Effect of power distribution on dynamic behavior of molten pool during laser oscillating welding of 5A06 aluminum alloy

-

摘要: 以5A06铝合金锁底对接焊缝为研究对象,在激光束摆动的基础上引入一种沿正弦摆动路径分布的激光功率(功率分布),实现功率相对于摆动路径的动态调控. 基于FLUENT有限元软件,建立激光摆动焊接过程的流体动力学模型,研究光斑摆动与功率分布对焊缝成形的影响机制,模拟对比了施加等功率与功率分布2种工艺下的焊缝截面形貌、熔池动态行为及气孔形成过程. 结果表明,与等功率焊接相比,施加功率分布焊缝成形更优,未出现咬边和烧穿等缺陷;由于功率分布的特点,有效缓和了熔池的平均流速,熔融金属呈现更为稳定的流动行为,进一步提高了匙孔的稳定性,并获得了深宽比较小的匙孔,有效降低了焊缝的孔隙率(0.9 %).Abstract: 5A06 aluminum alloy lock butt weld was used as the research object. Based on the laser beam oscillating, a laser power (power distribution) which is distributed along the oscillating path was added to achieve the dynamic control of power relative to the path. The fluid dynamics model of laser oscillating welding process was established by the finite element software FLUENT to research the effect mechanism of laser oscillating and power distribution on weld forming. The weld section morphology, molten pool dynamic behavior and porosity formation process were simulated and compared under two processes of equal power and power distribution. The results show that compared with the equal power weld, the better formed weld is obtained by power distribution and has no defects such as undercut and burn through. Due to the characteristics of power distribution, the average flow rate of molten pool is effectively reduced, the steady flow behavior of molten metal is exhibited, further improve the stability of the keyhole, and smaller depth-to-width ratio keyhole is obtained, effectively reduce the porosity of the weld (0.9%).

-

0. 序言

5A06铝合金因其高比强度、优异的抗蚀性和焊接性[1-2],已经在船舶、汽车和航空航天等领域广泛应用. 然而,铝合金的高反射率、强导热性和线膨胀系数大等特性导致其在传统的激光焊接中会存在激光能量大量浪费与易形成气孔和咬边等缺陷,从而降低接头的力学性能[3]. 为消除铝合金激光焊接过程中产生的气孔和咬边等缺陷,激光摆动焊接成为近几年来的热门研究之一.

激光摆动焊接是一种通过内部振镜的摆动来实现激光光斑的横向、纵向和往复运动的先进技术. 摆动的激光束有利于提高接头的力学性能并降低孔隙率. Wang等人[4]对5A06铝合金进行不同光束摆动模式的激光摆动焊接,分析了在不同的摆动模式下的熔池形貌和接头的显微组织与力学性能,发现摆动模式对焊缝表面形貌有相当大的影响,激光束摆动可以改善气孔缺陷并细化焊缝晶粒尺寸,使得力学性能得到极大地提高. Wu[5]和Pang等人[6]发现摆动的激光束有效地细化了晶粒组织,降低了焊缝的孔隙率,并且提高了接头断后伸长率. Zhang等人[7]发现摆动的本质作用是改变激光诱导的匙孔速度,摆动频率和摆动幅度越大对气孔的抑制效果越好.

综上可见,激光摆动焊接更稳定并且能产生更高质量的焊缝. 然而激光摆动焊接过程中复杂的流体动力学很难用实时试验来测试验证,而数值模拟可以实现焊接过程中熔池动态行为的可视化描述. 相关学者针对气孔形成过程的数值模拟开展了大量研究. Cho等人[8]提出了一种光线追踪模型,该模型成功实现了能量多次反射和菲涅耳吸收效应,并成功模拟了匙孔诱导孔隙的成形过程. Pang等人[9]开发了一个定量模型来研究匙孔稳定性的机理,发现可以通过匙孔深度的不稳定性来预测孔隙率大小. 从降低孔隙率的角度出发,Li等人[10]提出了一种瞬态模型来研究环境压力对激光摆动焊接过程中的流体动力和小孔形成行为的影响,发现低于大气压的环境压力有助于产生更稳定的匙孔从而降低孔隙率. 激光热源作为焊接过程中热能的直接来源,其热源模型越符合真实情况,仿真模拟结果越精确. 针对以上问题,Ke等人[11]提出了一种混合热源模型,很好地模拟了匙孔和熔池的流体动力学,并对有摆动和无摆动的激光焊接进行了数值分析,研究了匙孔致使气孔形成和摆动抑制气孔的机理.

激光功率随摆动路径变化,将进一步有效降低焊缝的孔隙率和提高接头的力学性能[12],目前对铝合金激光摆动焊接的数值模拟研究大多集中在匙孔致使气孔形成和摆动路径抑制气孔的机理上,在激光功率与激光束摆动的共同作用下对熔池影响的研究较少. 文中采用一种沿正弦摆动路径分布的功率分布,开展5A06铝合金进行锁底对接激光摆动焊接的数值仿真研究,结合工艺试验研究激光功率分布与摆动路径共同作用对焊接过程中熔池动态行为、焊缝成形、气孔缺陷的影响机制.

1. 试验方法

1.1 试验材料

采用5A06铝合金薄板进行锁底对接激光摆动焊接试验,薄板尺寸为200 mm × 100 mm × 4 mm和200 mm × 100 mm × 6 mm(锁底侧),对接厚度和锁底厚度分别为4 mm和2 mm. 母材的化学成分见表1. 焊前使用砂纸打磨母材薄板表面后,用丙酮溶液清洗去除薄板表面的油污和氧化层,以减少氢的来源[13]. 保护气体为26 L/min的氩气(99.9%),避免焊接过程中的氧化.

表 1 5A06铝合金母材的化学成分(质量分数,%)Table 1. Chemical composition of base metalSi Mg Fe Mn Zn Al 0.4 5.8 ~ 6.8 0.4 0.5 ~ 0.8 0.2 余量 1.2 试验设备及参数

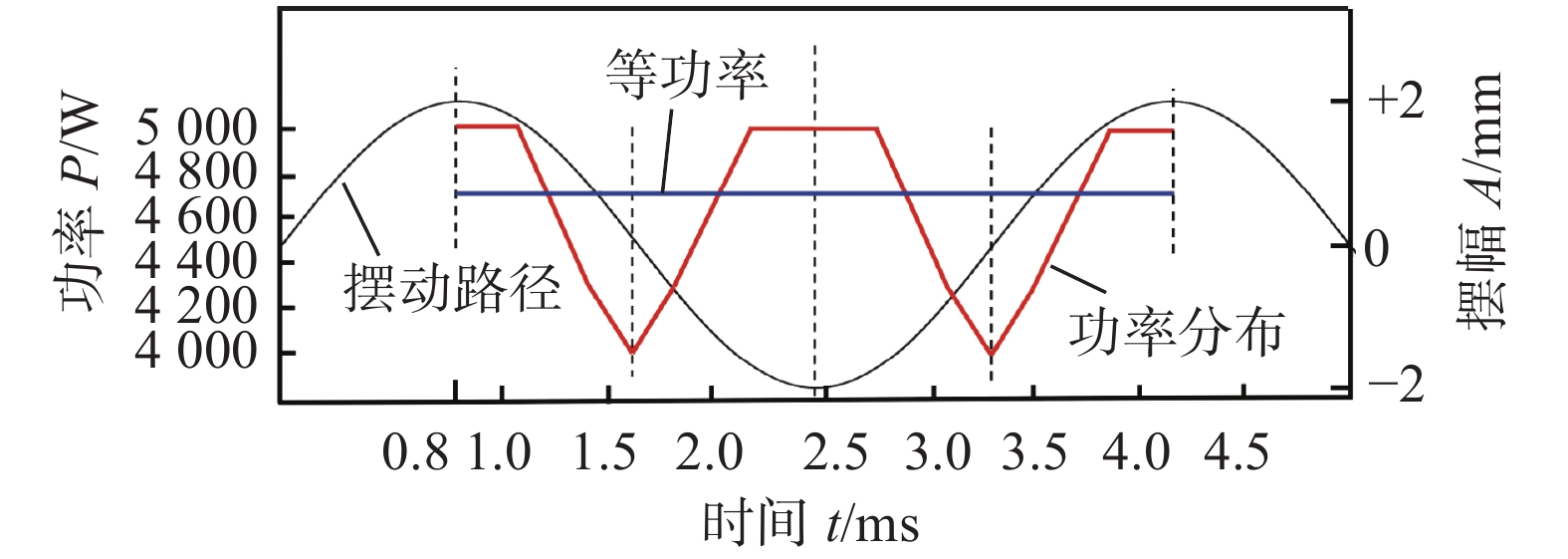

焊接设备采用IPG YLS-10000光纤激光器和YW52普雷茨特摆动头. 对恒等功率工艺的工艺参数进行了优化,得到一组最优参数,见表2中2号所示. 在此基础上,为优化2号的少量缺陷,通过大量工艺试验优化得到功率分布(1号)的工艺参数. 激光摆动路径为正弦,激光束斑直径为0.3 mm,离焦距离为7 mm. 1号试样施加变功率分布(5 000 ~ 4 300 ~ 4 000 W),2号试样施加4 700 W的等功率,两者平均功率相等,均为4 700 W. 功率分布特点如图1所示,激光功率从0.8 ms开始加载,此时激光束处于摆幅最大处且激光功率为最大值,激光功率随着激光向摆幅A为0 mm的位置移动而降低,并在A = 0 mm 时降到最低(4 000 W),因此,可以通过功率分布实现功率相对于摆动路径的相对动态调控. 试验结束后,使用YS-JX-07型光学显微镜和GP-2000C型LED工业射线探伤机分别分析焊缝截面形貌和焊缝内部质量,并使用ImageJ软件统计并计算焊缝的气孔及孔隙率.

表 2 激光摆动焊接工艺参数Table 2. Laser oscillating welding process parameters试样 激光功率P/W 摆幅A/mm 频率f/Hz 焊接速度v/(mm·min−1) 1 5 000 ~ 4 300 ~ 4 000 2 300 1 200 2 4 700 2 300 1 200 1.3 数值模拟

为进一步研究功率分布与摆动路径对匙孔及熔池流动行为的耦合影响,使用Fluent有限元软件建立5A06铝合金激光摆动焊接熔池传热和流动行为的仿真模型. 为提高计算效率,将仿真模型简化,图2为简化的数值模型中的2个区域:尺寸为24 mm × 7.5 mm × 4 mm和24 mm × 7.5 mm × 6 mm的流体域,以及流体域上表面厚度为2 mm的空气层. 采用六面体网格,最小尺寸为0.15 mm. 表3列出了数值模拟中使用的5A06铝合金热物理性能参数.

表 3 5A06铝合金热物理特性参数Table 3. Thermophysical properties of 5A06 aluminum alloy密度$ \rho $/(kg· m−3) 固相导热系数kS/(W·m−1·K−1) 液相导热系数kl/(W·m−1·K−1) 固相比热容CS/(J·kg−1·K−1) 液相比热容Cl/(J·kg−1·K−1) 动态粘滞度v/(kg·m−1·s−1) 固相线TS/K 液相线Tl/K 沸点Tg/K 熔化潜热LS/(105J·kg−1) 2 630 243 138 940 1 180 0.001 3 833.01 905.49 2 720 3.97 1.3.1 复合热源模型

采用复合热源模型[11]来模拟计算激光的热输入,此模型包括双椭球和自适应旋转高斯热源模型.

其中,双椭球热源方程[14]为

$$ {q_{\text{f}}} = P\frac{{12\sqrt 3 {\eta _{\text{e}}}{f_1}}}{{\left( {{{{a}}_{\text{f}}} + {{{a}}_{\text{r}}}} \right){{bc}}{\text{π}} \sqrt {\text{π}} }}\exp \left[ {\frac{{ - 3{{\left( {x - {x_0}} \right)}^2}}}{{{{a}}_{\text{f}}^2}} - \frac{{3{{\left( {y - {y_0}} \right)}^2}}}{{{{{b}}^2}}} - \frac{{3{{\textit{z}}^2}}}{{{{{c}}^2}}}} \right] $$ (1) $$ {q_{\text{r}}} = P\frac{{12\sqrt 3 {\eta _{\text{e}}}{f_1}}}{{\left( {{{{a}}_{\text{f}}} + {{{a}}_{\text{r}}}} \right){{bc}}{\text{π}} \sqrt {\text{π}} }}\exp \left[ {\frac{{ - 3{{\left( {x - {x_0}} \right)}^2}}}{{{{a}}_r^2}} - \frac{{3{{\left( {y - {y_0}} \right)}^2}}}{{{{{b}}^2}}} - \frac{{3{{\textit{z}}^2}}}{{{{{c}}^2}}}} \right] $$ (2) 式中:

$ {f_1} $ 为双椭球热源的能量分布系数;$ P $ 为激光功率;$ {\eta _e} $ 为热效率;$ {a_f} $ ,$ {a_r} $ ,$ b $ ,$ c $ 分别为双椭球的尺寸;$ {x_0} $ 和$ {y_0} $ 分别为激光束斑在工件上表面的x轴和y轴坐标值.自适应旋转高斯热源方程[11]为

$$\begin{split} & {q_{\text{g}}} = \frac{{36{\eta _{\text{g}}}{f_2}P\left[ {{\textit{z}}\left( {\chi - 1} \right) + {H_{(t)}}} \right]}}{{{H^2}_{(t)}{\text{π}} \left( {1 - {{{e}}^{ - 3}}} \right)\left[ {(\chi - 1)\left( {6r_{{i}}^2 + r_{{e}}^2} \right) + \left( {{\text{12}}r_{{i}}^2 + 4r_{{e}}^2} \right)} \right]}}\\&\qquad \exp \left\{ { - \frac{{3\left[ {{{\left( {x - {x_0}} \right)}^2} + {{\left( {y - {y_0}} \right)}^2}} \right]}}{{r_0^2({\textit{z}})}}} \right\} \end{split} $$ (3) $$ r_0^2({\textit{z}}) = - \frac{{r_{{e}}^2\ln \left( {{\textit{z}} - {H_{(t)}}} \right)}}{3} + r_{{i}}^2 $$ (4) 式中:

$ {f_2} $ 为旋转高斯热源的能量分布系数;$ {\eta _{\text{g}}} $ 为热效率;$ {r_0}\left({\textit{z}} \right) $ 为热源半径;$ {r_e} $ 为热源的开口半径;$ r_i^{} $ 为底部半径;$ {H_{(t)}} $ 为匙孔底部z轴坐标值;$ \chi $ 为常数2.0.1.3.2 路径方程

$$ {x_{\text{s}}}(t) = {{v}}t $$ (5) $$ {y_{\text{s}}}(t) = A\sin (2{\text{π}} {{f}}t) $$ (6) 式中:

$ f $ 为摆动频率;$ A $ 为振幅;$ v $ 为焊接速度.1.3.3 控制方程

通过质量、动量、能量及流体体积(VOF)方程来计算焊接过程中计算域内的温度、速度、压力分布及匙孔的自由表面,控制方程如下[15-16]

$$ \frac{{\partial \rho }}{{\partial t}} + \nabla \cdot (\rho \vec v) = {S_{\text{m}}} $$ (7) $$ \rho \left( {\frac{{\partial \vec v}}{{\partial t}} + \vec v \cdot \nabla \vec v} \right) = - \nabla P + \mu {\nabla ^2}\vec v - \frac{{\mu \vec v}}{{{K}}} + \rho \vec g\beta \left( {T - {{{T}}_{{\text{ref}}}}} \right) $$ (8) $$ \frac{{\partial (\rho H)}}{{\partial t}} + \vec v \cdot \nabla (\rho H) = \nabla \cdot (K\nabla T) + {S_{\text{v}}} $$ (9) $$ \frac{{\partial F}}{{\partial t}} + \nabla \cdot (\vec vF) = 0 $$ (10) 式中:

$ \rho $ 为密度;$ \vec v $ 为速度矢量;$ {S_{\rm{m}}} $ 为质量源项;$ P $ 为压力;$ \mu $ 为粘度;$ K $ 为阻力系数;$ \vec g $ 为重力矢量;$ \beta $ 为热膨胀系数;$ T $ 为工件的局部温度;$ {T_{{\text{ref}}}} $ 为参考温度;$ H $ 为热焓;$ {S_{\rm{v}}} $ 动量源项;$ F $ 为单元的体积分数.1.3.4 边界条件

如图2所示,上表层区域为2 mm厚空气层,其余灰色区域均为5A06母材. 上表面OPQR为压力出口,锁底对接面JEHM和ESTH在计算域内部,其余表面均为墙边界. 在墙边界上考虑由于热对流和热辐射导致的热损失,在匙孔自由表面上考虑热输入、热对流、热辐射和热蒸发损失.

$$ K\frac{{\partial T}}{{\partial \vec n}} = {q_{\rm{c}}} + {q_{\rm{r}}} $$ (11) $$ K\frac{{\partial T}}{{\partial \vec n}} = {q_{\rm{l}}} - {q_{\rm{r}}} - {q_{\rm{c}}} - {q_{\rm{v}}} $$ (12) 式中:

${q_{\rm{c}}} = {h_{\rm{c}}}\left( {T - {T_0}} \right)$ 和${q_{\rm{r}}} = \sigma \varepsilon \left( {{T^4} - T_0^4} \right)$ 分别为热对流和热辐射导致的热损失;$ {T_0} $ 为环境温度;$ {h_c} $ 为对流换热系数;$ \sigma $ 为玻尔兹曼常数;$ \varepsilon $ 为材料辐射发射率;${q_{\rm{l}}}$ 为激光热输入;${q_v} = W{L_{\rm{v}}}$ 为热蒸发损失;$ W $ 为蒸发率;${L_{\rm{v}}}$ 为蒸发潜势.1.3.5 平均热输入

使用平均线能量密度来衡量熔池的平均热输入.

$ \overline E $ 是同一时间段内单位长度的理论能量输入的平均值,经计算,1号与2号的平均线能量密度($ \overline E $ )相等,均为1.174 88 J/mm.$$ \overline{E}=\frac{{ \displaystyle\int }_{{a}_2}^{{a}_1}{ \displaystyle\int }_{{b}_2}^{{b}_1}{ \displaystyle\int }_{0}^{{T}}q(x,y,t){\rm{d}}x{\rm{d}}y{\rm{d}}t}{{ \displaystyle\int }_{0}^{t}\sqrt{{x}_{\text{s}}^{\prime 2}(t) + {y}_{\text{s}}^{\prime 2}(t)}} $$ (13) 式中:

$ a_1 $ ,$ a_2 $ ,$ b_1 $ ,$ b_2 $ 为从$ 0 $ 到$t $ 时间内激光能量分布的区域.2. 试验结果

2.1 功率分布对焊缝截面形状的影响

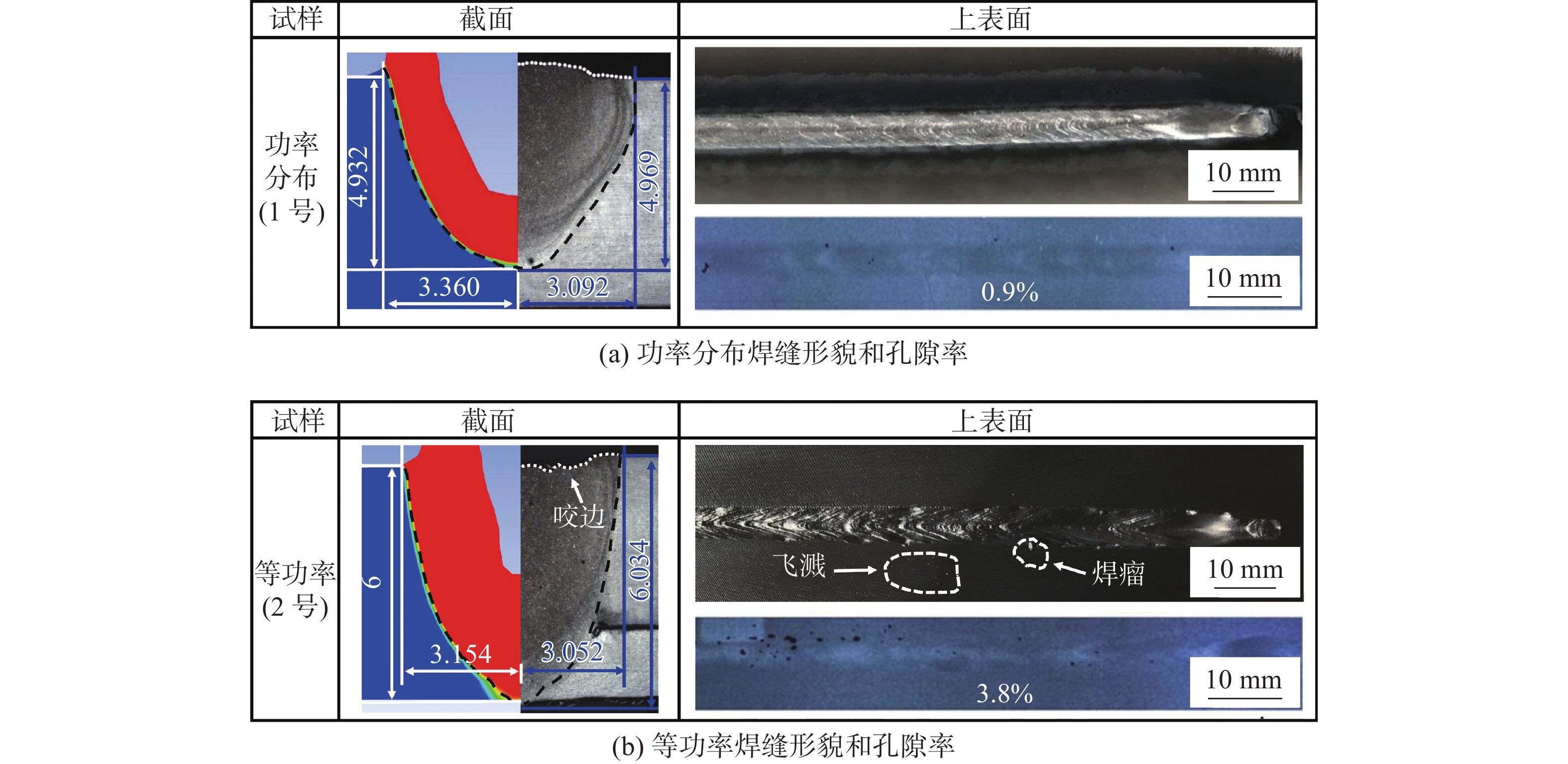

如图3所示,对比了2种工艺的数值模拟焊缝截面和试验结果,可以看出数值模拟的焊缝尺寸与试验结果接近,这证明了研究中数值模型的可靠性. 此外,相比于等功率的焊缝(2号),功率分布焊缝(1号)的熔宽略宽且熔深较小. 1号焊缝上表面堆积均匀且无飞溅、咬边和焊瘤缺陷,2号焊缝上表面堆积不均匀,存在飞溅、咬边和焊瘤缺陷.

为了进一步研究焊缝成形机理,计算功率分布和等功率沿摆动方向的能量分布.

$$ E={\int }_{0}^{t}q(x,y,t){\rm{d}}t $$ (14) 经计算,两者能量分布的峰值和谷值均分别在摆幅最大处和摆幅为0 mm处. 与等功率相比,在0.8 ms到17.5 ms内(即5个摆动周期),功率分布焊缝的能量峰值稍高(42.181 1 J/mm2 和39.653 7 J/mm2),而能量谷值稍低(13.431 5 J/mm2和 15.556 3 J/mm2),这是由功率分布的特点导致的. 能量分布大小与激光光斑速度成反比,与激光功率成正比,1号与2号焊缝的激光光斑速度相等,但与2号相比,1号焊缝在A = 2 mm位置的功率略大(5 000 W 和 4 700 W),而在A = 0 mm位置的功率较小(4 000 W 和 4 700 W),因此,1号在A = 2 mm的能量峰值高于2号,而在A = 0 mm的能量谷值低于2号. 由于2号在A = 0 mm处能量积累大,窄且深的匙孔增加了激光在匙孔中的反射次数,提高了激光的总热输入量,增强了匙孔对激光能量的菲涅尔吸收效应从而增大熔深;而1号在A = 0 mm处能量积累较小,宽且浅的匙孔减少了激光在匙孔中反射次数,降低了对激光能量的菲涅尔吸收效应[18],因此与2号相比,1号熔池的熔宽略大而熔深较小,且不存在烧穿缺陷.

2.2 熔池的动态行为

图4和图5为数值模拟的2号与1号熔池上表面的速度场与温度场. 如图4所示,2号中流体沿着匙孔壁的法线方向具有最高速度,高达950 mm/s,由于熔池较深,流体流速较高,流体在熔池中部和后部发生碰撞,形成更加不稳定和不规则的流体流动(如图4中黑色箭头),不利于匙孔的稳定[19-20]. 从温度场结果来看,2号熔池两侧的温度梯度较大,较高的冷却速度会导致焊缝边缘液态金属快速凝固,阻碍了焊趾处液态金属的填充,从而形成咬边缺陷[21].

如图5所示,相比于2号,1号熔池中沿小孔壁法线方向的流速小,其最高流速(500 mm/s)远低于2号中流体最高流速;1号熔池宽且浅,熔池前部流体不断流向熔池后方,流体流动较稳定,这有利于抑制流体对匙孔壁的冲击作用,提高匙孔的稳定性[11,20]. 从温度场结果看,1号与2号熔池的上表面积相当,但1号熔池在x方向较窄,而在y方向较宽,这是因为1号熔池在y方向两侧的热输入相对较大,使1号熔池两侧的温度梯度小,延长了冷却时间,增加了熔池边缘液态金属的流动性,不仅有利于液态金属向焊趾处填充,也有利于延长气泡漂浮时间[21-22].

图6为1号与2号熔池的平均流速和匙孔深度波动. 如图6a所示,光束摆动使流体流动呈现出周期性的振荡,1号与2号流体流速的振荡频率一致,这是因为激光束摆动频率主导了流体流速的振荡行为[20]. 此外,与2号相比,1号熔池的整体平均流速较低,这是由激光功率分布作用特点导致的,激光束施加在熔池中部的功率较低,使局部线能量和反冲压力较低,从而导致流体流速难以变大,这表明功率分布使熔融金属呈现更为稳定的流动行为;1号熔池的整体流速慢,液流之间的碰撞效应减弱,熔池流动更稳定,抑制了对匙孔的冲击作用[20-21],提高了熔池的稳定性. 此外,如图6b所示,从匙孔深度波动曲线可以看出,与2号相比,1号匙孔的平均深度更浅,并且匙孔深度表现出更好的稳定性.

2.3 功率分布对气孔的影响机制

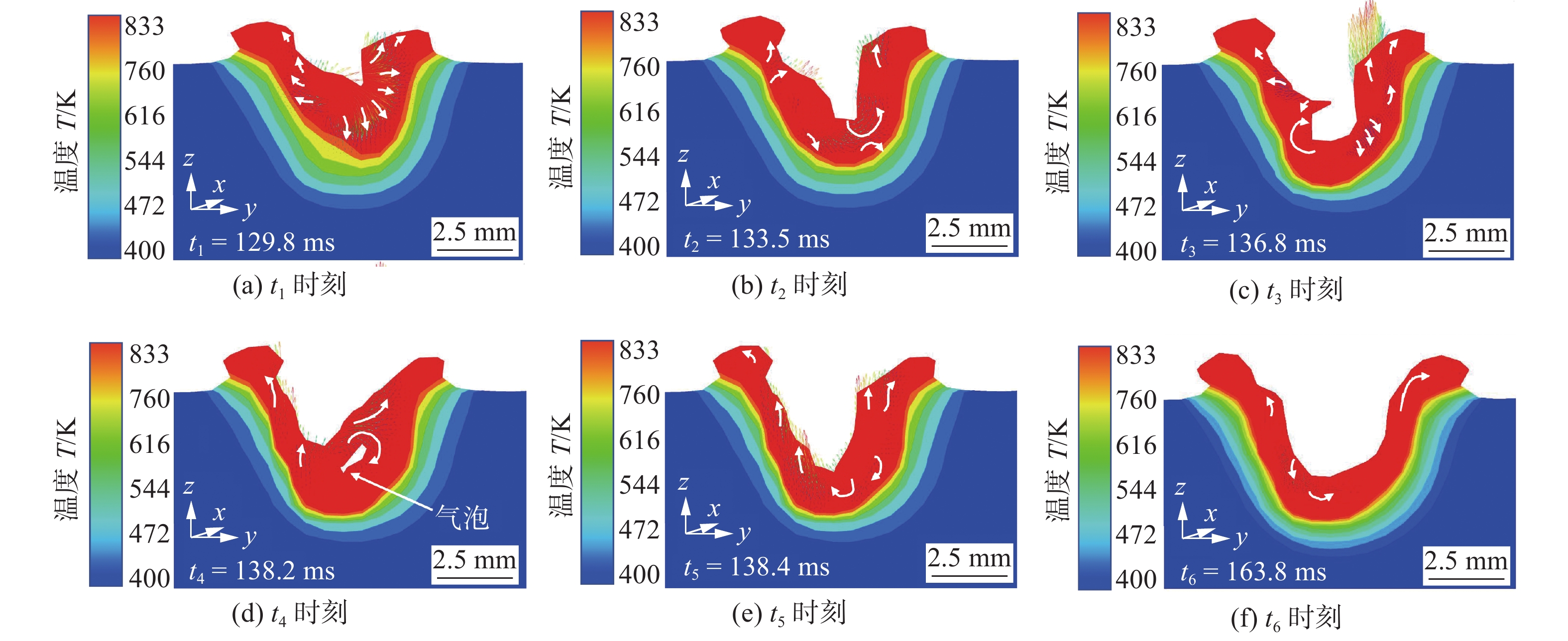

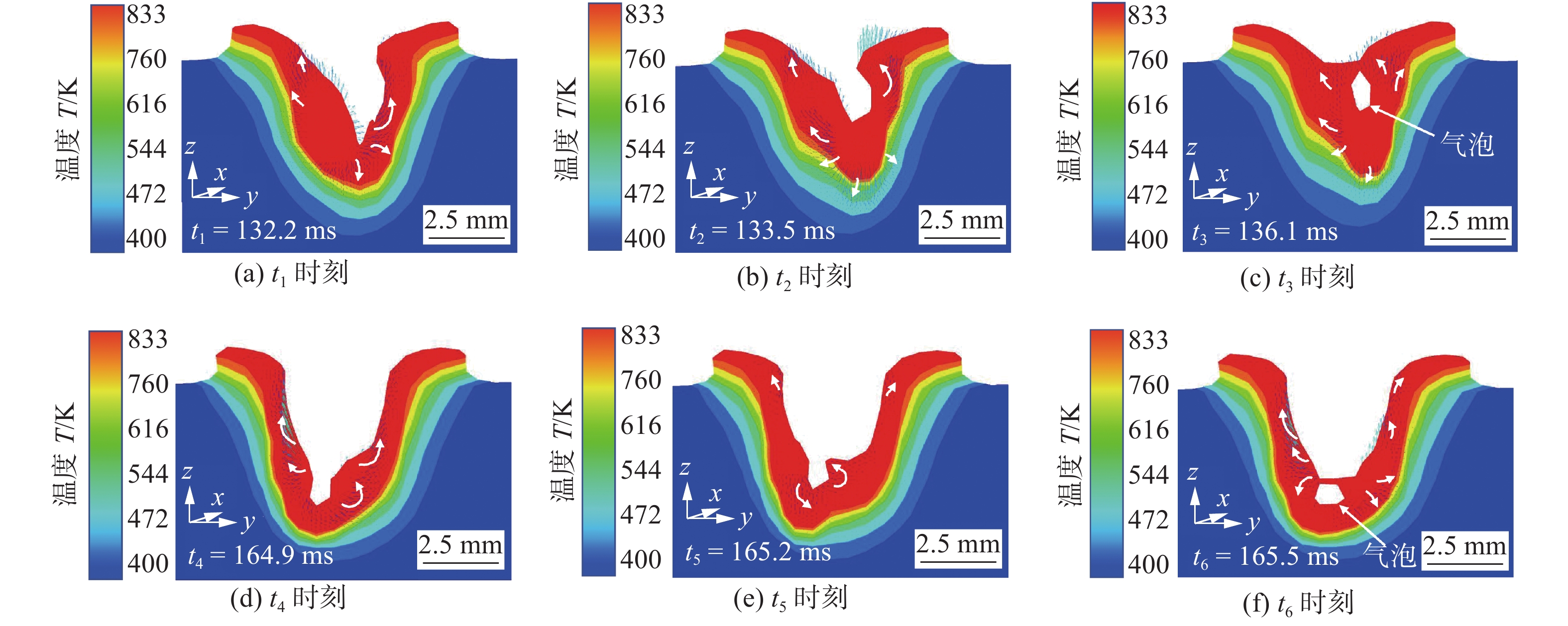

图7和图8为1号与2号在数值模拟焊接过程中气泡的形成过程. 如图7,在129.8 ms时,由于液态金属表面张力、金属反冲压力和剪切应力的综合作用,在1号的熔池中形成了一个较浅的匙孔,随着金属蒸汽反冲压力的增加,匙孔表面液态金属向熔池边缘移动,匙孔有扩大加深的趋势;在133.5 ms时,匙孔向下延伸;在136.8 ms时,匙孔后壁可以观察到一个由表面张力梯度引起的顺时针的涡流[23];在138.2 ms时,由于顺时针涡流的推动作用,匙孔后壁会与前壁融合形成一个气泡;在138.4 ms时,气泡被向下延伸的匙孔捕获而逸出;在163.8 ms以后,匙孔的开口和深度已经趋于稳定. 如图8所示,在132.2 ms时,2号熔池中形成一个较深且窄的匙孔;在133.5 ms时,匙孔后壁观察到一个由逆时针涡流的推动作用而形成的凸起;在136.1 ms,由于涡流的推动作用,匙孔前壁与后壁融合形成一个气泡;从164.9 ms到165.5 ms,再次观察到由于涡流的推动作用而使匙前壁和后壁融合形成的气泡.

1号与2号焊缝的孔隙率如图3所示,功率分布焊缝的孔隙率(0.9%)明显低于等功率焊缝的孔隙率(3.8%),这是因为相比于2号,1号的匙孔较浅且宽,会使匙孔壁附近的表面张力较小,可以降低匙孔塌陷的可能性[4,11];此外,1号熔池中的熔融金属获得了更稳定的流动模式,使匙孔更稳定且更不易发生塌陷,有利于抑制气泡的形成和促进气泡的逃逸[11],从而降低成形后的孔隙率. 此外,由于飞溅的形成主要受到匙孔稳定性的影响[7,24],因此在1号中未出现飞溅缺陷.

3. 结论

(1) 由于激光功率分布的特点,在光斑摆幅为0 mm时,熔池中的能量积累较低,会减少熔池中部熔融金属保持液态的时间,降低匙孔的穿透深度;而在摆幅最大处时,熔池中的能量积累较高,熔池两侧温度梯度小,冷却速度低,增加了熔池两侧液态金属流动性,因此功率分布作用下1号焊缝的深宽比较小且未出现烧穿和咬边等缺陷.

(2) 与等功率焊接相比,功率分布有效缓和了熔池的平均流速,减弱了液流之间的碰撞效应,抑制了流体对匙孔壁的冲击作用,使熔融金属呈现更为稳定的流动行为,提高了匙孔的稳定性.

(3) 与等功率摆动焊接相比,功率分布可以进一步降低焊缝的孔隙率(约为0.9 %). 这是因为功率分布降低了匙孔深度并扩大了匙孔直径,使匙孔的塌陷倾向更加困难,从而进一步减小了焊缝的孔隙率.

-

表 1 5A06铝合金母材的化学成分(质量分数,%)

Table 1 Chemical composition of base metal

Si Mg Fe Mn Zn Al 0.4 5.8 ~ 6.8 0.4 0.5 ~ 0.8 0.2 余量 表 2 激光摆动焊接工艺参数

Table 2 Laser oscillating welding process parameters

试样 激光功率P/W 摆幅A/mm 频率f/Hz 焊接速度v/(mm·min−1) 1 5 000 ~ 4 300 ~ 4 000 2 300 1 200 2 4 700 2 300 1 200 表 3 5A06铝合金热物理特性参数

Table 3 Thermophysical properties of 5A06 aluminum alloy

密度 $ \rho $ /(kg· m−3)固相导热系数kS/(W·m−1·K−1) 液相导热系数kl/(W·m−1·K−1) 固相比热容CS/(J·kg−1·K−1) 液相比热容Cl/(J·kg−1·K−1) 动态粘滞度v/(kg·m−1·s−1) 固相线TS/K 液相线Tl/K 沸点Tg/K 熔化潜热LS/(105J·kg−1) 2 630 243 138 940 1 180 0.001 3 833.01 905.49 2 720 3.97 -

[1] Guo N, Fu Y L, Wang Y Z, et al. Microstructure and mechanical properties in friction stir welded 5A06 aluminum alloy thick plate[J]. Materials & Design, 2017, 113: 273 − 283.

[2] Çam G, İpekoğlu G. Recent developments in joining of aluminum alloys[J]. The International Journal of Advanced Manufacturing Technology, 2016, 91: 1851 − 1866.

[3] Xu J J, Rong Y M, Huang Y, et al. Keyhole-induced porosity formation during laser welding[J]. Journal of Materials Processing Technology, 2018, 252: 720 − 727. doi: 10.1016/j.jmatprotec.2017.10.038

[4] Wang Z M, Oliveira J P, Zeng Z, et al. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties[J]. Optics and Laser Technology, 2019, 111: 58 − 65. doi: 10.1016/j.optlastec.2018.09.036

[5] Wu S K, Li Z X, Qi E Y, et al. Impact of Nb on microstructure and properties of oscillating laser-CMT hybrid welding joints of A7204P-T4 aluminum alloy sheets[J]. Science and Technology of Welding & Joining, 2021, 26(4): 273 − 278.

[6] Pang X B, Dai J H, Chen S, et al. Microstructure and mechanical properties of fiber laser welding of aluminum alloy with beam oscillation[J]. Applied Sciences-Basel, 2019, 23(9): 5096 − 5107. doi: 10.3390/app9235096

[7] Zhang C, Yan Y, Chen C, et al. Suppressing porosity of a laser keyhole welded Al-6Mg alloy via beam oscillation[J]. Journal of Materials Processing Technology, 2020, 278: 116382 − 116389. doi: 10.1016/j.jmatprotec.2019.116382

[8] Cho J H, Na S J. Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole[J]. Journal of Physics D-Applied Physics, 2006, 39(24): 5372 − 5378. doi: 10.1088/0022-3727/39/24/039

[9] Pang S Y, Chen W D, Wang W. A quantitative model of keyhole instability induced porosity in laser welding of titanium alloy[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Materials Science, 2014, 45(6): 2808 − 2818. doi: 10.1007/s11661-014-2231-3

[10] Li L Q, Peng G C, Wang J M, et al. Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminium alloys under subatmospheric pressures[J]. International Journal of Heat and Mass Transfer, 2019, 133: 812 − 826. doi: 10.1016/j.ijheatmasstransfer.2018.12.165

[11] Ke W C, Bu X Z, Oliveira J P, et al. Modeling and numerical study of keyhole-induced porosity formation in laser beam oscillating welding of 5A06 aluminum alloy[J]. Optics and Laser Technology, 2021, 133: 106540 − 106550. doi: 10.1016/j.optlastec.2020.106540

[12] Tan Z J, Pang B W, Oliveira J P, et al. Effect of S-curve laser power for power distribution control on laser oscillating welding of 5A06 aluminum alloy[J]. Optics and Laser Technology, 2022, 149: 107909 − 107916. doi: 10.1016/j.optlastec.2022.107909

[13] Xiao R S, Zhang X Y, Problems and issues in laser beam welding of aluminum-lithium alloys[J]. Journal of Manufacturing Processes, 2014, 16(2): 166–175.

[14] Wang H, Shi Y, Gong S, et al. Effect of assist gas flow on the gas shielding during laser deep penetration welding[J]. Journal of Materials Processing Technology, 2007, 184(1–3): 379–385.

[15] Xu G, Li P, Cao Q, et al. Modelling of fluid flow phenomenon in laser + GMAW hybrid welding of aluminum alloy considering three phase coupling and arc plasma shear stress[J]. Optics and Laser Technology, 2018, 100: 244 − 255. doi: 10.1016/j.optlastec.2017.10.009

[16] Gueyffier D, Li J, Nadim A, et al. Volume-of-fluid interface tracking with smoothed surface stress methods for three-dimensional flows[J]. Journal of Computational Physics, 1999, 152(2): 423 − 456. doi: 10.1006/jcph.1998.6168

[17] Schepper S C K D, Heynderickx G J, Marin G B. Modeling the evaporation of a hydrocarbon feedstock in the convection section of a steam cracker[J]. Computers & Chemical Engineering, 2009, 33(1): 122 − 132.

[18] 陈彦宾. 现代激光焊接技术[M]. 北京: 科学出版社, 2005. Chen Yanbin. Laser Welding Technology[M]. Beijing: Science Press, 2005.

[19] Liu T T, Mu Z Y, Hu R Z, et al. Sinusoidal oscillating laser welding of 7075 aluminum alloy: Hydrodynamics, porosity formation and optimization[J]. International Journal of Heat and Mass Transfer, 2019, 140: 346 − 358. doi: 10.1016/j.ijheatmasstransfer.2019.05.111

[20] Chen L, Mi G Y, Zhang X, et al. Effects of sinusoidal oscillating laser beam on weld formation, melt flow and grain structure during aluminum alloys lap welding[J]. Journal of Materials Processing Technology, 2021, 298(12): 117314 − 117328.

[21] Li S R, Mi G Y, Wang C M. A study on laser beam oscillating welding characteristics for the 5083 aluminum alloy: Morphology, microstructure and mechanical properties[J]. Journal of Manufacturing Processes, 2020, 53: 12 − 20. doi: 10.1016/j.jmapro.2020.01.018

[22] Li L Q, Gong J F, Xia H B, et al. Influence of scan paths on flow dynamics and weld formations during oscillating laser welding of 5A06 aluminum alloy[J]. Journal of Materials Research and Technology, 2021, 11: 19 − 32.

[23] Fuhrich T, Berger P, Hügel H. Marangoni effect in laser deep penetration welding of steel[J]. Journal of Laser Applications, 2001, 13(5): 178 − 186. doi: 10.2351/1.1404412

[24] Shi L, Li X, Jiang L, et al. Numerical study of keyhole-induced porosity suppression mechanism in laser welding with beam oscillation[J]. Science and Technology of Welding & Joining, 2021, 26(5): 349 − 355. doi: 10.1080/13621718.2021.1913562

-

期刊类型引用(2)

1. 栗振鑫,蔡创,余杰,陈梓琳,熊发帅,汤坪,陈辉. 激光摆动对TC4钛合金窄间隙焊接接头组织性能的影响. 中国激光. 2025(08): 77-86 .  百度学术

百度学术

2. 郭克星. 铝合金激光焊接技术研究进展. 热处理. 2024(06): 1-7 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: