同区域的力学性能差异,从而使SSRT试样的断裂位置发生了显著改变,这导致了SSRT结果中获得的不同疲劳周次下焊接接头力学性能参数及应力腐蚀开裂敏感性未出现明显规律.

2.3 断口形貌

为了进一步明确焊接接头试样的力学性能差异及应力腐蚀开裂机理,采用扫描电镜对空气和3.5% NaCl溶液中的SSRT试样断口进行观察,所得的典型断口形貌如图6 ~ 图10所示.

空气中断裂的试样断口为明显的杯口状断口形貌,断口中央为韧窝且面积占比较大,断口四周凹陷,这属于典型的延性断裂. 图7b和图7c为在3.5% NaCl溶液中经不同疲劳损伤的SSRT试样的断口形貌,不同于空气中的试样断口,断口四周都较为平整,有少量河流状花纹,表现出脆性断裂的特征,而中间的断口呈韧窝状. 此外,由于疲劳后试样的应变强化使接头的屈服增加,而屈服强度的增加会显著的增加应力腐蚀裂纹的扩展速率,使存在疲劳损伤的SSRT试样的收缩率下降(表2). 对比图7b和图7c,存在疲劳损伤的试样断口没有发现明显的脆性断裂和延性断裂的分界线,但相较于没有疲劳的图7b,其颈缩程度降低,即发生脆性断裂的面积增大.

值得注意的是,不同于空气中未疲劳试样的断口,不论在空气中还是腐蚀环境下,存在疲劳损伤的试样断口表面均出现较多二次裂纹. 对于空气中的裂纹,一旦形核扩展,位错就会不断向裂纹尖端运动,当裂纹尖端遇到晶界,且位错堆积不能使裂纹继续扩展,裂纹的扩展就会停止,而裂纹的扩展受阻,便会在裂纹两边扩展出二次裂纹[24]. 由表2中的力学性能数据可以看出,疲劳损伤增大了材料的强度,裂纹尖端便更容易受到阻碍,从而扩展出二次裂纹,呈现出图7a中的二次裂纹形貌. 此外,试样在拉伸过程中由于二次裂纹吸收了大量的能量,从而呈现出表2所示的存在疲劳损伤的试样在空气中的断后伸长率增加、塑性得到提高的现象.

在腐蚀环境中,不论是否受到疲劳损伤,均表现出明显的二次裂纹(图7b和图7c),这说明断口表面二次裂纹的形成机理不同于空气中的二次裂纹,是具有较强应力腐蚀开裂敏感性的典型特征.除了疲劳损伤增大了材料的强度外,随着裂纹的扩展,裂纹尖端的应力集中增大了局部附加电位,促进了裂纹尖端的阳极溶解和阴极反应[25]. 此外,裂纹尖端的高塑性变形区域也使阴极析出的氢加速在裂纹尖端的聚集,促进了二次裂纹的形成和扩展. 因此,SSRT试样中的二次裂纹是腐蚀环境和载荷协同作用的结果.

2.4 应力腐蚀裂纹扩展机理

空气中拉断的试样如图11所示,断口附近光滑无裂纹;而3.5% NaCl溶液中腐蚀环境下断裂位置附近的表面形貌如图12所示,可以观察到断裂位置附近的试样上有很多微小的裂纹,且都与拉伸的方向垂直. 图12a和图12c是典型的0周次和9 000周次的SSRT试样裂纹扩展的情况,其它周次的SSRT试样上的裂纹与9 000周次的类似,从图12可以看出裂纹都是穿过马氏体簇的,即裂纹扩展方式都为穿晶.

![]() 图 12 3.5%NaCl溶液中典型疲劳周次SSRT断裂位置附近表面形貌与裂纹形貌Figure 12. Surface topography near the typical fatigue fracture location and crack morphology in 3.5% NaCl solution. (a) 0 cycle ;(b) amplifying at A of 0 cycle; (c) 9 000 cycles; (d) amplifying at B of 9 000 cycles; (e) crack morphology of 0 cycle; (f) crack morphology of 9 000 cycles

图 12 3.5%NaCl溶液中典型疲劳周次SSRT断裂位置附近表面形貌与裂纹形貌Figure 12. Surface topography near the typical fatigue fracture location and crack morphology in 3.5% NaCl solution. (a) 0 cycle ;(b) amplifying at A of 0 cycle; (c) 9 000 cycles; (d) amplifying at B of 9 000 cycles; (e) crack morphology of 0 cycle; (f) crack morphology of 9 000 cycles裂纹通常沿组织中最容易扩展的方向进行,焊接接头中焊缝以马氏体组织为主,板条马氏体一般由几个板条束组成,而板条束由几个晶粒取向相似的板条块组成,由于马氏体簇的晶粒取向相似,其阻碍裂纹扩展的阻力小于取向不相同的晶粒,裂纹便会优先在板条马氏体中扩展,因此裂纹呈现出穿晶开裂的现象[26-27],表现出较强的应力腐蚀开裂敏感性.

为了进一步分析腐蚀介质对应力腐蚀开裂敏感性的影响,对裂纹尖端附近进行了能谱分析,如图12e和图12f所示. 从图12e和图12f可以看出,在腐蚀介质的作用下,整个裂纹都被氧化膜覆盖. 表3所列的是图12e和图12f裂纹不同位置氧化物和基体的元素分布,当裂纹扩展到一定程度后,由于SCC裂纹宽度只有微米级,在慢应变速率的作用下,裂纹由于力的作用快速向前扩展,O元素来不及进入裂纹尖端,呈现出表中从裂纹嘴到裂纹尖端覆盖的氧化物中O元素的比重不断下降的趋势;另一方面,正是由于SCC裂纹尖端的氧分压较低,铬的氧化物吉布斯自由能比周围氧化物高,导致了四周基体金属中的的Cr元素扩展至裂纹表面使Cr元素比重增加[27]. 裂纹嘴形成的铬、镍氧化层在基体上形成了一层保护层使得基体金属不会被继续腐蚀. 在拉伸的作用下,裂纹尖端氧化膜发生破裂,露出金属继续被腐蚀形成新的氧化膜,如此循环往复,加速了裂纹的形成与扩展.

表 3 典型周次裂纹形貌EDS元素分布(质量分数,%)Table 3. Distribution of crack morphology EDS element under typical cycles位置 O Cl Cr Fe Ni 0周次 9 000周次 0周次 9 000周次 0周次 9 000周次 0周次 9 000周次 0周次 9 000周次 1 25.73 25.35 0.09 0.07 0.61 1.06 63.53 71.14 1.93 2.38 2 16.27 21.57 0.01 0.11 0.3 0.65 29.36 75.56 0.7 2.11 3 18.67 18.05 0.11 0.11 1.3 0.98 59.49 77.69 1.35 2.36 4 0 0.43 0 0.07 0.71 0.85 80.67 95.63 1.73 3.01 3. 结论

(1)疲劳损伤影响了核电汽轮机焊接转子的应力腐蚀开裂敏感性,随循环周次增加的疲劳损伤增大了焊接接头的应力腐蚀开裂敏感性.

(2)不同循环周次下的疲劳损伤未表现出特定的应力腐蚀开裂敏感性规律,这与不同区域的微观组织和力学性能差异有关,在腐蚀环境的作用下,SSRT试样的断裂位置出现了显著变化.

(3)空气中和腐蚀环境下,疲劳后的SSRT试样断口均有大量二次裂纹. 前者环境下疲劳损伤产生的位错堆积促进了二次裂纹的形成,提高了焊接接头的塑性;而后者环境下应力和腐蚀环境的交互作用促进了二次裂纹的形核与扩展,降低了焊接接头的塑性.

-

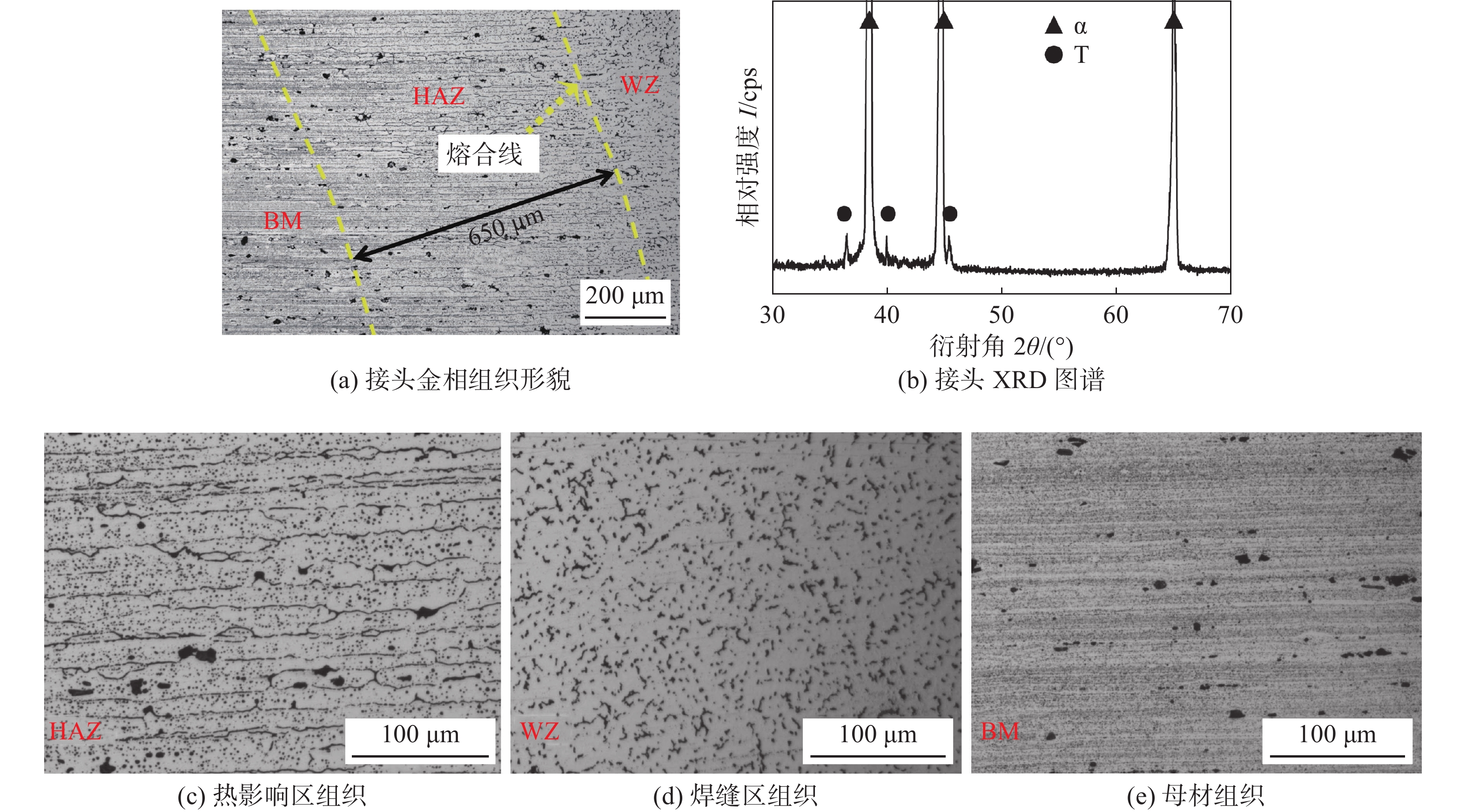

图 5 DW-CMTP焊接接头组织形貌(

$ \overline{{I}_{\mathrm{p}}} $ = 230 A 和$ \overline{I\mathrm{^{\prime}}}_{\mathrm{p}} $ = 114 A)及接头XRD图谱.Figure 5. Microstructure of DW-CMTP welded joint (

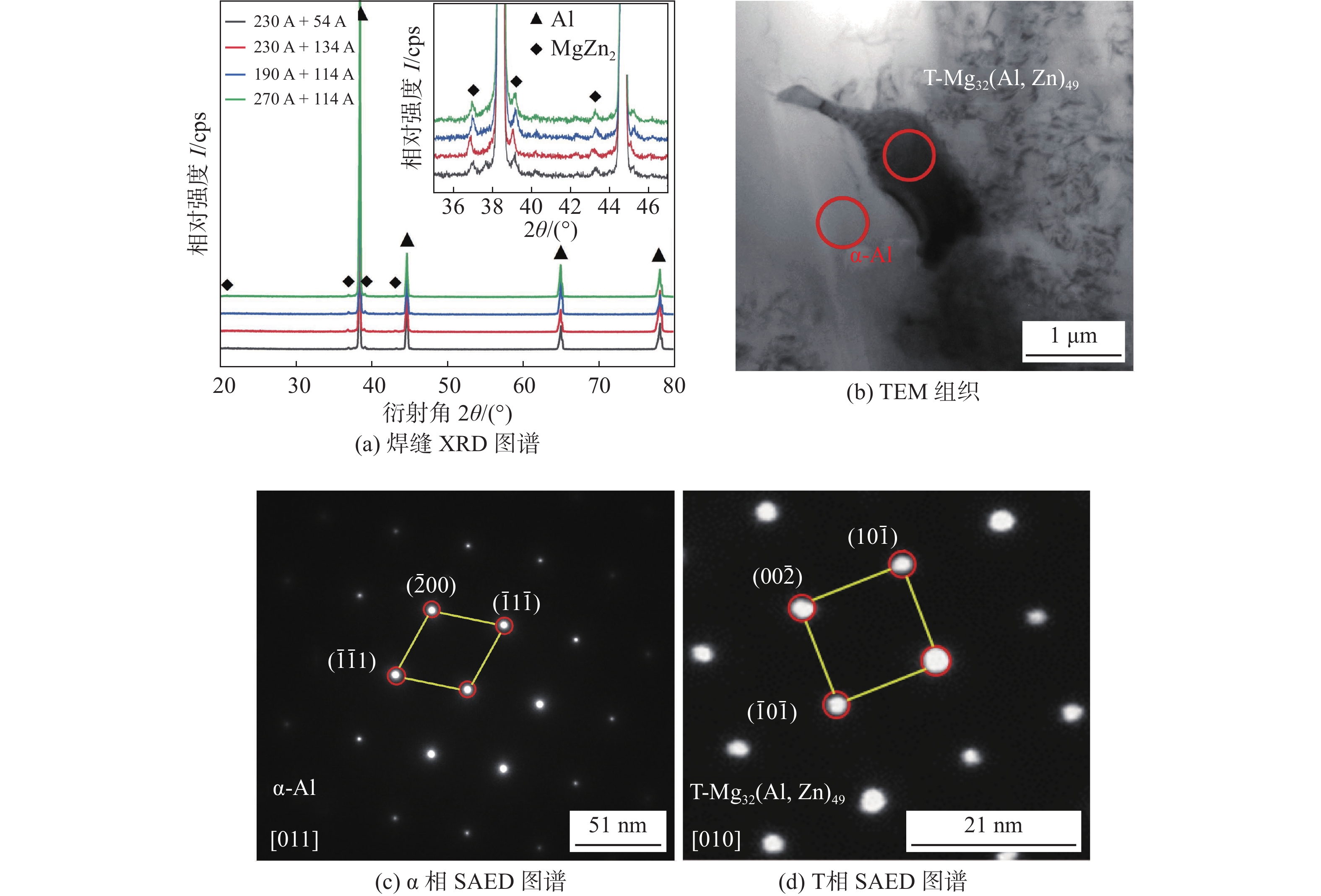

$ \overline{I}_{\mathrm{p}} $ = 230A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A) and XRD pattern of joint. (a) metallographic morphology of joint; (b) XRD pattern of joint; (c) HAZ microstructure; (d) WZ microstructure; (e) BM microstructure图 6 不同工艺下焊缝中心处的XRD图谱和主、从丝电流分别为230 A和134 A时焊缝中心组织形貌

Figure 6. XRD patterns of the weld center of different welding parameters and TEM image of the weld center responding to 230 A leading wire current and 114 A trailing wire current. (a) XRD pattern of weld center; (b) TEM image; (c) SAED pattern of α phase; (d) SAED pattern of T phase

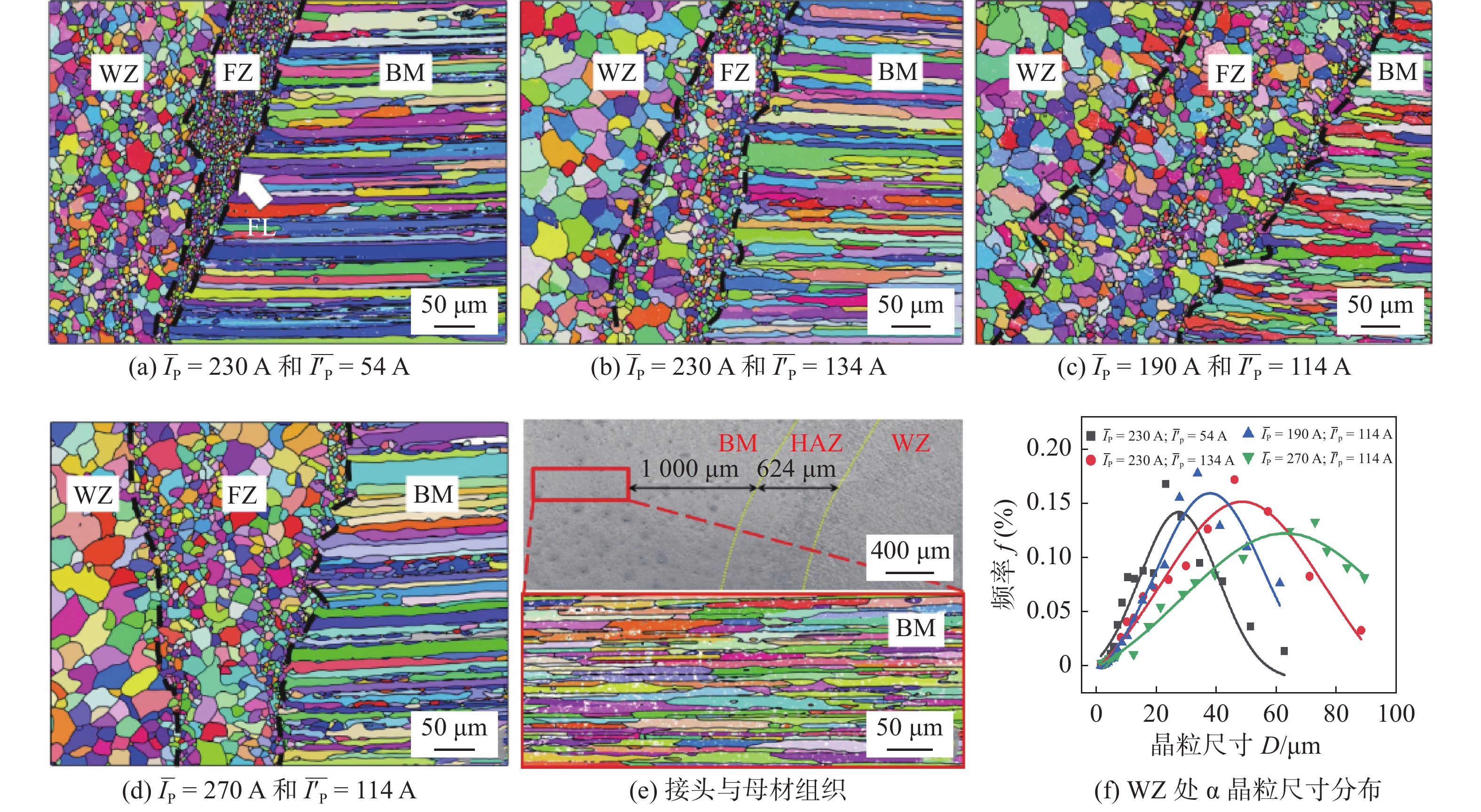

图 7 不同主、从丝电流下对应的接头和母材组织的EBSD图以及焊缝中心α晶粒尺寸分布图

Figure 7. EBSD graphs of the joints and BM under different leading and trailing current parameters and α grain size distribution of weld center. (a)

$ \overline{{I}_{\mathrm{p}}} $ = 230 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 54 A; (b)$ \overline{{I}_{\mathrm{p}}} $ = 230 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 134 A; (c)$ \overline{{I}_{\mathrm{p}}} $ = 190 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A; (d)$ \overline{{I}_{\mathrm{p}}} $ = 270 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A; (e) microstructure of joint and BM; (f) α grain size distribution of weld center图 8 主丝电流(

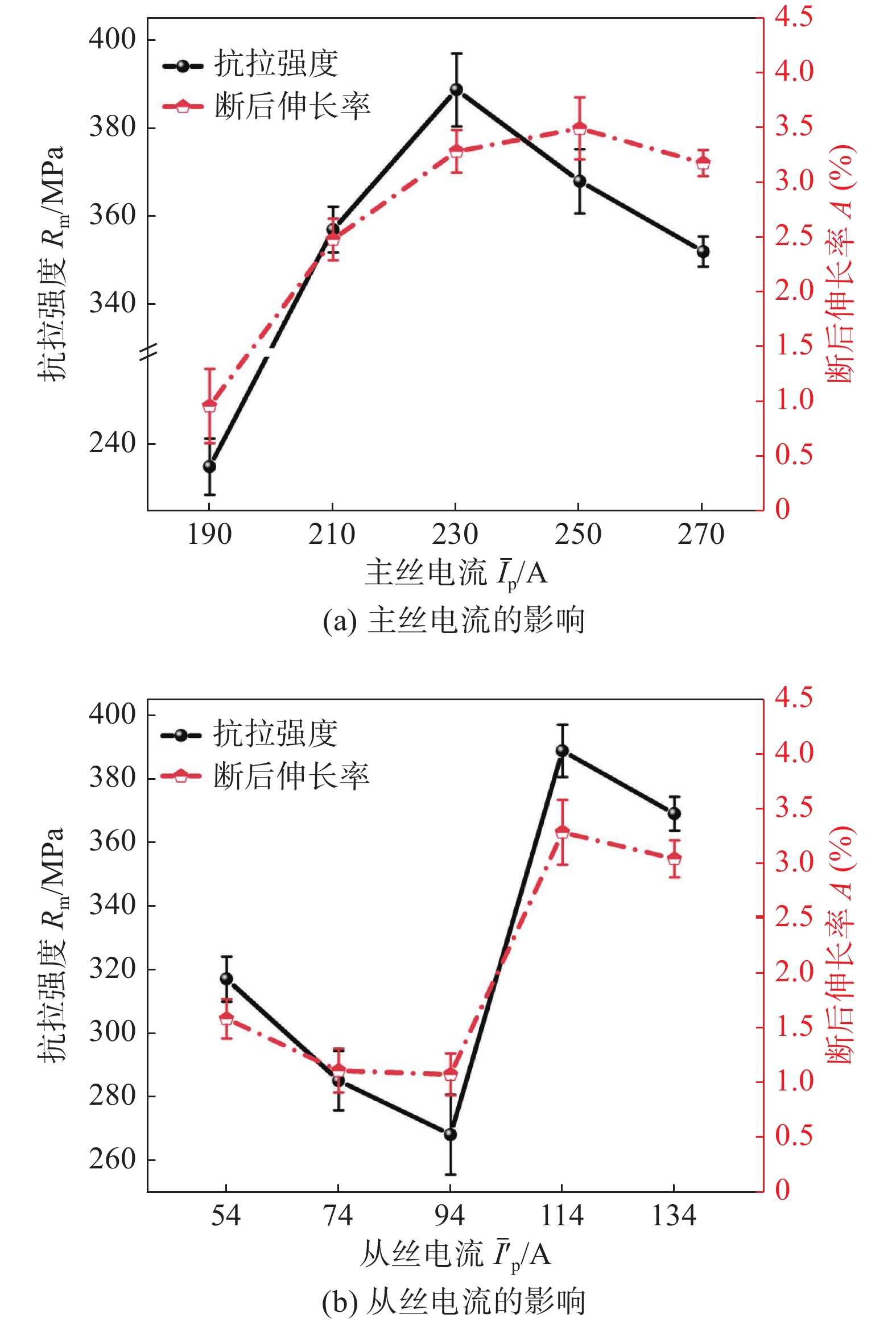

$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A)和从丝电流($ \overline{{I}_{\mathrm{p}}} $ = 230 A)变化对接头抗拉性能的影响Figure 8. Effects of leading wire current (

$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A) and trailing wire current ($ \overline{{I}_{\mathrm{p}}} $ = 230 A) on joint tensile strength. (a) effect of leading wire current; (b) effect of trailing wire current图 9 主丝电流(

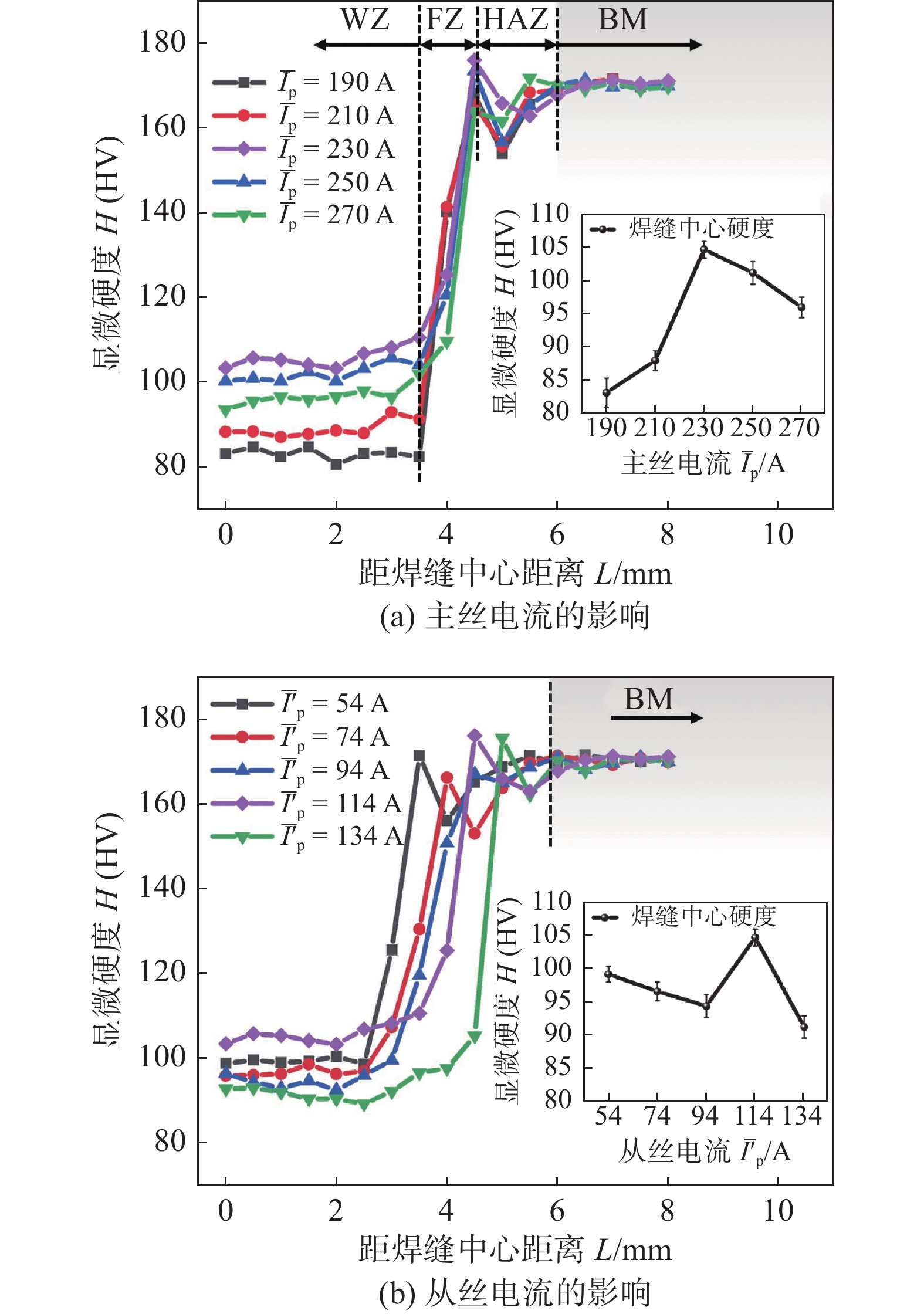

$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A)和从丝电流($ \overline{{I}_{\mathrm{p}}} $ = 230 A)变化对接头硬度的影响Figure 9. Effects of leading wire current (

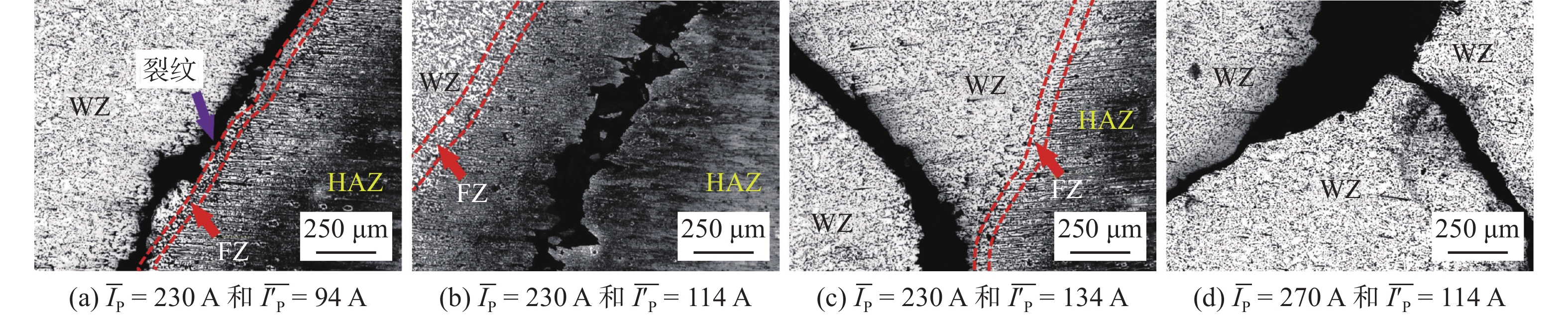

$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A) and trailing wire current ($ \overline{{I}_{\mathrm{p}}} $ = 230 A) on joint hardness. (a) effect of leading wire current; (b) effect of trailing wire current图 10 不同主、从丝电流对应的拉伸断口位置

Figure 10. Tensile fracture positions corresponding to different leading and trailing wire currents. (a)

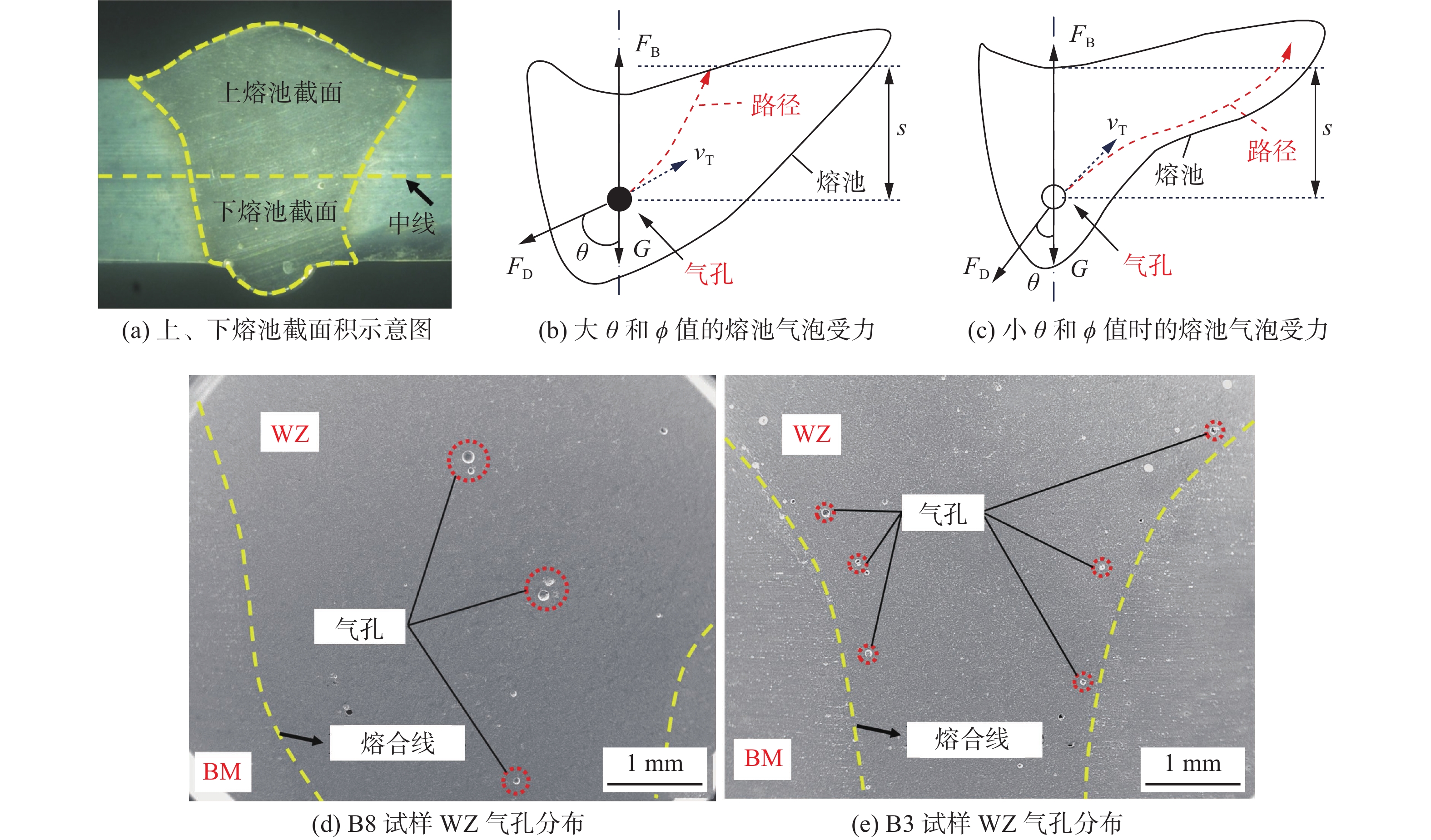

$ \overline{{I}_{\mathrm{p}}} $ = 230 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 94 A; (b)$ \overline{{I}_{\mathrm{p}}} $ = 230 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A; (c)$ \overline{{I}_{\mathrm{p}}} $ = 230 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ =134 A; (d)$ \overline{{I}_{\mathrm{p}}} $ = 270 A and$\overline{I\mathrm{^{\prime}}}_{\mathrm{p}}$ = 114 A图 13 熔池中气泡受力情况和DW-CMTP焊接接头气孔分布

Figure 13. Force condition of bubble in weld pool and pore distribution of in DW-CMTP welded joint. (a) schematics of the cross-sectional area of upper and lower weld pool; (b) force condition of bubble under bigger θ and ϕ; (c) force condition of bubble under smaller θ and ϕ; (d) pore distribution of WZ in sample B8; (e) pore distribution of WZ in sample B3

表 1 母材和焊丝的化学成分(质量分数,%)

Table 1 Chemical compositions of base metal and welding wire

材料 Si Fe Mn Zn Mg Cu Al 7075-T6 0.13 0.24 0.20 6.03 2.22 1.42 余量 ER5356 0.05 0.30 0.16 — 5.050 0.01 余量 表 2 母材和焊丝的力学性能

Table 2 Mechanical properties of base metal and welding wire

材料 抗拉强度Rm/MPa 屈服强度ReL/MPa 断后伸长率A(%) 7075-T6 548 476 12 ER5356 278 165 21 表 3 焊接工艺参数

Table 3 Welding process parameters

组别 主丝

($ {I}_{\mathrm{b}1} $ = 160 A,$ {I}_{\mathrm{p}2} $ = 130 A,$ {I}_{\mathrm{b}2} $ = 50 A)从丝

($ {I^{\prime}}_{\mathrm{b}1} $ = 50 A,$ {I^{\prime}}_{\mathrm{p}2} $ = 45 A,$ {I^{\prime}}_{\mathrm{b}2} $ =30 A)$ {I}_{\mathrm{p}1} $ /A$\overline{ {I}_{\mathrm{p} } }$ /A$\overline{U}$ /V$ {I^{\prime}}_{\mathrm{p}1} $ /A$\overline{I^{\prime} }_{\mathrm{p} }$ /A$\overline{U^{\prime} }$ /VB1 330 230 21.4 91 54 2.4 B2 330 230 21.4 133 74 3.7 B3 330 230 21.4 175 94 5.3 B0 330 230 21.4 218 114 7.0 B4 330 230 21.4 260 134 7.0 B5 245 190 20.2 218 114 7.0 B6 287 210 20.9 218 114 7.0 B7 372 250 22.0 218 114 7.0 B8 415 270 24.5 218 114 10.4 -

[1] Lee W S, Lin C R. Deformation behavior and microstructural evolution of 7075-T6 aluminum alloy at cryogenic temperatures[J]. Cryogenics, 2016, 79: 26 − 34. doi: 10.1016/j.cryogenics.2016.07.007

[2] Pickin C G, Young K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy[J]. Science and Technology of Welding and Joining, 2013, 11(5): 583 − 585.

[3] Alatorre N, Ambriz R R, Noureddine B, et al. Tensile properties and fusion zone hardening for GMAW and MIEA welds of a 7075-T651 aluminum alloy[J]. Acta Metallurgica Sinica (English Letters), 2014, 27(4): 694 − 704. doi: 10.1007/s40195-014-0103-x

[4] 刘长军, 刘政军, 阮祥钢, 等. 焊后热处理对AA7075铝合金DP-MIG焊接接头组织及力学性能的影响[J]. 焊接学报, 2016, 37(10): 81 − 84,88. Liu Changjun, Liu Zhengjun, Ruan Xianggang, et al. Effect of post-weld heat treatment on microstructure and mechanical properties of welded joint of 7075 aluminum alloy by double-plused metal inert-gas welding process[J]. Transactions of the China Welding Institution, 2016, 37(10): 81 − 84,88.

[5] Yang K, Wang F, Liu H B, et al. Double-pulse triple-wire MIG welding of 6082-T6 aluminum alloy: process characteristics and joint performances[J]. Metals, 2021, 11(9): 1388. doi: 10.3390/met11091388

[6] Liu A H, Tang X H, Lu F G. Weld pool profile characteristics of Al alloy in double-pulsed GMAW[J]. The International Journal of Advanced Manufacturing Technology, 2013, 68: 2015 − 2023. doi: 10.1007/s00170-013-4808-1

[7] Wu K Y, Liang Z Y, Yin T, et al. Double pulse low-frequency modulation for high-power double-wire pulsed GMAW[J]. Journal of Manufacturing Science and Engineering, 2018, 140(9): 091004. doi: 10.1115/1.4040319

[8] Alatorre N, Ambriz R R, Amrouche A, et al. Fatigue crack growth in Al-Zn-Mg (7075-T651) welds obtained by modified indirect and gas metal arc welding techniques[J]. Journal of Materials Processing Technology, 2017, 248: 207 − 217. doi: 10.1016/j.jmatprotec.2017.05.025

[9] Yang B J, Fu Z H, Li T, et al. Microstructure and fracture toughness properties of CMT repairing welded 7075-T651 MIG welding joint[J]. Materials Research Express, 2019, 6(12): 1265d6.

[10] Selvi S, Vishvaksenan A, Rajasekar E. Cold metal transfer (CMT) technology-an overview[J]. Defence Technology, 2018, 14(1): 28 − 44. doi: 10.1016/j.dt.2017.08.002

[11] Gandhi C, Dixit N, Aranke O, et al. Characterization of AA7075 weldment using CMT process[J]. Materials Today: Proceedings, 2018, 5(11): 24024 − 24032. doi: 10.1016/j.matpr.2018.10.195

[12] Elrefaey A. Effectiveness of cold metal transfer process for welding 7075 aluminium alloys[J]. Science and Technology of Welding and Joining, 2015, 20(4): 280 − 285. doi: 10.1179/1362171815Y.0000000017

[13] Li J J, Shen J Q, Hu S S, et al. Microstructure and mechanical properties of 6061/7N01 CMT + P joints[J]. Journal of Materials Processing Technology, 2019, 264: 134 − 144. doi: 10.1016/j.jmatprotec.2018.09.011

[14] Liang Y, Hu S S, Shen J Q, et al. Geometrical and microstructural characteristics of the TIG-CMT hybrid welding in 6061 aluminum alloy cladding[J]. Journal of Materials Processing Technology, 2017, 239: 18 − 30. doi: 10.1016/j.jmatprotec.2016.08.005

[15] Hu B, Richardson I M. Microstructure and mechanical properties of AA7075(T6) hybrid laser/GMA welds[J]. Materials Science and Engineering:A, 2007, 459(1-2): 94 − 100. doi: 10.1016/j.msea.2006.12.094

[16] Geng S N, Jiang P, Shao X Y, et al. Heat transfer and fluid flow and their effects on the solidification microstructure in full-penetration laser welding of aluminum sheet[J]. Journal of Materials Science & Technology, 2020, 46: 50 − 63.

[17] Chen D, Cai Y H, Luo Y, et al. Analysis on the microstructure regulation based on the pulsed laser oscillating molten pool in Laser-PTA additive manufacturing[J]. Journal of Manufacturing Processes, 2020, 59: 587 − 594. doi: 10.1016/j.jmapro.2020.10.004

[18] Katayama S, Naito Y, Uchiumi S, et al. Physical phenomena and porosity prevention mechanism in laser-arc hybrid welding[J]. Transactions of JWRI, 2006, 35(1): 13 − 18.

[19] Zhang C, Gao M, Wang D Z, et al. Relationship between pool characteristic and weld porosity in laser arc hybrid welding of AA6082 aluminum alloy[J]. Journal of Materials Processing Technology, 2017, 240: 217 − 222. doi: 10.1016/j.jmatprotec.2016.10.001

-

期刊类型引用(2)

1. 翁硕,孟超,朱江峰,王艾,常馨,康妘,何小田,赵礼辉. 应力控制模式下疲劳损伤对AA7075-T651铝合金腐蚀行为影响的研究. 中国腐蚀与防护学报. 2024(04): 1029-1037 .  百度学术

百度学术

2. 王志鹏,朱明亮,轩福贞. CrMoV与NiCrMoV异种钢焊接接头的高周疲劳性能及寿命模型. 焊接学报. 2024(07): 67-73 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: