Research progress on micro/nano joining technologies and failure behaviors in electronic packaging

-

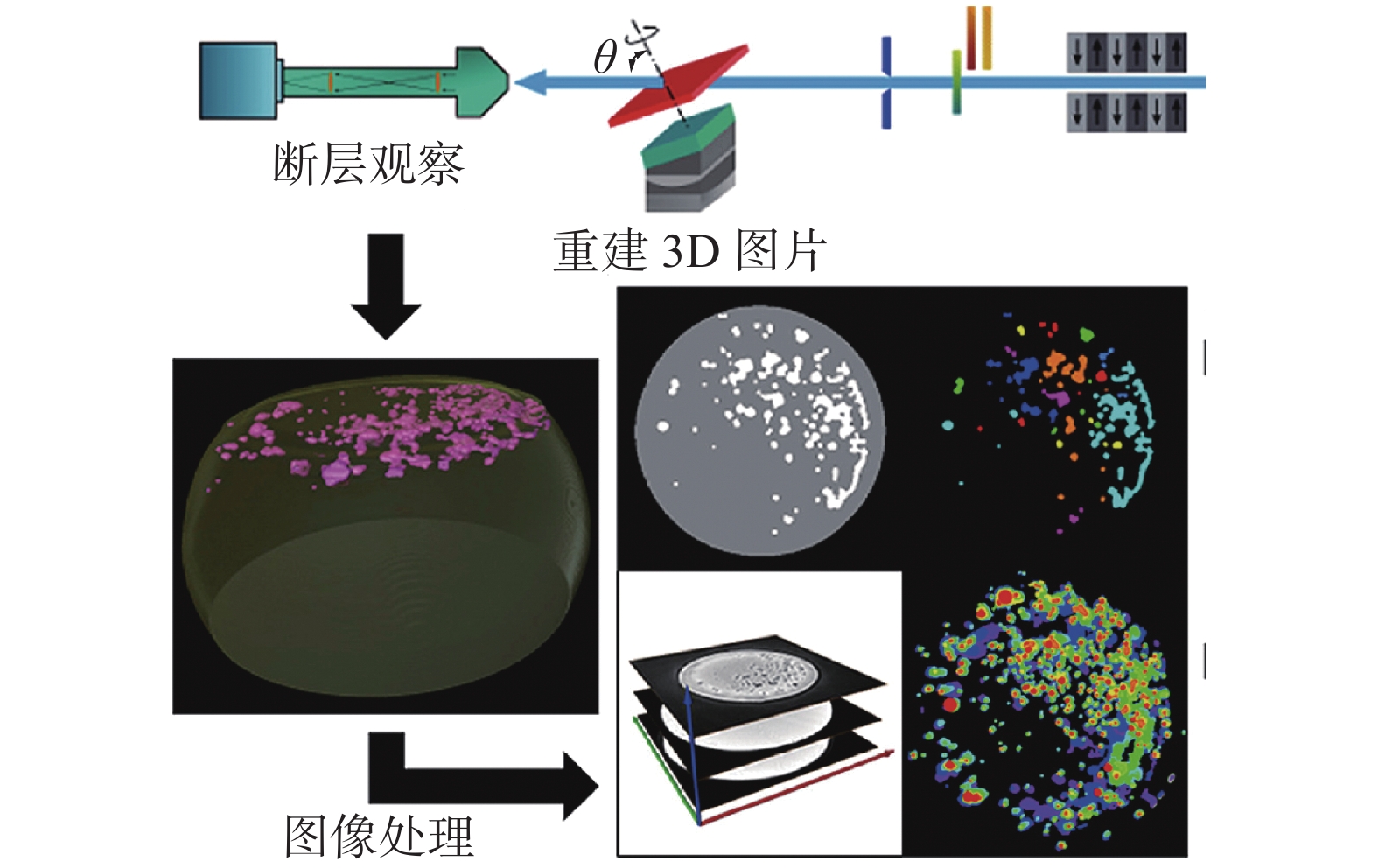

摘要: 微纳连接技术是电子封装中的关键技术,近年来,随着电子产品逐渐小型化、轻量化的方向发展,各种先进的微纳连接层出不穷,但仍缺少系统的归纳及总结. 文中对引线键合技术,熔化微连接技术、软钎焊技术、纳米焊膏烧结技术、导电胶连接技术、表面活化键合技术及新兴的纳米连接技术等具有代表性的微纳连接技术进行了综述,并针对软钎焊焊点在热载荷、电载荷、机械载荷及多物理场耦合作用下微互连的失效行为研究进行了总结. 结果表明,未来的微纳连接技术将朝向互连尺寸更加微小,互连方法逐渐智能化,互连材料更加绿色,互连焊点更可靠的方向发展. 软钎焊互连焊点的失效行为分析也将逐渐从单一热场、电场载荷的研究拓展至热—电—力多物理场耦合载荷,与实际工况更加贴合,随着如同步辐射,三维X射线等先进表征技术的不断发展,失效行为及机制的研究也将更加精准.Abstract: Micro/nano joining are the key technologies in electronic packaging. With the development of electronic products in the direction of miniaturization and lightweight, various advanced micro/nano joining techniques have emerged in an endless flow, but there is still a lack of systematic summary. In this paper, the representative micro-nano bonding technologies are reviewed, including wire bonding, melting micro-bonding, soldering, nano-paste sintering, conductive adhesive bonding, surface-activated bonding and emerging nano joining technology. The failure behaviors of solder joints under thermal, electrical, mechanical and multi-physics coupling load are summarized. In the future, the micro/nano joining technology will be developed in the direction of smaller interconnect size, intelligent interconnect method, green interconnect material and more reliable interconnect solder joint. The failure behavior analysis of solder joints will gradually expand from the study of single load to thermo-electric-mechanical multiple physical field coupling load, which is more suitable for the actual working conditions. With the continuous development of advanced characterization technologies such as synchrotron radiation and 3D X-ray, the study of failure behaviors and mechanisms will also be more accurate.

-

Keywords:

- electronic packaging /

- micro/nano joining /

- failure behavior /

- reliability /

- multiple field coupling

-

0. 序言

电子封装是通过软钎焊的方式将电子元器件与电路板连接起来,长期以来封装使用的钎料是锡铅合金,尽管锡铅合金具有诸多优越性能,但由于电子设备更新周期越来越短,会产生大量电子垃圾,焊点内的铅会污染土壤和地下水. 随着人们环保意识的增强,发达国家和地区纷纷出台法令法规来限制或禁止铅的使用[1-6],因此,人们正在积极开发研究新型无铅钎料[7-11]. 在应力作用下,焊接界面金属间化合物(intermetallic compound, IMC)层附近是焊点中变形最不匹配的区域,容易产生应变失稳,一些研究结果表明,焊接界面的IMC层会影响焊点的应力分布状态,此区域应力集中严重时容易发生裂纹的萌生和扩展,引发焊点失效[12-13].

由于焊接界面金属间化合物形貌和尺寸会直接影响到连接界面应力分布、结合强度等力学性能. 因此,研究界面化合物的尺寸分布和生长规律对进一步指导工艺优化、调控界面化合物层具有重要意义. Suh等人[14]发现Cu/Sn45Pb焊点界面化合物粒径与回流时间的立方根成正比,也有研究表明Sn/Cu回流反应时,Cu6Sn5粒径与t0.5成正比[15]. 这种差异来源于钎料种类的不同,不同钎料在熔融状态时对Cu的饱和溶解度不同,这会引起基体Cu原子向钎料的扩散通量的差异. 总体上Cu6Sn5化合物的粒径平均值

$\bar d $ 与回流时间t的关系均可写作$\bar d $ =ktm的形式,k为常数,m为粗化常数. 对于不同的钎料而言,粗化常数存在差异,但m总是小于1,代表晶粒的生长速度随着回流时间的增加逐渐变慢.在诸多无铅钎料中,Sn-Ag-Cu合金被认为是最有可能取代传统锡铅钎料的合金[16-23]. 目前对Sn-Ag-Cu合金的力学性能已有了深入研究[24-25],但有关Sn-Ag-Cu无铅钎料回流过程中IMC层生长规律的研究相对较少. 文中选用Sn-Ag-Cu合金作为钎料,多晶Cu为基体,制备了一系列Sn3.0Ag0.5Cu/Cu焊点. 在回流温度为240 ℃条件下研究了界面化合物沿平行于界面和垂直于界面方向的生长速度. 通过对大量Cu6Sn5化合物的统计分析得到界面化合物的尺寸分布规律,与理论模型进行对比并给出解释,讨论了界面化合物层的生长机制.

1. 试验方法

选用冷拔多晶Cu为基体材料,其纯度为99.99%,选用Sn3.0Ag0.5Cu焊膏作为钎料. 首先用电火花线切割机按设计好的尺寸加工小块基体材料,依次使用800,1000,2000号的SiC砂纸打磨,随后依次使用粒度分别为2.5,1.0,0.5 μm的金刚石研磨膏进行机械抛光,之后进行电解抛光,消除残余应力,获得平整光亮表面. 电解抛光液配方为:蒸馏水1 000 mL、磷酸500 mL、酒精500 mL、尿素10 g、异丙醇100 mL. 将Sn3.0Ag0.5Cu焊膏均匀地涂覆在抛光好的几组Cu基体表面,然后放入温度为240 ℃的恒温炉中,待钎料熔化后分别在回流态保持2,5,10,15,20 min后,立即将试样从炉中取出,在空气中冷却至室温. 为了观测焊接界面金属间化合物层的厚度,将焊接好的试样按上述方法再次进行打磨和抛光后,使用LEO SUPRA 35型和Gemini SEM 300型场发射扫描电子显微镜观察焊点微观组织和确定成分. 为统计测量界面化合物Cu6Sn5的形貌和粒径分布特征,取一组焊接好的试样,将焊接界面层上面的绝大部分钎料打磨掉,只剩一薄层钎料时直接进行化学腐蚀,使焊接界面上的Cu6Sn5晶粒完全暴露出来,在扫描电镜下观测. 使用Image-Pro Plus软件对界面化合物晶粒的粒径和厚度进行统计测量,IMC的厚度按化合物层的面积除以化合物层的宽度计算.

2. 结果与讨论

2.1 界面化合物的尺寸分布

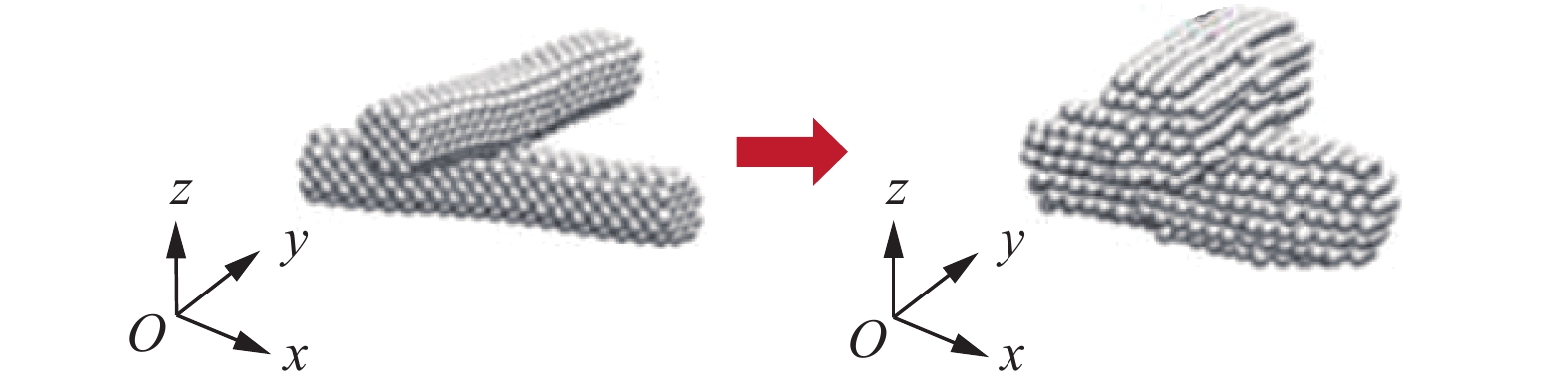

图1为240 ℃回流2,5,15,20 min时焊接界面化合物Cu6Sn5晶粒的俯视显微形貌. 可以看出,随着回流时间增加,Cu6Sn5晶粒逐渐长大,小晶粒所占比例明显减少.

使用Image-Pro Plus 软件统计了多张扫描照片中的Cu6Sn5晶粒尺寸,图2为Cu6Sn5晶粒的粒径平均值与回流时间的变化关系,可以拟合为表达式(1).

$$ \bar d = k{t^{0.38}} $$ (1) 为了更直观地反应Cu6Sn5晶粒尺寸的分布情况,对多张显微形貌中大量的Cu6Sn5晶粒进行了尺寸统计分析,图3为回流2,5,15,20 min的界面化合物Cu6Sn5晶粒的统计结果,图中横坐标表示Cu6Sn5晶粒的粒径,纵坐标代表每个尺寸区间内的晶粒数占晶粒总数的百分比. 可以看出,随着回流时间增加,晶粒尺寸增大的同时,每个尺寸间隔所对应百分比的差异逐渐减小,即晶粒的尺寸分布更加均匀.

有关晶粒尺寸分布的规律,Lifshitz, Slyozov和Wagner在闭系反应的假设条件下曾提出了Lifshitz-Slyozov-Wagner(LSW)理论[26-27],假设晶粒长大时总体积不变,认为晶粒长大的驱动力是由于晶粒表面积减少引起的表面自由能的降低. 然而,在钎料/Cu反应生成的Cu6Sn5晶粒逐渐长大的过程中,Cu基体和钎料之间存在物质交换,界面化合物的总体积是变化的. 因此,回流焊接过程中焊接界面处Cu6Sn5化合物的生长规律不应该套用LSW理论模型. 针对钎料/Cu界面反应时Cu6Sn5体系是一种开放系统的特点,Gusak等人[28]提出了FDR (flux-driven ripening)模型,并给出了晶粒尺寸的分布函数.简要地说,FDR模型的基本前提是总表面积不变而体积增长,尺寸分布律可表示为[14]

$$ g\left( u \right) = c\frac{u}{{{{\left( {2 - u} \right)}^4}}}\exp\left( { - \frac{4}{{2 - u}}} \right) $$ (2) $$ u = \frac{r}{{ < r > }} $$ (3) 式中:g(u)为概率密度;c为常数;u为某一晶粒的半径与平均晶粒半径之比. 为与FRD理论模型对比,对晶粒的统计数据进行了归一化处理. 图4为Sn3.0Ag0.5Cu/Cu界面化合物Cu6Sn5晶粒尺寸分布. 横轴代表某一晶粒半径与平均半径之比,纵轴代表半径为r附近区间内的晶粒个数与平均半径附近区间内的晶粒个数之比,将其定义为该尺寸晶粒出现的频次. 图4中曲线是FDR理论模型曲线,从图4可以看出,回流时间为20 min时试验数据与FDR理论曲线基本符合. 对于回流时间为2,5,15 min的试验结果而言,FRD理论曲线与试验结果偏离较大,频次最大位置在r/<r>略小于1的位置,即出现频次最高的晶粒尺寸小于平均值,而不是模型曲线中大于1的位置. Suh等人[14]发现Sn45Pb钎料与Cu基体生成的Cu6Sn5粒径分布与FDR模型符合很好. 文献[15]报道,纯Sn在Cu基体上回流时,Cu6Sn5晶粒尺寸FDR理论有偏离. 这种偏离一方面与不同钎料对Cu溶解度不同有关,也与FDR模型基本假设和简化处理有关. FDR模型假定在晶粒生长过程中总的表面积不变,忽略了晶粒之间间隙处基体与钎料间的表面积. 随着回流时间的延长,晶粒尺寸长大,相应的间隙面积减小,回流时间较长时可以被忽略. 而回流初期晶粒尺寸较小,界面存在大量的间隙,这些间隙面积对Cu原子向钎料内扩散起着重要作用,此时不应被忽略. 因此,对于回流时间较短的焊点,在界面Cu6Sn5晶粒的尺寸分布中,小于平均值的晶粒尺寸出现频次最高.

2.2 界面化合物的生长机制

图5为Sn3.0Ag0.5Cu/Cu在240 ℃回流2,5,10,15 min后焊接界面的侧面显微形貌. 由图5可以看出,界面化合物层厚度随回流时间增加而增大,Cu6Sn5之间的晶粒间隙逐渐变小,Cu6Sn5/钎料界面的起伏程度降低,变得更为平坦. 表1为Sn3.0Ag0.5Cu钎料在铜基体上不同回流时间所生成的界面化合物层的平均厚度.

表 1 Sn3.0Ag0.5Cu/Cu在240 ℃不同回流时间所生成的界面化合物层的平均厚度Table 1. Average thickness of interfacial compounds formed between Sn3.0Ag0.5Cu solder and Cu for different reflow time回流时间t/min 界面化合物层的平均厚度h/μm 2 2.485 5 3.569 10 4.011 15 4.848 20 5.355 图6为界面化合物层的生长曲线与生长机制示意图. 图6a为界面化合物平均厚度随回流时间的变化关系,拟合曲线方程为h=2t0.32. 由图6a可以看出,界面化合物平均厚度随着回流时间的增加而增大,随着回流时间的延长,界面化合物平均厚度增长速率变慢,界面化合物平均厚度正比于t0.32,而晶粒平均粒径正比于t0.38,表明界面Cu6Sn5晶粒沿垂直焊接界面的生长速度略低于沿平行焊接界面的生长速度. Deng等人[29]曾报道Sn3.5Ag/Cu界面化合物的厚度与时间的平方根成正比. Suh等人[14]发现Sn-Pb/Cu界面化合物层厚度正比于t1/3. 回流过程中Cu原子与钎料中的Sn原子反应生成Cu6Sn5化合物,不同成分的钎料在液态时对Cu原子的溶解度不同,过饱和生成Cu6Sn5的速度不同. 随着回流时间的延长,原子扩散速度对Cu6Sn5的生长的影响变得显著,而Cu原子的扩散能力与钎料的成分也是密切相关的,因此,钎料成分不同会导致Cu6Sn5化合物生长速度的差异.

图6b为回流过程中钎料与铜基体生成界面化合物的示意图,Cu6Sn5化合物的生长通过两种途径完成. 一种方式是间隙反应,熔融的Sn直接与铜基体中的Cu原子反应生成Cu6Sn5,如图6b中方式(1)所示;另一种方式是大晶粒吞并小晶粒过程,如图6b中方式(2)所示,半径为r的Cu6Sn5晶粒表面Cu原子浓度C可表示为[30]

$$ {C_r} = {C_0}\left( {1 + \frac{{2\gamma {V_{\rm{m}}}}}{{rRT}}} \right) $$ (5) 式中:C0为Cu在钎料中的平衡浓度;γ为Cu6Sn5与熔融钎料之间单位面积的界面能;Vm为Cu6Sn5化合物的摩尔体积;R为气体常数;T为热力学温度. 半径小的Cu6Sn5晶粒表面Cu原子浓度大,而半径大的Cu6Sn5晶粒表面Cu原子浓度小,这样在不同尺寸的晶粒之间存在Cu原子的浓度梯度,所以半径小的Cu6Sn5晶粒表面的Cu原子会向半径大的晶粒表面扩散,如图6b中方式(2)所示,结果导致半径大的晶粒不断长大,而半径小的晶粒却越来越少甚至消失. Cu原子的扩散通量J1可写作

$$ {J_1} = - D\frac{{{\rm{d}}C}}{{{\rm{d}}x}} \cong - \frac{{2\gamma {V_{\rm{m}}}{C_0}D}}{{3LRT{r^2}}} $$ (6) 式中:L为无量纲的系数;D为Cu原子的扩散系数.在回流初期,两种生长方式同时进行,随着回流时间的增加,Cu6Sn5晶粒之间的间隙逐渐减少,方式(1)对Cu6Sn5晶粒的生长所起的作用减弱,方式(2)占据主导地位,随着界面化合物的长大,Cu原子的扩散通量降低,界面Cu6Sn5化合物生长速度变缓.

3. 结论

(1) 研究了Sn3.0Ag0.5Cu/Cu焊接界面化合物Cu6Sn5晶粒的尺寸分布特点和Cu6Sn5晶粒的生长机制. 统计结果显示,对于回流时间较短的样品,出现频次最高的晶粒尺寸小于平均值,对于回流时间较长的样品,出现频次最高的晶粒尺寸约等于平均值.

(2) Sn3.0Ag0.5Cu/Cu焊点界面化合物层平均厚度随回流时间按t0.32关系增长,随着回流时间的增加,生长速度变慢,这与Cu6Sn5晶粒的生长方式密切相关.

(3) Cu6Sn5晶粒的生长通过间隙反应和大晶粒吞并小晶粒两种方式实现,回流时间较短时,两种方式同时进行,随着回流时间增加,间隙反应所起作用下降,大晶粒吞并小晶粒成为主要生长方式.

-

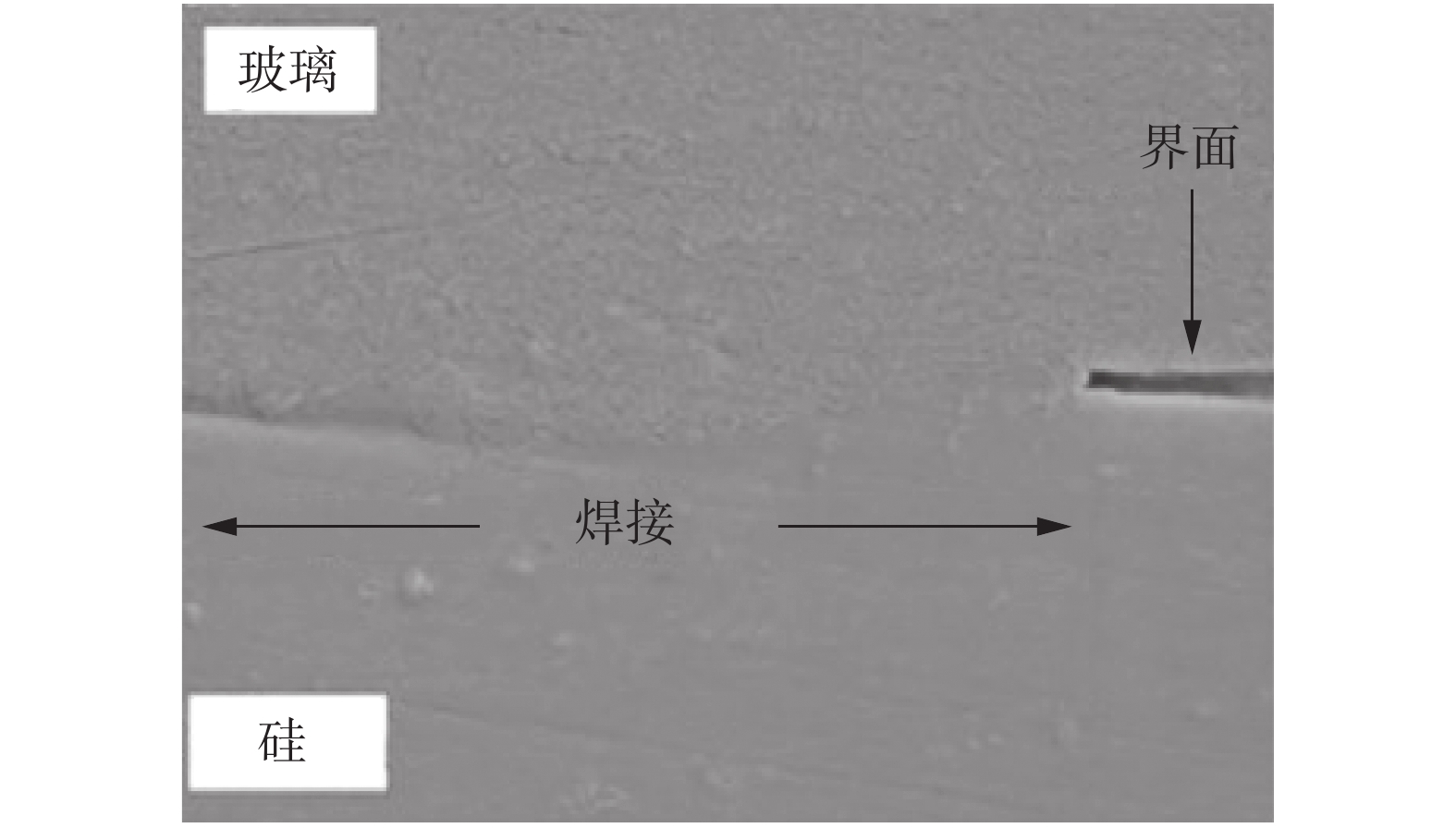

图 2 激光焊连接玻璃和硅微观形貌[13]

Figure 2. Microstructure of bonded glass and silicon by laser joining

图 3 微电阻连接铝丝与镀金铜焊盘微观形貌[19]

Figure 3. Microstructure of bonded Al wire with gold plated copper pad by micro-resistance welding

图 4 电流辅助全IMC焊点的微观形貌[27]

Figure 4. Microstructure of full-IMC solder joint assisted by electric current

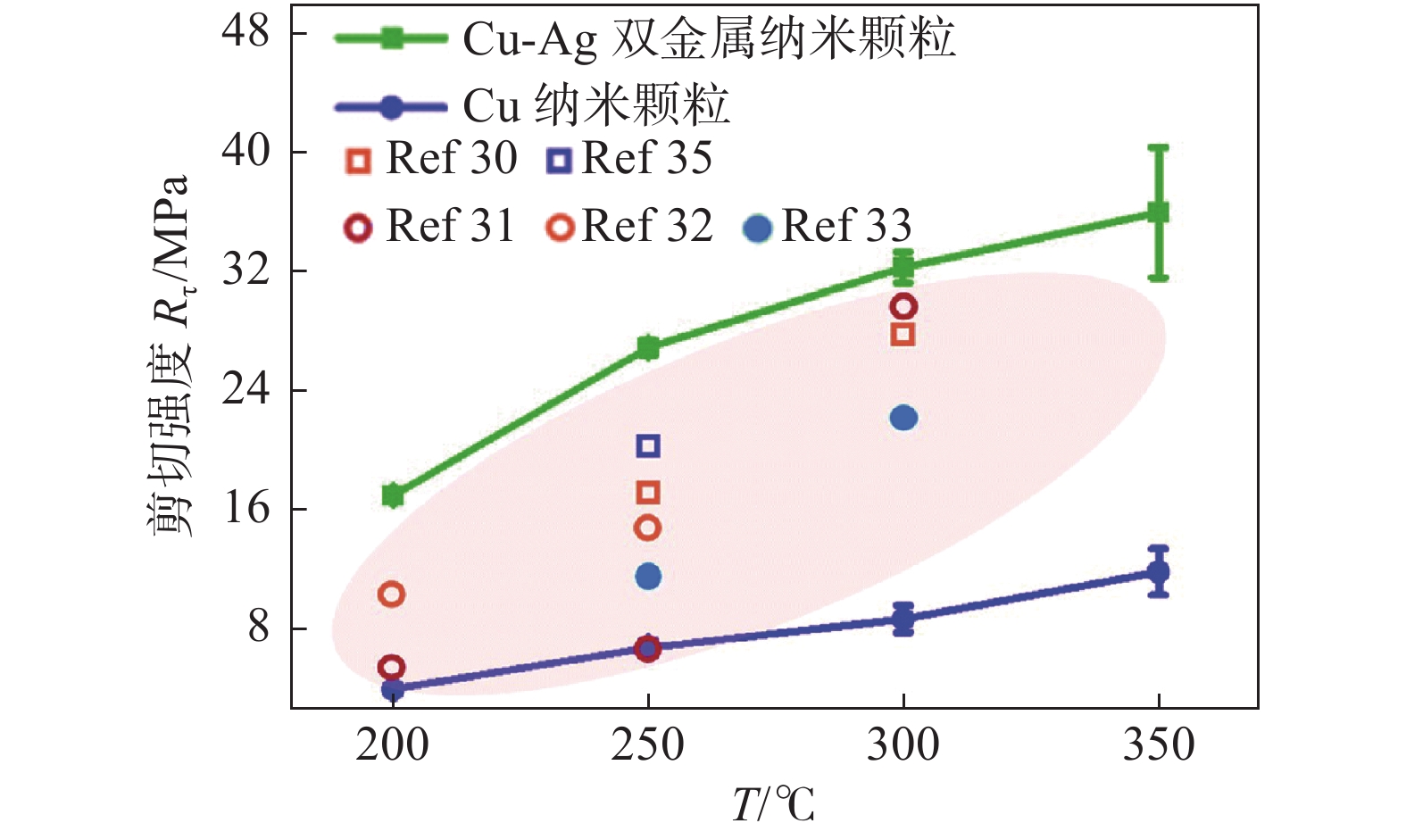

图 5 Cu/Cu@Ag纳米焊膏/Cu三明治焊点抗剪强度[31]

Figure 5. Shear strength of sintered Cu/Cu@Ag nanopaste/Cu sandwich joint

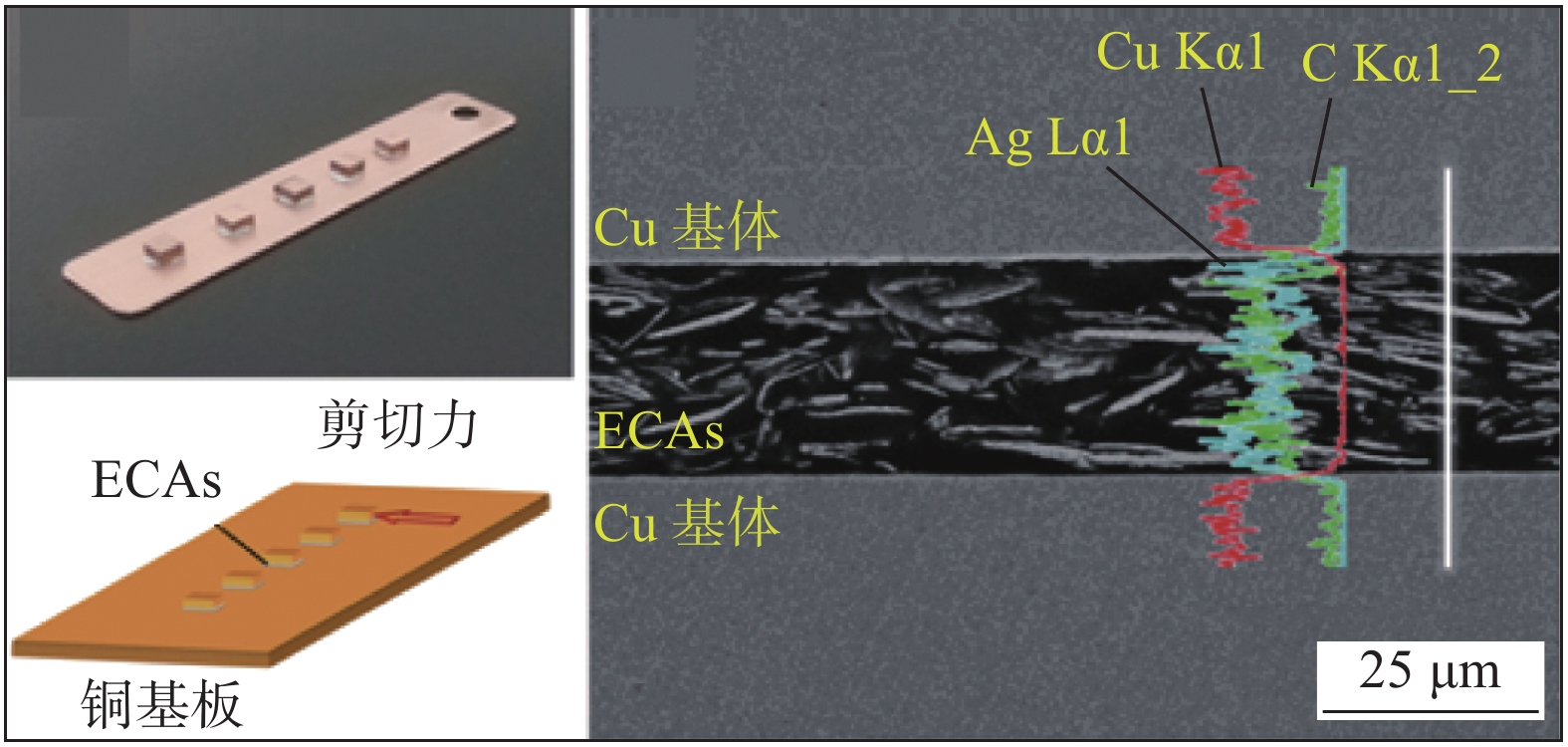

图 6 聚苯胺改性的各向同性导电胶连接Cu-Cu焊盘的微观结构[42]

Figure 6. Microstructure of Cu-Cu pad joined by polyaniline modified isotropic conductive adhesive

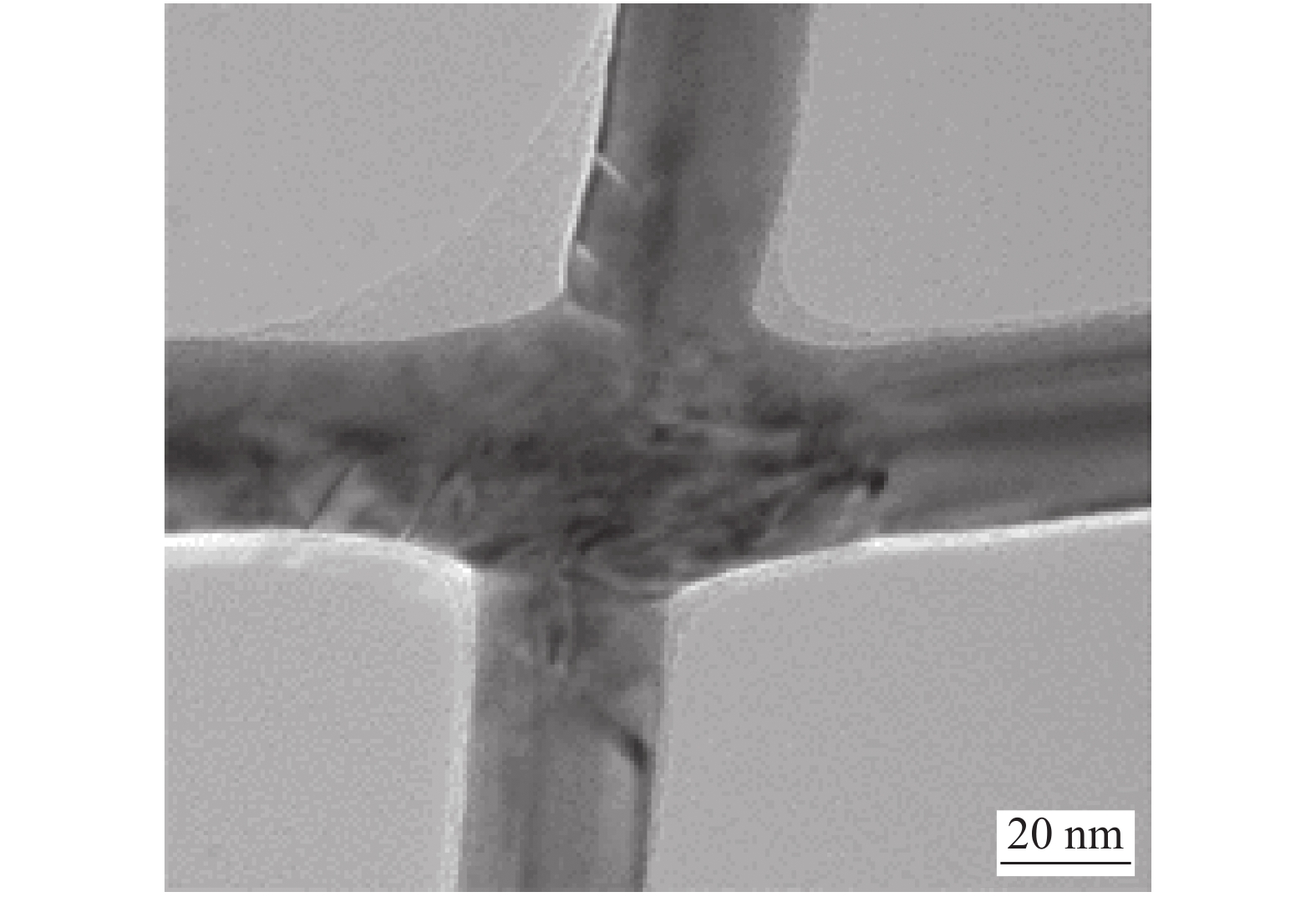

图 7 自限制纳米钎焊连接银纳米线[52]

Figure 7. Joining of silver nanowires by self-limited nanosoldering

图 8 添加氧化石墨烯前后的仿真[53]

Figure 8. Simulation before and after adding graphene oxide

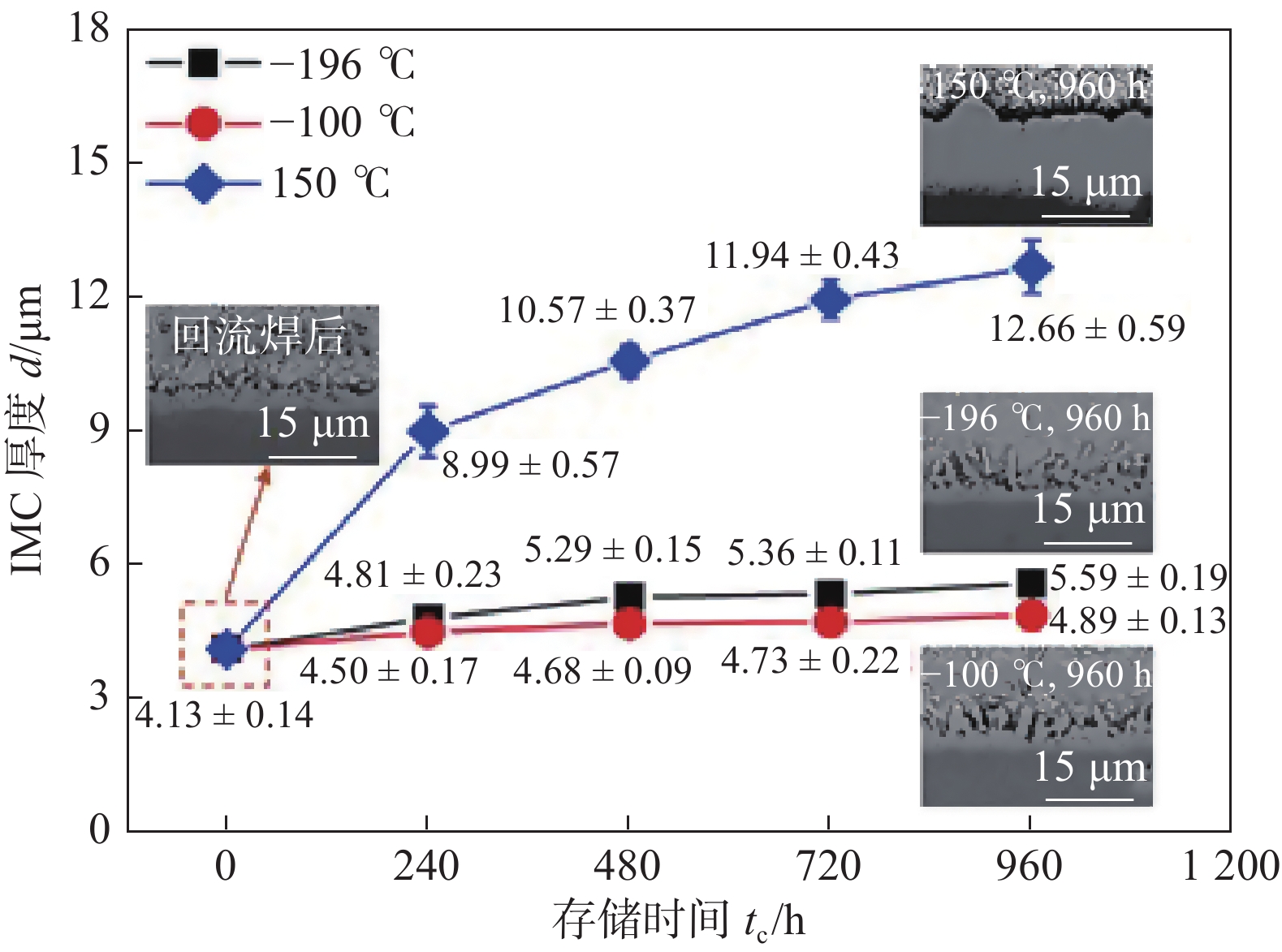

图 9 不同温度下贮存不同时间IMC厚度变化[57]

Figure 9. Variation of IMC thickness after storing at different time at different temperature

图 10 焊点电迁移失效行为[59]

Figure 10. Failure behavior of solder joints under electromigration

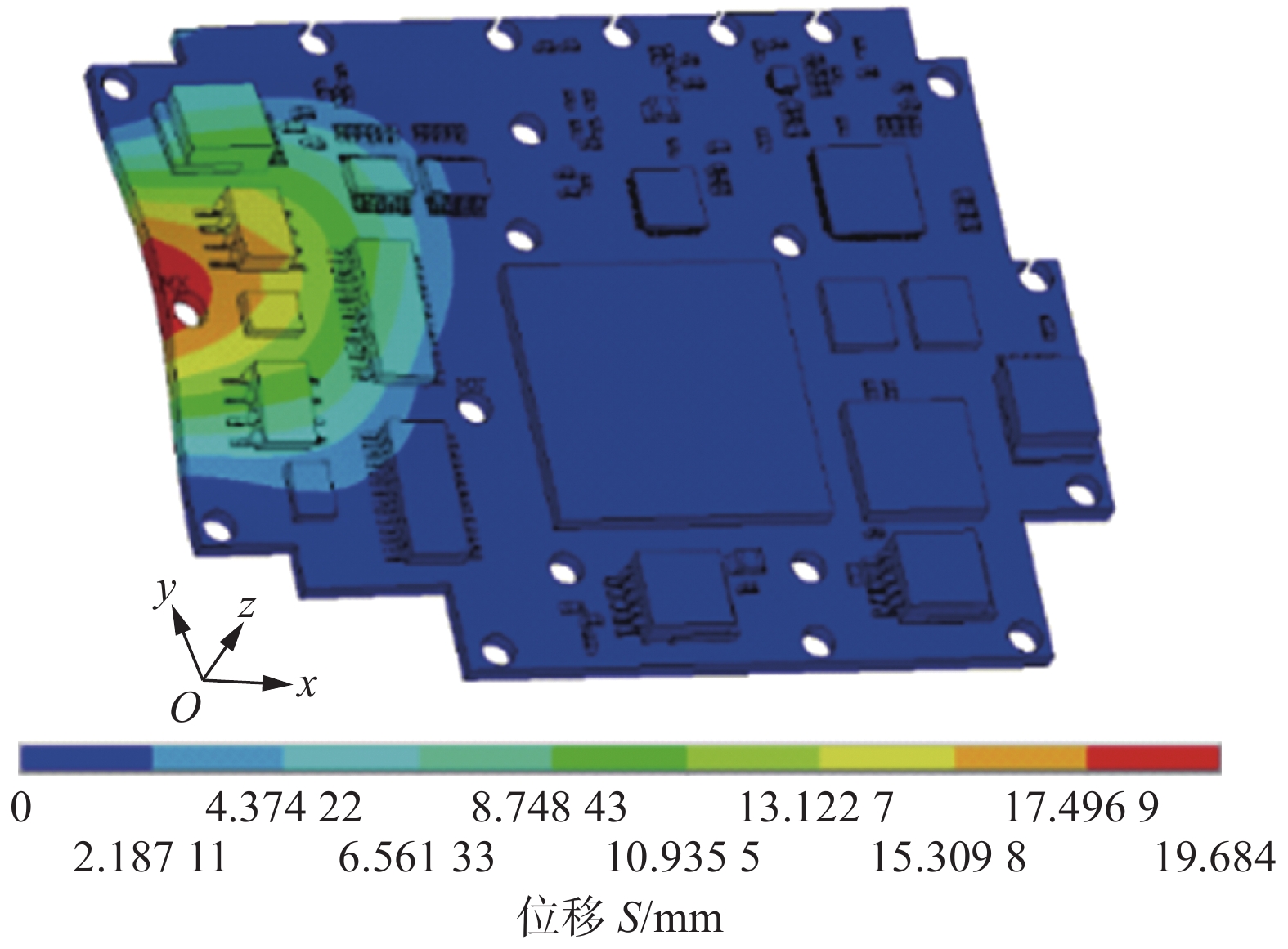

图 11 机械固定对应力分布的影响[64]

Figure 11. Effect of fixation on stress distribution

-

[1] Tummala R. Fundamentals of microsystems packaging[M]. New York: McGraw-Hill Professional, 2001.

[2] Kaimori S, Nonaka T, Mizogucgi A. The development of Cu bonding wire with oxidation-resistant metal coating[J]. IEEE Transactions on Advanced Packaging, 2006, 29: 227 − 231. doi: 10.1109/TADVP.2006.872999

[3] 王星星, 上官林健, 何鹏, 等. 基于熵模型镀锡银钎料钎焊性能的定量表征[J]. 焊接学报, 2020, 41(1): 18 − 22. Wang Xingxing, Shangguan Linjian, He Peng, et al. Quantitative characterization of brazability for Sn-plated Ag brazing filler metals based on entropy model devices[J]. Transactions of the China Welding Institution, 2020, 41(1): 18 − 22.

[4] 杨婉春, 王帅, 祝温泊, 等. 低温烧结纳米铜焊膏的制备及其连接性能分析[J]. 焊接学报, 2018, 39(6): 72 − 76. doi: 10.12073/j.hjxb.2018390152 Yang Wanchun, Wang Shuai, Zhu Wenbo, et al. Preparation and connection performance analysis of solder paste by low-temperature sintering Cu nanoparticles[J]. Transactions of the China Welding Institution, 2018, 39(6): 72 − 76. doi: 10.12073/j.hjxb.2018390152

[5] Hu A, Jolanta JR, Sano T. Joining technology innovations at the macro, micro, and nano levels[J]. Applied Sciences, 2019, 9(17): 3568. doi: 10.3390/app9173568

[6] 邹贵生, 闫剑峰, 母凤文. 微连接和纳连接的研究新进展[J]. 焊接学报, 2011, 32(4): 107 − 112,118. Zou Guisheng, Yan Jianfeng, Mu Fengwen, et al. Recent progress in microjoining and nanojoining[J]. Transactions of The China Welding Institution, 2011, 32(4): 107 − 112,118.

[7] Chen M, Zhang Y, Guo Y, et al. Research on flip-chip bonding process and thermal cycle reliability simulation of 3-D stacked structure[J]. IEEE Transactions on Componentrs Packaging and Manufacturing Technology, 2022, 12(1): 51 − 58. doi: 10.1109/TCPMT.2021.3127157

[8] Che F, Wai L, Chai T. Failure mode and mechanism analysis for Cu wire bond on Cu/low-k chip by wire pull test and finite-element analysis[J]. IEEE Transactions on Device and Materials Reliability, 2018, 18: 163 − 172. doi: 10.1109/TDMR.2018.2808348

[9] 邹军, 谢昶. 多芯片组件中金丝金带键合互连的特性比较[J]. 微波学报, 2010, 26(增刊): 378 − 380. Zou Jun, Xie Chang. Recent progress in microjoining and nanojoining[J]. Journal of Microwaves, 2010, 26(supplement): 378 − 380.

[10] 王尚, 王凯枫, 张贺, 等. 射频器件超细引线键合工艺及性能研究[J]. 机械工程学报, 2021, 57(22): 201 − 208. doi: 10.3901/JME.2021.22.201 Wang Shang, Wang Kaifeng, Zhang He, et al. Study on ultrafine wire bonding and performance of radio frequency devices[J]. Journal of Mechanical Engineering, 2021, 57(22): 201 − 208. doi: 10.3901/JME.2021.22.201

[11] 王尚, 马竟轩, 杨东升, 等. 射频器件超细引线键合射频性能仿真[J]. 焊接学报, 2021, 42(10): 1 − 7. Wang Shang, Ma Jingxuan, Yang Dongsheng, et al. Research on the RF performance simulation of ultra-fine wire bonding of RF devices[J]. Transactions of the China Welding Institution, 2021, 42(10): 1 − 7.

[12] Norrdin I H W, Okamoto Y, Okada A, et al. Effect of focusing condition on molten area characteristics in micro-welding of borosilicate glass by picosecond pulsed laser[J]. Applied Physics, A. Materials Science & Processing, 2016, 122(5): 492.

[13] 程战, 郭伟, 刘磊, 等. 石英玻璃与硅的飞秒激光微连接及其接头性能研究[J]. 中国激光, 2015, 42(9): 225 − 231. Cheng Zhan, Guo Wei, Liu Lei, et al. Mechanical properties of microweld of silica glass to silicon by femtosecond laser[J]. Chinese Journal of Laser, 2015, 42(9): 225 − 231.

[14] Huang Y D, Pequegnat A, Zou G S, et al. Crossed-wire laser microwelding of Pt-10 Pct Ir to 316 LVM stainless steel: Part II. effect of orientation on joining mechanism[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Materials Science, 2012, 43A: 1234 − 1243.

[15] Zou G, Huang Y, Pequegnat A, et al. Crossed-wire laser microwelding of Pt-10 Pct Ir to 316 low-carbon vacuum melted stainless steel: Part I. mechanism of joint formation[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Materials Science, 2012, 43A: 1223 − 1233.

[16] 陈伟彦, 张延松. 太阳能电池互连片平行间隙电阻焊工艺优化[J]. 机械设计与研究, 2019, 35(5): 75 − 79. doi: 10.13952/j.cnki.jofmdr.2019.0279 Chen Weiyan, Zhang Yansong. Study on process optimization of parallel gap resistance welding of solar cell and interconnector based on temperature field analysis[J]. Machine Design and Research, 2019, 35(5): 75 − 79. doi: 10.13952/j.cnki.jofmdr.2019.0279

[17] Zhang W, Cong S, Wen Z, et al. Experiments and reliability research on bonding process of micron copper wire and nanometer gold layer[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92: 4073 − 4080. doi: 10.1007/s00170-017-0490-z

[18] Zhang H, Wang S, Wu B, et al. Ultrafast parallel micro-gap resistance welding of an AuNi9 microwire and Au microlayer[J]. Micromachines, 2021, 12(1): 51. doi: 10.3390/mi12010051

[19] Wang S, Zhang H, Li Y, et al. Phase transformation behavior of Al-Au-Cu intermetallic compounds under ultra-fast micro resistance bonding process[J]. Materials Characterization, 2021, 180: 111401. doi: 10.1016/j.matchar.2021.111401

[20] Cong S, Zhang W, Zhang H, et al. Growth kinetics of (Cu xNi1- x)6Sn5 intermetallic compound at the interface of mixed Sn63Pb37/SAC305 BGA solder joints during thermal aging test[J]. Materials Research Express, 2021, 8: 106301. doi: 10.1088/2053-1591/ac3168

[21] Rajendran S, Jung D, Jung J. Investigating the physical, mechanical, and reliability study of high entropy alloy reinforced Sn-3.0Ag-0.5Cu solder using 1608 chip capacitor/ENIG joints[J]. Journal of Materials Science: Materials in Electronics, 2022, 33: 3687 − 3710. doi: 10.1007/s10854-021-07562-2

[22] Tian Y, Wang C, Zhang X, et al. Interaction kinetics between PBGA solder balls and Au/Ni/Cu metallisation during laser reflow bumping[J]. Soldering & Surface Mount Technology, 2003, 15(2): 17 − 21.

[23] Tian Y, Wang C. Formation and change of AuSn4 compounds at interface between PBGA solder ball and Au/Ni/Cu metallization during laser and infrared reflow soldering[J]. Acta Metallurgica Sinica (English Letters), 2004, 17(2): 199 − 204.

[24] Yao P, Li X, Liang X B, et al. Investigation of soldering process and interfacial microstructure evolution for the formation of full Cu3Sn joints in electronic packaging[J]. Materials Science in Semiconductor Processing, 2017, 58: 39 − 50. doi: 10.1016/j.mssp.2016.11.019

[25] Li M, Li Z, Xiao Y, et al. Rapid formation of Cu/Cu3Sn/Cu joints using ultrasonic bonding process at ambient temperature[J]. Applied Physics Letters, 2013, 102(9): 094104. doi: 10.1063/1.4794684

[26] Feng J, Hang C, Tian Y, et al. Effect of electric current on grain orientation and mechanical properties of Cu-Sn intermetallic compounds joints[J]. Journal of Alloys and Compounds, 2018, 753: 203 − 211. doi: 10.1016/j.jallcom.2018.04.041

[27] Liu B, Tian Y, Wang C, et al. Ultrafast formation of unidirectional and reliable Cu3Sn-based intermetallic joints assisted by electric current[J]. Intermetallics, 2017, 80: 26 − 32. doi: 10.1016/j.intermet.2016.10.004

[28] Liu B, Tian Y, Feng J, et al. Enhanced shear strength of Cu–Sn intermetallic interconnects with interlocking dendrites under fluxless electric current-assisted bonding process[J]. Journal of Materials Science, 2017, 52: 1943 − 1954. doi: 10.1007/s10853-016-0483-6

[29] Schwarzbauer H, Kuhnert R. Novel large area joining technique for improved power device performance[J]. IEEE Transactions on Industry Applications, 1991, 27(1): 93 − 95. doi: 10.1109/28.67536

[30] Dai Y, Ng M, Anantha P, et al. Enhanced copper micro/nano-particle mixed paste sintered at low temperature for 3D interconnects[J]. Applied Physics Letters, 2016, 108: 263103. doi: 10.1063/1.4954966

[31] Tian Y, Jiang Z, Wang C, et al. Sintering mechanism of the Cu–Ag core–shell nanoparticle paste at low temperature in ambient air[J]. RSC Advances, 2016, 6: 91783 − 91790. doi: 10.1039/C6RA16474A

[32] Liu X, Liu W, Wang C, et al. Optimization and modeling for one-step synthesis process of Ag-Cu nano-particles using DOE methodology[J]. Journal of Materials Science: Materials in Electronics, 2016, 27: 4265 − 4274. doi: 10.1007/s10854-016-4292-0

[33] Zhong Y, An R, Wang C, et al. Low temperature sintering Cu6Sn5 nanoparticles for superplastic and super-uniform high temperature circuit interconnections[J]. Small, 2015, 11: 4097 − 4103. doi: 10.1002/smll.201500896

[34] Guo L, Liu W, Ji X, et al. Facile synthesis of Cu10Sn3 nanoparticles and their sintering behavior for power device packaging[J]. Results in Materials, 2021, 10: 100187. doi: 10.1016/j.rinma.2021.100187

[35] Jia Q, Zou G, Zhang H, et al. Sintering mechanism of Ag-Pd nanoalloy film for power electronic packaging[J]. Applied Surface Science, 2021, 554: 149579. doi: 10.1016/j.apsusc.2021.149579

[36] 付善灿. 纳米银焊膏无压低温烧结连接方法的绝缘栅双极型晶体管(IGBT)模块封装应用研究[D]. 天津: 天津大学, 2016. Fu Shancan. Research on application of insulated gate bipolar transistor (IGBT) module fabrication by pressureless low temperature sintering of nanosilver paste[D]. Tianjin: Tianjin University, 2016.

[37] Zhang Z, Chen C, Suetake, et al. Pressureless and low-temperature sinter-joining on bare Si, SiC and GaN by a Ag flake paste[J]. Scripta Materialia, 2021, 198: 113833. doi: 10.1016/j.scriptamat.2021.113833

[38] 黄圆, 杭春进, 田艳红, 等. 纳米铜银核壳焊膏脉冲电流快速烧结连接铜基板研究[J]. 机械工程学报, 2019, 55(24): 51 − 56. doi: 10.3901/JME.2019.24.051 Huang Yuang, Hang Chunjin, Tian Yanhong, et al. Rapid sintering of nano copper-silver core-shell paste and interconnection of copper substrates by pulse current[J]. Journal of Mechanical Engineering, 2019, 55(24): 51 − 56. doi: 10.3901/JME.2019.24.051

[39] Ji H, Zhou J, Liang M, et al. Ultra-low temperature sintering of Cu@Ag core-shell nanoparticle paste by ultrasonic in air for high-temperature power device packaging[J]. Ultrasonics Sonochemistry, 2018, 41: 375 − 381. doi: 10.1016/j.ultsonch.2017.10.003

[40] Liu W, Wang Y, Zheng Z, et al. Laser sintering mechanism and shear performance of Cu-Ag-Cu joints with mixed bimodal size Ag nanoparticles[J]. Journal of Materials Science: Materials in Electronics, 2019, 30: 7787 − 7793. doi: 10.1007/s10854-019-01094-6

[41] Liu H, Ma R, Zhao D, et al. Application of silver nanoparticles in electrically conductive adhesives with silver micro flakes[J]. China Welding, 2022, 31(2): 23 − 28.

[42] Wen J, Tian Y, Hang C, et al. Fabrication of novel printable electrically conductive adhesives (ECAs) with excellent conductivity and stability enhanced by the addition of polyaniline nanoparticles[J]. Nanomaterials, 2019, 9(7): 960. doi: 10.3390/nano9070960

[43] Cao G, Cui H, Wang L, et al. Highly conductive and highly dispersed polythiophene nanoparticles for fabricating high-performance conductive adhesives[J]. ACS Applied Electronic Materials, 2020, 2: 2750 − 2759. doi: 10.1021/acsaelm.0c00457

[44] 马跃辉. PS/金属核壳结构复合微球的制备及其在各向异性导电胶膜上的应用[D]. 上海: 东华大学, 2013. Ma Yuehui. Preparation of polystyrene/metal core/shell microspheres and their application in anisotropic conductive film[D]. Shanghai: Donghua University, 2013.

[45] 王正家. ACA互连的多因素作用分析与性能优化[D]. 武汉: 华中科技大学, 2010. Wang Zhengjia. Analysis of anisotropic conductive adhesive interconnection under multi-factors influence and optimization for its performance [D]. Wuhan: Huazhong University of Science and Technology, 2010.

[46] 陈显才. 倒装键合中各向异性导电胶微互连电阻形成机理研究[D]. 武汉: 华中科技大学, 2012. Chen Xiancai. The research on the formation mechanism of micro ACA joints resistance in the flip chip bonding[D]. Wuhan: Huazhong University of Science and Technology, 2012.

[47] Bo G, Yu H, Ren L, et al. Gallium-indium-tin liquid metal nanodroplet-based anisotropic conductive adhesives for flexible integrated electronics[J]. ACS Applied Nano Materials, 2021, 4: 550 − 557. doi: 10.1021/acsanm.0c02870

[48] Wang C, Wang Y, Tian Y, et al. Room-temperature direct bonding of silicon and quartz glass wafers[J]. Applied Physics Letters, 2017, 110: 221602. doi: 10.1063/1.4985130

[49] 张贺, 王尚, 冯佳运, 等. 金属/非金属纳米线连接及应用研究进展[J]. 机械工程学报, 2022, 58(2): 76 − 87. Zhang He, Wang Shang, Feng Jiayun, et al. Recent progress of metal/nonmetal nanowire joining technology and its applications[J]. Journal of Mechanical Engineering, 2022, 58(2): 76 − 87.

[50] Lin L, Liu L, Peng P, et al. In situ nanojoining of Y- and T-shaped silver nanowires structures using femtosecond laser radiation[J]. Nanotechnology, 2016, 27: 125201. doi: 10.1088/0957-4484/27/12/125201

[51] Zhang H, Tian Y, Wang S, et al. Highly stable flexible transparent electrode via rapid electrodeposition coating of Ag-Au alloy on copper nanowires for bifunctional electrochromic and supercapacitor device[J]. Chemical Engineering Journal, 2020, 399(20): 125075.

[52] Huang Y, Tian Y, Hang C, et al. Self-limited nanosoldering of silver nanowires for high-performance flexible transparent heaters[J]. ACS Applied Materials & Interfaces, 2019, 11: 21850 − 21858.

[53] Ding S, Zhang S, Tong X, et al. Room-temperature nanojoining of silver nanowires by graphene oxide for highly conductive flexible transparent electrodes[J]. Nanotechnology, 2022, 34: 045201.

[54] Gao L, Liu Z, Li C. Failure mechanisms of SAC/Fe-Ni solder joints during thermal cycling[J]. Journal of Electronic Materials, 2017, 46: 5338 − 5348. doi: 10.1007/s11664-017-5554-1

[55] Mattila T, Kivilahti J. The role of recrystallization in the failure of SnAgCu solder interconnections under thermomechanical loading[J]. IEEE Transactions on Components and Packaging Technologies, 2010, 33: 629 − 635. doi: 10.1109/TCAPT.2010.2051268

[56] Ji X, An Q, Xia Y, et al. Maximum shear stress-controlled uniaxial tensile deformation and fracture mechanisms and constitutive relations of Sn-Pb eutectic alloy at cryogenic temperatures[J]. Materials Science and Engineering: A, 2021, 819: 141523. doi: 10.1016/j.msea.2021.141523

[57] Tian R, Hang C, Tian Y, et al. Interfacial intermetallic compound growth in Sn-3Ag-0.5Cu/Cu solder joints induced by stress gradient at cryogenic temperatures[J]. Journal of Alloys and Compounds, 2019, 800: 180 − 190. doi: 10.1016/j.jallcom.2019.05.295

[58] Chen C, Tong H, Tu K. Electromigration and thermomigration in Pb-Free flip-chip solder joints[J]. Annual Review of Materials Research, 2010, 40: 531 − 555. doi: 10.1146/annurev.matsci.38.060407.130253

[59] Chang Y, Cheng Y, Xu F, et al. Study of electromigration-induced formation of discrete voids in flip-chip solder joints by in-situ 3D laminography observation and finite-element modeling[J]. Acta Materialia, 2016, 117: 100 − 110. doi: 10.1016/j.actamat.2016.06.059

[60] Liu B, Tian Y, Qin J, et al. Degradation behaviors of micro ball grid array (μBGA) solder joints under the coupled effects of electromigration and thermal stress[J]. Journal of Materials Science: Materials in Electronics, 2016, 27: 11583 − 11592. doi: 10.1007/s10854-016-5289-4

[61] Luan J, Tee T, Pek E, et al. Dynamic responses and solder joint reliability under board level drop test[J]. Microelectronics Reliability, 2007, 47: 450 − 460. doi: 10.1016/j.microrel.2006.05.012

[62] Marjamaki P, Mattila T T, Kivilahti J K. A comparative study of the failure mechanisms encountered in drop and large amplitude vibration tests[C]//56th Electronic Components and Technology Conference 2006. San Diego, CA, USA, 2006: 95-101.

[63] Liu F, Meng G. Random vibration reliability of BGA lead-free solder joint[J]. Microelectronics Reliability, 2014, 54: 226 − 232. doi: 10.1016/j.microrel.2013.08.020

[64] 李跃, 田艳红, 丛森, 等. PCB组装板多器件焊点疲劳寿命跨尺度有限元计算[J]. 机械工程学报, 2019, 55(6): 54 − 60. doi: 10.3901/JME.2019.06.054 Li Yue, Tian Yanhong, Cong Sen, et al. Multi-scale finite element analysis into fatigue lives of various component solder joints on printed circuit board[J]. Journal of Mechanical Engineering, 2019, 55(6): 54 − 60. doi: 10.3901/JME.2019.06.054

[65] Feng D, Wang F, Li D, et al. Atomic migration on Cu in Sn-58Bi solder from the interaction between electromigration and thermomigration[J]. Materials Research Express, 2019, 6: 046301. doi: 10.1088/2053-1591/aaf91c

[66] Ye H, Basaran C, Hopkins D. Thermomigration in Pb-Sn solder joints under joule heating during electric current stressing[J]. Applied Physics Letters, 2003, 82: 1045 − 1047. doi: 10.1063/1.1554775

[67] 李望云. 电-热-力耦合场作用下无铅微焊点的变形和断裂行为及其尺寸效应研究[D]. 广州: 华南理工大学, 2017. Li Wangyun. Deformation and fracture behavior of microscale lead-free solder joints under electro-thermo-mechanical coupled loads and their size effects[D]. Guangzhou: South China University of Technology, 2017.

[68] 李胜利, 任春雄, 杭春进, 等. 极端热冲击和电流密度耦合Sn-3.0Ag-0.5Cu焊点组织演变[J]. 机械工程学报, 2022, 58(2): 291 − 299. doi: 10.3901/JME.2022.02.291 Li Shengli, Ren Chunxiong, Hang Chunjin, et al. Microstructure evolution of Sn-3.0Ag-0.5Cu solder joints under extreme temperature changes and current stressing[J]. Journal of Mechanical Engineering, 2022, 58(2): 291 − 299. doi: 10.3901/JME.2022.02.291

-

期刊类型引用(6)

1. 汪松英,李志豪,曾世堂,洪少健,丘翰琳,苏慧珍,杜昆. 功率模块封装的纳米银焊膏烧结工艺气氛影响研究. 广州化工. 2025(08): 91-94 .  百度学术

百度学术

2. 奚思,刘斌,蔡传辉,李金伟,陆玉. 纳米银烧结设备热压系统设计及仿真分析. 电子工业专用设备. 2025(02): 6-9+30 .  百度学术

百度学术

3. 李志豪,汪松英,洪少健,孙啸寒,曾世堂,杜昆. 镀银板表面粗糙度对纳米银焊膏快速烧结互连质量的影响. 电子与封装. 2024(07): 5-11 .  百度学术

百度学术

4. 鲍金祥,关俊卿,何金江,王鹏,侯智超. 大功率器件低温烧结纳米银膏的研究进展. 贵金属. 2024(S1): 71-77 .  百度学术

百度学术

5. 黄玺,张亮,王曦,陈晨,卢晓. 电子封装用纳米级无铅钎料的研究进展. 材料导报. 2024(23): 136-148 .  百度学术

百度学术

6. 汪智威,林丽婷,李欣. 低温烧结银与金基界面互连研究进展. 焊接学报. 2023(12): 116-123+143-144 .  本站查看

本站查看

其他类型引用(6)

下载:

下载: