Influence of N2 protection on microstructure and properties of CMT-P composite arc welded joints

-

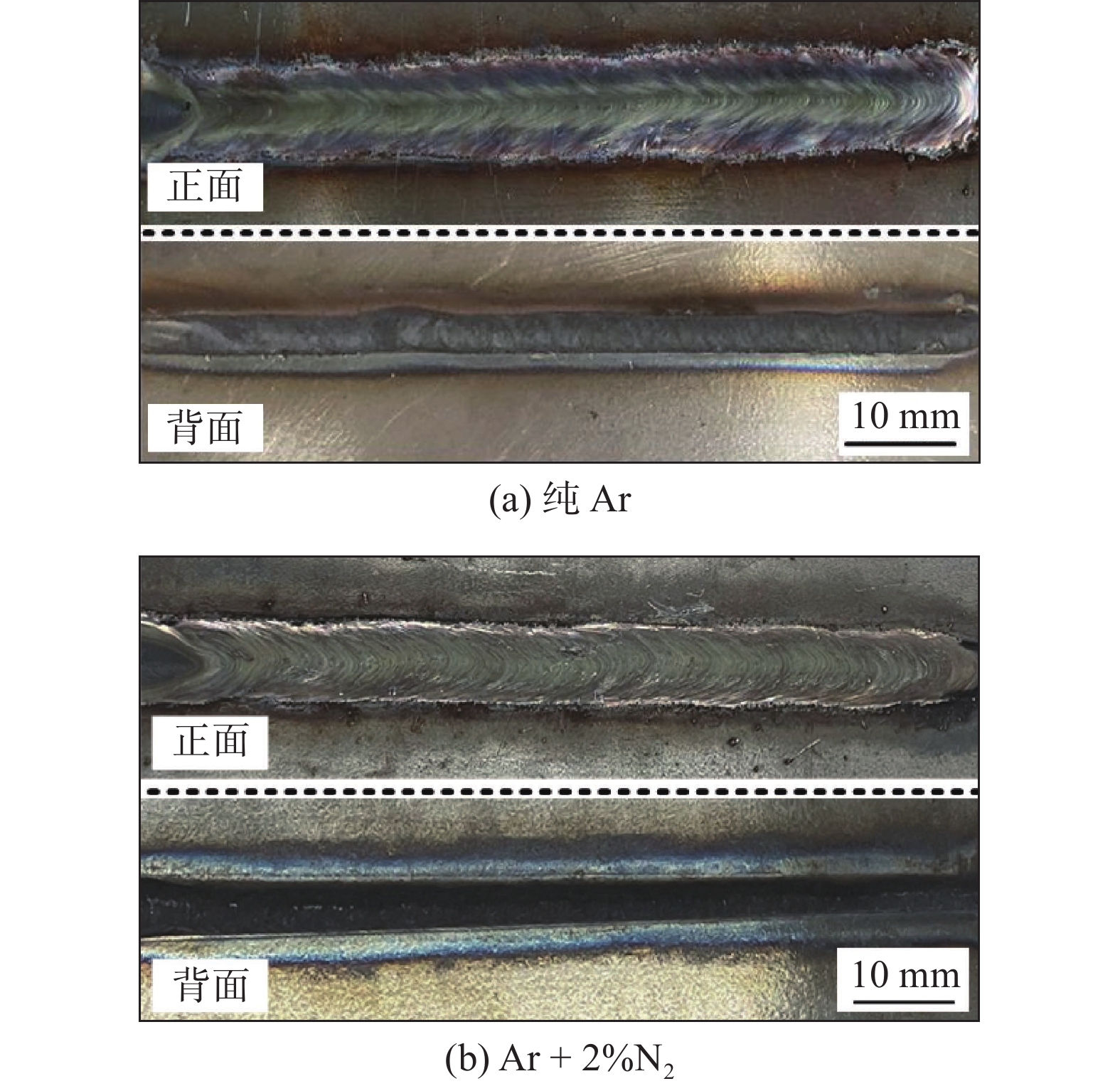

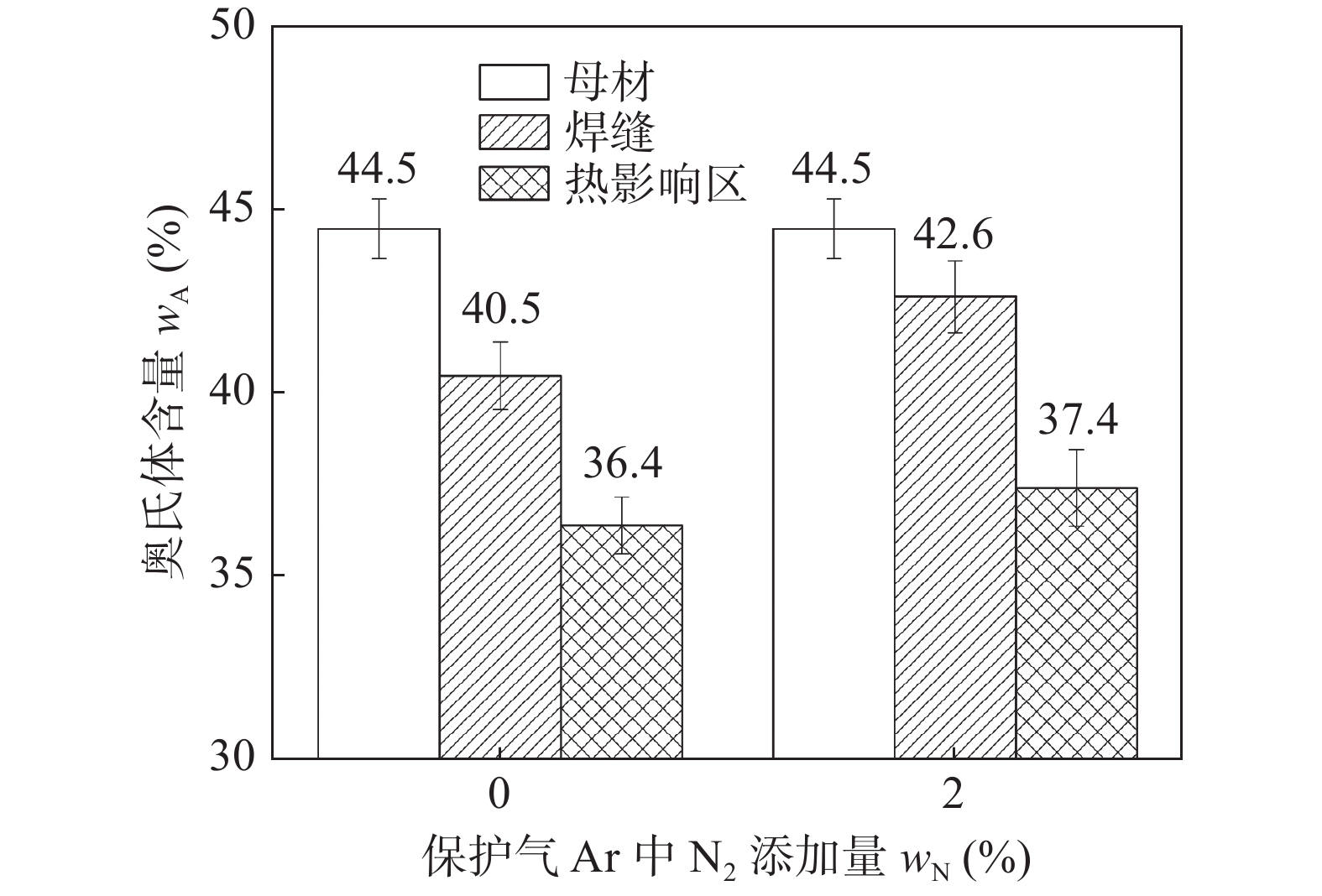

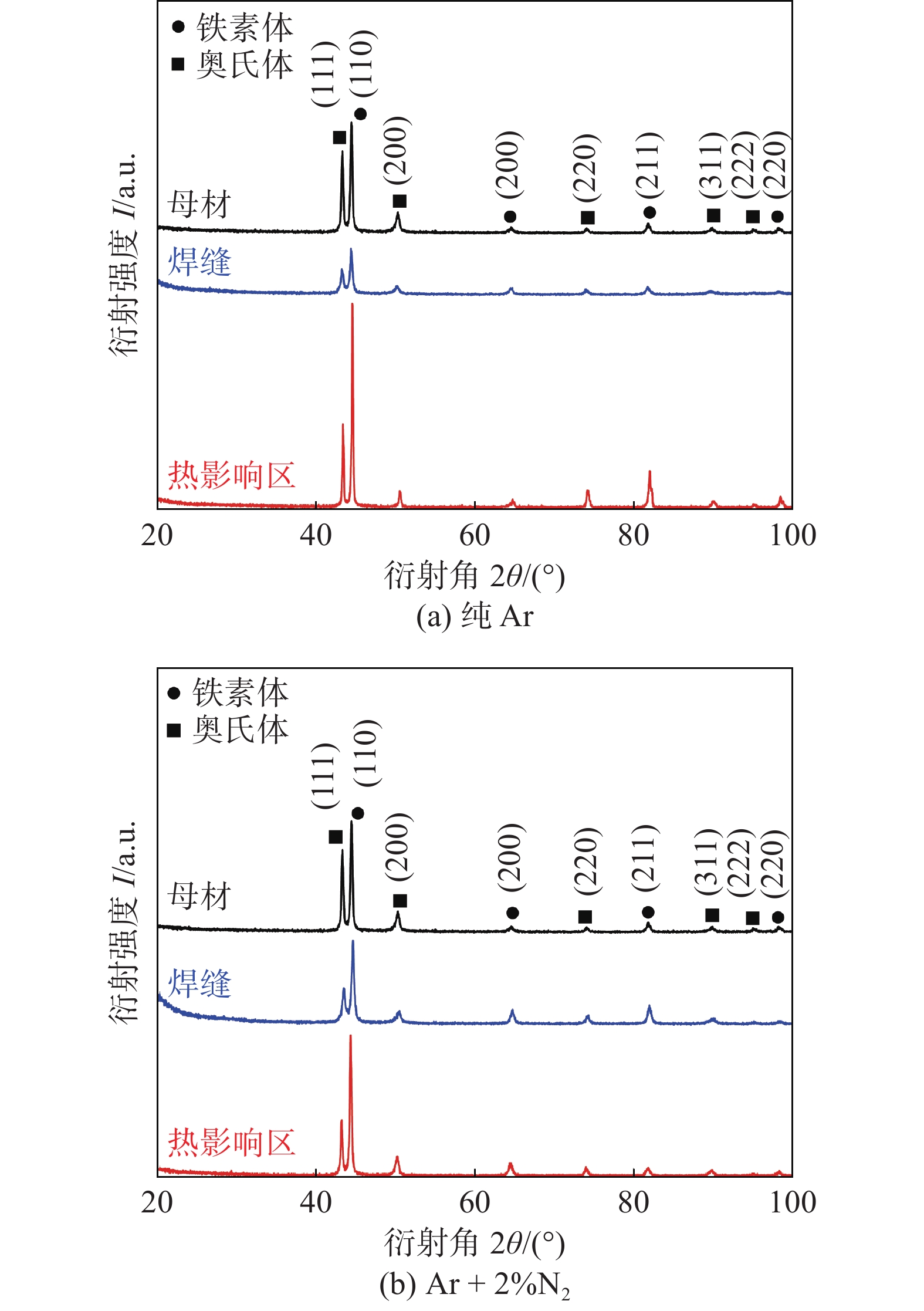

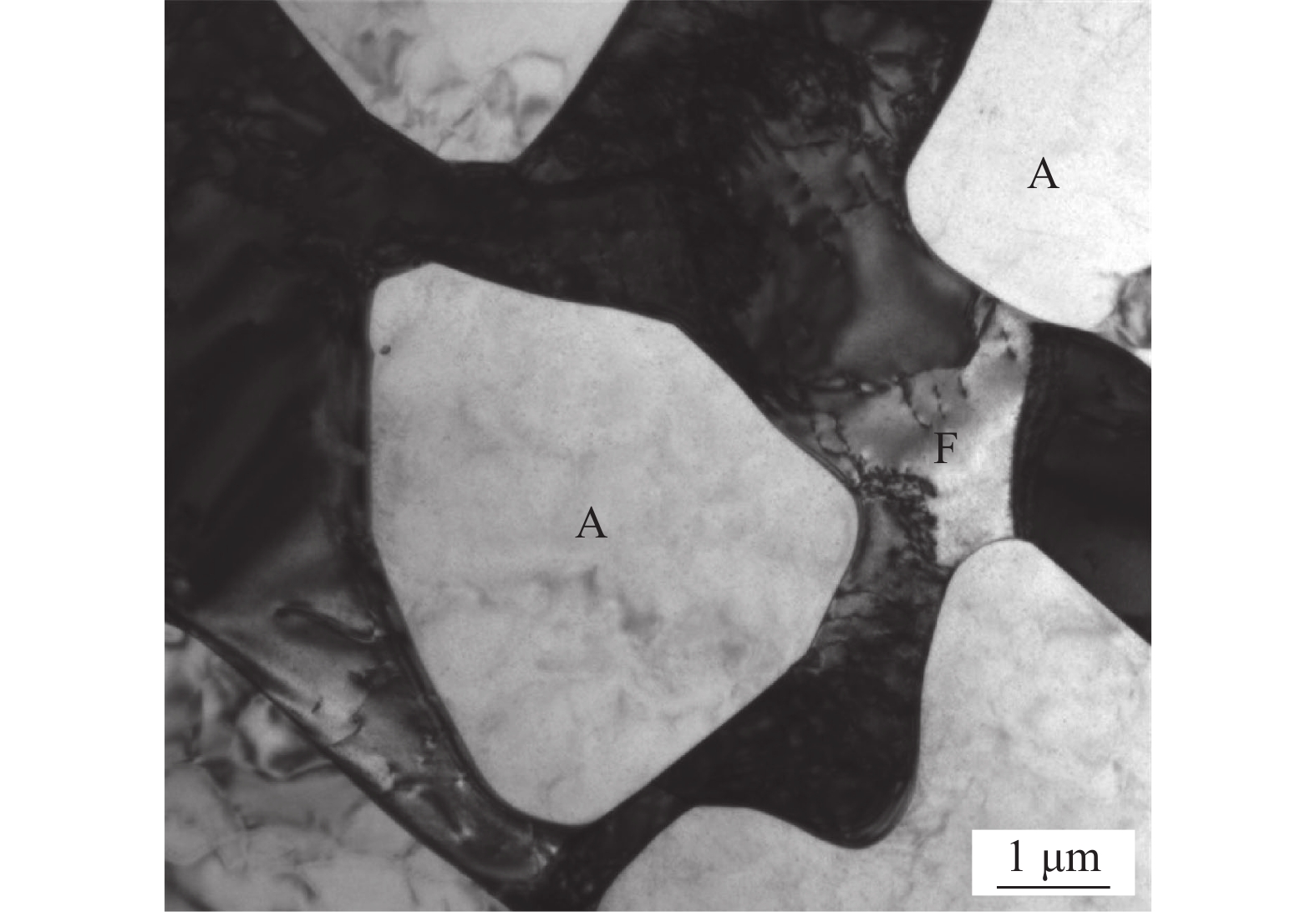

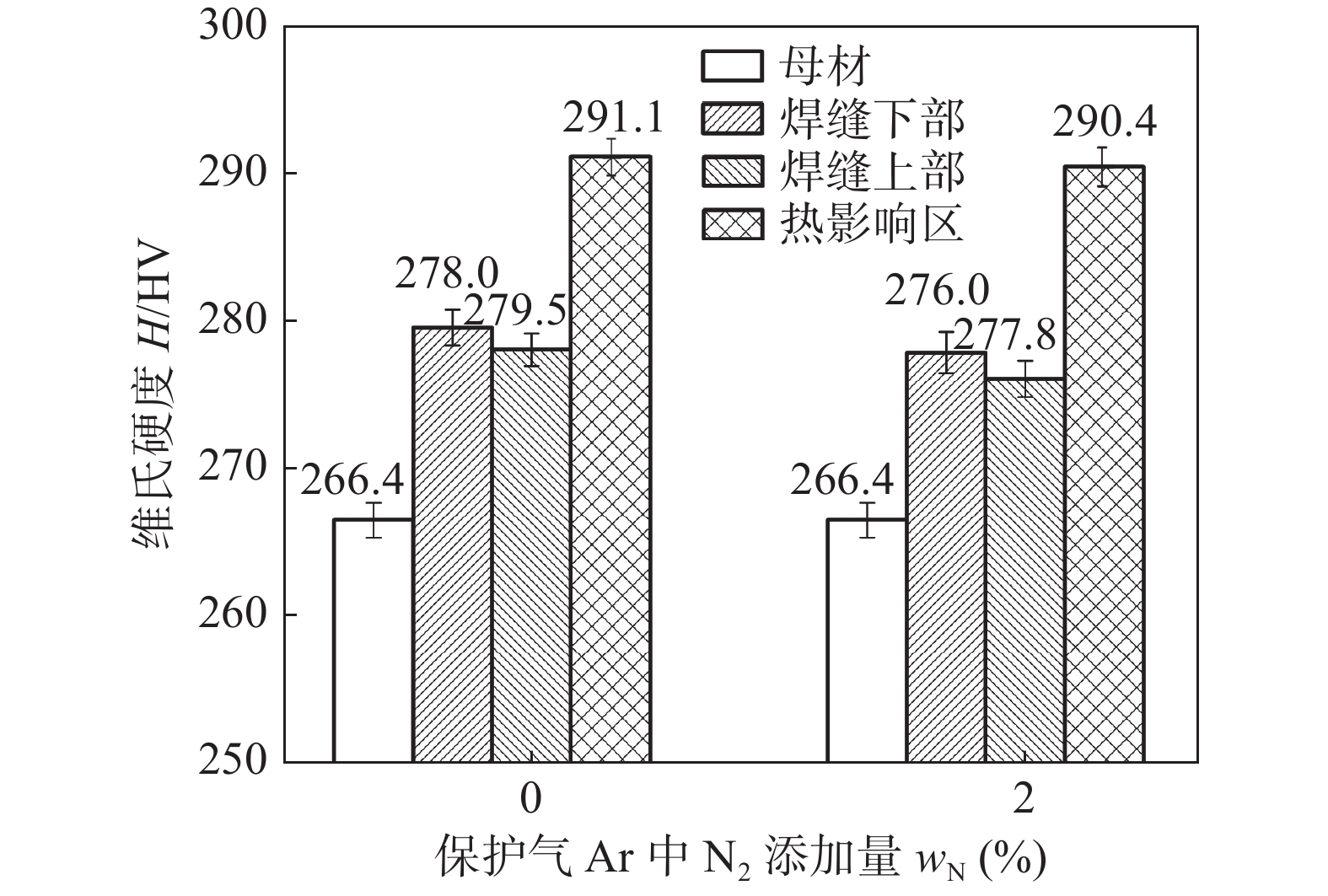

摘要: 以UNS S32750超级双相不锈钢为研究对象,采用冷金属过渡脉冲(cold metal transfer pulse,CMT-P)复合电弧焊接技术,运用光学显微镜、扫描电子显微镜、透射电子显微镜、X射线衍射仪和电子探针组织表征手段以及显微硬度和低温冲击韧性性能测试方法,对比研究了纯Ar和Ar + 2%N2气体保护对焊接接头的微观组织、硬度和低温韧性的影响规律.结果表明,与纯Ar保护气相比,添加2%N2保护的焊接过程飞溅较少,焊缝平整笔直,鱼鳞纹更加细致紧密.此外,热影响区主要由过量的铁素体和少量的奥氏体组成,并伴随有害的Cr2N析出.因此,与CMT-P复合电弧焊接头的其它区域相比,热影响区的硬度较高和韧性较低.添加2%N2气体保护增加了焊缝和热影响区奥氏体含量和N原子在铁素体与奥氏体内的固溶量,从而提高了接头各区域的低温韧性.Abstract: Taking UNS S32750 super duplex stainless steel as research object, cold metal transfer pulse (CMT-P) composite arc welding technology was adopted. Using optical microscopy, scanning electron microscopy, transmission electron microscopy, X-ray diffraction, electron probe microstructure characterisation tools, microhardness, low temperature impact toughness properties test methods, this paper comparatively studied the influence mechanism of pure Ar and Ar + 2%N2 as shielding gas on the microstructure, micro-hardness and low temperature toughness of welded joint. The result showed that compared with pure Ar in shielding gas, the welding process with 2%N2 protection has less spatter, the weld metal is flat, straight and the fish scale pattern is more detailed and tight. In addition, the heat affected zone (HAZ) is mainly composed of excess ferrite and a small amount of austenite, accompanied by some harmful precipitation of Cr2N. Therefore, compared with other areas of CMT-P composite arc welded joints, HAZ is with higher microhardness and lower toughness. The addition of 2%N2 increases the austenite content in the weld metal and HAZ, the solid solution amount of N atoms in the ferrite and austenite, thereby improves the low-temperature toughness of the welded joints.

-

0. 序言

焊接过程中工件受热不均匀引起焊接残余应力[1]. 铝合金热膨胀系数大,在焊接时容易形成较大的残余应力. 残余应力影响产品的承载性能和使用寿命[2-5],准确测试焊接残余应力具有重要的工程意义. 在残余应力测试方法中,X射线法因测试成本适中、设备便携、对产品无损伤等优点而得到较为广泛的应用[6-9].

材料的均匀性假设是X射线法应力测试的基本假设之一,但是材料中晶粒的择优取向破坏了材料的均匀性,使材料呈现出微观应变不均匀的特点[10-11],进而降低X射线应力测试的精度.

国内外学者对多晶体材料微观应变不均匀现象做了大量研究[12],Withers等人[13]指出微观应变与宏观弹性应变不同,它只在几个晶粒尺寸范围内平衡,即使卸载宏观应力,这种微观应变也依然存在. Stukowski等人[14]采用试验研究与数值计算相结合的方法证明了多晶体材料普遍存在着微观应变导致的X射线宽化现象. Wilkens[15]采用理论推演的方法证明了小角度晶界处微观应变导致X射线宽化. 现有关于铝合金X射线衍射的研究表明,当晶粒尺寸大于100 nm时,X射线衍射峰半高宽能够反应材料微观应变的大小[16-17]. 虽然以上研究揭示了微观应变对X射线衍射的影响,但关于微观应变对X射线衍射应力测试的影响及其解决办法却少有报道. 文中以6061-T6铝合金为研究对象,基于对X射线衍射峰半高宽的分析,研究在不同准直器直径及摇摆角条件下X射线衍射晶粒群的微观应变的均匀性,进而探究合理的X射线应力测试工艺参数,并对6061-T6铝合金MIG焊接接头残余应力进行测试.

1. 预置应力测试及焊接试验

1.1 等强梁预置应力及测试

图1为等强梁尺寸及其预置应力方案图. 对3 mm厚6061-T6铝合金板用电火花加工方法按图1a所示加工2个等强梁1,2,并按图1b所示令等强梁一端固定,另一端悬挂3 kg配重块. 对1号等强梁采用单向应变片测试P点预置应力大小,对2号等强梁上P点应力采用加拿大Proto-MG40P X射线应力分析仪测试.对2号等强梁上P点采用X射线应力测试时,测试方法为同倾

${\sin ^2}\psi $ 法[18],入射X射线为Cr-Kα射线,测试晶面选取Al(311)晶面,衍射晶面的法线方向取向范围为${\sin ^2}\psi \in [0,0.6]$ ,并在此范围内等差值地选取30个$\psi $ 角进行衍射角测试,为研究不同准直器直径和摇摆角条件下X射线衍射晶粒群微观应变的均匀性,按表1设计对比试验.表 1 对比试验方案Table 1. Comparative test plan组号 准直器直径d/mm 摇摆角$\;\beta$/(°) A-1 2 0 A-2 3 0 A-3 4 0 B-1 4 0 B-2 4 1 B-3 4 2 对2号等强梁应力测试完成后,采用电火花线切割机以P点为中心沿其四周切取8 mm × 6 mm × 3 mm试样,依次经机械磨抛和电解抛光后,采用FEI Quanta 650场发射电镜进行EBSD数据采集,并使用CHANNEL 5软件进行数据后处理.

1.2 焊接试验及残余应力测试

选取与等强梁相同批次的3 mm厚6061-T6铝合金板,采用全自动MIG焊机,以对接接头形式焊接铝合金试板,焊接电流76 A,焊接电压24 V,送丝速度3.6 mm/s,焊枪行走速度10 mm/s,气体(99.99% Ar)流量15 L/min. 焊后对焊接接头进行X射线衍射应力测试,应力测试点分布如图2所示.

2. 结果与分析

2.1 准直器直径对X射线应力测试的影响

在X射线衍射应力测试过程中,从靶材激发出的X射线通过准直器后,输出平行X射线束照射在待测材料表面,准直器直径的大小决定了被X射线照射区域的面积,进而决定了能够发生衍射的晶粒数目,对不同

$\psi $ 角处衍射X射线的强度和半高宽(full width at half maximum,FWHM)进行统计,结果如图3所示.图3表明随着准直器直径的增加,在各

$\psi $ 角处X射线衍射强度增大,在$0< {\sin ^2}\psi < 0.3$ 范围内,衍射X射线的半高宽随着${\sin ^2}\psi $ 的增大而快速减小,而在$0.3<{\sin ^2}\psi < 0.6$ 范围内,衍射线半高宽随着${\sin ^2}\psi $ 的变化而小幅震荡,这表明随着准直器直径的增加,参与衍射的晶粒数目增加. 但是,当晶粒的择优取向较弱时,衍射晶粒群的平均微观应变依然不均匀. 而当晶粒的择优取向较强时,衍射晶粒群的平均微观应变的不均匀程度降低.对1号等强梁的P点采用应变片测试应力的结果为79.2 MPa. 对2号等强梁的P点采用X射线测试以后,采用公式(1)计算P点处的应力值.

$$\sigma = \left[ { - \frac{1}{2} \cdot \frac{{\text{π}} }{{180}} \cdot {\rm{cot}}{\theta _0}\frac{E}{{\left( {1 + \varepsilon } \right)}}} \right]\frac{{\partial 2{\theta _\psi }}}{{\partial {\rm{si}}{{\rm{n}}^2}\psi }}$$ (1) 式中:2θ0为Al(311)晶面无应力时的衍射角;2θψ为衍射晶面的法线位于ψ角处时测得的衍射角[18].E和ε为其弹性模量和泊松比,取值分别为2θ0 = 139.31°,E = 69 GPa,ε = 0.35. 由于测试应力值仅与不同ψ角处测得的2θΨ相对于sin2ψ的变化率有关,与sin2ψ的具体值无关. 而在

$0 < {\sin ^2}\psi < 0.3$ 和$0.3 < {\sin ^2}\psi < 0.6$ 两个区间内参与X射线衍射的晶粒数目和平均微观应变的均匀性差异较大,因此分别采用这两个区间内测试得到的衍射角计算应力,结果如图4所示.随着准直器直径的增加,X射线应力测试的精度提高. 在

$0 <{\sin ^2}\psi < 0.3$ 范围内,由于晶体择优取向较弱,参与X射线衍射的晶粒数目较少,尽管增加准直器直径,其应力测试的精度依然较低.2.2 摇摆角对X射线应力测试的影响

通过增加准直器直径可增加参与衍射的晶粒数目,但是若过分增加准直器直径,则测试区域内应力梯度的影响将增大,同时X射线束的发散度也增大,这些都将增加测试误差. 因此B组试验考虑在不改变准直器直径的条件下增加摇摆角. 随着摇摆角的增大,各ψ角处衍射峰半高宽的变化如图5所示.

在

$0 < {\sin ^2}\psi < 0.3$ 范围内,衍射峰半高宽随着sin2ψ的增大而快速减小,并且摇摆角的增大并没有明显改变半高宽随sin2ψ的变化趋势,这表明当晶体择优取向较弱时,参与X射线衍射的晶粒数目少,增加摇摆角并不会明显改善各$\psi $ 角处衍射晶粒群微观应变的均匀性. 而在$0.3 < {\sin ^2}\psi < 0.6$ 范围内,晶体的择优取向较强,随着摇摆角的增加,各$\psi $ 角处衍射晶粒群的微观应变趋于均匀化.为分析增大摇摆角时衍射晶粒群变化的本质,对材料晶粒群亚晶之间的取向差进行统计分析,分别标记出晶粒内部大于0.5°,1°,2°的小角度晶界,结果如图6所示.

图6中黑色线条表示的晶界为大于10°的晶界,晶粒内部白色线条分别表示大于0.5°,1°,2°的小角度晶界. 对比三幅图可知晶粒内部大部分亚晶之间的取向差值小于1°,在一个晶粒内部,不同亚晶所受的应力不均匀,而在多个晶粒尺度范围内,晶粒内部所有的亚晶所受应力的总和趋于平衡[4, 6]. 因此当入射X射线摇摆角从0°增加到1°时,参与衍射的亚晶数目明显增加,使衍射晶粒群的微观应变趋于均匀化. 而当摇摆角从1°继续增加到2°时,参与衍射的亚晶数目已不再明显增加,因此这两种条件下衍射晶粒群微观应变的均匀性差异较小.

在

$0 < {\sin ^2}\psi < 0.3$ 和$0.3 < {\sin ^2}\psi < 0.6$ 两个区间内,随着摇摆角的增加,应力测试结果如图7所示. 结果表明当摇摆角从0°增加到1°时,X射线应力测试精度明显提高,且在晶粒择优取向较强的取向范围内应力测试精度较高.以上测试结果表明,增加摇摆角能够使各

$\psi $ 角处衍射晶粒群的微观应变趋于均匀化,这有利于提高X射线法应力测试的精度.2.3 焊接接头残余应力测试

由以上分析,使用4 mm准直器、1°摇摆角,在

$0.3 < {\sin ^2}\psi < 0.6$ 测试区间内对焊接接头残余应力进行测试,测试结果如图8所示.3. 结论

(1) 增加准直器直径可以增加各个

$\psi $ 角处衍射晶粒的数目,提高X射线衍射强度,但对各个$\psi $ 角处衍射晶粒群微观应变的均匀性影响较小,因此不能明显提高应力测试精度.(2) 在0° ~ 1°范围内增加摇摆角可使小角度晶界附近的亚晶都参与衍射,使各个

$\psi $ 角处衍射晶粒群微观应变趋于均匀,应力测试精度明显提高.(3) 衍射晶粒群微观应变的均匀性与晶粒择优取向的强弱有关,晶粒择优取向越强,衍射晶粒群微观应变越均匀,应力测试精度越高.

-

表 1 UNS S32750母材和ER2594焊丝的化学成分 (质量分数,%)

Table 1 Chemical compositions of UNS S32750 base metal and ER2594 welding wire

材料 C N Cr Mn Ni Mo Fe UNS S32750 0.054 0.28 25.55 0.97 6.45 3.69 余量 ER2594 0.014 0.30 25.39 0.39 9.33 3.72 余量 表 2 焊缝区铁素体和奥氏体化学成分和耐点蚀指数

Table 2 Chemical compositions of ferrite and austenite and pitting resistance eqivalent number in weld metal

保护气 相 元素含量w(%) 耐点蚀指数

PRENCr Ni Mo N 纯Ar F 26.63 7.50 3.59 0.015 38.72 GBA 25.97 8.45 3.32 0.355 42.61 IGA 25.38 8.59 3.01 0.340 40.75 WA 26.18 7.77 3.33 0.400 43.57 Ar + 2%N2 F 26.36 7.84 3.81 0.079 40.20 GBA 25.89 8.58 3.54 0.410 44.13 IGA 25.06 8.11 3.30 0.430 42.83 WA 25.80 7.73 3.50 0.440 44.39 -

[1] Wan Y, Jiang W C, Wei W, et al. Characterization of inhomogeneous microstructure and mechanical property in an ultra-thick duplex stainless steel welding joint[J]. Materials Science and Engineering: A, 2021, 822: 141640. doi: 10.1016/j.msea.2021.141640

[2] Cho Y H, Kim T S, Kim D K, et al. Block shear strength in thin-walled lean duplex stainless steel fillet welded connection with base metal fracture[J]. Structures, 2022, 35: 1243 − 1255. doi: 10.1016/j.istruc.2021.09.012

[3] 高站起, 荆洪阳, 徐连勇, 等. 超级双相不锈钢多层多道焊接接头组织及腐蚀性能[J]. 焊接学报, 2019, 40(7): 143 − 148. Gao Zhanqi, Jing Hongyang, Xu Lianyong, et al. Research on microstructure and corrosion behavior of multi-pass welded joints of hyper duplex stainless steel[J]. Transactions of the China Welding Institution, 2019, 40(7): 143 − 148.

[4] Brytan Z, Niagaj J, Reiman L, et al. Corrosion studies using potentiodynamic and EIS electrochemical techniques of welded lean duplex stainless steel UNS S82441[J]. Applied Surface Science, 2016, 388: 160 − 168. doi: 10.1016/j.apsusc.2016.01.260

[5] Verma J, Taiwade R V. Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review[J]. Journal of Manufacturing Processes, 2017, 25(1): 134 − 152.

[6] Cui S W, Shi Y H, Cui Y X, et al. The impact toughness of novel keyhole TIG welded duplex stainless steel joints[J]. Engineering Failure Analysis, 2018, 94: 226 − 231. doi: 10.1016/j.engfailanal.2018.08.009

[7] 陈庆宏, 吕小青, 徐连勇, 等. P92钢的CMT + P焊接接头组织性能[J]. 焊接学报, 2018, 39(12): 110 − 114. doi: 10.12073/j.hjxb.2018390308 Chen Qinghong, Lyu Xiaoqing, Xu Lianyong, et al. Microstructures and properties of P92 welding joint obtained by CMT + P welding[J]. Transactions of the China Welding Institution, 2018, 39(12): 110 − 114. doi: 10.12073/j.hjxb.2018390308

[8] Cai H Y, Xu L, Zhao L Y, et al. Cold metal transfer plus pulse (CMT + P) welding of G115 steel: Mechanisms, microstructure, and mechanical properties[J]. Materials Science and Engineering: A, 2022, 843: 143 − 156.

[9] Arun D, Devendranath R K, Vimala R. Multi-pass arc welding techniques of 12 mm thick super-duplex stainless steel[J]. Journal of Materials Processing Technology, 2019, 271: 126 − 143. doi: 10.1016/j.jmatprotec.2019.03.031

[10] Zhang Z, Jing H, Xu L, et al. Effects of nitrogen in shielding gas on microstructure evolution and localized corrosion behavior of duplex stainless steel welding joint[J]. Applied Surface Science, 2017, 404(15): 110 − 128.

[11] Sales A M, Westin E M, Jarvis B L. Effect of nitrogen in shielding gas of keyhole GTAW on properties of duplex and super duplex welds[J]. Welding in the World, 2017, 61(6): 1133 − 1140. doi: 10.1007/s40194-017-0486-1

[12] 沈波. 不同保护气体组分对S32205双相不锈钢焊接接头性能的影响[J]. 金属加工(热加工), 2021(11): 39 − 44. Shen Bo. Effects of different shielding gas components on the properties of S32205 duplex stainless steel welded joints[J]. MW Metal Forming, 2021(11): 39 − 44.

[13] 金鸣. 高氮钢四元保护气CMT电弧增材工艺研究[D]. 南京: 南京理工大学, 2019. Jin Ming. Study on CMT arc additive manufacturing process of high nitrogen steel for quaternary shielding gas[D]. Nanjing: Nanjing University of Science and Technology, 2019.

[14] 刘联盟. 保护气体对BN4奥氏体不锈钢光纤激光焊接接头组织和性能的影响[D]. 天津: 天津理工大学, 2021. Liu Lianmeng. Effect of shielding gas on microstructure and performance of BN4 austenitic stainless steel fiber laser welded joints[D]. Tianjin: Tianjin University of Technology, 2021.

[15] Kordatos J D, Fourlaris G, Papadimitriou G. The effect of cooling rate on the mechanical and corrosion properties of SAF 2205 (UNS 31803) duplex stainless steel welds[J]. Scripta Materialia, 2001, 44(3): 401 − 408. doi: 10.1016/S1359-6462(00)00613-8

[16] 张莹莹, 刘政军, 金美玲, 等. 热输入对双相钢药芯焊丝电弧焊接头组织和性能的影响[J]. 机械工程材料, 2020, 44(4): 30 − 34. Zhang Yingying, Liu Zhengjun, Jin Meiling, et al. Effect of heat input on microstructure and properties of flux-cored wire arc welding joint of duplex stainless steel[J]. Materials for Mechanical Engineering, 2020, 44(4): 30 − 34.

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载: