High-temperature wear resistance of Co-based cladding layers by ultra-high speed laser cladding on the surface of the cast-rolling roller sleeve

-

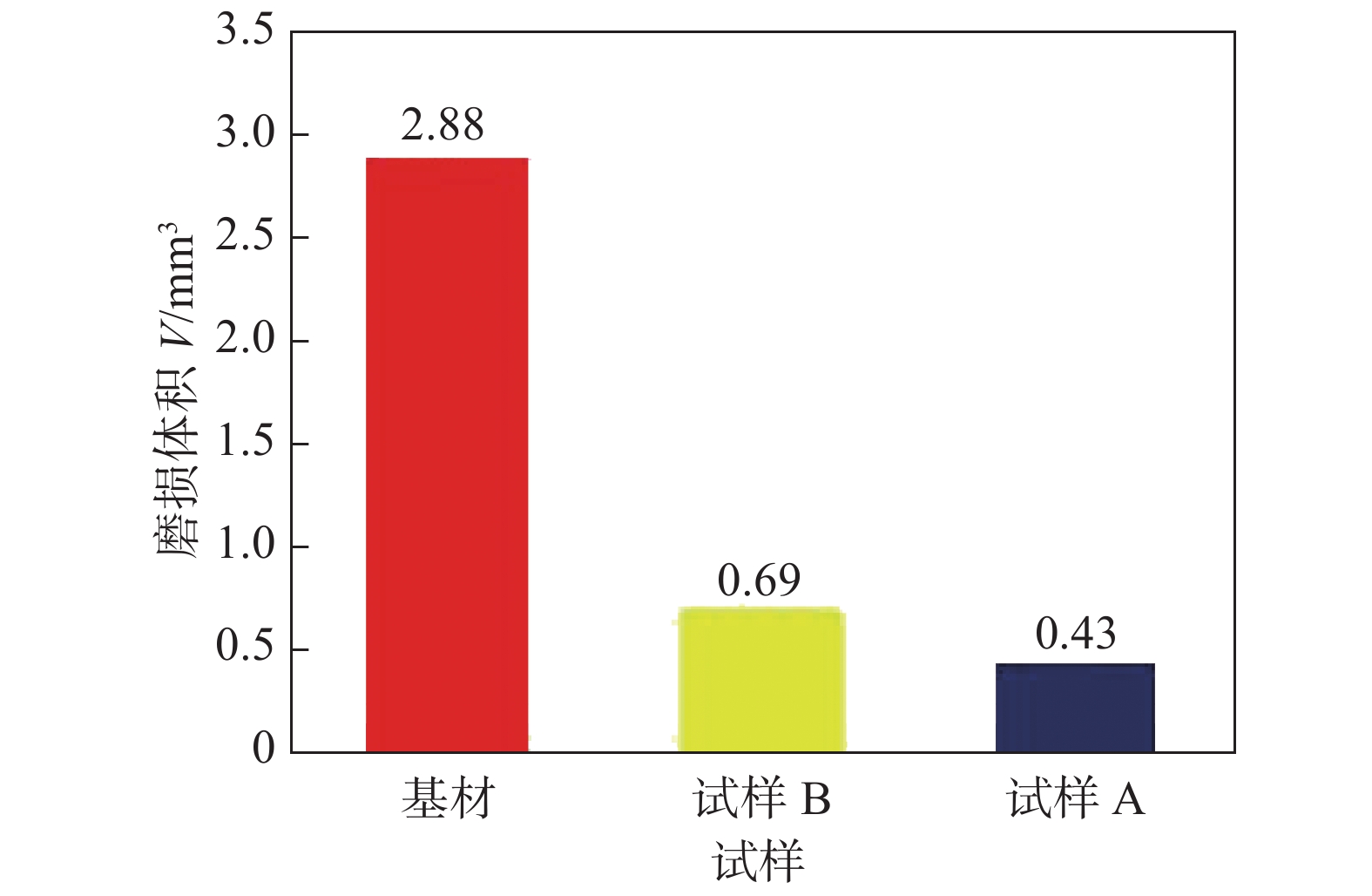

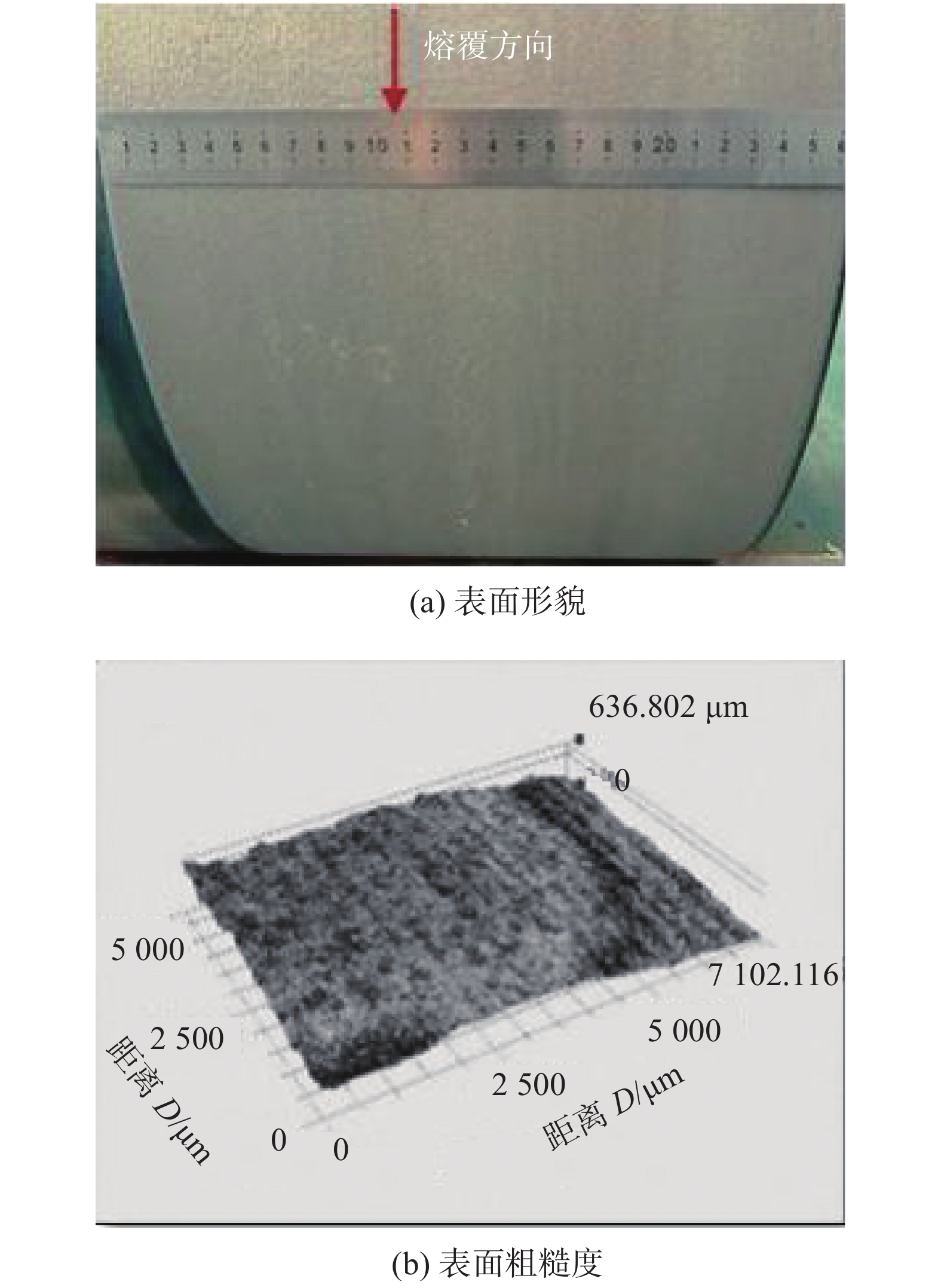

摘要: 为了提高铸轧辊辊套的使用寿命,采用超高速激光熔覆技术在32Cr3Mo1V铸轧辊辊套表面制备了钴基熔覆层.分析了熔覆层的表面形貌、显微组织及高温摩擦磨损性能,并与优选常规激光熔覆层进行了对比. 结果表明,优选的超高速以及常规激光熔覆层均表面平整,与基体结合良好,无明显裂纹、气孔等缺陷. 超高速激光熔覆层显微组织非常均匀细小,枝晶轴间距极小,很大程度上抑制了枝晶偏析的范围,使得熔覆层的元素分布更加均匀. 在700 ℃高温摩擦磨损试验中,超高速激光熔覆层产生的氧化物磨屑更小,更容易发生团聚效应,有利于釉质层的形成,熔覆层变形量更小,对釉质层进行了有效支撑,出现大面积具有减摩耐磨作用的釉质层,表现出优异的耐高温摩擦磨损性能.Abstract: In order to improve the service life of the cast-rolling roller sleeve, a Co-based cladding layer was prepared on the surface of the 32Cr3Mo1V cast-rolling roller sleeve using ultra-high-speed laser cladding technology. The surface morphology, microstructure, high-temperature friction and wear properties of the cladding layer were analyzed. And which was compared with that of the preferred conventional laser cladding layer. The results show that the preferred ultra-high-speed and conventional laser cladding layers all have a smooth surface and a good combination with the substrate without obvious cracks, pores and other defects. In contrast, the microstructure of the layer by ultra-high-speed laser cladding is very uniform and fine. And the dendrite axis spacing is extremely small, which largely suppresses the range of dendrite segregation. As a result, the more uniform distribution of element was obtained. During the process of 700 ℃ high temperature friction and wear test, the super oxide wear debris produced from the high-speed laser cladding layer is more smaller compared with that of conventional laser cladding layer. Therefore the agglomeration effect is more likely to occur, which is conducive to the formation of the enamel layer with anti-friction resistance. As the same time, the deformation of the layer by ultra-high-speed laser cladding is smaller, which has more effectively support for the enamel layer, consequently a large area enamel layer can be obtained. Thus the ultra-high-speed laser cladding layer exhibits excellent high-temperature friction and wear resistance.

-

-

表 1 Co基合金粉末的化学成分(质量分数,%)

Table 1 Chemical composition of Co-based powder

C Cr Si Fe W Ni Mo Mn Co 1.14 29.95 1.26 1.92 5.47 2.31 0.65 0.24 余量 表 2 优化后的激光熔覆工艺参数

Table 2 Optimized laser cladding process parameters

试样 功率

P/kW熔覆速度

v/(m·min−1)离焦量

f/mm搭接率

η(%)A 2.5 15 5 83 B 1.35 0.6 5 50 位置 Co Cr Fe Si C a 58.17 24.81 5.67 0.95 5.51 b 46.81 31.83 3.68 0.73 10.37 c 40.61 19.84 25.88 1.06 6.17 d 25.64 27.68 16.96 — 12.59 位置 Co Cr O Ni Fe W Si C e — 16.51 24.33 — 59.15 — — — f — 1.29 27.37 — 68.03 — — 3.31 g 40.79 16.91 23.15 — 14.31 1.95 — 2.89 h 32.57 16.15 25.62 — 17.39 2.36 0.74 4.9 i 30.32 19.24 24.67 4.57 12.68 3.04 1.04 1.09 j 39.47 14.56 23.69 3.28 10.48 2 0.85 5.67 -

[1] Haga T, Suzuki S. A high speed twin roll caster for aluminum alloy strip[J]. Journal of Materials Processing Technology, 2001, 113(1): 291 − 295.

[2] 刘素华. 铸轧辊辊套使用寿命的探讨[J]. 轻合金加工技术, 2009, 37(9): 34 − 35. Liu Suhua. Discussion on the service life of casting roll sleeve[J]. Light Alloy Fabrication Technology, 2009, 37(9): 34 − 35.

[3] 张晓东, 董世运, 王志坚, 等. 激光再制造金属零件熔覆层组织及耐磨性能[J]. 焊接学报, 2010, 31(2): 75 − 77. Zhang Xiaodong, Dong Shiyun, Wang Zhijian, et al. Microstructure and wear resistance of laser remanufacturing metal parts[J]. Transactions of the China Welding Institution, 2010, 31(2): 75 − 77.

[4] 员霄, 王井, 朱青海, 等. H13钢的铁基和钴基熔覆层组织与耐磨性[J]. 焊接学报, 2018, 39(12): 105 − 109. doi: 10.12073/j.hjxb.2018390307 Yun Xiao, Wang Jing, Zhu Qinghai, et al. Microstructure and abrasion resistance of Fe-based and Co-based coatings of AISI H13[J]. Transactions of the China Welding Institution, 2018, 39(12): 105 − 109. doi: 10.12073/j.hjxb.2018390307

[5] 张春华, 张松, 李春彦, 等. 热作模具钢表面激光熔覆StelliteX-40钴基合金[J]. 焊接学报, 2005, 26(1): 17 − 21. Zhang Chunhua, Zhang Song, Li Chunyan, et al. Laser cladding Stellite X-40 Co-based alloy on hot die steel[J]. Transactions of the China Welding Institution, 2005, 26(1): 17 − 21.

[6] 李俐群, 申发明, 周远东, 等. 超高速激光熔覆与常规激光熔431不锈钢涂层微观组织和耐蚀性的对比[J]. 中国激光, 2019, 46(10): 174 − 183. Li Liqun, Shen Faming, Zhou Yuandong, et al. Comparison of microstructure and corrosion resistance of 431 stainless steel coatings prepared by extreme high-speed laser cladding and conventional laser cladding[J]. Chinese Journal of Lasers, 2019, 46(10): 174 − 183.

[7] 袁庆龙, 冯旭东, 曹晶晶, 等. 激光熔覆技术研究进展[J]. 材料导报, 2010, 24(3): 112-116. Yuan Qinglong, Feng Xudong, Cao Jingjing, et al. Research progress in lasear cladding technology[J]. Materials Review, 2010, 24(3): 112 − 116.

[8] 娄丽艳, 张煜, 徐庆龙, 等. 超高速激光熔覆低稀释率金属涂层微观组织及性能[ J]. 中国表面工程, 2020, 33(2): 149-159. Lou Liyan, Zhang Yu, Xu Qinglong, et al. Microstructure and properties of metallic coatings with low dilution ratio by high speed laser cladding[ J]. China Surface Engineering, 2020, 33( 2): 149-159.

[9] Li Liqun, Shen Faming, Zhou Yuandong, et al. Comparative study of stainless steel AISI 431 coatings prepared by extreme-high-speed and conventional laser cladding[J]. Journal of Laser Applications, 2019, 31(4): 042009. doi: 10.2351/1.5094378

[10] 崔岗, 韩彬, 崔娜, 等. 扫描速度对激光熔覆Ni基WC合金涂层组织与性能的影响[J]. 中国表面工程, 2014, 27(4): 82 − 88. doi: 10.3969/j.issn.1007-9289.2014.04.013 Cui Gang, Han Bin, Cui Na, et al. Effects of scanning speed on microstructure and properties of laser cladding Ni-based WC alloy coating[J]. China Surface Engineering, 2014, 27(4): 82 − 88. doi: 10.3969/j.issn.1007-9289.2014.04.013

[11] Song L J, Zeng G C, Xiao H, et al. Repair of 304 stainless steel by laser cladding with 316L stainless steel powders followed by laser surface alloying with WC powders[J]. Journal of Manufacturing Processes, 2016, 24(1): 116 − 124.

[12] 澹台凡亮, 田洪芳, 陈峰, 等. 高速激光熔覆在27SiMn液压支架立柱上的应用探讨[J]. 新技术新工艺, 2019(3): 52 − 54. Tantai Fanliang, Tian Hongfang, Chen Feng, et al. Discussion on application of high-speed laser cladding on 27SiMn hydraulic support column[J]. New Technology & New Process, 2019(3): 52 − 54.

[13] 张煜, 娄丽艳, 徐庆龙, 等. 超高速激光熔覆镍基WC涂层的显微结构与耐磨性能[J]. 金属学报, 2020, 56( 11): 1530-1541. Zhang Yu, Lou Liyan, Xu Qinglong, et al. Microstructure and wear resistance of Ni-based WC coating by ultra-high speed laser cladding[ J]. Acta Metallurgica Sinica, 2020, 56(11): 1530-1541.

-

期刊类型引用(6)

1. 黄丹,蒋国志,先泽均,陈俊,牟坤. 山地管道全位置自动焊工艺. 焊接技术. 2023(09): 69-72 .  百度学术

百度学术

2. 冯靖,武少杰,高洪明,程方杰. 基于熔池受力的全位置STT打底焊分段工艺. 焊接. 2022(02): 1-5+17 .  百度学术

百度学术

3. 戴鹏飞,张先龙,宋刚,刘黎明. 低功率脉冲激光诱导电弧复合仰焊工艺适应性研究. 焊管. 2022(05): 1-9 .  百度学术

百度学术

4. 王彦坤,段莉蕾. 法兰密封面全位置TIG自动焊接设备及工艺. 焊管. 2022(11): 47-51 .  百度学术

百度学术

5. 樊云博,王丹,欧阳凯. UNS N04400管道全位置脉冲TIG焊数值模拟及工艺研究. 焊接技术. 2021(02): 26-30 .  百度学术

百度学术

6. 赵翔,朱政强,王小乐. 铝合金搅拌摩擦焊温度场的数值模拟分析. 焊接技术. 2018(04): 15-17+7 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: