Effect of pin rotational speed on microstructure and properties of SSFSW weld for thick-plate magnesium alloy

-

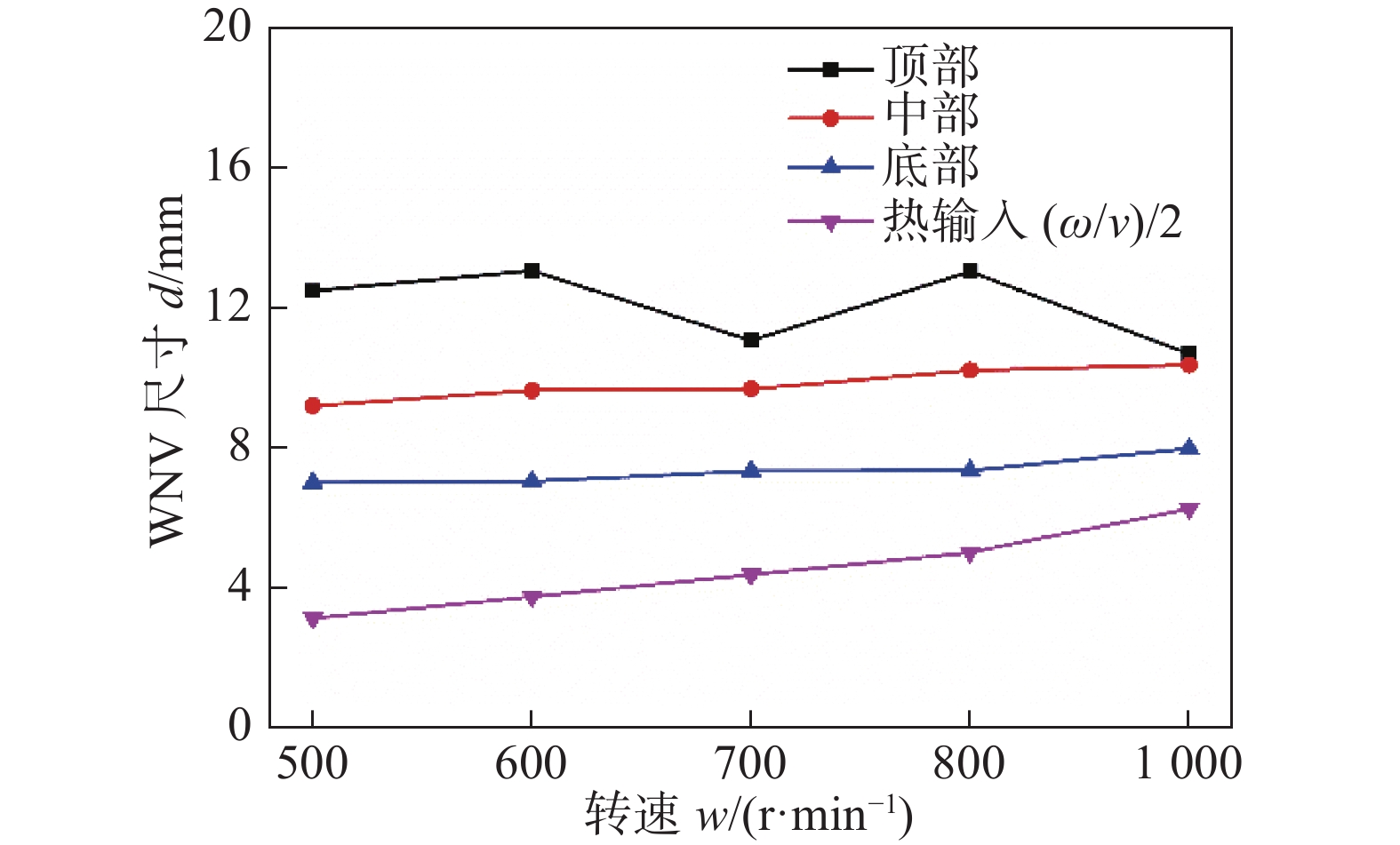

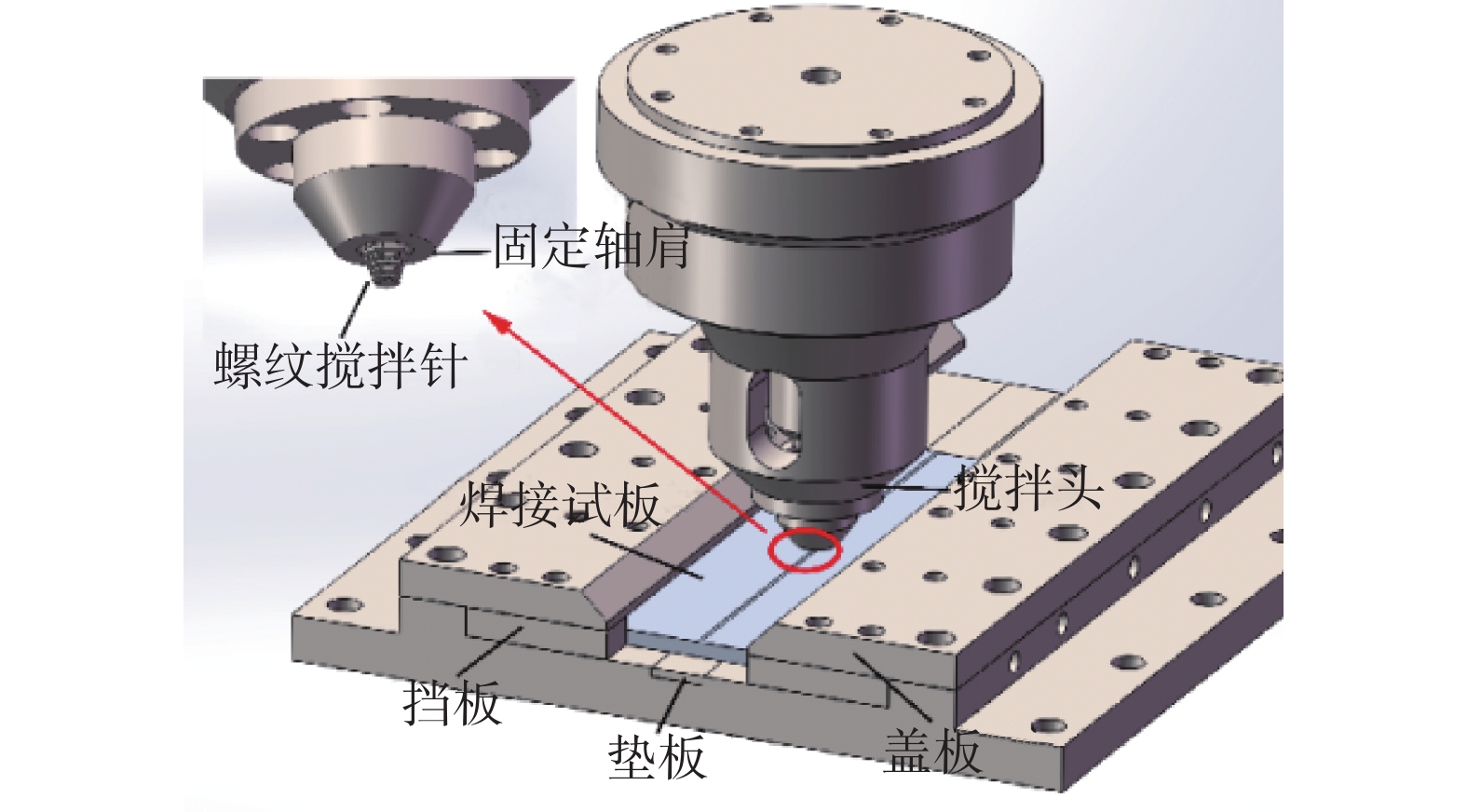

摘要: 对9 mm厚板AZ31B镁合金进行静止轴肩搅拌摩擦焊(stationary shoulder friction stir welding,SSFSW)工艺试验,探讨搅拌针转速(500 ~ 1000 r/min)对焊缝组织及力学性能的影响规律. 结果表明,在给定焊接速度80 mm/min下,搅拌针转速在600 ~ 800 r/min范围可获得表面光滑、无内部缺陷的对接焊缝,当转速为1 000 r/min时焊缝表面出现不连续凹坑但内部仍无缺陷. 随着转速增加,晶粒尺寸由(11.11 ± 1.68) μm增加到(18.95 ± 1.83) μm;在700 r/min时焊核区晶粒尺寸沿板厚差异最小. 焊缝中间硬度分布具有不均匀性且随转速增加而减小,最大差异为10.97 HV,最低硬度47 HV位于前进侧的热力影响区与焊核区界面处. 在700 r/min下接头力学性能最佳,强度系数为90.2%、对应断后伸长率为母材69.3%. 随着转速增加,断裂模式由韧-脆混合断裂转变为剪切-韧性混合断裂.

-

关键词:

- AZ31B镁合金厚板 /

- 静止轴肩搅拌摩擦焊 /

- 搅拌针转速 /

- 组织特征 /

- 力学性能

Abstract: The thick-plates of AZ31B magnesium alloy with 9 mm thickness were joined successfully by stationary shoulder friction stir welding (SSFSW) to explore the influence of stirring needle speed (500 – 1000 r/min) on the microstructure and mechanical properties of weld. The results show that the butt weld with smooth surface and no internal defects can be obtained at the rotation speed of 600 − 800 r/min under the given welding speed of 80 mm/min. When the rotation speed is 1000 r/min, discontinuous pits appear on the surface but there are still no defects in the weld. With the increase of rotating speed, the grain size increase from (11.11 ± 1.68) μm to (18.95 ± 1.83) μm. At 700 r/min, the grain size difference in the nugget zone is the smallest along the plate thickness. The inhomogeneity of hardness distribution in the WNZ decreases with the increase of rotational speed. The maximum difference of hardness in the middle of the plate thickness is 10.97 HV, and the minimum hardness is 47 HV at the interface between the heat affected zone and the nugget zone of the advancing side. The joint has the best mechanical properties at 700 r/min, the strength coefficient is 90.2% and the corresponding elongation is 69.3% of the BM. With the increase of rotational speed, the fracture mode changes from ductile-brittle mixed fracture to shear-ductile mixed fracture. -

-

图 12 不同转速下WNZ硬度值分布

Figure 12. Microhardness distributions in WNZ at different rotational speed. (a) Microhardness distributions of the top WNZ; (b) Microhardness distributions of the middle WNZ; (c) Microhardness distributions of the bottom WNZ; (d) Microhardness distributions along WNZ thickness direction

表 1 AZ31B化学成分(质量分数,%)

Table 1 The chemical compositions of AZ31B

Al Zn Mn Si Fe Cu Ni Ca Mg 3.1 0.99 0.38 <0.08 <0.003 <0.01 <0.001 <0.04 余量 表 2 AZ31B物理性能

Table 2 Physical properties of AZ31B

抗拉强度Rm/MPa 屈服强度Rel/MPa 断后伸长率A50(%) 熔点T/℃ 热导率λ/W·(m−1·K−1) 硬度H/HV 256 156 14 650 155 52 ~ 59 表 3 不同转速下WNZ硬度值的平均值和方差

Table 3 Mean and variance of Microhardness distributions in WNZ at different rotational speed

转速w/(r·min−1) WNZ顶部 WNZ中部 WNZ底部 沿WNZ厚度方向 硬度平均值H/HV 方差 硬度平均值H/HV 方差 硬度平均值H/HV 方差 硬度平均值H/HV 方差 600 56.38 10.90 54.22 6.30 52.41 5.28 57.71 4.07 700 54.07 2.53 54.65 10.97 52.93 5.24 60.83 3.28 800 56.02 6.90 55.11 9.82 53.65 3.84 56.70 4.08 1 000 56.68 2.39 59.23 9.02 54.65 3.00 59.63 5.40 表 4 SSFSW接头和BM的拉伸性能

Table 4 Tensile properties of SSFSW joint and BM

转速w/(r·min−1) 抗拉强度Rm/MPa 屈服强度Rel/MPa 断后伸长率A(%) 强度系数B(%) 600 205 88 5.5 80.1 700 231 96 9.7 90.2 800 227 94 9.3 88.7 1000 227 93 8.9 88.7 -

[1] Xu R Z, Ni D R, Yang Q, et al. Pinless Friction Stir Spot Welding of Mg-3Al-1Zn Alloy with Zn Interlayer[J]. Journal of Materials Science & Technology, 2016, 32(1): 76 − 88.

[2] Liu F J. Microstructure, mechanical properties, and corrosion resistance of friction stir welded Mg-Al-Zn alloy thick plate joints[J]. Welding in the World, 2021, 65: 229 − 241. doi: 10.1007/s40194-020-01012-z

[3] 徐安莲. 镁合金搅拌摩擦焊接头的显微组织及力学性能[D]. 重庆: 重庆大学, 2016. Xu Anlian. Microstructure and mechanical properties of magnesium alloy friction stir welded joints[D]. Chongqing: Chongqing university, 2016.

[4] 车朋卫. 静轴肩搅拌摩擦焊的工艺及焊接接头性能研究[D]. 甘肃: 兰州理工大学, 2019. Che Pengwei. Study on stationary shoulder friction stir welding technology and joint properties[D]. Gansu: Lanzhou University of Technology, 2019.

[5] Li W Y, Niu P L, Yan S R, et al. Improving microstructural and tensile properties of AZ31B magnesium alloy joints by stationary shoulder friction stir welding[J]. Journal of Manufacturing Processes, 2018, 37: 159 − 167.

[6] Patel V, Li W Y, Wen Q, et al. Surface analysis of stationary shoulder friction stir processed AZ31B magnesium alloy[J]. Materials Science and Technology, 2019, 35(5): 628 − 631. doi: 10.1080/02670836.2019.1570692

[7] Patel V, Li W Y, Wen Q, et al. Homogeneous Grain Refinement and Ductility Enhancement in AZ31B Magnesium Alloy Using Friction Stir Processin[C]//Magnesium Technology 2019: Springer, 2019, 1: 83 − 87.

[8] Patel V, Li W Y, Liu X C, et al. Tailoring grain refinement through thickness in magnesium alloy via stationary shoulder friction stir processing and copper backing plate[J]. Materials Science and Engineering: A, 784: 1-10.

[9] Patel V, Li W Y, Xu Y X. Stationary shoulder tool in friction stir processing: a novel low heat input tooling system for magnesium alloy[J]. Advanced Manufacturing Processes, 2019, 34(2): 177 − 182.

[10] 马宗义, 商 乔, 倪丁瑞, 等. 镁合金搅拌摩擦焊接的研究现状与展望[J]. 金属学报, 2018, 54(11): 1597 − 1617. doi: 10.11900/0412.1961.2018.00392 Ma Zongyi, Shang Qiao, Ni Dingrui, et. al. Friction stirwelding of magnesium alloys: a review[J]. Acta Metallurgica Sinica, 2018, 54(11): 1597 − 1617. doi: 10.11900/0412.1961.2018.00392

[11] 杨素媛, 张保垒. 厚板AZ31镁合金搅拌摩擦焊焊接接头的组织与性能[J]. 焊接学报, 2009, 30(5): 1 − 4. doi: 10.3321/j.issn:0253-360X.2009.05.001 Yang Suyuan, Zhang Baolei. Microstructures and mechanical properties of thick AZ31 magnesium alloy welded joint by friction stir welding[J]. Thansactions of the China Welding Institution, 2009, 30(5): 1 − 4. doi: 10.3321/j.issn:0253-360X.2009.05.001

[12] Chowdhury S H, Chen D L, Bhole S D, et al. Friction Stir Welded AZ31 Magnesium Alloy: Microstructure, Texture, and Tensile Properties[J]. Metallurgical& Materials Transactions A, 2013, 44(1): 323 − 336.

[13] Wang Y N, Lee C J, Huang C C, et al. Influence from extrusion parameters on high strain rate and low temperature superplasticity of AZ series Mg-based alloys[C]//Materials Science Forum. 2003, 426(432): 2655-2660

[14] Chang C I, Lee C J, Huang J C, et al. Relationship between grain size and Zener–Holloman parameter during friction stir processing in AZ31 Mg alloys[J]. Scripta Materialia, 2004, 51: 509 − 514. doi: 10.1016/j.scriptamat.2004.05.043

[15] Arbegast W J, Hartley P J. Proceedings of the fifth international conference on trends in welding research[C]. Georgia, The fifth international conference, 1998.

[16] Watanabe H, Tsutsui H, Mukai T, et al. Grain size control of commercial wrought Mg-Al-Zn alloys utilizing dynamic recrystallization[J]. Materials transactions, 2001, 42(7): 1200 − 1205. doi: 10.2320/matertrans.42.1200

[17] Shang Q, Ni D R, Xue P, et al. Evolution of local texture and its effect on mechanical properties and fracture behavior of friction stir welded joint of extruded Mg-3Al-1Zn alloy[J]. Materials Characterization, 2017, 128: 14 − 22. doi: 10.1016/j.matchar.2017.03.018

[18] Park S, Sato Y S, Kokawa H. Effect of micro-texture on fracture location in friction stir weld of Mg alloy AZ61 during tensile test[J]. Scripta Materialia, 2003, 49(2): 161 − 166. doi: 10.1016/S1359-6462(03)00210-0

[19] Peng J, Zhang Z, Liu Z, et al. The effect of texture and grain size on improving the mechanical properties of Mg-Al-Zn alloys by friction stir processing[J]. Scientific Reports, 2018, 8(1): 4196. doi: 10.1038/s41598-018-22344-3

[20] Bruni C, Forcellese A, Gabrielli F, et al. Effect of the ω/v ratio and sheet thickness on mechanical properties of magnesium alloy FSWED joints[J]. International Journal of Material Forming, 2010, 3(1 Supplement): 1007 − 1010.

[21] Chowdhury S M, Chen D L, Bhole S D, et al. Tensile properties of a friction stir welded magnesium alloy: Effect of pin tool thread orientation and weld pitch[J]. Materials Science & Engineering A, 2010, 527(21-22): 6064 − 6075.

[22] Afrin N, Chen D L, Cao X, et al. Microstructure and tensile properties of friction stir welded AZ31B magnesium alloy[J]. Materials Science & Engineering A, 2008, 472(1-2): 179 − 186.

[23] Commin L, Dumont M, Masse J E, et al. Friction stir welding of AZ31 magnesium alloy rolled sheets: Influence of processing parameters[J]. Acta Materialia, 2009, 57(2): 326 − 334. doi: 10.1016/j.actamat.2008.09.011

[24] Shang Q, Ni D R, Xue P, et al. Improving joint performance of friction stir welded wrought Mg alloy by controlling non-uniform deformation behavior[J]. Materials Science and Engineering:A, 2017, A707: 426 − 434.

[25] Xin R L, Liu D J, Shu X G, et al. Influence of welding parameter on texture distribution and plastic deformation behavior of as-rolled AZ31 Mg alloys[J]. Journal of Alloys & Compounds An Interdisciplinary Journal of Materials Science & Solid State Chemistry & Physics, 2016, 670: 64 − 71.

[26] Luo J, Mei Z, Tian W, et al. Diminishing of work hardening in electroformed polycrystalline copper with nano-sized and uf-sized twins[J]. Materials Science and Engineering:A, 2006, 441(1-2): 282 − 290. doi: 10.1016/j.msea.2006.08.051

[27] Afrin N, Chen D L, Cao B X, et al. Strain hardening behavior of a friction stir welded magnesium alloy[J]. Scripta Materialia, 2007, 57(11): 1004 − 1007. doi: 10.1016/j.scriptamat.2007.08.001

[28] Fu R D, Ji H S, Li Y J, et al. Effect of weld conditions on microstructures and mechanical properties of friction stir welded joints on AZ31B magnesium alloys[J]. Science and Technology of Welding & Joining, 2012, 17: 174 − 180. doi: 10.1179/1362171811Y.0000000056

[29] Woo W, Choo H, Brown D W, et al. Texture variation and its influence on the tensile behavior of a friction-stir processed magnesium alloy[J]. Scripta Materialia, 2006, 54(11): 1859 − 1864. doi: 10.1016/j.scriptamat.2006.02.019

-

期刊类型引用(1)

1. 王鹏,吴璇,张喆,钱志杰,高吉成. 搅拌摩擦焊在镁合金焊接中的应用与进展. 兵器材料科学与工程. 2025(01): 155-164 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: