PAW−MIG wire oscillating hybrid welding technology

-

摘要: 针对现有的等离子弧-MIG复合焊接过程中的双弧排斥问题,基于MIG焊丝位移规律性改变提出了一种新型的MIG焊丝振荡与等离子弧共熔池的复合焊接工艺. 通过调节MIG焊丝电机转速(振荡频率)和振荡振幅进行了焊接工艺试验. 结果表明,随着电机转速(振荡频率0 ~ 41 Hz)的增加,等离子弧与MIG电弧排斥减弱,耦合趋势增大. 尤其是电机转速为2 000 r/min(振荡频率33 Hz)时,共熔池复合焊接效果较好;MIG焊炬振荡振幅为1 mm时,电弧形状最为稳定,但振荡频率和振荡振幅过大均不利于焊接过程稳定性;MIG焊炬振荡提高了熔滴过渡频率,使焊丝尖部呈现小熔滴过渡,减小了焊接飞溅. 对接试验力学性能测试表明,抗拉强度、抗弯强度均随振荡频率的提高呈现先增大后减小趋势,分析认为MIG焊炬振荡具有一定搅拌熔池的作用,有效提高了焊接接头的力学性能.

-

关键词:

- 等离子弧−MIG复合焊接 /

- 振荡频率 /

- 电弧形态 /

- 力学性能

Abstract: In order to solve the problem of double arc repulsion in the existing PAW−MIG hybrid welding process, a new welding process based on the regular change of MIG wire displacement was proposed, which combined MIG wire oscillation with plasma arc in common weld pool. The welding process test was carried out by adjusting the rotation (oscillation frequency) and amplitude of MIG welding wire motor. The results show that with the increase of rotational speed (oscillation frequency), the repulsion between plasma arc and MIG arc decreases and the coupling trend increases. Especially when the rotational speed is 2000 r/min(oscillation frequency 33 Hz), the common weld pool effect is obvious. When the amplitude of MIG torch is 1 mm, the arc shape is the most stable. When the oscillation frequency and amplitude are too large, it is not conducive to the stability of welding process. The oscillation speeds up the droplet transition frequency so that the tip of the welding wire presents a small droplet transition and reduces the welding splash. The mechanical properties of the butt test show that the tensile strength and bending strength increase first and then decrease with the increase of the oscillation frequency. The oscillation enhances the stirring ability of the molten pool metal and effectively improves the mechanical properties of the welded joint. -

0. 序言

近年来,复合焊工艺在航空航天、船舶制造、工程机械等领域成为研究与应用的热点[1-4]. 其中,等离子弧−MIG复合焊接是将两电弧共熔池作用于工件,兼具等离子弧能量集中、熔深大[5-6]和MIG电弧效率高、速度快的优点[7],但焊接过程中等离子弧直流正接,MIG电弧直流反接,电弧在电磁力作用下发生排斥,影响焊接过程稳定性和质量.国内外大多采用外加磁场辅助的方式促使电弧有效耦合,但该方法焊接工艺参数较多,结构复杂[8-10].

为解决这一问题,提出了一种新型的等离子弧−MIG焊丝振荡式复合焊接工艺,即在复合焊接中使MIG焊丝发生位移振荡,可有效促进双弧耦合,增强对熔池的搅拌作用加快气体的排出,使焊缝组织更加均匀.系统介绍了该方法的振荡频率、振荡振幅对电弧形态、熔滴过渡行为的影响以寻求一种优化的等离子弧−MIG复合焊接方法,实现稳定高效焊接.

1. 试验方法

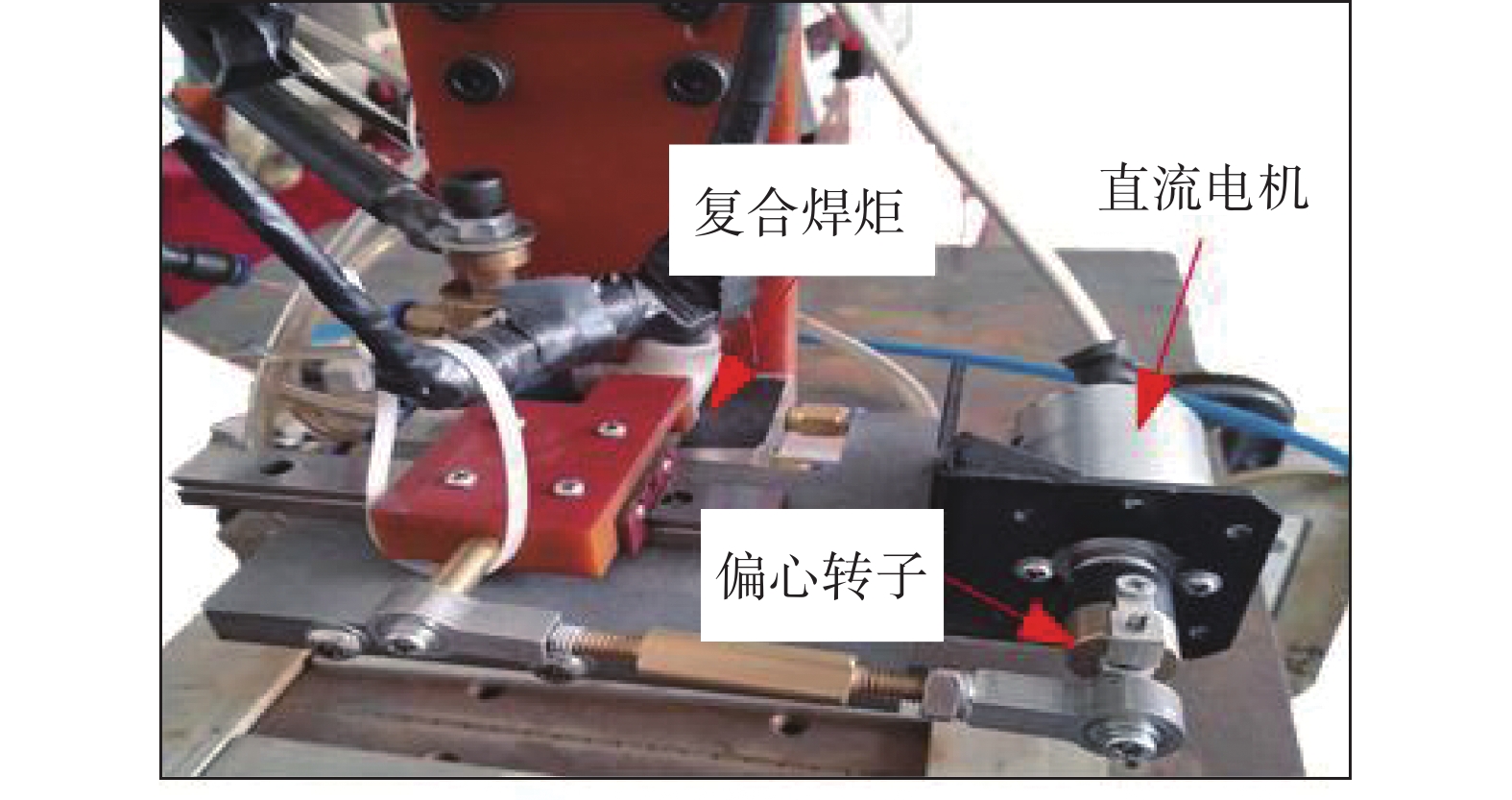

试验所用等离子弧−MIG焊丝振荡式复合焊接试验系统如图1所示,系统主要由自主设计的复合焊炬、LHM8-300A型直流脉冲等离子弧焊电源、德国乐驰S8 MIG焊机、安川DX100型焊接机器人组成. 复合焊炬是由自主设计的等离子弧焊枪、MIG焊枪旁轴式构成.

为探究MIG焊丝位移规律性的振荡焊接效果,设计了焊丝振荡系统. 通过可调式偏心转子带动曲柄连杆间接调节MIG焊炬的振荡振幅,设计振荡振幅调节范围为0 ~ 6 mm;利用直流电机的无级变速调节MIG焊丝的水平振荡频率. 电机电源采用KXN-3030D型电源,驱动电机采用DC-12V 775型号直流电机,转速0 ~ 2 500 r/min可调,对应理论振荡频率范围为0 ~ 41 Hz. 冷却循环装置用来避免喷嘴温度过高,利用机器人控制振荡式复合焊枪姿态完成焊接过程.振荡式复合焊接平台可实现MIG焊炬振荡振幅和频率的调节,如图2所示.

平板堆焊试验母材为200 mm × 50 mm × 6 mm的Q235钢板,对接试验所用试板尺寸为200 mm × 80 mm × 6 mm,采用尺寸规格为ϕ1.2 mmER50-6焊丝,母材和焊丝成分如表1所示. 等离子弧喷嘴在前,离子气流量2 L/min,轴线垂直于工件表面,喷嘴距离工件高度为4 mm. 经过对比试验确定等离子弧−MIG堆焊工艺参数如表2中试验组别1 ~ 3所示,对接工艺参数如表2中试验组别4 ~ 7所示. 电机转速0,1 000,1 500,2 000 r/min分别对应振荡频率0,16,25,33 Hz.

表 1 Q235钢和ER50-6焊丝的化学成分(质量分数,%)Table 1. Chemical compositions of Q235 steel and ER50-6 welding wire材料 C Mn Si P S Ni Fe Q235 ≤0.18 0.35 ~ 0.80 ≤0.30 ≤0.040 — — 余量 ER50-6 0.06 ~ 0.15 1.40 ~ 1.85 0.80 ~ 1.15 0.025 0.025 0.15 余量 表 2 焊接工艺参数Table 2. Welding process parameters组别 等离子弧电流IP /A MIG电流IM /A 焊接速度v/(mm·s−1) 电机转速n/(r·min−1) 振荡振幅A/mm 1 40 120 4 0 0 2 40 120 4 1 000,1 500,2 000,2500 3 3 40 120 4 1 000 1,2,3,4,5,6 4 100 100 4 0 3 5 100 100 4 1 000,1 500,2 000 3 6 100 100 4 1 000 4 7 100 100 4 1 500 3 根据标准GB/T 2651—2008《焊接接头拉伸试验方法》采用WAW-600型微机控制电液伺服万能试验机进行力学性能试验,设定拉伸速度为3 mm/min. 采用线切割切取拉伸试样,去除焊缝表面余高,每组参数选定3个试样进行拉伸试验,取3个拉伸试样检测结果的平均值作为最终测试结果. 根据标准GB/T 2653—2008《焊接接头弯曲试验方法》采用的弯曲压头直径为20 mm的弯曲半圆弧压头和三点式弯曲方法进行弯曲试验.从每组焊接试样中切取制作3个弯曲试样.

2. 试验结果与分析

2.1 振荡频率对电弧形态和熔滴过渡行为的影响

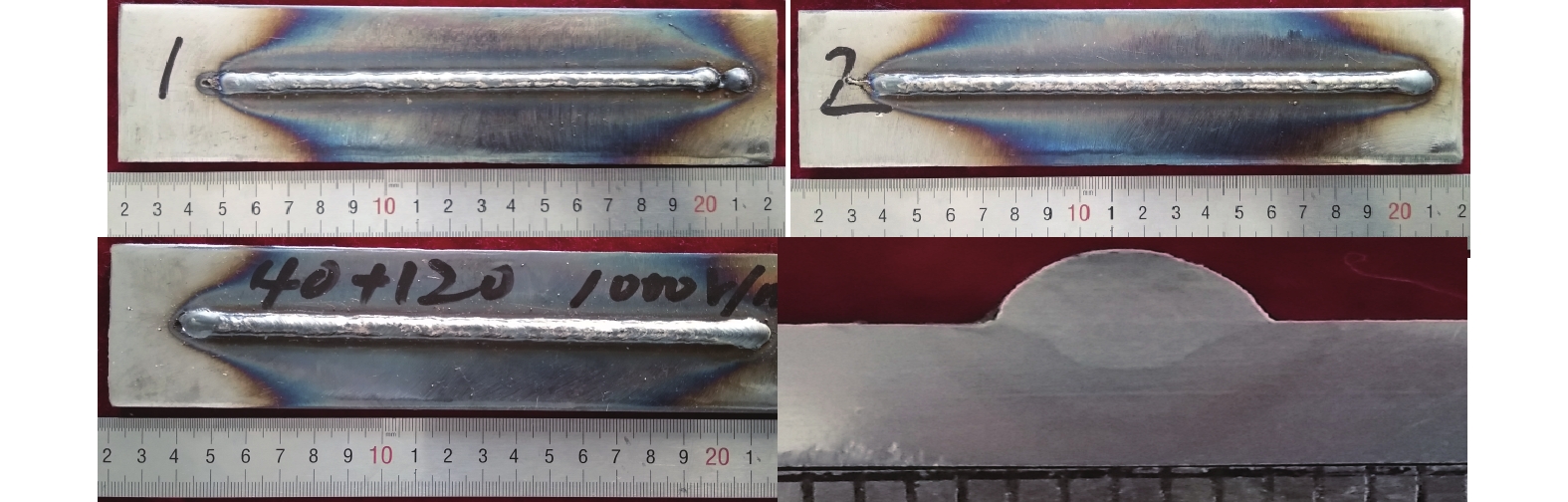

图3为在无振荡条件下,当电机转速为1 000 r/min(振荡频率16 Hz)、振荡振幅为3 mm时,等离子弧−MIG复合焊接所得焊缝成形情况. 从图3可知,焊缝宏观成形均未有明显缺陷.

固定MIG焊炬振荡振幅为3 mm,采集电机转速0,1 000,1 500,2 000,2 500 r/min下,对应振荡频率理论值为0,16,25,33,41 Hz的复合焊接电弧形态如图4所示. 当电机转速为0 r/min即无振荡时,等离子弧在前,MIG电弧在后,两电弧耦合效果较差,如图4a所示. 这是由于等离子弧采用直流正接,而MIG电弧采用直流反接,由于电磁力影响两电弧势必会产生排斥现象,不利于共熔池焊接过程. 随着MIG电弧进行水平位移振荡后,两电弧耦合程度发生了变化. 伴随着电机转速(振荡频率)的增加,等离子弧与MIG电弧排斥效果减弱,耦合趋势增大,尤其是电机转速为2 000 r/min(振荡频率为33 Hz)时,焊接过程更稳定;MIG焊丝熔滴过渡过程中产生的爆破效果比无振荡时更加明显,并且指向等离子弧方向;随着MIG焊丝振荡运动,其电弧形状不断变化,有时呈爆破状,有时呈钟形,因此MIG电弧的熔滴过渡形式可能为短路过渡和射流过渡并存.焊接过程中,等离子弧受到电磁压缩能量集中[11]且由于惯性作用会偏向MIG电弧一侧,有利于电弧发生耦合. 随着振荡频率的增大,MIG电弧与等离子弧形态之间相互影响变小,耦合区域变大,MIG焊丝振荡也会增强对熔池的搅拌作用. 当电机转速2 500 r/min(振荡频率为41 Hz)时,发现等离子弧出现不稳定的波动,如图4e所示. 这是由于电机转速(振荡频率)增大,使整个复合焊接装置尤其是等离子弧焊炬产生晃动,影响了焊接效果.

![]() 图 4 不同转速(振荡频率)下复合焊接电弧形态Figure 4. Arc morphology of hybrid welding at different rotational speed (oscillation frequency). (a) rotational speed 0 r/min (0 Hz); (b) rotational speed 1 000 r/min (16 Hz); (c) rotational speed 1 500 r/min (25 Hz); (d) rotational speed 2 000 r/min (33 Hz); (e) rotational speed 2 500 r/min (41 Hz)

图 4 不同转速(振荡频率)下复合焊接电弧形态Figure 4. Arc morphology of hybrid welding at different rotational speed (oscillation frequency). (a) rotational speed 0 r/min (0 Hz); (b) rotational speed 1 000 r/min (16 Hz); (c) rotational speed 1 500 r/min (25 Hz); (d) rotational speed 2 000 r/min (33 Hz); (e) rotational speed 2 500 r/min (41 Hz)图5为不同转速下复合焊接熔滴过渡及电信号采集. 从图5可以看出,焊接过程中MIG焊丝振荡频率不同,但熔滴过渡方式均表现为短路过渡形式. 从图5a看出,MIG电源形式为直流脉冲且每3个脉冲完成一次短路过渡;而当电机转速为1 500 r/min(振荡频率25 Hz)时,图5c中4 ~ 9完成当前一次熔滴过渡用时减少为约0.007 5 s,同时在两次熔滴过渡之间,存在多次电弧点燃且熔滴短路过程总是表现出高电压低电流特点.

2.2 振荡振幅对电弧形态和熔滴过渡行为的影响

在表2中第3组工艺参数下,保持电机转速为1 000 r/min(振荡频率16 Hz),调节MIG焊炬振荡振幅分别为1,2,3,4,5和6 mm情况下观察复合焊接电弧形态和熔滴过渡行为,如图6所示. 当振荡振幅为1 mm时,MIG电弧形状较为规则,相对于较大的振荡振幅,电弧形态较为稳定,如图6a所示. 在较大振荡振幅复合焊接中,作往复运动的MIG电弧对熔池具有更强的搅拌能力,显然更能促进气体的排出;而振荡振幅达到6 mm时,等离子电弧与MIG电弧耦合作用减弱,这主要是由于过大的振动使整个装置不稳定造成的.

通过对不同转速和振荡振幅下振荡焊接熔滴过渡和电信号分析发现,MIG熔滴过渡频率受振荡影响显著. 由熔滴过渡图像可以看出,在无振荡复合焊接下熔滴过渡呈现多脉一滴的短路过渡行为;而在振荡加入后,熔滴过渡行为发生了变化如图7所示.

相比于无振荡时的多脉一滴,加入振荡后存在一个脉冲周期内出现两次短路过渡的情况.每次短路过渡,焊丝尖部均为小熔滴过渡[12],与熔池短暂接触后快速分离,爆破力很小,因此振荡式复合焊接减小了焊接飞溅,整个过渡过程更为平稳,焊接热输入更稳定.

2.3 焊缝的力学性能

图8为不同转速(振荡频率)下对接焊缝成形.每组焊缝均未出现明显焊接缺陷,实现了单面焊双面成形.但是在背部也存在热输入不稳定问题.

表3为拉伸试验和弯曲试验的测试结果.振荡加入后,焊接接头的抗拉强度均大于无振荡时接头的抗拉强度,并且随着转速(振荡频率)的提高呈现先增大再减小的趋势,抗拉强度最大值为278 MPa. 这是由于一定频率的焊丝振荡起到了搅拌熔池的作用,有利于熔池中气孔的消除.弯曲试验结果表明,在无振荡情况下,弯曲90º时出现了裂纹;振荡加入后转速为1000,2 000 r/min时均未发现裂纹.从表3可知,随振荡频率的提高,抗弯强度呈先增大后减小趋势,最大为272 MPa;焊丝水平位移振荡后,两电弧排斥减弱,提高了焊接接头的力学性能;但振荡过大会使焊接过程的稳定性受影响,造成了抗拉强度和抗弯强度先增大后减小的现象.

表 3 拉伸和弯曲试验的测试结果Table 3. Results of tensile and bending tests电机转速n/( r·min−1) 抗拉强度Rm /MPa 抗弯强度Rτ /MPa 实测值 平均值 实测值 平均值 0 167,178,155 167 200,175,179 185 1 000 220,240,285 248 280,235,300 272 1 500 325,275,235 278 260,220,265 248 2 000 260,225,174 220 305,200,205 237 3. 结论

(1) 基于等离子弧和MIG弧焊工艺设计了一种新型焊丝振荡式复合焊接系统,实现了MIG焊炬振荡频率为0,16,25,33,41 Hz及振荡振幅0 ~ 6 mm可调的稳定复合焊接过程.

(2) 研究了振荡式复合焊接焊丝振荡频率和振荡振幅对电弧形态及熔滴过渡行为的影响. 结果表明,振荡系统有效促进了等离子弧和MIG电弧的耦合,尤其是振荡频率为33 Hz时,两电弧之间的排斥减弱,共熔池耦合作用明显;随着MIG焊丝振荡频率和振荡振幅的增大,MIG电弧对熔池的搅拌能力增强,可以有效促进熔池中的气体排出;振动中的MIG焊炬能实现小熔滴短路过渡,减少飞溅,增加熔滴过渡频率.其中当电机转速为1 500 r/min(振荡频率25 Hz)时,完成当前一次熔滴过渡用时减少为约0.007 5 s,使焊接过程更稳定.

(3)从拉伸和弯曲试验结果发现,振荡式复合焊接相比于不振荡情况下接头的抗拉强度和抗弯强度均有较大提高;随振荡频率的增大,接头的抗拉强度和抗弯强度呈现先增大后减小的趋势.

-

图 4 不同转速(振荡频率)下复合焊接电弧形态

Figure 4. Arc morphology of hybrid welding at different rotational speed (oscillation frequency). (a) rotational speed 0 r/min (0 Hz); (b) rotational speed 1 000 r/min (16 Hz); (c) rotational speed 1 500 r/min (25 Hz); (d) rotational speed 2 000 r/min (33 Hz); (e) rotational speed 2 500 r/min (41 Hz)

表 1 Q235钢和ER50-6焊丝的化学成分(质量分数,%)

Table 1 Chemical compositions of Q235 steel and ER50-6 welding wire

材料 C Mn Si P S Ni Fe Q235 ≤0.18 0.35 ~ 0.80 ≤0.30 ≤0.040 — — 余量 ER50-6 0.06 ~ 0.15 1.40 ~ 1.85 0.80 ~ 1.15 0.025 0.025 0.15 余量 表 2 焊接工艺参数

Table 2 Welding process parameters

组别 等离子弧电流IP /A MIG电流IM /A 焊接速度v/(mm·s−1) 电机转速n/(r·min−1) 振荡振幅A/mm 1 40 120 4 0 0 2 40 120 4 1 000,1 500,2 000,2500 3 3 40 120 4 1 000 1,2,3,4,5,6 4 100 100 4 0 3 5 100 100 4 1 000,1 500,2 000 3 6 100 100 4 1 000 4 7 100 100 4 1 500 3 表 3 拉伸和弯曲试验的测试结果

Table 3 Results of tensile and bending tests

电机转速n/( r·min−1) 抗拉强度Rm /MPa 抗弯强度Rτ /MPa 实测值 平均值 实测值 平均值 0 167,178,155 167 200,175,179 185 1 000 220,240,285 248 280,235,300 272 1 500 325,275,235 278 260,220,265 248 2 000 260,225,174 220 305,200,205 237 -

[1] 韩蛟, 韩永全, 洪海涛, 等. 铝合金等离子-MIG复合焊接电弧行为[J]. 焊接学报, 2022, 43(2): 45 − 49. doi: 10.12073/j.hjxb.20210702001 Han Jiao, Han Yongquan, Hong Haitao, et al. Arc behavior in plasma-MIG welding of aluminum alloy[J]. Transactions of the China Welding Institution, 2022, 43(2): 45 − 49. doi: 10.12073/j.hjxb.20210702001

[2] Han Y, Tong J, Hong H, et al. The influence of hybrid arc coupling mechanism on GMAW arc in VPPA-GMAW hybrid welding of aluminum alloys[J]. The International Journal of Advanced Manufacturing Technology, 2019, 101(1): 989 − 994.

[3] 刘甲, 徐家磊, 马照伟, 等. 钛合金等离子和MIG复合焊接技术研究[J]. 材料导报, 2021, 35(S2): 358 − 360. Liu Jia, Xu Jialei, Ma Zhaowei, et al. Study on plasma and MIG hybrid welding of titanium alloy[J]. Materials Reports, 2021, 35(S2): 358 − 360.

[4] Han Yongquan, Han Jiao, Chen Yan, et al. Stability of fiber laser-MIG hybrid welding of high strength aluminum alloy[J]. China Welding, 2021, 30(3): 7 − 11.

[5] Jia C B, Liu X F, Wu C S, et al. Stereo analysis on the keyhole and weld pool behaviors in K-PAW with triple CCD cameras[J]. Journal of Manufacturing Processes, 2018, 32: 754 − 762. doi: 10.1016/j.jmapro.2018.03.026

[6] Jia C B, Liu X F, Zhang G K, et al. Penetration/keyhole status prediction and model visualization based on deep learning algorithm in plasma arc welding[J]. The International Journal of Advanced Manufacturing Technology, 2021, 117(11): 3577 − 3597.

[7] 张洪涛, 桑健, 王琪晨, 等. TATM700钢等离子-MIG复合焊接工艺[J]. 焊接学报, 2019, 40(12): 25 − 30. Zhang Hongtao, Sang Jian, Wang Qichen, et al. Plasma MIG hybrid welding of TATM700 steel[J]. Transactions of the China Welding Institution, 2019, 40(12): 25 − 30.

[8] Yu J, Zhang H, Yang X, et al. Arc characteristics and welding process of magnetic field assisting plasma-GMAW-P[J]. Welding Journal, 2021, 100(1): 1s − 12s. doi: 10.29391/2021.100.001

[9] Yu J, Wang B, Zhang H, et al. Characteristics of magnetic field assisting plasma GMAW-P[J]. Welding Journal, 2020, 99(1): 25s − 38s. doi: 10.29391/2020.99.003

[10] Wu H, Chang Y, Lu L, et al. Review on magnetically controlled arc welding process[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91: 4263 − 4273. doi: 10.1007/s00170-017-0068-9

[11] 李岩, 王领, 张冀翔, 等. 基于电弧-熔池耦合的小孔型等离子弧焊接简化模型[J]. 机械工程学报, 2021, 57(18): 144 − 152. doi: 10.3901/JME.2021.18.144 Li Yan, Wang Ling, Zhang Jixiang, et al. Simplified model of small-pass plasma arc welding based on arc-molten pool coupling[J]. Journal of Mechanical Engineering, 2021, 57(18): 144 − 152. doi: 10.3901/JME.2021.18.144

[12] 王林, 武传松, 杨丰兆, 等. 外加磁场对高速GMAW电弧和熔池行为的主动调控效应[J]. 机械工程学报, 2016, 52(2): 1 − 6. doi: 10.3901/JME.2016.02.001 Wang Lin, Wu Chuansong, Yang Fengzhao, et al. Active regulation effect of applied magnetic field on high speed GMAW arc and molten pool behavior[J]. Journal of Mechanical Engineering, 2016, 52(2): 1 − 6. doi: 10.3901/JME.2016.02.001

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: