Effect of copper vapor on arc characteristics under DC magnetic field

-

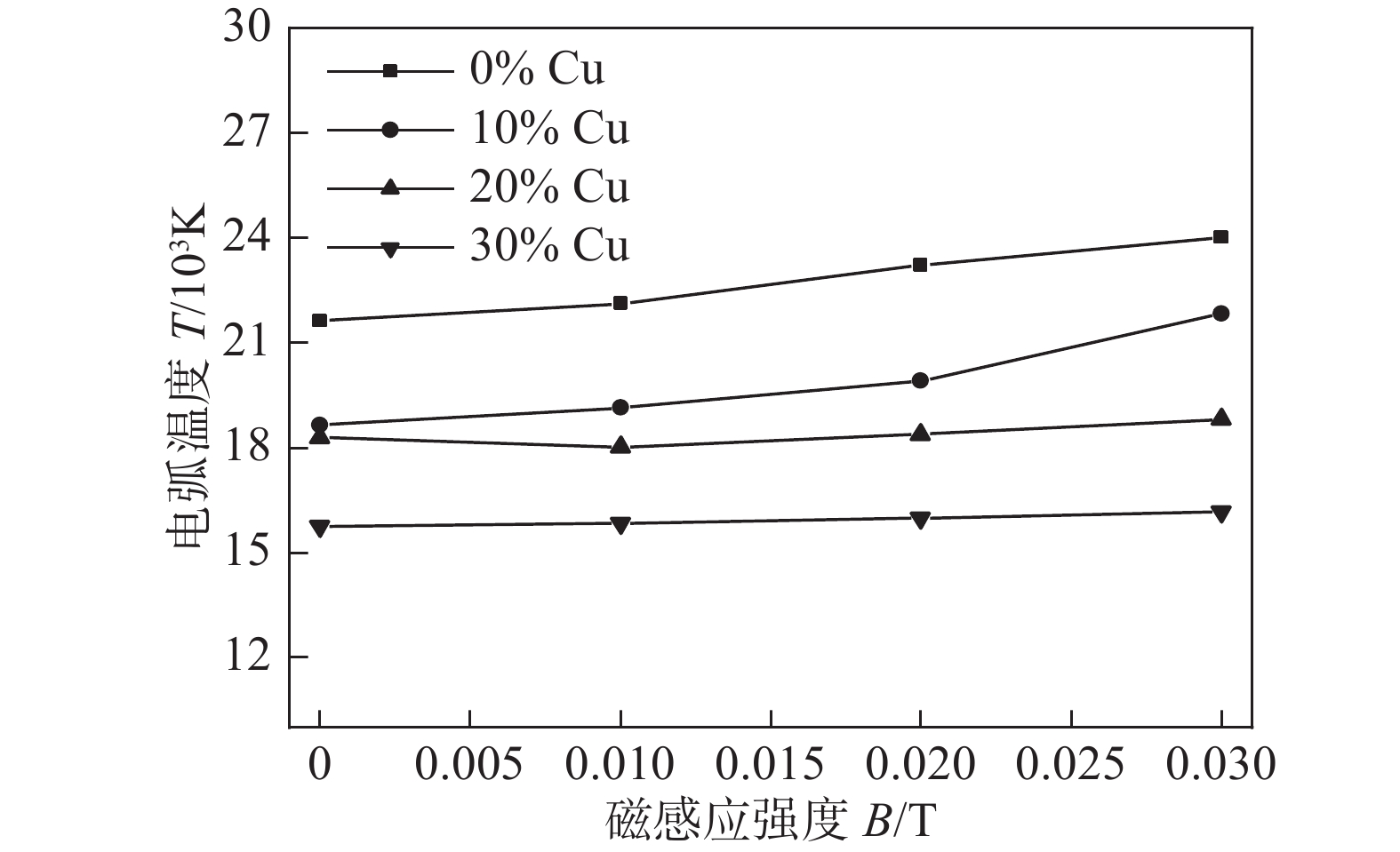

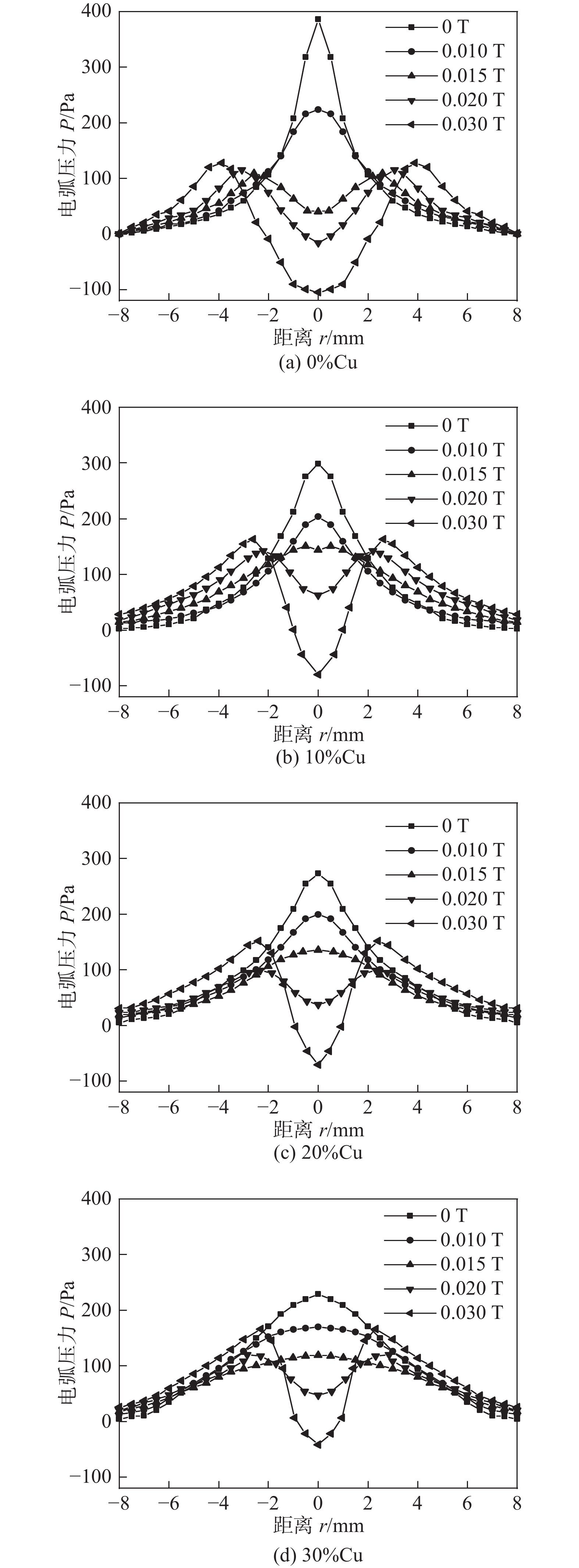

摘要: 为研究直流纵向磁场作用下金属蒸气对熔化极气体保护焊(gas metal arc welding,GMAW)电弧特性的影响,将钨铜复合材料制成特殊钨极代替熔化极产生铜蒸气,利用高速摄像法、光谱测温法以及小孔探测法对其进行了测试研究. 结果表明,铜蒸气进入电弧等离子体后,电弧出现分层,随铜蒸气含量的增加,弧芯外围区域半径随之增加,弧芯区的尺寸减小. 当铜含量为0%时,外加直流磁场后,电弧在阴极区收缩阳极区扩张,其轴向最高温度明显上升;电弧压力峰值偏离轴线,在外加磁场强度为0.015 T时呈现双峰分布,电流密度与电弧压力分布趋势相似;随着铜蒸气的介入,弧芯区电弧表现为阴极区收缩,阳极区扩张,弧芯周围的铜蒸气则明显收缩,电弧轴向最高温度上升的幅度明显降低. 随着铜含量的增加,电弧的导电面积增加,环向电磁力作用减弱,电弧中心压力下降幅度显著降低,阳极电流密度的分布趋势逐渐趋于扁平化.Abstract: In order to study the effect of metal vapor on the arc characteristics of gas metal arc welding (GMAW) under the action of DC longitudinal magnetic field, tungsten-copper composites were made into special tungsten electrode instead of molten electrode to produce copper vapor, which was tested and studied by high speed camera method, spectral temperature measurement method and keyhole detection method. The results show that when copper vapor enters the arc plasma, the arc appears delamination. With the increase of copper vapor content, the outer radius of arc core increases, and the size of the arc core area decreases. When the Cu content is 0%, after the DC magnetic field is applied, the arc shrinks in the cathode and expands in anode with an notable increase in the axial maximum temperature of the arc. The peak value of the arc pressure deviates from the axis, and when the magnetic field intensity B = 0.015 T , the arc pressure shows a bimodal distribution. The distribution of current density is similar to that of arc pressure. With the intervention of copper vapor, the arc in the arc core region shrinks in the cathode and expands in the anode region. While the copper vapor around the arc core shrinks obviously, and the rise of the maximum axial temperature of the arc decreases obviously. At the same time, the copper vapor expands the conductive area of the arc, weakens the circumferential electromagnetic force. The pressure at the arc center decreases, and the distribution of anode current density was flattened.

-

Keywords:

- gas metal arc welding /

- DC magnetic field /

- copper vapor /

- arc characteristics

-

-

表 1 焊接工艺参数

Table 1 Welding process parameters

焊接电流

I/A钨极直径

D/mm钨极角度

θ/(°)弧长

L/mm氩气流量

Q/(L·min−1)100 3.2 60 4 10 表 2 平均蒸发率

Table 2 Average evaporation rate

铜含量w(%) 蒸发率E/(mg·s−1) 0 0 10 0.173 5 20 0.566 7 30 1.315 3 -

[1] 闫飞, 周一凡, 唐本刊, 等. 基于磁控冶金的铝/钢异种金属焊接特性[J]. 焊接学报, 2022, 43(5): 98 − 103. doi: 10.12073/j.hjxb.20220101004 Yan fei, Zhou Yifan, Tang Benkan, et al. Welding characteristics of Al/steel dissimilar metals based on magnetically controlled metallurgy[J]. Transactions of the China Welding Institution, 2022, 43(5): 98 − 103. doi: 10.12073/j.hjxb.20220101004

[2] 孙雅杰, 常云龙. 磁控电弧焊接过程及新技术研究进展[J]. 材料导报, 2020, 34(21): 21155 − 21165. doi: 10.11896/cldb.19060200 Sun Yajie, Chang Yunlong. Development of magnetically controlled arc welding process and new technology[J]. Materials Reports, 2020, 34(21): 21155 − 21165. doi: 10.11896/cldb.19060200

[3] Wu Hong, Chang Yunlong, Lu Lin, et al. Review on magnetically controlled arc welding process[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(9-12): 4263 − 4273. doi: 10.1007/s00170-017-0068-9

[4] Fan Ding, Yao Xinlong, Hou Yingjie, et al. The study of arc behavior with different content of copper vapor in GTAW[J]. China Welding, 2022, 31(2): 1 − 14.

[5] Tanaka K, Shigeta M, Tanaka M, et al. Investigation of transient metal vapour transport processes in helium arc welding by imaging spectroscopy[J]. Journal of Physics D:Applied Physics, 2020, 53(42): 1 − 8.

[6] Xiang J A, Chen F, Phb C, et al. Numerical study of the metal vapour transport in tungsten inert-gas welding in argon for stainless steel[J]. Applied Mathematical Modelling, 2020, 79: 713 − 728. doi: 10.1016/j.apm.2019.11.001

[7] 肖磊, 樊丁, 黄健康, 等. 外加高频纵向磁场作用下的 TIG 焊电弧数值模拟[J]. 焊接学报, 2017, 38(2): 66 − 70. Xiao Lei, Fan Ding, Huang Jiankang, et al. Numerical simulation of TIG welding arc with extra high-frequency longitudinal magnetic field[J]. Transactions of the China Welding Institution, 2017, 38(2): 66 − 70.

[8] Schupp J, Fischer W, Mecke H. Welding arc control with power electronics[C]//8th International Conference on Power Electronics and Variable Speed Drives. London, 2000: 443−450.

[9] Murphy A B. The effects of metal vapour in arc welding[J]. Journal of Physics D: Applied Physics, 2010, 43(43): 434001.

[10] Tanaka M, Yamamoto K, Tashiro S, et al. Time-dependent calculations of molten pool formation and thermal plasma with metal vapour in gas tungsten arc welding[J]. Journal of Physics D: Applied Physics, 2010, 43(43): 434009.

[11] 斯红, 华学明, 张旺, 等. 基于Boltzmann光谱法的焊接电弧温度场测量计算[J]. 光谱学与光谱分析, 2012, 32(9): 2311 − 2313. doi: 10.3964/j.issn.1000-0593(2012)09-2311-03 Si Hong, Hua Xueming, Zhang Wang, et al. Welding Arc temperature field measurements based on Boltzmann Spectrometry[J]. Spectroscopy and Spectral Analysis, 2012, 32(9): 2311 − 2313. doi: 10.3964/j.issn.1000-0593(2012)09-2311-03

[12] 黄勇, 瞿怀宇, 樊丁, 等. 耦合电弧AA-TIG焊电弧压力测量与分析[J]. 焊接学报, 2013, 34(3): 33 − 36. Huang Yong, Zhai Huaiyu, Fan Ding, et al. Arc pressure measurement and analysis of coupling arc AA-TIG[J]. Transactions of the China Welding Institution, 2013, 34(3): 33 − 36.

[13] Murphy A B. A comparison of treatments of diffusion in thermal plasmas[J]. Journal of Physics D: Applied Physics, 1996, 29(7): 1922 − 1932. doi: 10.1088/0022-3727/29/7/029

[14] Gleizes A, Gonzalez J J, Liani B, et al. Calculation of net emission coefficient of thermal plasmas in mixtures of gas with metallic vapour[J]. Journal of Physics D: Applied Physics, 1999, 26(11): 1921 − 1927.

[15] Xiao L, Fan D, Huang J. Tungsten cathode-arc plasma-weld pool interaction in the magnetically rotated or deflected gas tungsten arc welding configuration[J]. Journal of Manufacturing Processes, 2018, 32: 127 − 137.

-

期刊类型引用(8)

1. 涂文斌,胡志华,邹雨柔,刘冠鹏,王善林,陈玉华. 时效时间和Sb添加对Sn-9Zn-3Bi/Cu焊点界面金属间化合物生长行为的影响. 材料导报. 2025(06): 193-198 .  百度学术

百度学术

2. 涂文斌,吴鸿燕,梅琪,王韩冰,吴吉洋,颜文俊. 添加Sb对Sn-9Zn-3Bi/Cu钎料接头显微组织及力学性能的影响. 电子元件与材料. 2024(09): 1154-1160+1166 .  百度学术

百度学术

3. 任安世,曲松涛,董新华,史清宇,张弓,朱忠言. 氧含量对Sn-9Zn-2.5Bi-1.5In低温波峰焊焊接性能的影响. 焊接学报. 2022(04): 68-73+99+117 .  本站查看

本站查看

4. 薛鹏,何鹏,龙伟民,宋闽. 稀土、Ga元素及其协同效应对无铅钎料组织和性能的影响. 焊接学报. 2021(04): 1-19+97 .  本站查看

本站查看

5. 刘广柱,岳迪,康宇,谢宏宇,何定金. 纳米Cr颗粒对Sn-Zn-Bi-In/Cu钎焊焊点性能的影响. 材料工程. 2021(11): 163-170 .  百度学术

百度学术

6. 刘广柱,岳迪,康宇,孙建宇. 含Bi、Ga元素的Sn-9Zn低温无铅钎料研究. 热加工工艺. 2021(23): 36-40 .  百度学术

百度学术

7. 孙文栋,龚世良,张弓,史清宇. 氮气气氛下氧含量对Sn-Zn/Cu焊接接头组织的影响及其产业应用. 机械制造文摘(焊接分册). 2020(02): 1-6 .  百度学术

百度学术

8. 李正兵,胡德安,陈益平,程东海,何凯,郭义乐. Fe颗粒对时效过程中SnBi/Cu接头组织及性能影响. 焊接学报. 2020(08): 22-28+98 .  本站查看

本站查看

其他类型引用(5)

下载:

下载: