Numerical simulation and mechanical properties of spray-assisted friction stir welding RAFM steel

-

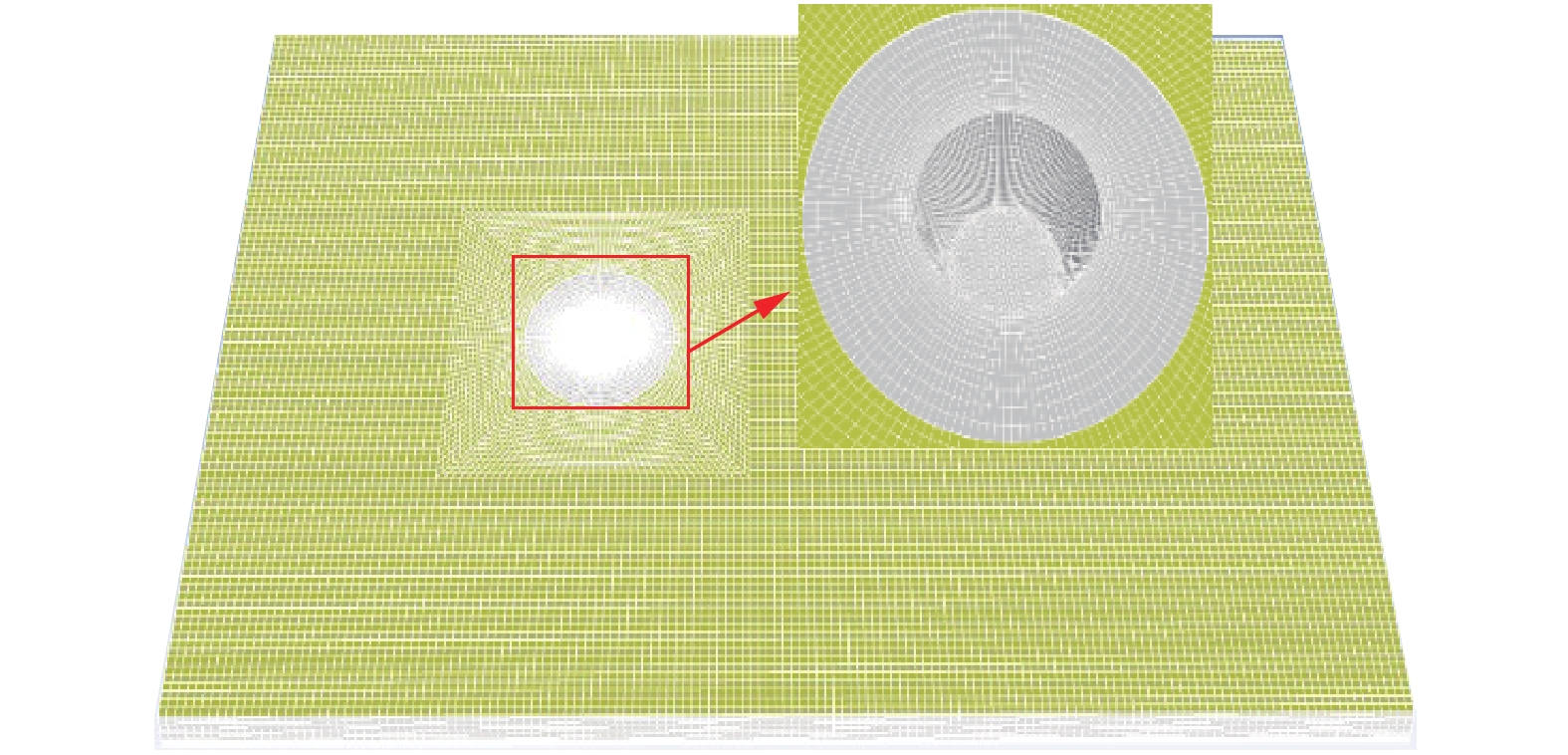

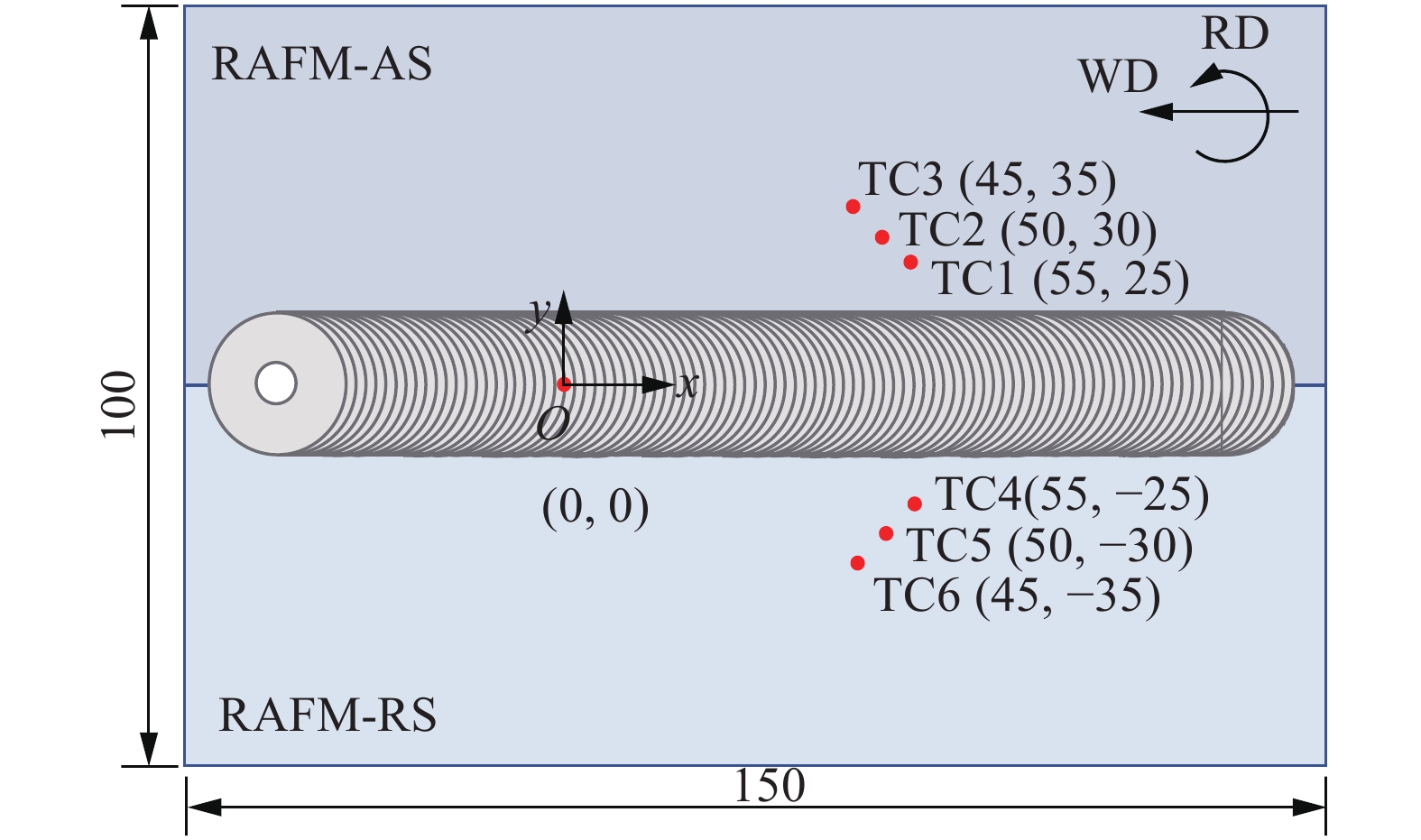

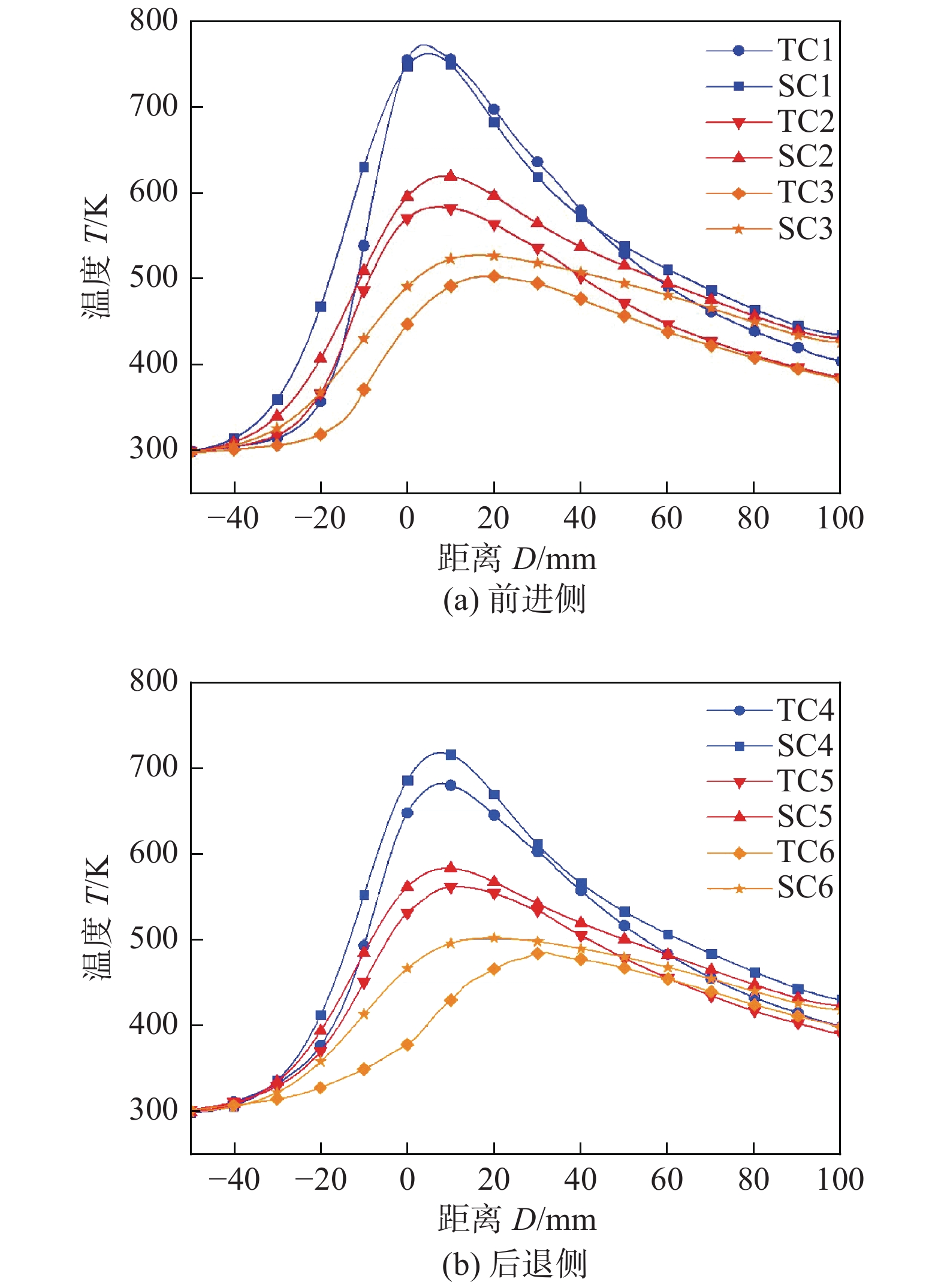

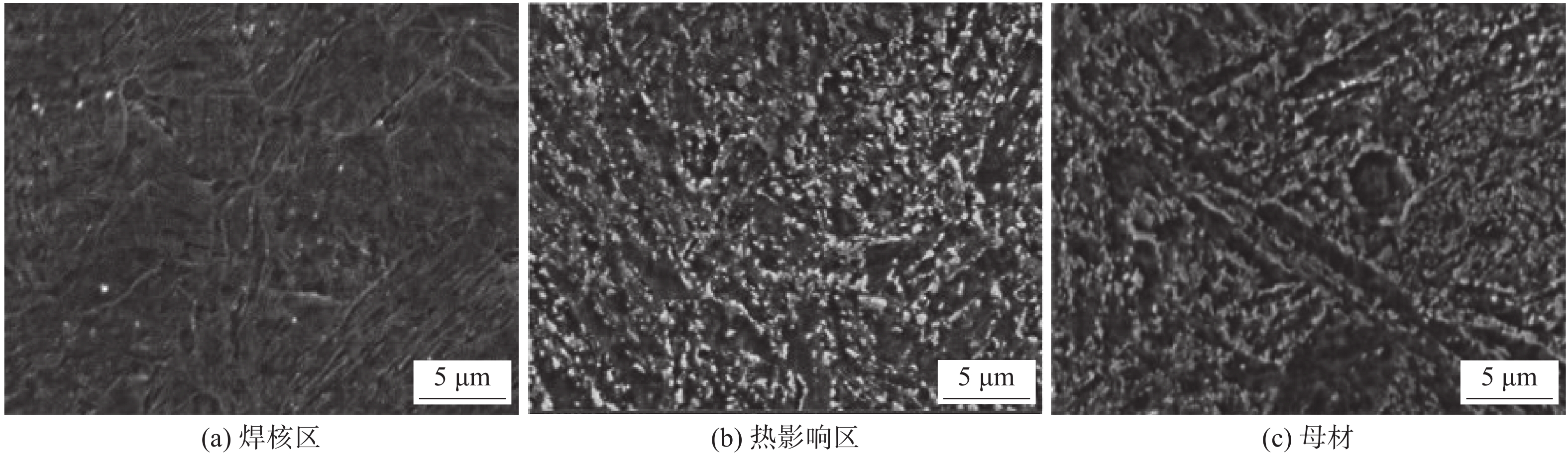

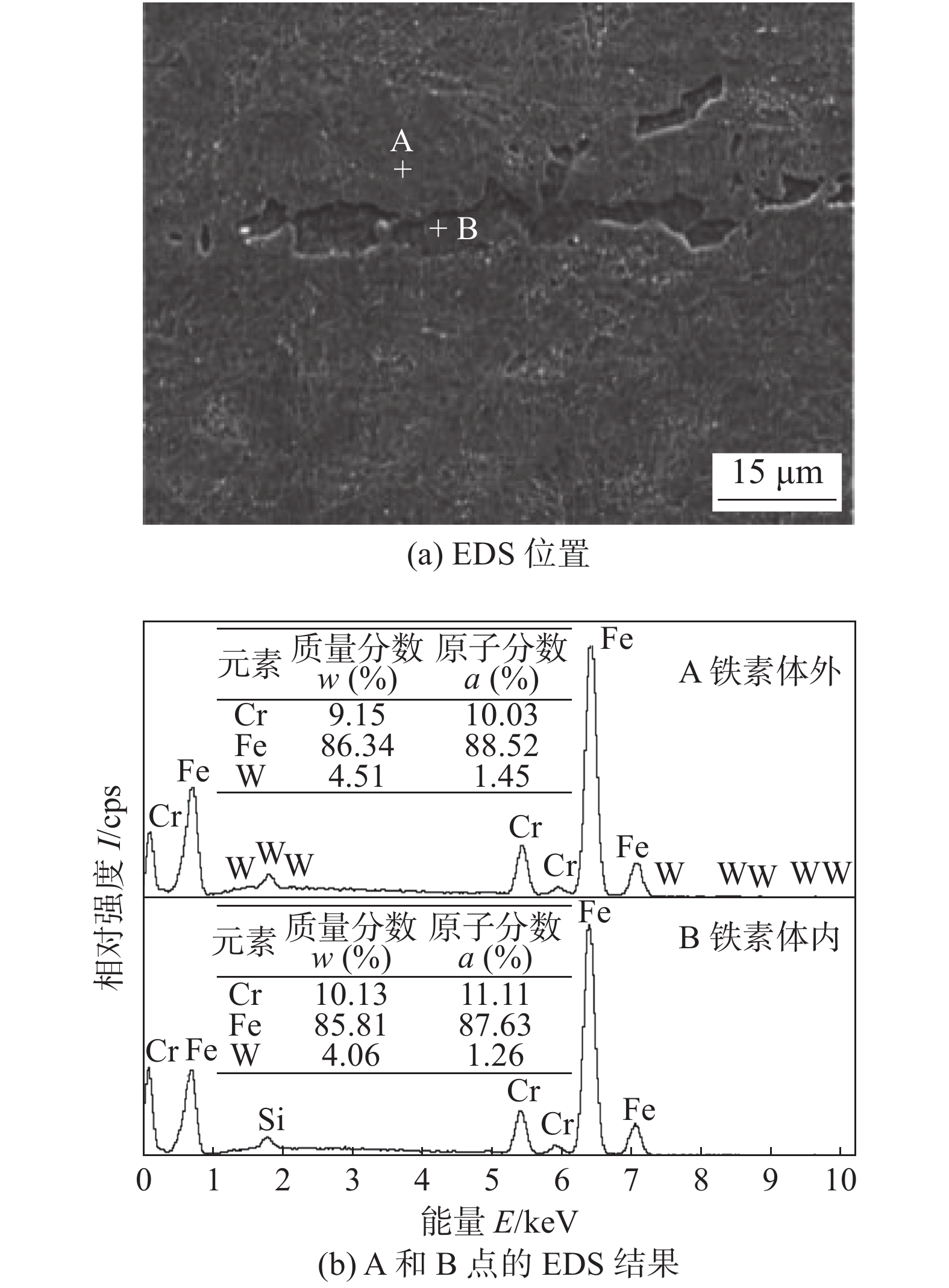

摘要: 低活化铁素体/马氏体(reduced activation ferritic/martensitic,RAFM)钢搅拌摩擦焊(friction stir welding,FSW)接头中的高温δ铁素体是影响其冲击韧性的主要因素. 通过喷雾冷却,降低焊接峰值温度并对接头进行快速降温,从而达到抑制δ铁素体生成的目的. 采用Fluent流体软件对RAFM钢FSW在不同喷雾冷却工况下的温度场进行模拟研究,综合模拟结果进行试验验证. 结果表明,液氮辅助FSW(FSW + LN2)可有效降低焊接接头的峰值温度并加速焊后的降温速率. FSW + LN2焊接接头冲击韧性由常规FSW接头的冲击吸收能量23 J提升至33 J,达到与母材等韧匹配,硬度变化趋势与常规FSW接头基本一致,焊接接头硬度远高于母材.

-

关键词:

- 低活化铁素体/马氏体钢 /

- 搅拌摩擦焊 /

- 喷雾冷却 /

- 数值模拟 /

- 力学性能

Abstract: High temperature δ ferrite in the friction stir welding (FSW) joint of reduced activation ferrite/martensitic (RAFM) steel is the main factor affecting its impact toughness. This paper combined spray cooling to decreases the peak temperature of welding thermal cycles and provide rapid cooling of the joint to inhibit δ-ferrite formation. Fluid simulation software Fluent was used to simulate the temperature field for FSW of RAFM steel under different working conditions of spray cooling, and the integrated simulation results were verified experimentally. The results show that liquid nitrogen-assisted friction stir welding (FSW + LN2) reduce the peak temperature of the welded joint effectively and accelerate the cooling rate of welding temperature reduction. The impact toughness of FSW + LN2 joint improves from 23 J to 33 J, which matches equal toughness of the base material. Besides this, the change tendency of hardness is basically consistent with that of conventional FSW joints, the microhardness of the welded joint is much higher than that of the base material. -

-

表 1 仿真中使用的参数[19]

Table 1 Parameters used in the simulation

密度

ρ/(kg·m−3)有效应变

速率ε环境温度

T/K材料常数

A/s−1温度相关常数

a/Pa−1温度相关净

应力指数n气体常数

R/(J·mol−1·K−1)活化能

Q/(J·mol−1)7 800 0.35 298 3.1014 × 107 1.07 + 1.70 × 10−4T −

2.81 × 10−7T0.2 + 3.966 × 10−4T 8.314 471205 表 2 RAFM钢的热物理性能参数[20]

Table 2 Thermo-physical properties parameters for the RAFM steel

温度T/K 热导率λ/(W·m−1·K−1) 比热容cρ/(J·kg−1·K−1) 373 26.7 446 473 26.3 469 573 25.9 493 673 26.5 542 773 25.8 623 873 23.7 669 973 22.9 765 1073 24.9 699 1173 24.9 587 1273 26.2 590 表 3 不同工艺下RAFM钢接头与母材冲击吸收能量(J)

Table 3 Impact toughness of base metals and RAFM steel joints in different welding processes

试样 实测值 平均值 BM 35,35,38 36 FSW 21,26,22 23 FSW + LN2 32,32,35 33 -

[1] Zhou Xiaosheng, Liu Chenxi, Yu Liming, et al. Phase transformation behavior and microstructural control of high-Cr martensitic/ferritic heat-resistant steels for power and nuclear plants: A review[J]. Journal of Materials Science & Technology, 2015, 31(3): 235 − 242.

[2] 张启航, 李佳霖, 谌继明, 等. V4Cr4Ti合金和RAFM钢的热等静压扩散连接及其界面特性[J]. 焊接学报, 2022, 43(7): 57 − 62. doi: 10.12073/j.hjxb.20211119002 Zhang Qihang, Li Jialin, Shen Jiming, et al. Hot isostatic pressing diffusion bonding of V4Cr4Ti alloy/RAFM steel and interface properties of the joints[J]. Transactions of the China Welding Institution, 2022, 43(7): 57 − 62. doi: 10.12073/j.hjxb.20211119002

[3] Zhang Chao, Cui Lei, Wang Dongpo, et al. The heterogeneous microstructure of heat affect zone and its effect on creep resistance for friction stir joints on 9Cr-1.5W heat resistant steel[J]. Scripta Materialia, 2019, 158: 6 − 10. doi: 10.1016/j.scriptamat.2018.08.028

[4] 田超博, 杨新岐, 李胜利, 等. CLAM钢搅拌摩擦焊接头高温蠕变行为[J]. 焊接学报, 2021, 42(2): 38 − 45. doi: 10.12073/j.hjxb.20200811003 Tian Chaobo, Yang Xinqi, Li Shengli, et al. High temperature creep behavior of friction stir welding joints for CLAM steel[J]. Transactions of the China Welding Institution, 2021, 42(2): 38 − 45. doi: 10.12073/j.hjxb.20200811003

[5] 高恒, 宋元元, 赵明久, 等. 回火对9Cr2WVTa钢电子束焊接接头组织和力学性能的影响[J]. 金属学报, 2014, 50(12): 1429 − 1436. doi: 10.11900/0412.1961.2014.00333 Gao Heng, Song Yuanyuan, Zhao Mingjiu, et al. Effects of tempering on the microstructure and mechanical property of electron beam welding joint of 9Cr2WVTa steel[J]. Acta Metallurgica Sinica, 2014, 50(12): 1429 − 1436. doi: 10.11900/0412.1961.2014.00333

[6] Rouzbehani R. , Kokabi A H, Sabet H, et al. Metallurgical and mechanical properties of underwater friction stir welds of Al7075 aluminum alloy[J]. Journal of Materials Processing Technology, 2018, 262: 239 − 256. doi: 10.1016/j.jmatprotec.2018.06.033

[7] Mofid M A, Abdollah Z A, Malek G F. The effect of water cooling during dissimilar friction stir welding of Al alloy to Mg alloy[J]. Materials and Design, 2011, 36: 161 − 167.

[8] Mofid M A, Abdollah Z A, Gür C H. Submerged friction-stir welding (SFSW) underwater and under liquid nitrogen: An improved method to join Al alloys to Mg alloys[J]. Metallurgical and Materials Transactions, 2012, 43(13): 5106 − 5114. doi: 10.1007/s11661-012-1314-2

[9] Mofid M A, Abdollah Z A, Gür C H. Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen[J]. The International Journal of Advanced Manufacturing Technology, 2014, 71(5-8): 1493 − 1499. doi: 10.1007/s00170-013-5565-x

[10] Mudawar I, Estes K A. Optimizing and predicting CHF in spray cooling of a square surface[J]. Journal of Heat Transfer: Transaction of the ASME, 1996, 118(3): 672 − 679. doi: 10.1115/1.2822685

[11] Moriyama A, Araki K, Yamagami M, et al. Local heat-transfer coefficient in spray cooling of hot surface[J]. Transactions of the Iron & Steel Institute of Japan, 2006, 28(2): 104 − 109.

[12] Visaria M, Mudawar I. Theoretical and experimental study of the effects of spray inclination on two-phase spray cooling and critical heat flux[J]. International Journal of Heat and Mass Transfer, 2007, 51(9): 2398 − 2410.

[13] Wang Yaqing, Liu Minghou, Liu Dong, et al. Spray cooling no-boiling zone heat transfer characteristics when tilted[J]. Jounal of Chemical Industry, 2009, 60(8): 1912 − 1919.

[14] Abbasi B, Kim J. Development of a general dynamic pressure based single-phase spray cooling heat transfer correlation[J]. Journal of Heat Transfer, 2011, 133(5): 746 − 758.

[15] Kurt A. Mudawar I. Correlation of sauter mean diameter and critical heat flux for spray cooling of small surfaces[J]. International Journal of Heat and Mass Transfer, 1995, 38(16): 2985 − 2996. doi: 10.1016/0017-9310(95)00046-C

[16] Sozbir N, Chang Y W, Yao S C. Heat transfer of impacting water mist on high temperature metal surfaces[J]. Journal of Heat Transfer, 2003, 125(1): 70 − 74. doi: 10.1115/1.1527913

[17] Shi Lei, Wu Chuansong, Liu Xiaochao. Modeling the effects of ultrasonic vibration on friction stir welding[J]. Journal of Mechanical Processing Technology, 2015, 222: 91 − 102. doi: 10.1016/j.jmatprotec.2015.03.002

[18] Seidel T U, Reynolds A P. Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique[J]. Metallurgical and Materials Transactions A, 2001, 32(11): 2879 − 2884. doi: 10.1007/s11661-001-1038-1

[19] Patrick F K, Brian G T, Jean A A. Simple constitutive equations for steel at high temperature[J]. Metallurgical Transactions A, 1992, 23(3): 903 − 918. doi: 10.1007/BF02675567

[20] Lei Yucheng, Zhu Qian, Zhang Ling, et al. Simulation on the welding of CLAM steel[J]. Fusion Engineering and Design, 2010, 85(7): 1503 − 1507.

[21] 修腾飞. 激光辅助加热搅拌摩擦焊数值模拟与试验研究[D]. 长沙: 湖南大学, 2015. Xiu Tengfei. Numerical simulation and experimental study on laser-heated friction stir welding [D]. Changsha: Hunan University, 2015.

下载:

下载: