Design and modeling analysis of saddle seam welding robot

-

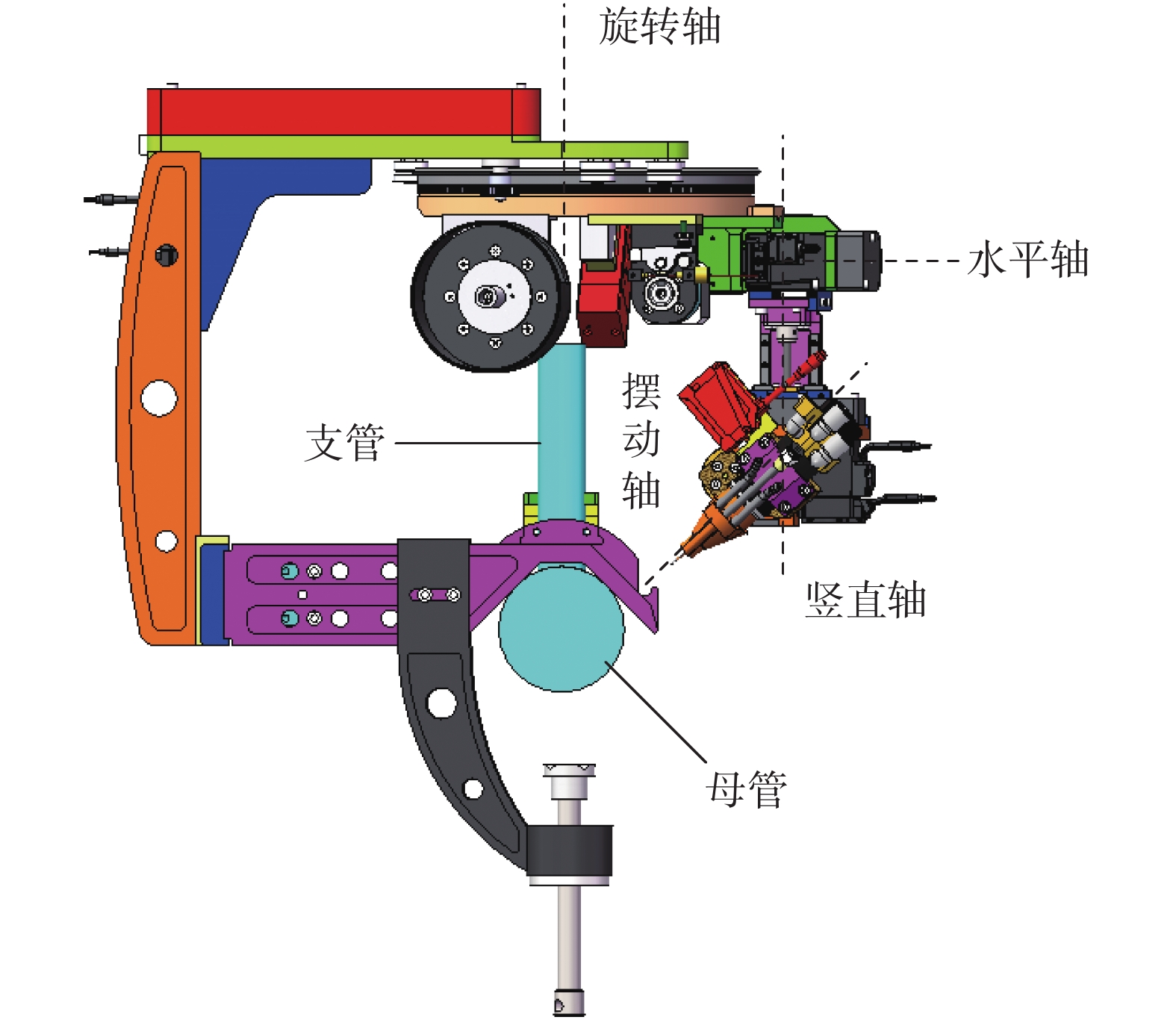

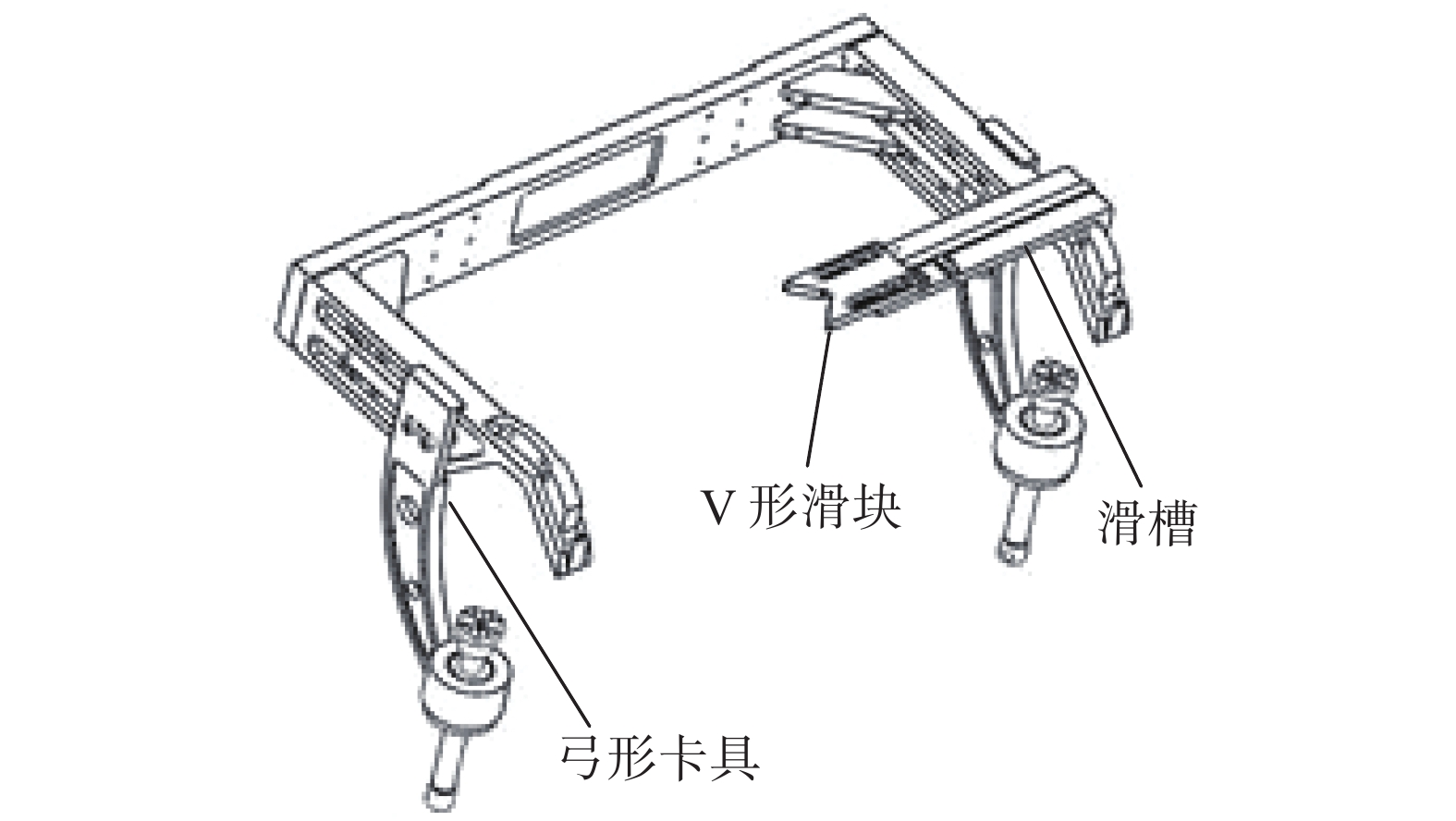

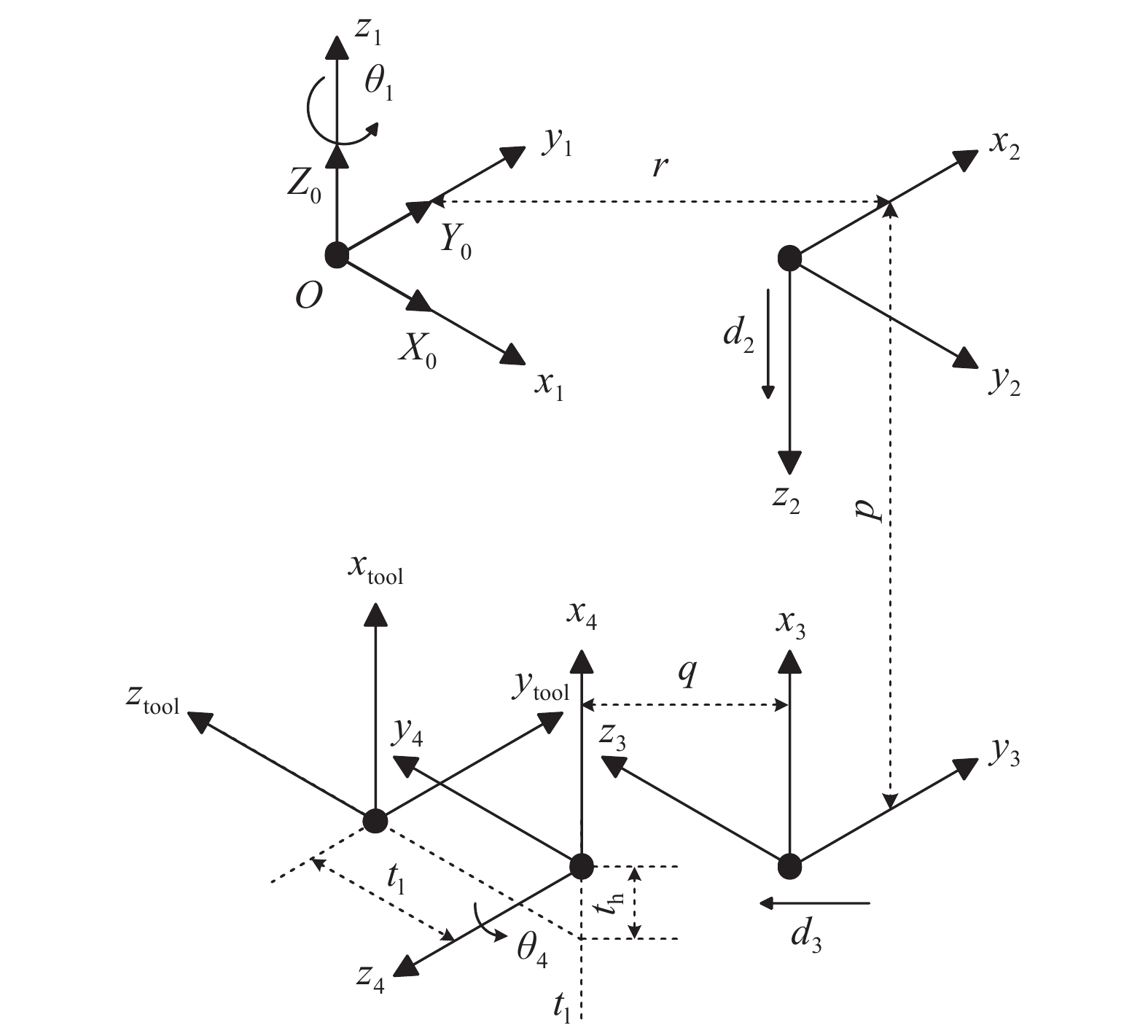

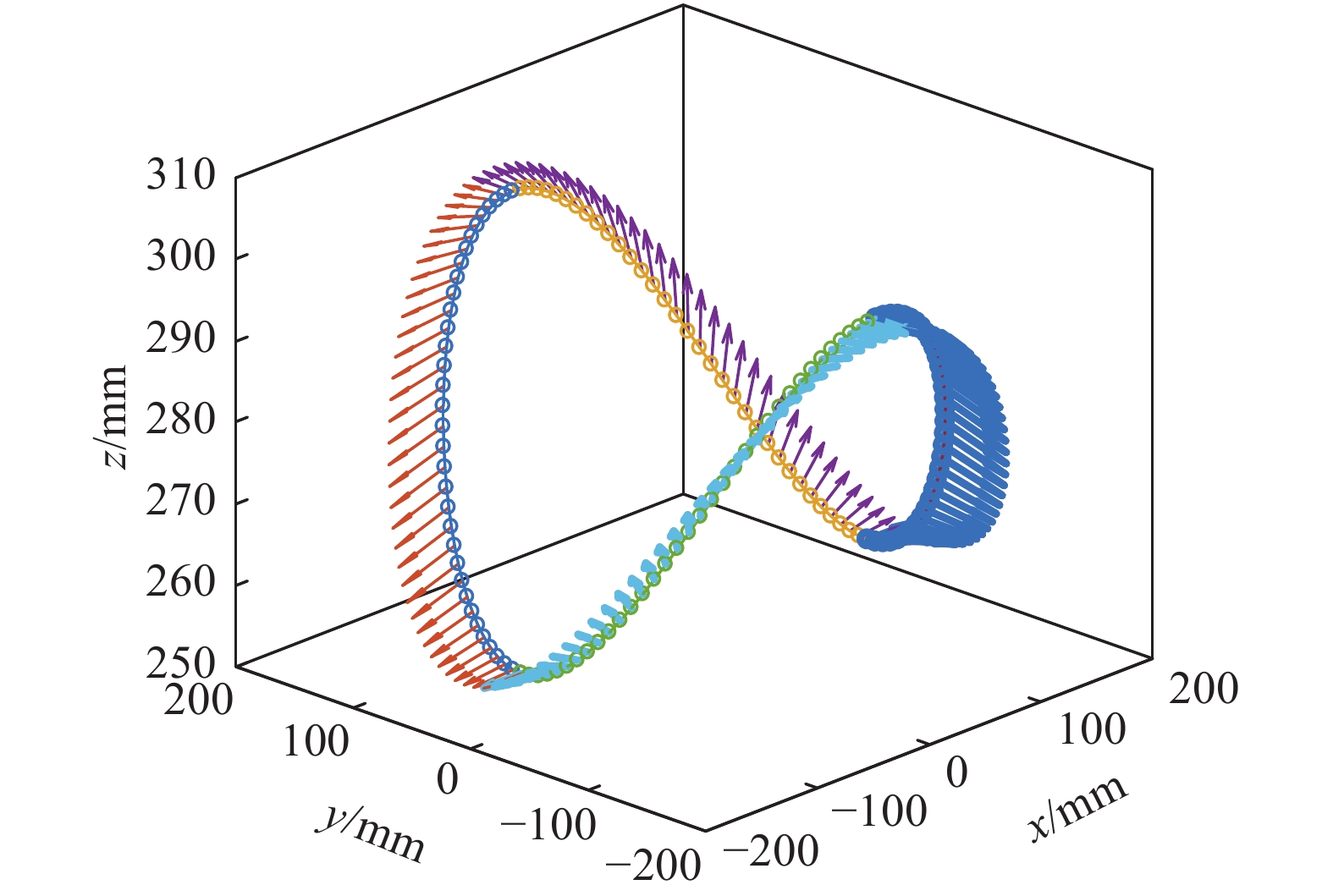

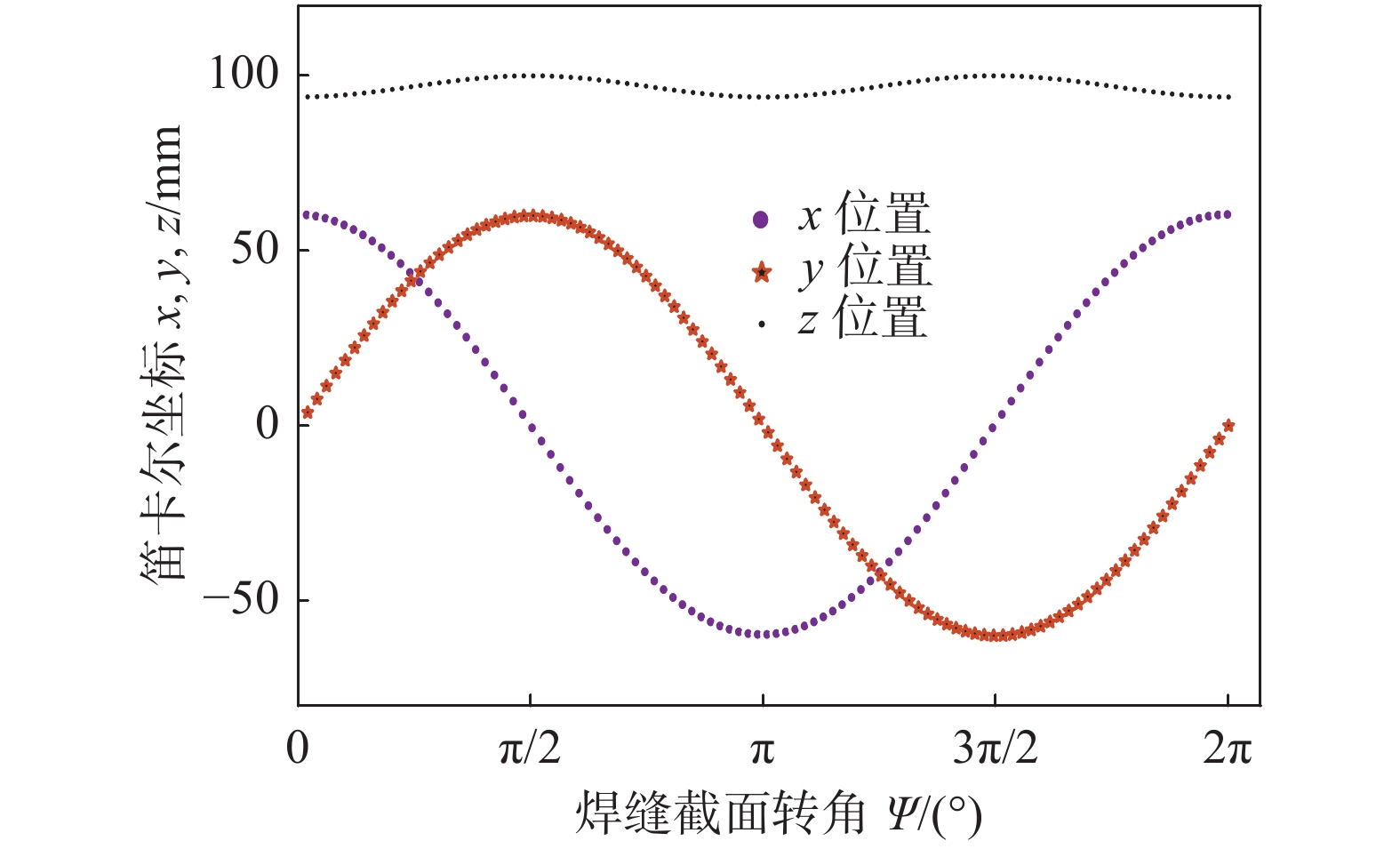

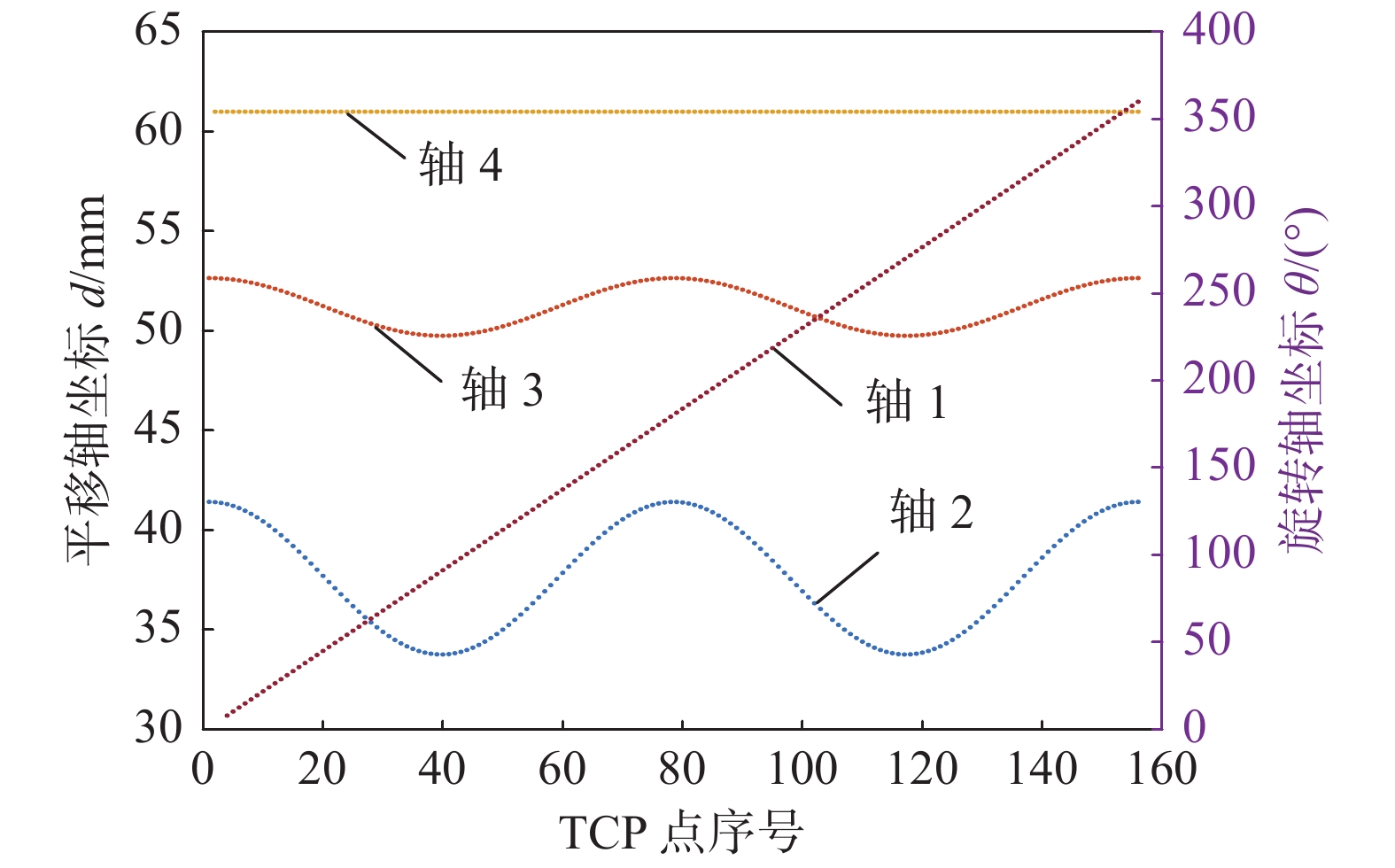

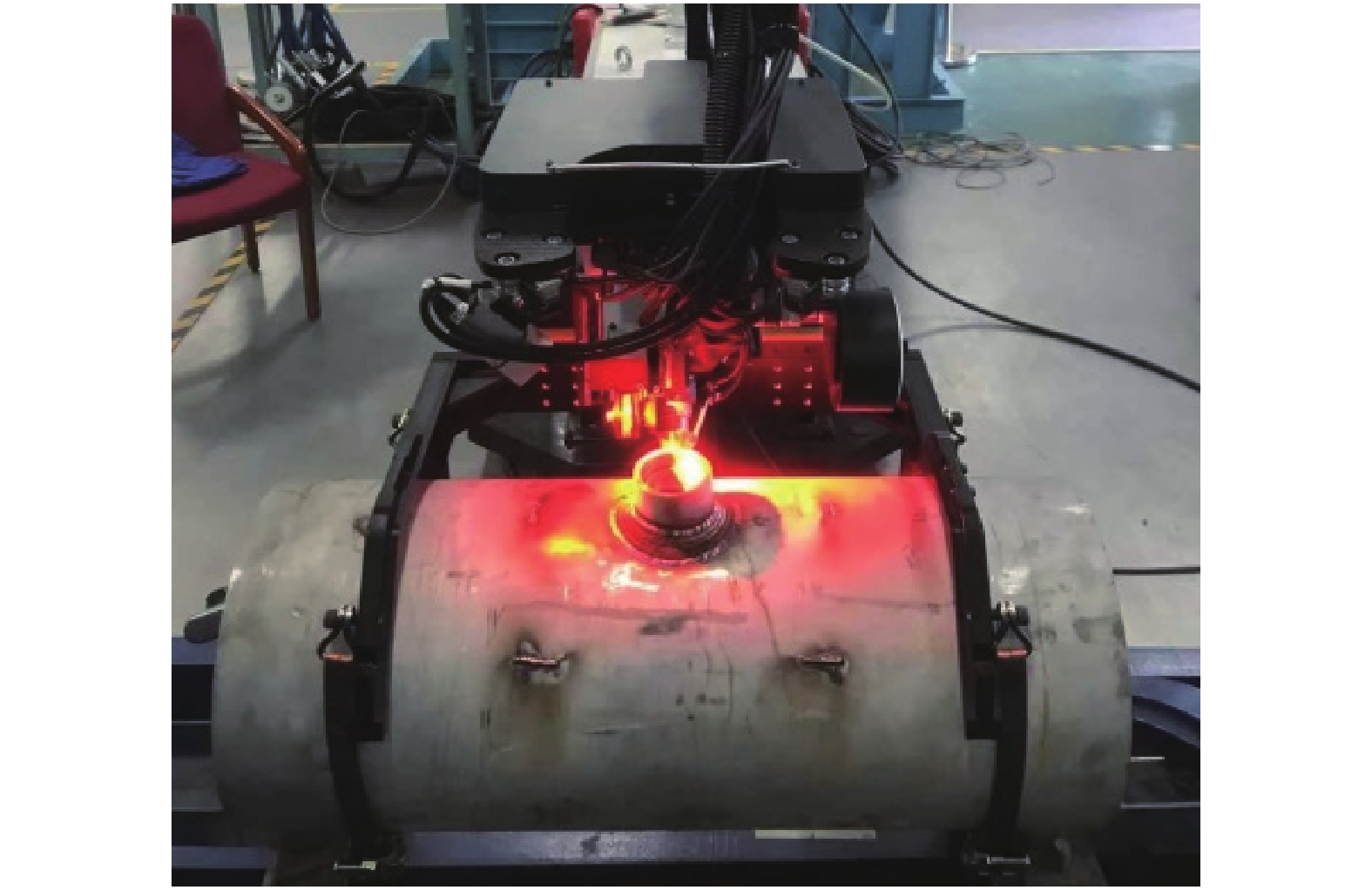

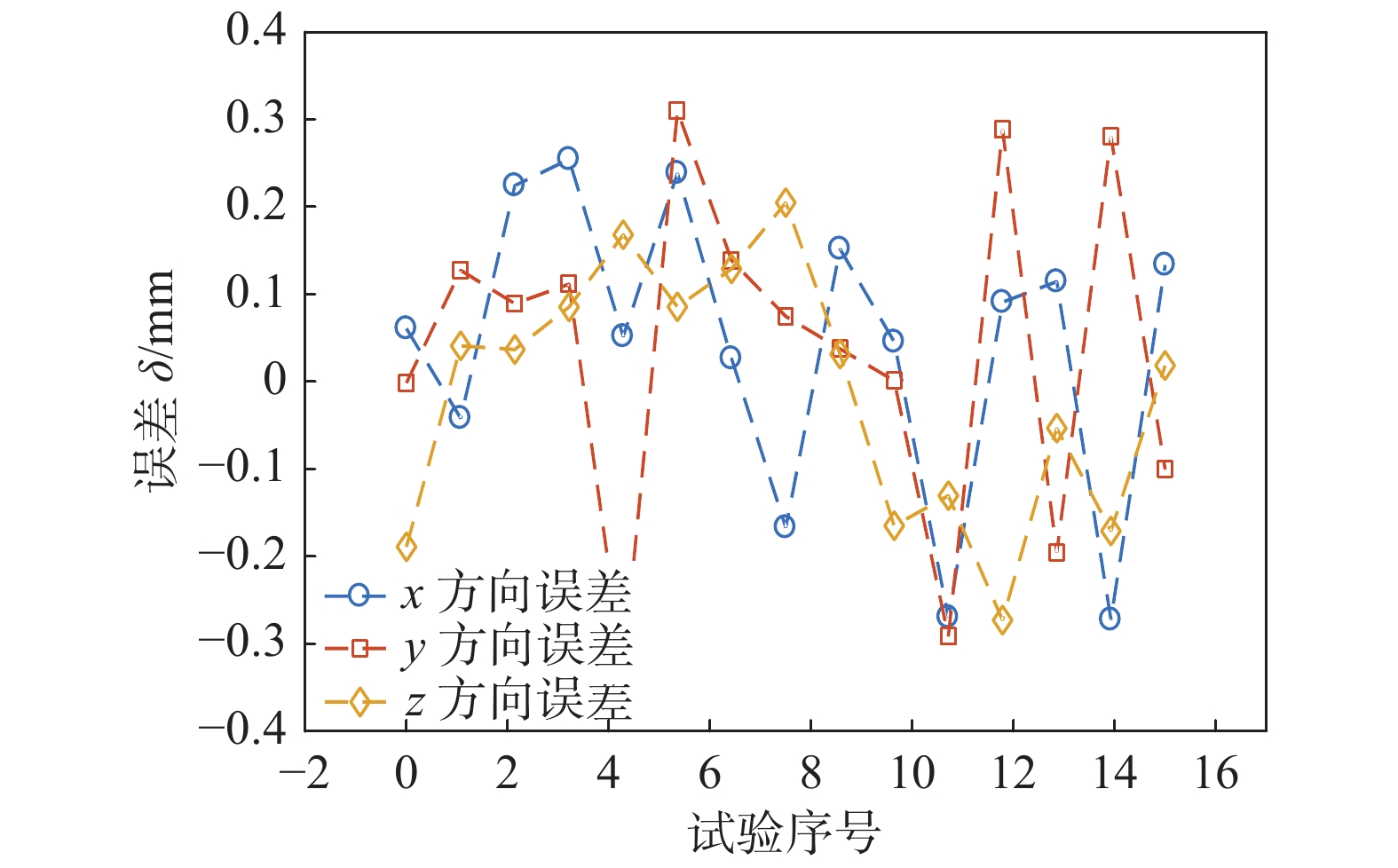

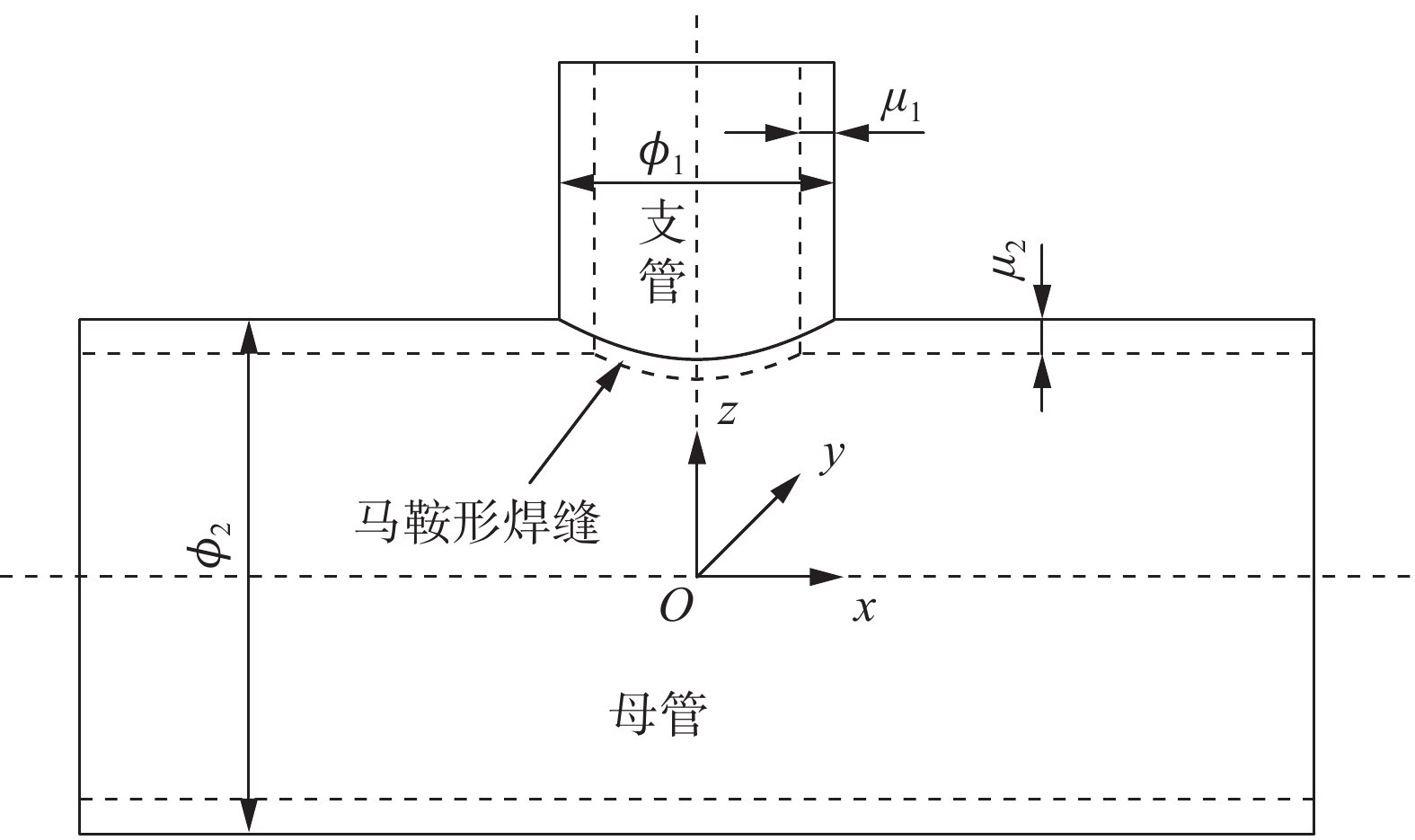

摘要: 针对目前马鞍形焊缝焊接装备灵活性差,自动化程度低,接头质量稳定性不足等问题,开发了一种新型的管外锚固式四轴焊接机器人. 通过对机器人机构合理简化建立了D-H连杆坐标系,推导了机器人的正逆运动学表达式,并结合机器人关节变量的限位值确定了逆运动学解的唯一性. 通过MATLAB软件对机器人运动学进行了仿真,仿真结果表明,推导的正逆运动学方程模型完全正确. 通过制作样机进行焊接试验,结果表明,焊缝成形致密美观,机器人焊枪末端在x,y,z方向的误差均在±0.35 mm以内,完全满足工程上自动化焊接的需要,为马鞍形焊缝焊接机器人的连续轨迹控制和离线规划提供了依据和算法支持.Abstract: In view of the problems of poor flexibility, low degree of automation, and insufficient stability of joint quality of the current saddle-shaped weld welding equipment, a new type of external anchored four-axis welding robot was developed. The D-H link coordinate system is established by rationally simplifying the robot mechanism, the forward and inverse kinematics expressions of the robot are deduced, and the uniqueness of the inverse kinematics solution is determined by combining the limit values of the robot joint variables. The kinematics of the robot is simulated by MATLAB software, and the simulation results show that the derived forward and inverse kinematic equations are completely correct. Welding experiment by making a prototype, the experimental results show that the welding seam is compact and beautiful, and the deviation of the robot welding torch trajectory in the x, y and z directions is within ±0.35 mm, which fully meets the needs of automatic welding in engineering. It provides the theoretical basis and algorithm support for the continuous trajectory control and offline programming of the saddle-shaped seam welding robot.

-

-

表 1 机器人各连杆D-H参数

Table 1 D-H parameters of robot links

连杆转角 ${\alpha _{i - 1} }/(^{\circ})$ 连杆长度 ${a_{i - 1}}/\rm mm$ 连杆偏距 ${d_i}/\rm mm$ 关节变量

θi /(°)0 0 0 ${\theta _1}$ 180 $r$ $ - {d_2}$ −90 90 $p$ $ - {d_3}$ −90 90 0 $q$ ${\theta _4}$ 表 2 TIG焊接工艺参数

Table 2 TIG welding parameters

焊接电流

I/A电弧电压

U/V送丝速度

vs/(mm·min−1)焊接速度

v/(mm/min−1)气体流量

Q/(L·min−1)220 38 800 130 15 -

[1] 王丽, 龚君, 赵寿宽, 等. 便携式相贯线切割焊接一体机的设计与实际应用[J]. 科技与创新, 2020, 165(21): 158 − 159. Wang Li, Gong Jun, Zhao Shoukuan, et al. Design and practical application of portable intersecting wire cutting and welding machine[J]. Science and Technology & Innovation, 2020, 165(21): 158 − 159.

[2] Liu Y, Tian X. Robot path planning with two-axis positioner for non-ideal sphere-pipe joint welding based on laser scanning[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(1-4): 1295 − 1310. doi: 10.1007/s00170-019-04344-3

[3] Xue Lianghao, Wei Min, Yang Tao, et al. A new welding robot for intersected weld of pipes used in large pressure vessels[C]//MATEC Web of Conferences. EDP Sciences, 2019, 267: 01006.

[4] 危文灏, 贠超, 宋德政, 等. 机器人多层多道焊接的路径规划[J]. 机器人, 2014, 36(3): 257 − 262,270. Wei Wenhao, Yun Chao, Song Dezheng, et al. Path planning for robotic multi-path/multi-layer welding[J]. Robot, 2014, 36(3): 257 − 262,270.

[5] 李向春, 毛志伟, 陈记超, 等. 新型相贯线焊接机器人设计与研究[J]. 热加工工艺, 2019, 48(5): 226 − 230. Li Xiangchun, Mao Zhiwei, Chen Jichao, et al. Design and research of a new type of intersecting line welding robot[J]. Hot Working Technology, 2019, 48(5): 226 − 230.

[6] 李东洁, 李潜, 王世伟, 等. 全位置相贯线自动焊接新型焊枪设计[J]. 焊接学报, 2018, 39(3): 117 − 119,123. doi: 10.12073/j.hjxb.2018390081 Li Dongjie, Li Qian, Wang Shiwei, et al. Design of a new type of welding torch for automatic welding of all-position intersecting lines[J]. Transactions of the China Welding Institution, 2018, 39(3): 117 − 119,123. doi: 10.12073/j.hjxb.2018390081

[7] 丛志文, 王好臣, 高茂源, 等. KR16-2机器人运动学分析及路径规划[J]. 机床与液压, 2020, 48(15): 50 − 55. doi: 10.3969/j.issn.1001-3881.2020.15.011 Cong Zhiwen, Wang Haochen, Gao Maoyuan, et al. Kinematics analysis and path planning of KR16-2 robots[J]. Machine Tool & Hydraulics, 2020, 48(15): 50 − 55. doi: 10.3969/j.issn.1001-3881.2020.15.011

[8] 吕志忠, 张成维, 钟功祥, 等. 一种四足磁吸附爬壁机器人运动学分析及仿真[J]. 四川大学学报(工程科学版), 2020, 52(2): 121 − 129. Lyu Zhizhong, Zhang Chengwei, Zhong Gongxiang, et al. Kinematics analysis and simulation of a quadruped magnetic sdsorption wall-climbing robot[J]. Journal of Sichuan University(Engineering Science Edition), 2020, 52(2): 121 − 129.

[9] 吉阳珍, 侯力, 罗岚, 等. 基于组合优化算法的6R机器人逆运动学求解[J]. 中国机械工程, 2021, 32(10): 1222 − 1232. doi: 10.3969/j.issn.1004-132X.2021.10.011 Ji Yangzhen, Hou Li, Luo Lan, et al. Solution of inverse kinematics for 6R robots based on combinatorial optimization algorithm[J]. China Mechanical Engineering, 2021, 32(10): 1222 − 1232. doi: 10.3969/j.issn.1004-132X.2021.10.011

[10] 宋德政, 贠超, 危文灏. 管管相贯的焊接坡口模型分析[J]. 机械设计与制造, 2013(11): 171 − 174. doi: 10.3969/j.issn.1001-3997.2013.11.052 Song Dezheng, Yun Chao, Wei Wenhao. Welding groove model analysis of the intersecting pipe[J]. Machinery Design & Manufacture, 2013(11): 171 − 174. doi: 10.3969/j.issn.1001-3997.2013.11.052

[11] Liu Y, Liu Y, Tian X. Trajectory and velocity planning of the robot for sphere-pipe intersection hole cutting with single-Y welding groove[J]. Robotics and Computer-Integrated Manufacturing, 2019, 56: 244 − 253. doi: 10.1016/j.rcim.2018.10.005

-

期刊类型引用(4)

1. 杨康,艾新港,王志英,臧喜民,施文杰,王晓峰. 耐磨钢的发展与耐磨性强化. 辽宁科技大学学报. 2024(03): 174-184 .  百度学术

百度学术

2. 尹中会,曹志森,杨建军,马建国,刘振飞. TU1无氧铜/316L不锈钢电子束焊接接头组织与性能. 黑龙江工业学院学报(综合版). 2023(05): 114-119 .  百度学术

百度学术

3. 冯道臣,郑文健,高国奔,周州,贺艳明,杨建国. AlCoCrFeNi_(2.1)高熵合金电子束焊接接头耐蚀性. 机械制造文摘(焊接分册). 2023(04): 8-14 .  百度学术

百度学术

4. 冯道臣,郑文健,高国奔,周州,贺艳明,杨建国. AlCoCrFeNi_(2.1)高熵合金电子束焊接接头耐蚀性. 焊接学报. 2022(05): 43-48+116 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: