Large diameter hollow stud welding process based on longitudinal magnetic field control

-

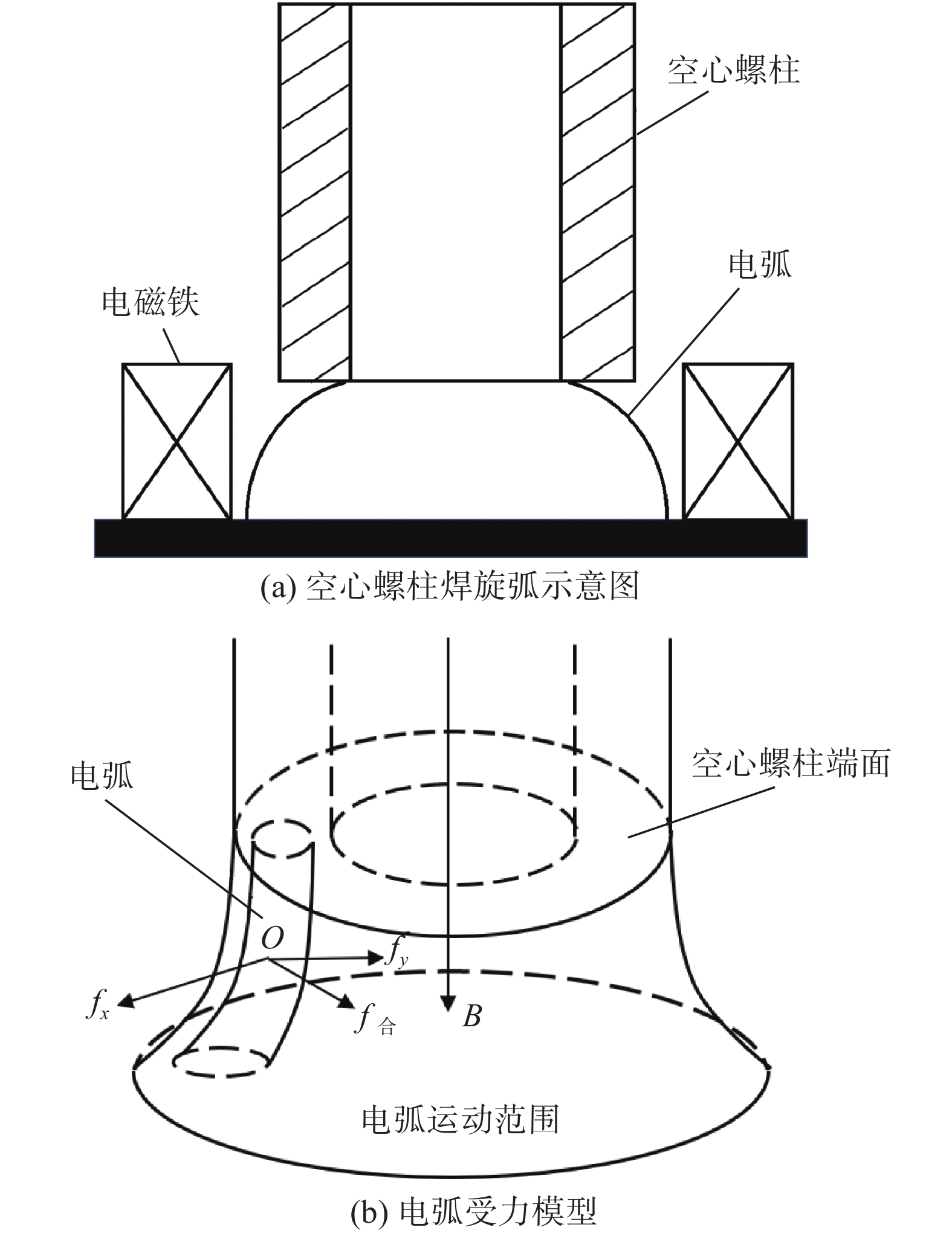

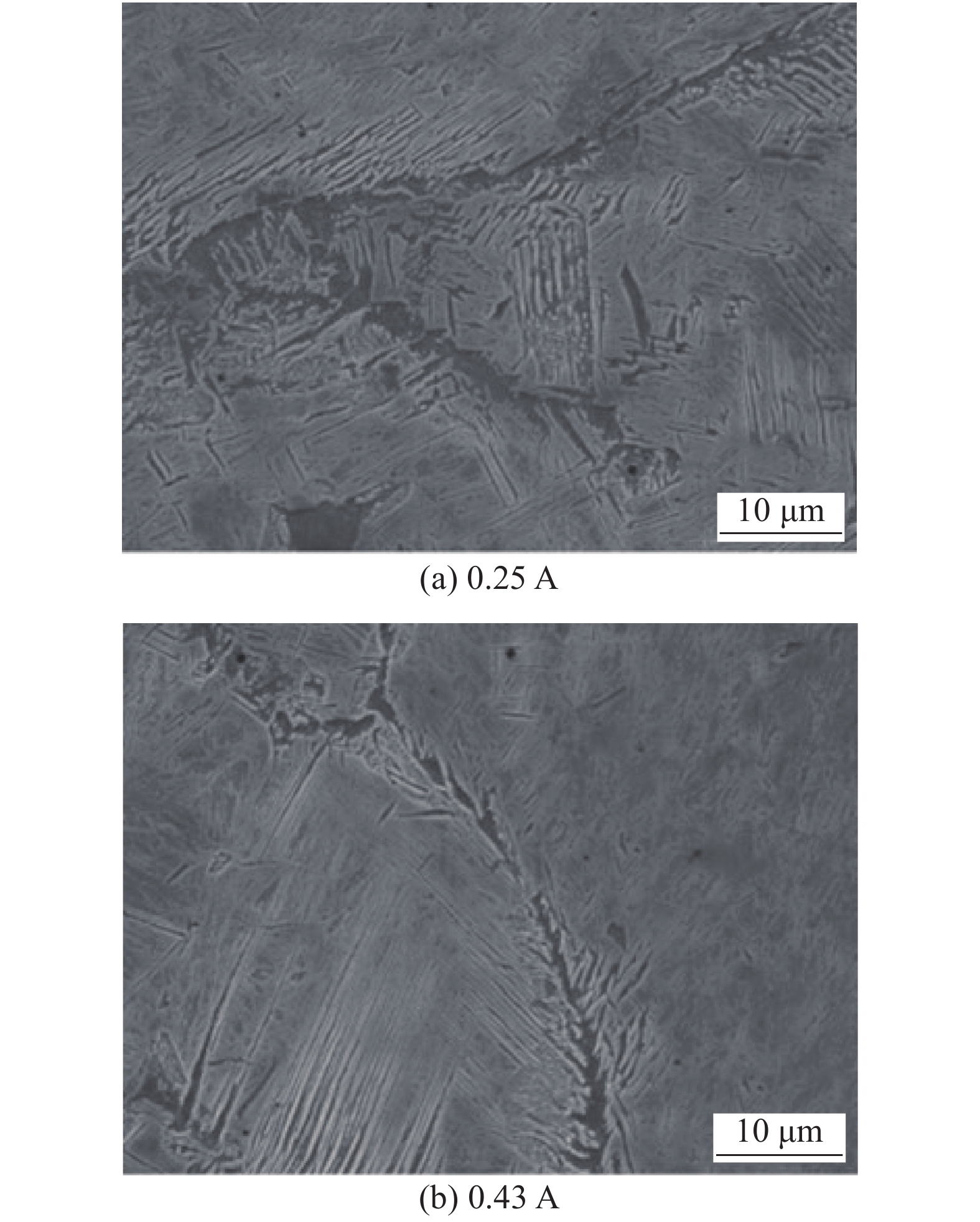

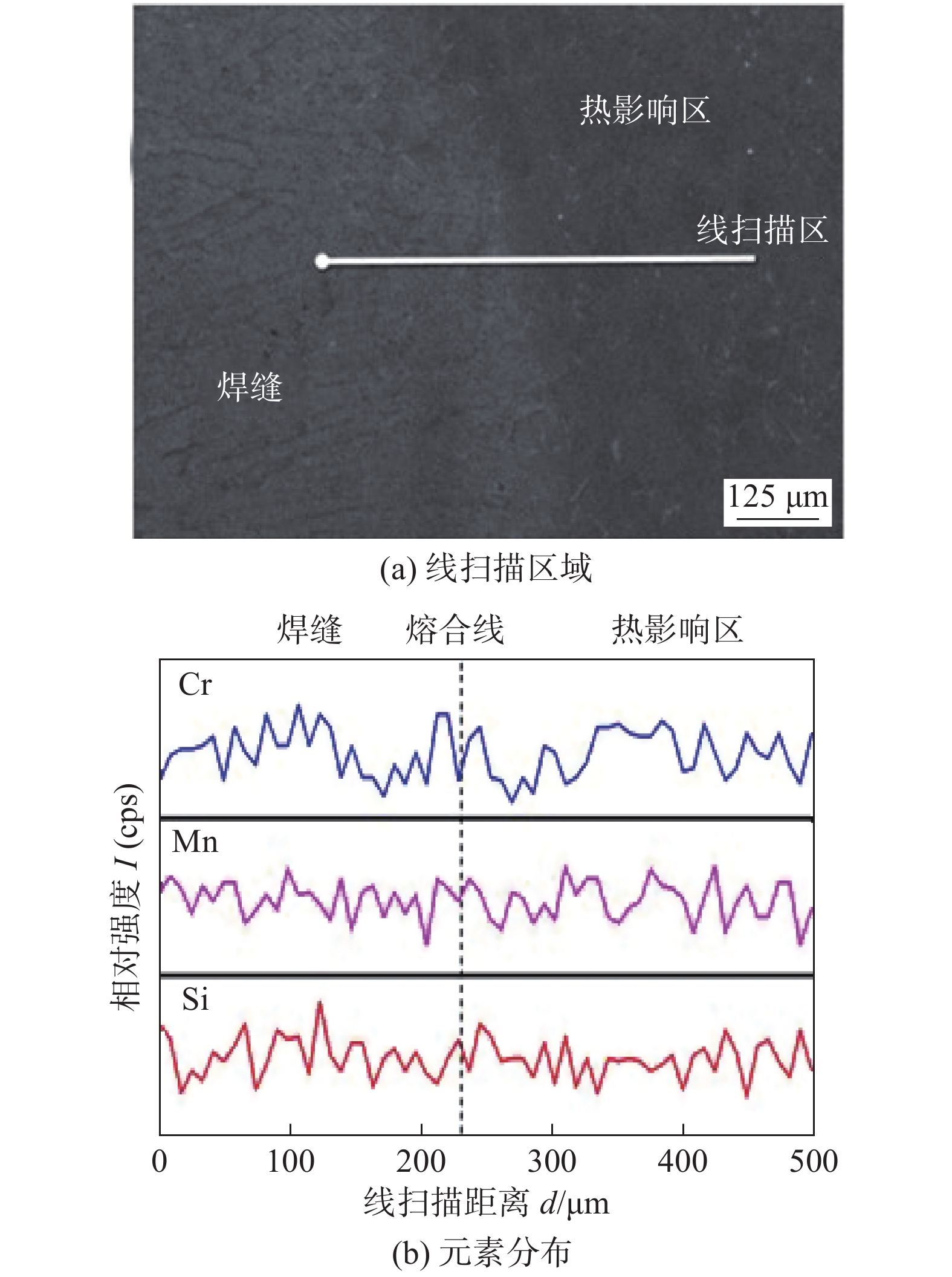

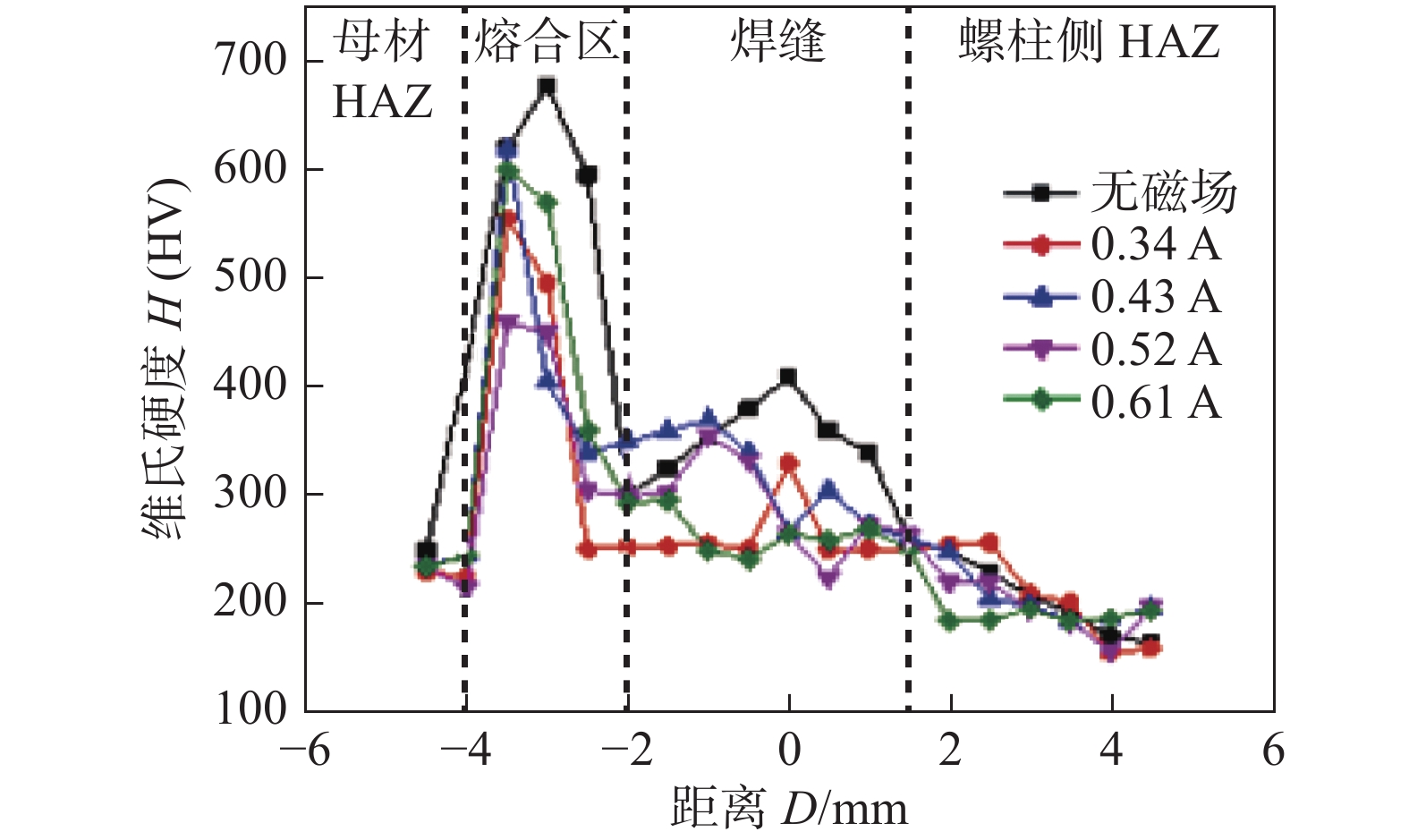

摘要: 采用电弧螺柱焊方法对外径20 mm、内径10 mm的空心螺柱与45钢板材进行焊接,研究了旋弧磁场对接头显微组织特征及力学性能的影响. 结果表明,在纵向旋弧磁场作用下,电弧中电荷受洛伦兹力作用呈螺旋运动,接头外观成形得到改善. 受磁场控制的电弧持续搅拌熔池,改善了焊接热循环条件,影响了熔池凝固结晶过程. 接头中先共析铁素体呈有规律的网状分布,珠光体也变得细化. 接头温度梯度减小使得固态相变时间增长,母材侧热影响区马氏体数量显著下降,热影响区宽度变小. 但旋弧磁场电流过大时焊接过程飞溅倾向明显增大,焊缝中气孔增多. 在焊接时间1 400 ms、焊接电流800 A、旋弧磁场电流0.43 A时,电弧在空心螺柱端面充分燃烧,接头抗剪强度可达到325 MPa.Abstract: The arc stud welding method was used to weld 45 steel plate and hollow stud with outer diameter of 20 mm and inner diameter of 10 mm. Effects of the rotating arc magnetic field on microstructure and mechanical properties were studied. The results show that with the longitudinal rotating arc magnetic field, the charge in the arc moved spirally under the action of Lorentz force, which extended outward to some extent and the appearance of the joint was improved. The thermal cycle condition of joint was improved thanks to the continuous stirring of molten pool by controlled arc, and the solidification and crystallization of molten pool was affected. The proeutectoid ferrite showed a regular network distribution and the pearlite became fine. For the decrease of joint temperature gradient, the solid-state phase transition time increased, the martensite content in the heat affected zone of the parent metal of 45 steel side decreased significantly and the width of HAZ became smaller. When the rotating arc magnetic field current was too large, the spatter tendency increased obviously as well as the porosity in the weld increased. When the welding time of 1 400 ms, the welding current of 800 A and the rotating arc current of 0.43 A, the arc was fully burned at the full end face of the hollow stud, the shear strength of joints can reach 325 MPa.

-

Keywords:

- arc stud welding /

- hollow stud /

- magnetic field /

- arc

-

-

图 5 旋弧磁场对空心螺柱焊接头组织的影响

Figure 5. Effects of rotating arc magnetic field on the microstructure of hollow stud welded joints. (a) non-magnetic field stud welding seam; (b) weld microstructure of rotating arc stud welding; (c) non-magnetic field stud welding fusion line; (d) rotating arc stud welding fusion line

表 1 45钢的化学成分(质量分数,%)

Table 1 Chemical compositions of 45 steel

C Si Mn Cr+Ni+Cu P S Fe 0.42~0.50 0.17~0.37 0.5~0.8 0.7 0.035 0.035 余量 表 2 焊接工艺参数及接头抗剪强度

Table 2 Welding process parameters and shear strength of joints

编号 焊接电流

I/A焊接时间

t/ms旋弧电流

I/A抗剪强度

Rτ/MPa1 800 1 400 0 278 2 800 1 400 0.25 302 3 800 1 400 0.43 325 4 800 1 400 0.61 310 -

[1] Harada Y, Sada Y, Kumai S. Dissimilar joining of AA2024 aluminum studs and AZ80 magnesium plates by high-speed solid-state welding[J]. Journal of Materials Processing Technology, 2014, 214(2): 477 − 484. doi: 10.1016/j.jmatprotec.2013.10.005

[2] 王克鸿, 张德库, 薛鹏飞, 等 . 复合热源螺柱焊方法[J]. 焊接学报, 2008, 29(11): 45 − 48. doi: 10.3321/j.issn:0253-360X.2008.11.012 Wang Kehong, Zhang Deku, Xue Pengfei, et al. Compound heat source stud welding method[J]. Transactions of the China Welding Institution, 2008, 29(11): 45 − 48. doi: 10.3321/j.issn:0253-360X.2008.11.012

[3] 顾艳红, 马慧娟, 高辉, 等. 16Mn钢摩擦螺柱焊接头的微观组织与局部腐蚀[J]. 上海交通大学学报, 2017, 51(11): 1348 − 1354. Gu Yanhong, Ma Huijuan, Gao Hui, et al. Microstructure and local corrosion behavior of friction stud welding of 16Mn steel[J]. Journal of Shanghai Jiaotong University, 2017, 51(11): 1348 − 1354.

[4] 高辉, 焦向东, 周灿丰, 等. 基于Abaqus的水下摩擦螺柱焊焊接过程仿真[J]. 焊接学报, 2014, 35(12): 50 − 54. Gao Hui, Jiao Xiangdong, Zhou Canfeng, et al. Simulation of underwater friction stud welding process based on Abaqus[J]. Transactions of the China Welding Institution, 2014, 35(12): 50 − 54.

[5] 王克鸿, 张德库, 郑石雄, 等. 空心螺柱旋弧焊接方法[J]. 焊接学报, 2008, 29(12): 101 − 103. doi: 10.3321/j.issn:0253-360X.2008.12.026 Wang Kehong, Zhang Deku, Zheng Shixiong, et al. Rotating arc welding method of hollow stud[J]. Transactions of the China Welding Institution, 2008, 29(12): 101 − 103. doi: 10.3321/j.issn:0253-360X.2008.12.026

[6] 艾星宇. 纵向磁场与活性剂联合下镁合金焊接接头组织性能的研究[D]. 沈阳: 沈阳工业大学, 2017. Ai Xingyu. Study on microstructure property of magnesium alloy welded joint under the longitudinal magnetic field associated with active agents[D]. Shenyang: Shenyang University of Technology, 2017.

[7] Kamikawa S, Ishii I, Takezawa K, et al. Elastic softening due to the quadrupole interaction and anomalous magnetic phase diagram under the magnetic field in HoRu2Al10[J]. Physical Review B, 2017, 96(15): 155131. doi: 10.1103/PhysRevB.96.155131

[8] Zhang Xun, Zhao Zeyang, Mi Gaoyang, et al. Effect of external longitudinal magnetic field on arc plasma characteristics and droplet transfer during laser-MIG hybrid welding[J]. International Journal of Advanced Manufacturing Technology, 2017, 92(5-8): 2185 − 2195. doi: 10.1007/s00170-017-0293-2

[9] 姚猛. 空心螺柱焊接工程化质量控制研究[D]. 南京: 南京理工大学, 2018. Yao Meng. Study on quality control of hollow stud welding engineering[D]. Nanjing: Nanjing University of Science and Technology, 2018.

[10] Egry I, Ricci E, Novakovic R, et al. Surface tension of liquid metals and alloys recent developments[J]. Advances in Colloid & Interface Science, 2010, 159(2): 198 − 212.

[11] 孙莉, 张腾, 刘晨曦, 等. 单组分活性剂对二氧化碳气体保护焊熔池形态的影响[J]. 天津科技, 2017, 44(6): 29 − 34. doi: 10.3969/j.issn.1006-8945.2017.06.010 Sun Li, Zhang Teng, Liu Chenxi, et al. Effect of single component active flux on weld pool for carbon dioxide welding[J]. Tianjin Science and Technology, 2017, 44(6): 29 − 34. doi: 10.3969/j.issn.1006-8945.2017.06.010

[12] 陈荣. 磁场辅助激光_MIG复合焊接对316L焊缝组织与性能影响的研究[D]. 武汉: 华中科技大学, 2018. Chen Rong. Research on influence of microstructure and properties of 316L welds via magnetic field assisted laser-MIG hybrid welding[D]. Wuhan: Huazhong University of Science and Technology, 2018.

[13] Kohout J. An alternative to the JMAK equation for a better description of phase transformation kinetics[J]. Journal of Materials Science, 2008, 43(4): 1334 − 1339. doi: 10.1007/s10853-007-2255-9

-

期刊类型引用(3)

1. 张景祺,林健,雷永平,许海亮,王细波. 316L超薄板激光焊接的失稳变形规律. 材料工程. 2020(12): 126-134 .  百度学术

百度学术

2. 束钰,李光提,尹力,刘树峰,张磊. 基于三维扫描技术的焊接变形实验设计与实践. 实验室科学. 2018(06): 8-11 .  百度学术

百度学术

3. 钱承,鄂加强. 基于FSVM的起重机臂筒焊接变形测量研究. 振动.测试与诊断. 2018(06): 1229-1233+1297 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: