Effect of W on microstructure and properties of Fe-Cr-C-W-B surfacing alloy

-

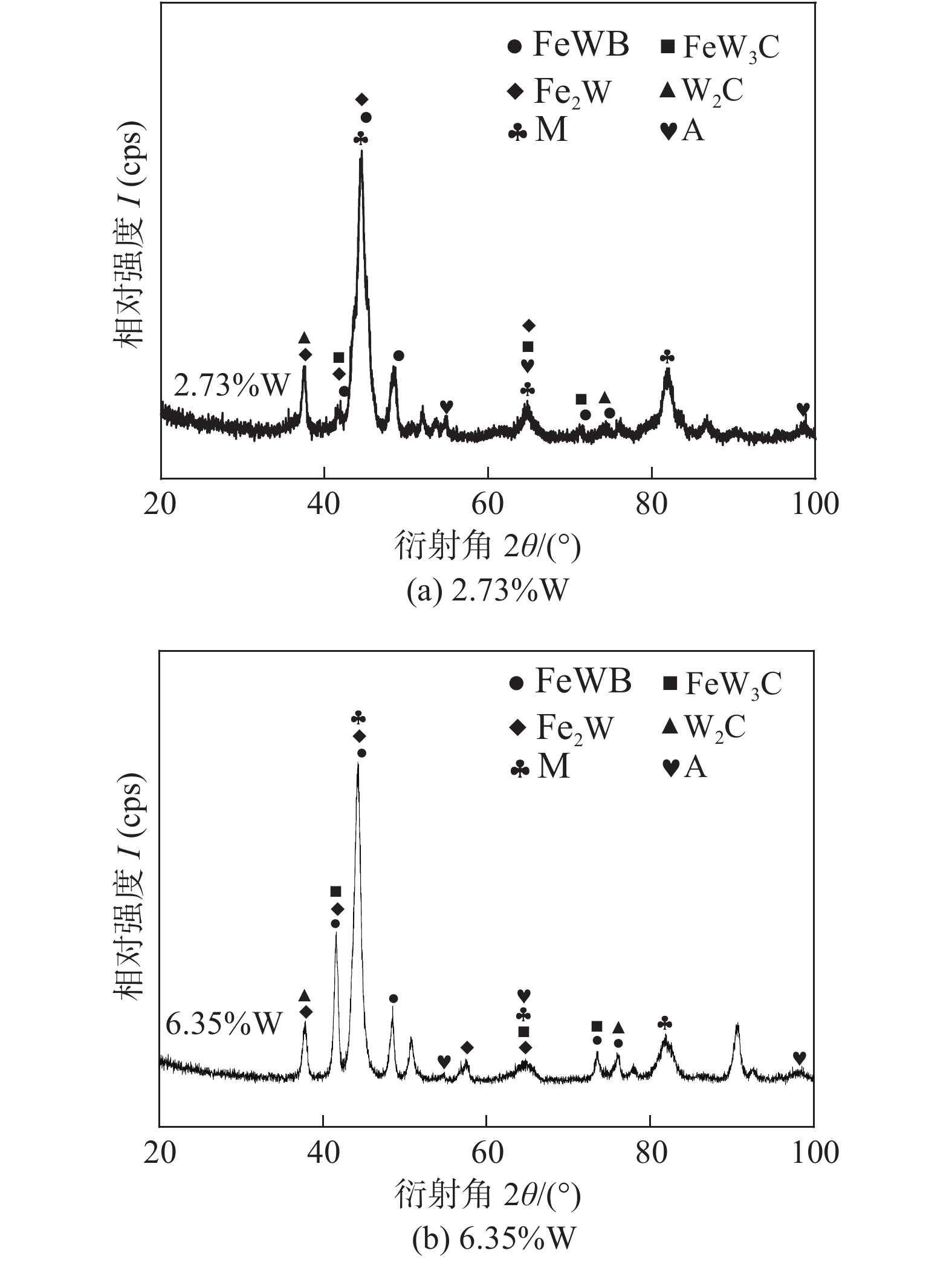

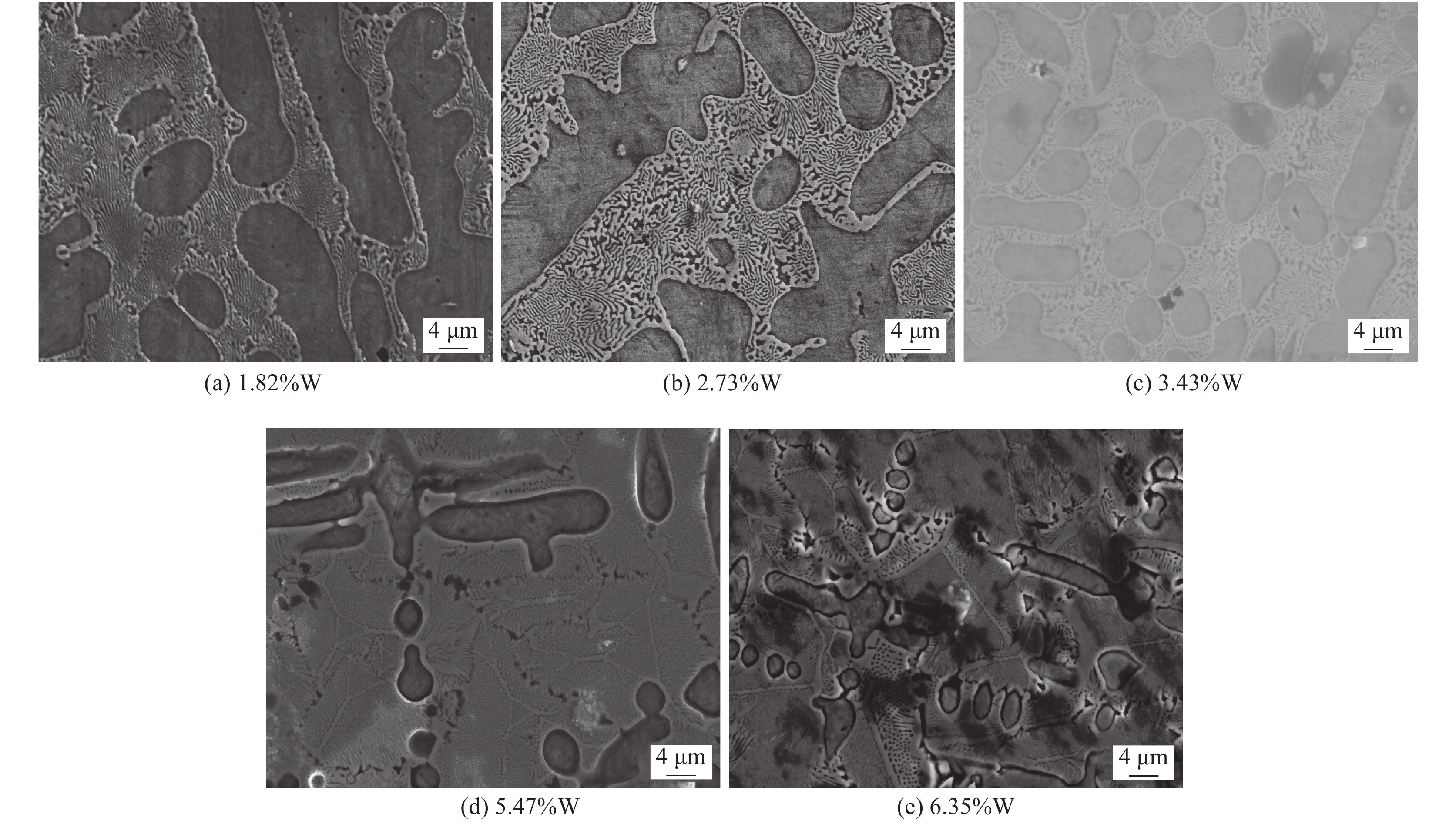

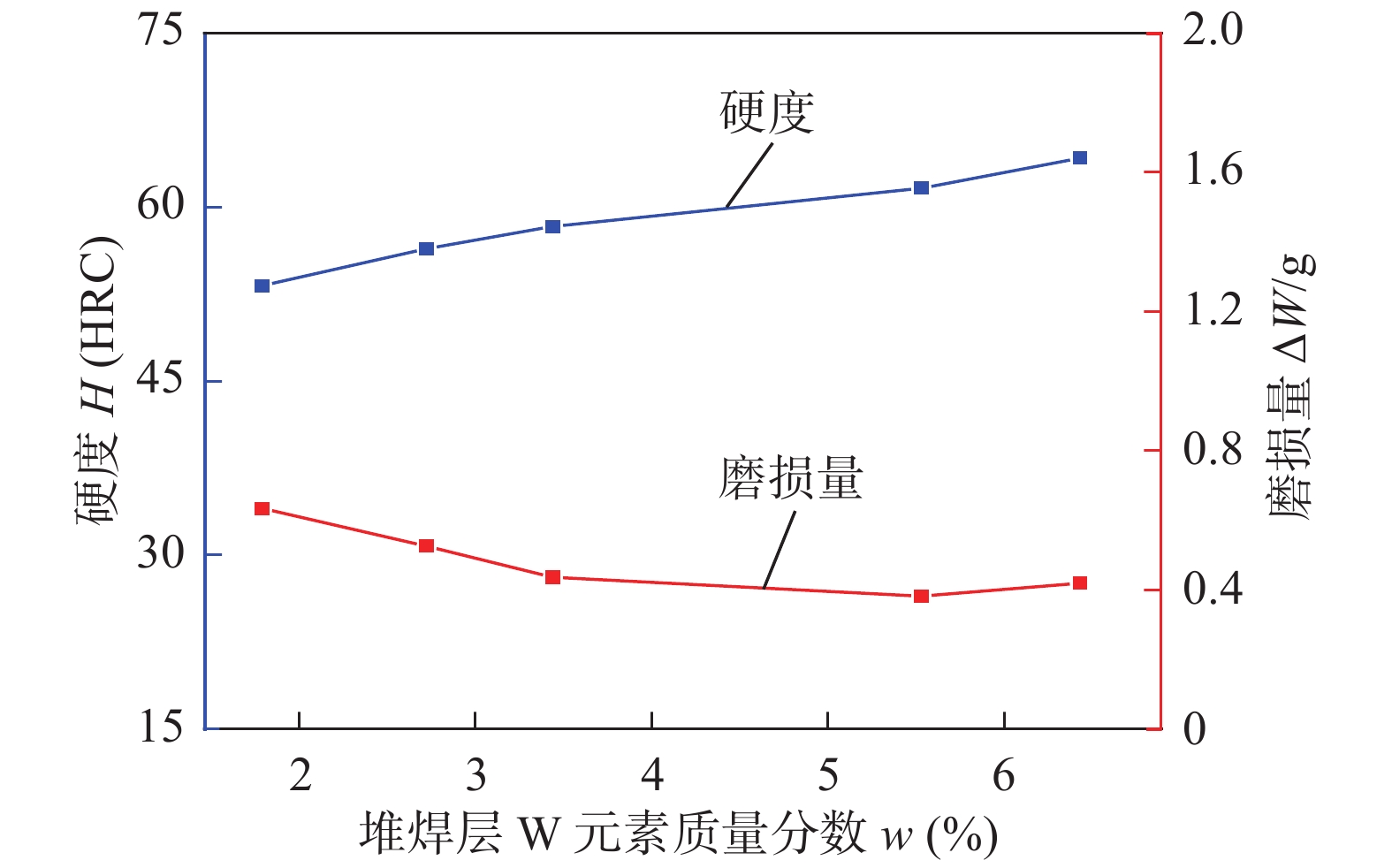

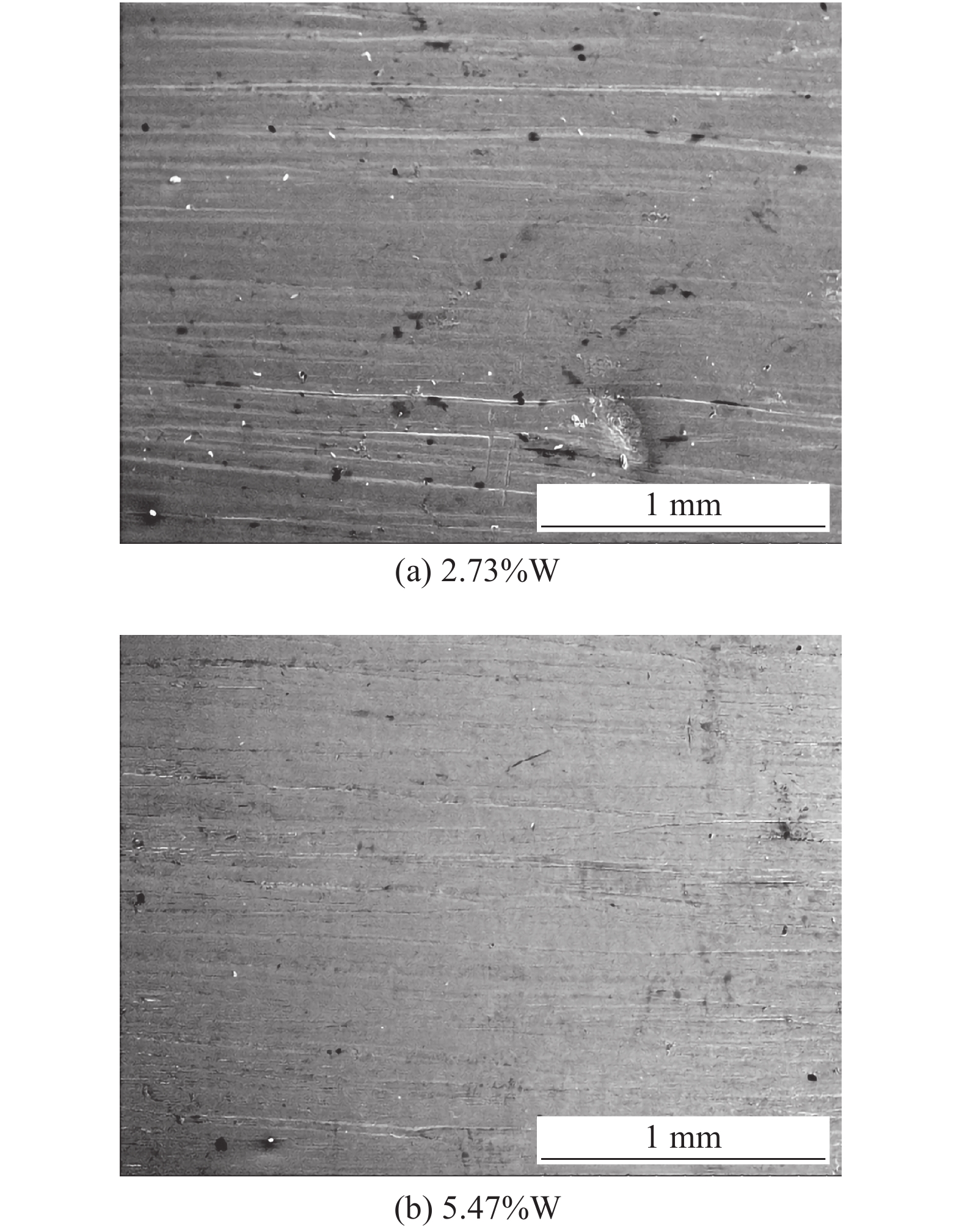

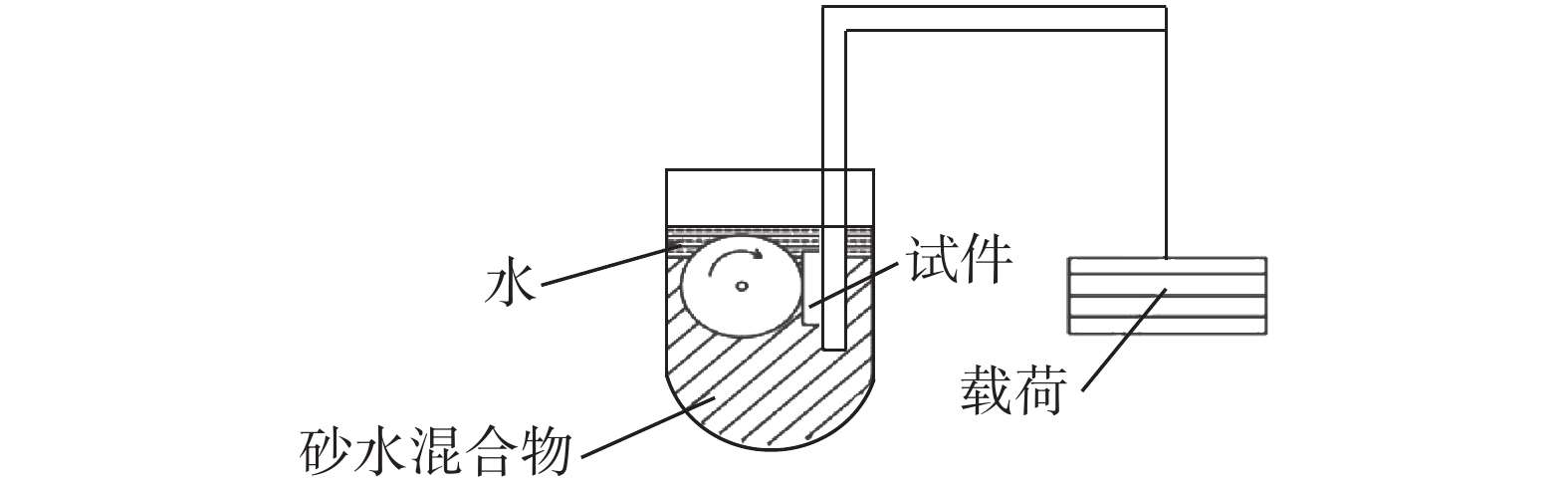

摘要: 机械设备的使用寿命会因为磨损而减少,因而应该提升材料耐磨性能以提高机械设备的使用时间. 利用埋弧焊机采用明弧堆焊的方法制备Fe-Cr-C-W-B堆焊合金,在一定试验条件下分析了改变药芯焊丝中W的质量比例后堆焊合金硬质相的数量以及耐磨性能的变化情况. 结果表明,当W含量提高后,堆焊层中硬质相的所占比例增加,从而显著改善其硬度和耐磨性能. 在堆焊层金属W质量分数为2.73%时,堆焊层主要含钨硬质相为FeWB,Fe2W,FeW3C. 当堆焊层金属W含量在5.47%时堆焊层耐磨性能达到最佳,磨损量为0.382 5 g,洛氏硬度为61.63 HRC. 当堆焊层金属W含量为6.35%时,堆焊层洛氏硬度达到最高为64.22 HRC,磨损量为0.418 2 g,由于堆焊层的淬硬性增加,在磨损过程中硬质相易脱落,导致耐磨性能稍有下降. 为了获得更好的耐磨性能,W质量分数应控制在5.47%左右.Abstract: The service life of mechanical equipment will be reduced due to wear, so the wear resistance of materials should be improved to increase the service time of mechanical equipment. Fe-Cr-C-W-B surfacing alloy was prepared by open arc surfacing with he submerged arc welding machine. The changes of hard phase quantity and wear resistance of surfacing alloy after changing the mass proportion of W in flux-cored wire were analyzed under certain test conditions. The results show that when the W content increases, the proportion of the hard phase in the surfacing layer increases, thereby significantly improving its hardness and wear resistance. When the mass fraction of metal W in the surfacing layer is 2.73%, the surfacing layer mainly contains tungsten hard phases of FeWB, Fe2W, FeW3C. When W content of the surfacing layer is 5.47%, the wear resistance of the surfacing layer reaches the best, the wear amount is 0.382 5 g, and the hardness is 61.63 HRC. When W content of the surfacing layer is 6.35%, the hardness of the surfacing layer reaches the highest 64.22 HRC, the wear extent is 0.418 2 g. As the hardenability of the surfacing layer increases, the hard phase is easy to fall off during the wear process, so the wear resistance decreases slightly. In order to obtain better wear resistance, the W mass fraction should be controlled at about 5.47% .

-

Keywords:

- surfacing alloy /

- wear resistance /

- flux-cored wire /

- surfacing /

- hard phase

-

-

表 1 Q235钢和H08A低碳钢带的化学成分(质量分数, %)

Table 1 Chemical compositions of Q235 steel and H08A low carbon steel strip

材料 Mn Si C S P Fe Q235 0.45 ~ 0.55 < 0.30 < 0.15 < 0.045 < 0.045 余量 H08A 0.20 ~ 0.25 0.01 0.01 < 0.020 < 0.020 余量 表 2 药芯焊丝渣系成分(质量分数, %)

Table 2 Compositions of flux cored wire slag

CaF2 CaO Al Al2O3 0.5 0.3 2.0 0.2 表 3 堆焊工艺参数

Table 3 Surfacing process parameters

电弧电压

U/V焊接电流

I/A焊接速度

v/(mm·s−1)焊丝伸长度

l/mm25 160 12 16 表 4 堆焊合金成分 (质量分数, %)

Table 4 Surfacing alloy compositions

编号 Cr C B W W1 12.32 1.47 2.34 1.82 W2 12.57 1.53 2.61 2.73 W3 12.44 1.52 2.73 3.43 W4 12.62 1.61 2.51 5.47 W5 12.83 1.49 2.62 6.35 表 5 堆焊合金的硬度和磨损量

Table 5 Hardness and wear of surfacing alloy

W质量分数w(%) 硬度H(HRC) 磨损量△W/g 1.82 53.24 0.634 7 2.73 56.43 0.525 7 3.43 58.35 0.436 3 5.47 61.63 0.382 5 6.35 64.22 0.419 5 -

[1] Tian H, Wang C, Guo M, et al. Study of the frictional-wear performance and abrasion resistance mechanism of a high-speed arc-sprayed FeNiCrAl coating[J]. Surface and Coatings Technology, 2019, 370: 320 − 330. doi: 10.1016/j.surfcoat.2019.04.092

[2] Yuan Xiao, Wang Jing, Zhu Qinghai, et al. Microstructure and wear resistance of Fe-based and Co-based coating of AISI H13[J]. China Welding, 2019, 28(3): 57 − 63.

[3] 魏炜, 黄智泉, 张海燕, 等. 钒对铁基碳化钨耐磨堆焊层组织和性能的影响[J]. 焊接学报, 2019, 40(6): 131 − 136. doi: 10.12073/j.hjxb.2019400167 Wei Wei, Huang Zhiquan, Zhang Haiyan, et al. Effect of vanadium on Microstructure and properties of Fe based WC hardfacing layer[J]. Transactions of the China Welding Institution, 2019, 40(6): 131 − 136. doi: 10.12073/j.hjxb.2019400167

[4] Li Peng. Microstructures and surface performance of laser melting deposited composites on a Ti alloy[J]. Science and Engineering of Composite Materials, 2014, 21(2): 159 − 163. doi: 10.1515/secm-2013-0066

[5] Li Dongrui, Liu Zhengjun, Su Yunhai. Effect of TiN on microstructure and wear resistance of Fe-Cr-C hardfacing alloy: experimental research and first-principles calculation[J]. Materials Research Express, 2018, 8(5): 338 − 342.

[6] Colao F H G, Maranho O. Evaluation of mass loss of weld-deposited hardfacing with cored wire Ti-FeCrC alloy[J]. Soldagem & Inspecao, 2014, 19(10): 58 − 68.

[7] Wang W, Ferree S. New wire an advancement in self-shielded flux-cored arc welding[J]. Welding Journal, 2011, 90(7): 26 − 27.

[8] Katherasan D, Srivastava S, Sathiya P. Process parameter optimization of AISI 316L(N) weld joints produced using flux-cored arc welding process[J]. Transactions of the Indian Institute of Metals, 2013, 66(2): 152 − 157.

[9] 刘政军, 勾健, 贾华, 等. Fe-Cr-C-B-Nb堆焊合金的显微组织和耐磨性[J]. 焊接学报, 2018, 39(3): 78 − 81. Liu Zhengjun, Gou Jian, Jia Hua, et al. Microstructure and wear resistance of Fe-Cr-C-B-Nb Hardfacing alloy[J]. Transactions of the China Welding Institution, 2018, 39(3): 78 − 81.

[10] Lad V I, Menghani J V, Channiwala S A. Studies on the effect of alloying element in iron base hardfacing alloy[J]. Transactions of the Indian Institute of Metals, 2014, 67(3): 343 − 349. doi: 10.1007/s12666-013-0352-9

[11] Prijanovi M T, Kosec L. Heat affected zone in surfacing chromium ledeburitic steel[J]. Metalurgija, 2010, 49(3): 155 − 160.

[12] Gou Junfeng, Wang You, Sun Jinping, et al. Bending strength and wear behavior of Fe-Cr-C-B hardfacing alloys with and without rare earth oxide nanoparticles[J]. Surface & Coatings Technology, 2017, 3(11): 113 − 126.

[13] Yang Q, Xing X, Gao Y, et al. Low-stress abrasion behaviors of Fe-Cr-C (1.4 similar to 5.6 wt-%) hardsurface coatings[J]. Welding Journal, 2016, 8(2): 39 − 45.

[14] Hülya Durmuş, Nilay Çömez, Canser Gül, et al. Wear performance of Fe-Cr-C-B hardfacing coatings: Dry sand/rubber wheel test and ball-on-disc test[J]. International Journal of Refractory Metals and Hard Materials, 2018, 77: 37 − 43. doi: 10.1016/j.ijrmhm.2018.07.006

[15] 旺虎. 耐磨堆焊用自保护药芯焊丝渣系研究[D]. 南京: 南京航空航天大学, 2010. Wang Hu. Study on slag system of self shielded flux cored wire for hardfacing[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010.

[16] 史冠勇, 张廷安, 牛丽萍, 等. Al2O3和Cr2O3对自蔓延冶金法制备CuCr合金冶炼渣性能的影响[J]. 有色金属科学与工程, 2019, 10(1): 8 − 12. Shi Guanyong, Zhang Tingan, Niu Liping, et al. Effect of Al2O3 and Cr2O3 on properties of CuCr alloy slag prepared by SHS method[J]. Science and Engineering of Nonferrous Metals, 2019, 10(1): 8 − 12.

[17] Suetin D V, Shein I R, Ivanovskii A L. Structural, electronic and magnetic properties of η carbides (Fe3W3C, Fe6W6C, Co3W3C and Co6W6C) from first principles calculations[J]. Physica B-Condensed Matter, 2009, 404(20): 3544 − 3549. doi: 10.1016/j.physb.2009.05.051

下载:

下载: