Electro-thermal-mechanical response analysis of plastic deformation of resistance heating metal wire

-

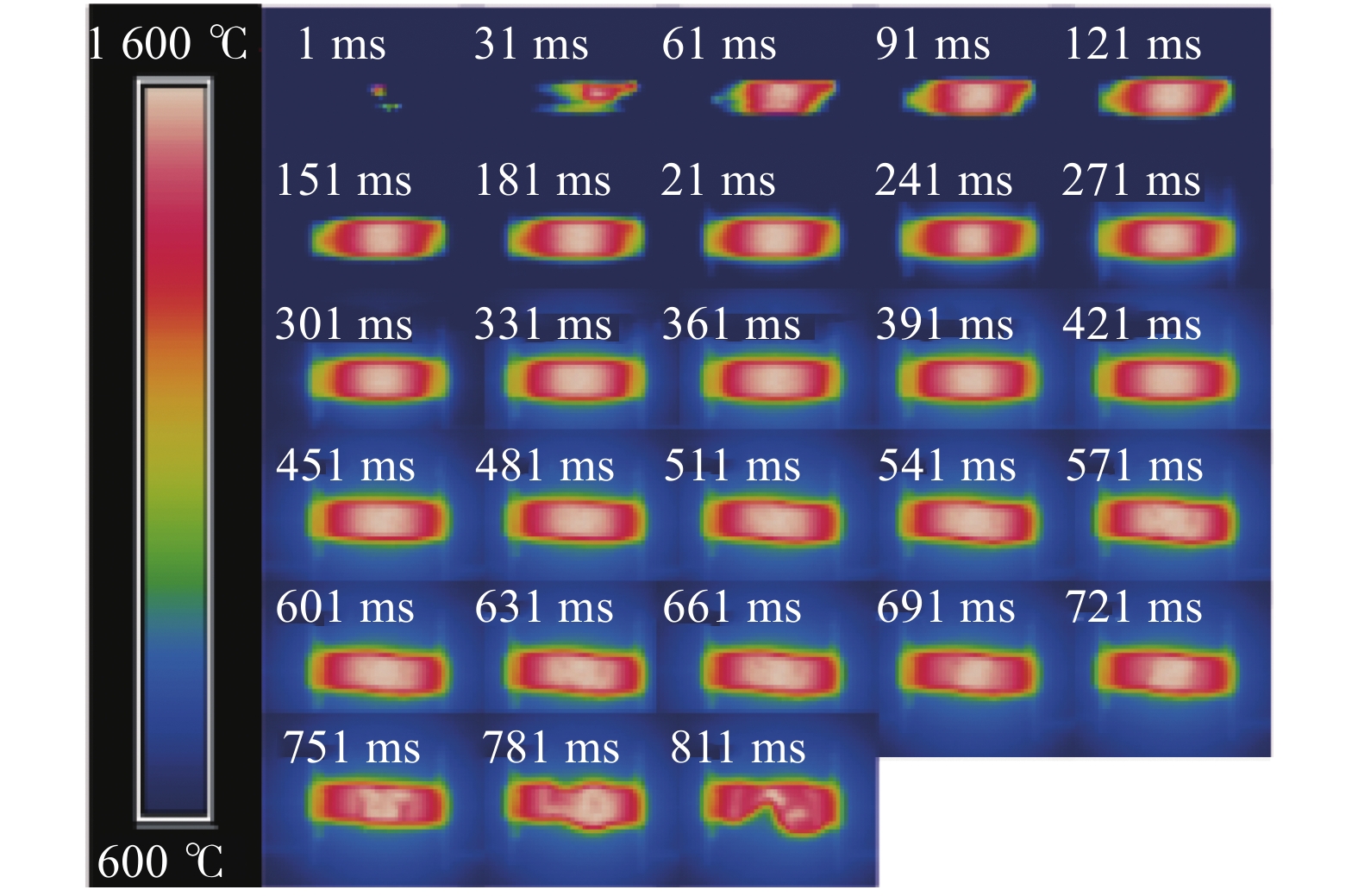

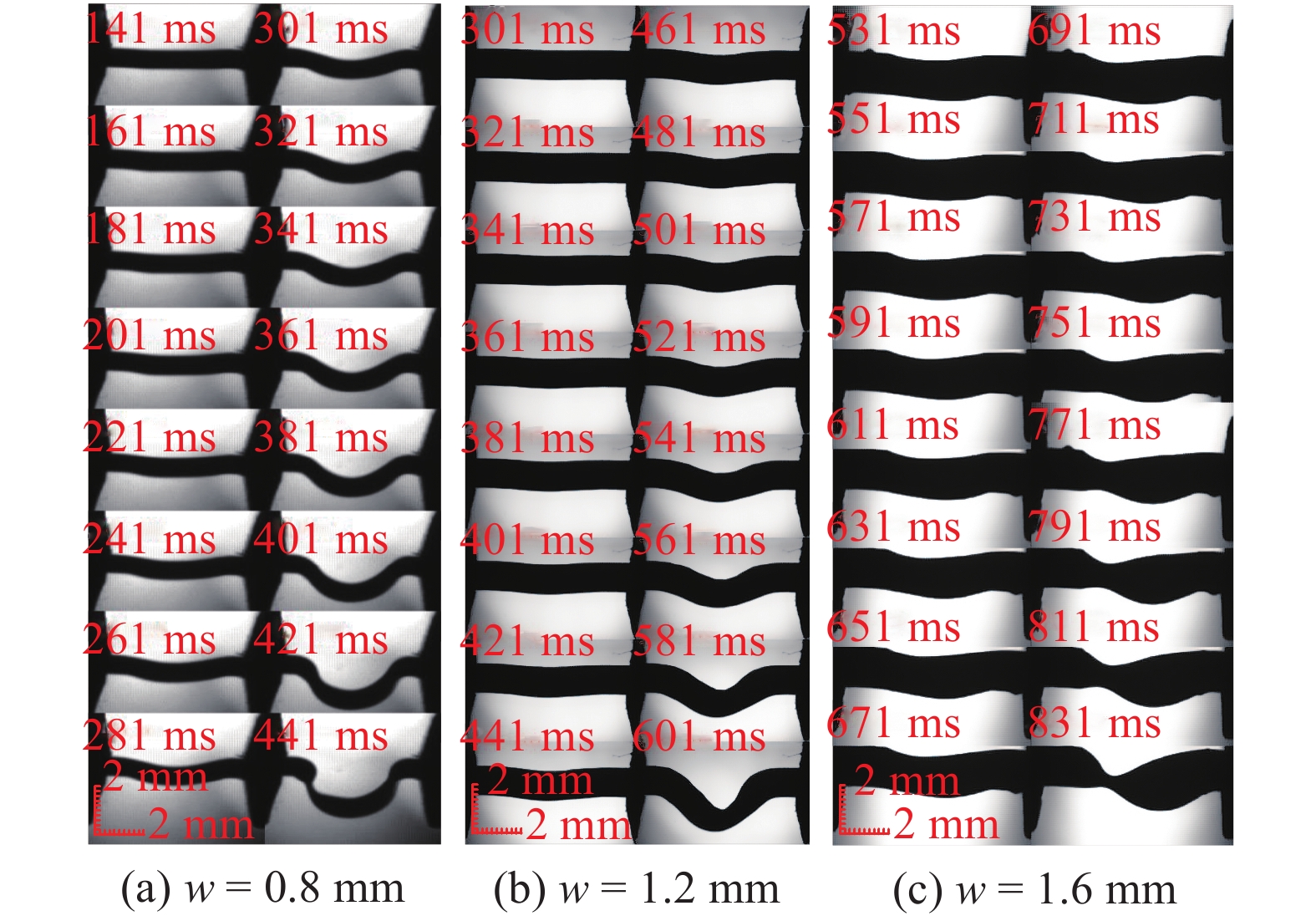

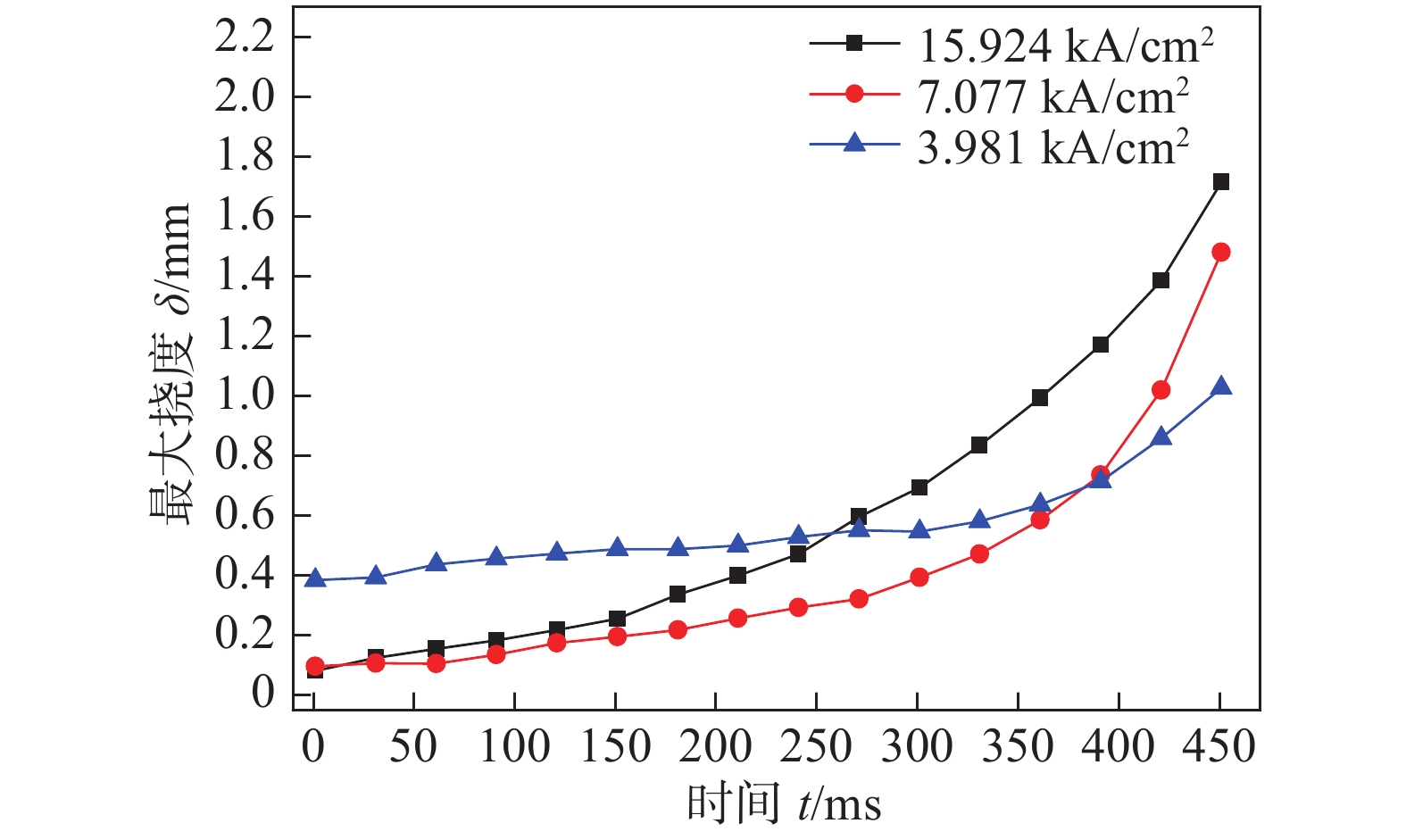

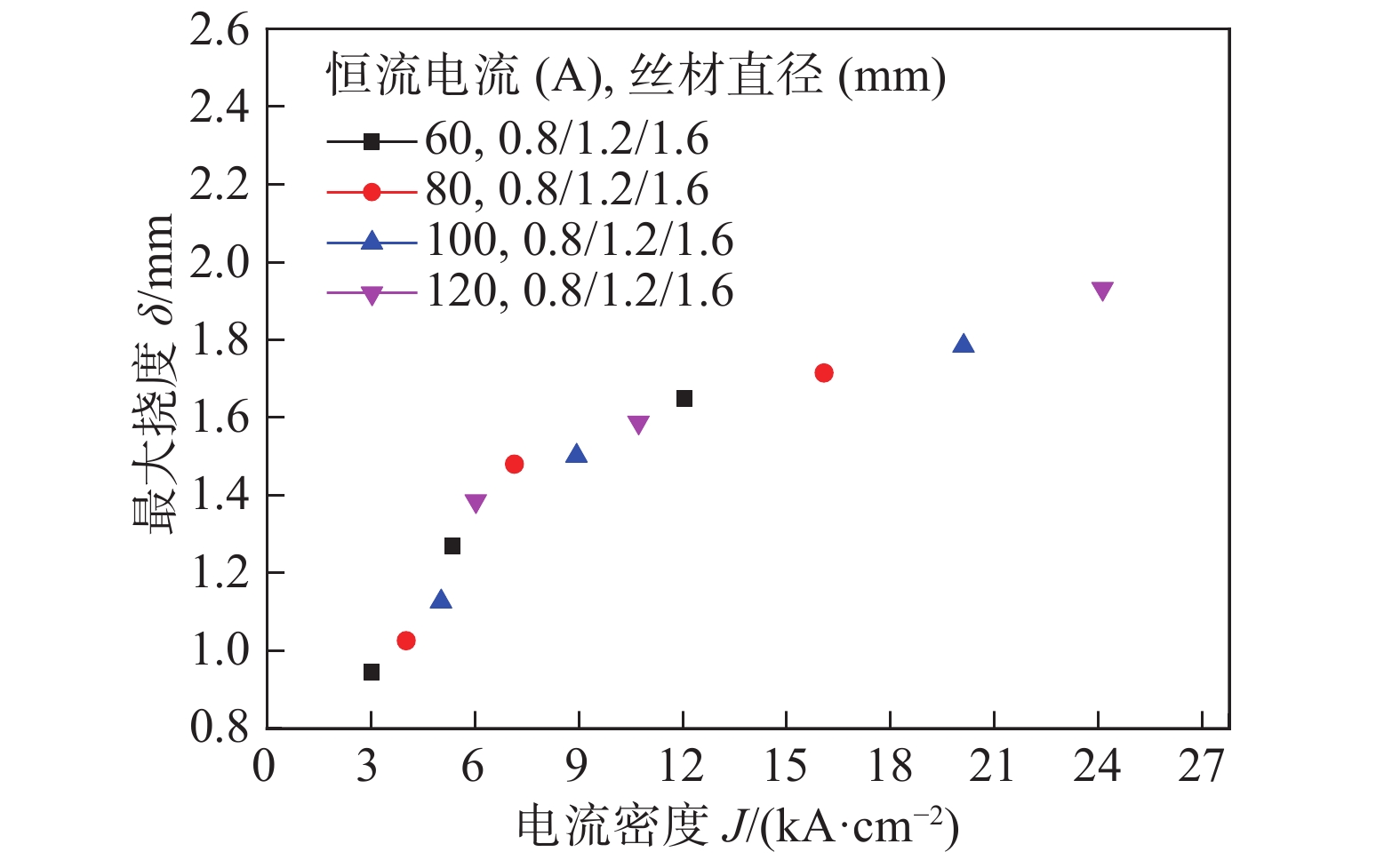

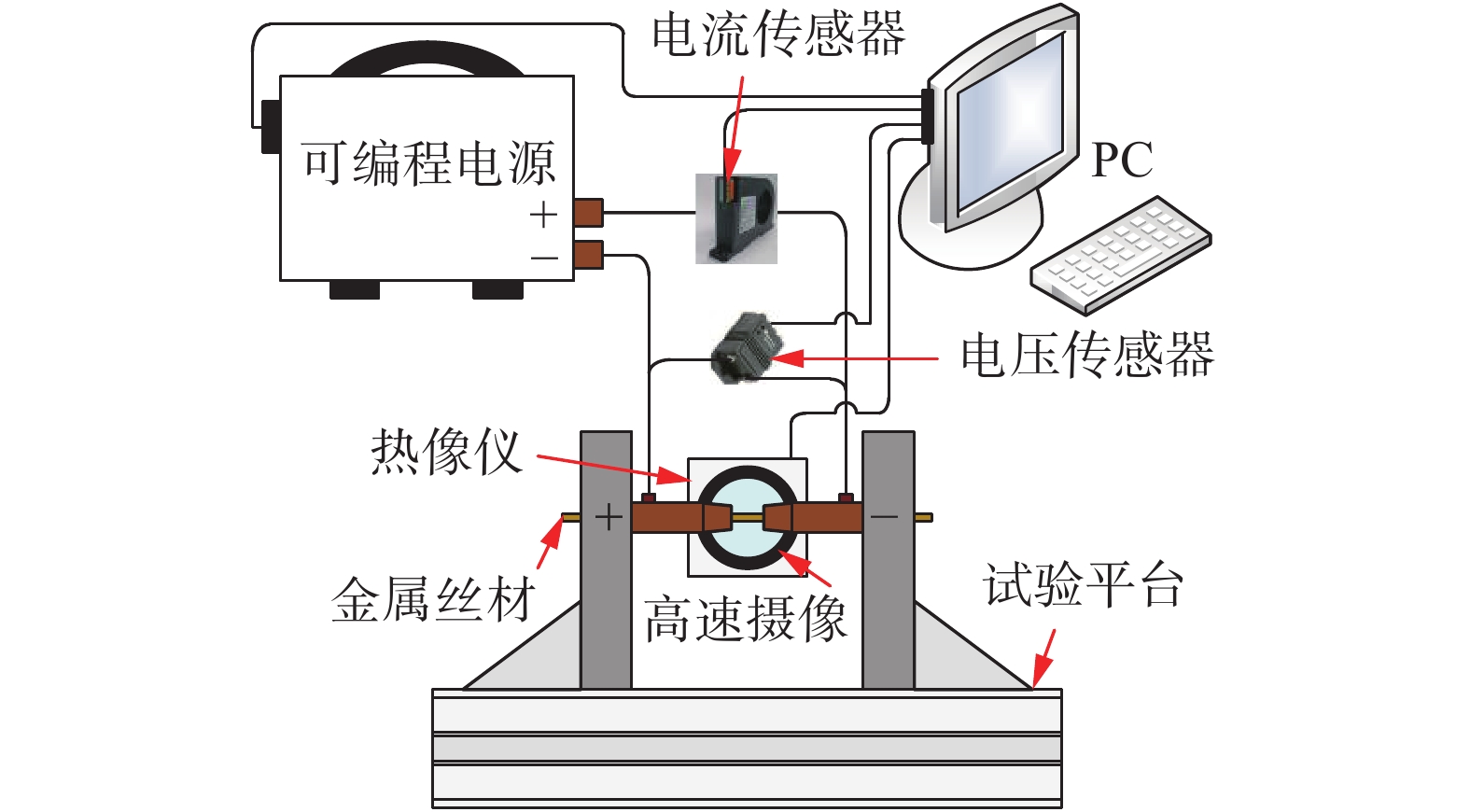

摘要: 电阻加热金属丝材增材制造技术对空间设备的修复和制造具有重要意义,在电阻加热金属丝材熔化沉积成形过程中,金属熔体的塑性变形影响金属零件的成形形貌. 为了精确探究金属熔体的塑性变形,将不同的电流密度通过短路的金属丝材,通过高速摄像机观测金属丝材塑性变化,采用热像仪和电压电流采集系统分别采集了金属丝材熔化过程的温度变化和电信号变化. 数值分析金属丝材塑性变形的机电热响应状态. 结果表明,数值计算得出最大挠度是电流密度的线性函数,与试验结果一致,通过高密度电流的金属丝材会发生显着的塑性变形. 在高电流密度的电流的作用下,释放出大量的焦耳热会引起局部温度的显着升高,从而导致屈服应力的降低,由于电-热-机械相互作用的原因,容易在电子互连中引起塑性变形.Abstract: Resistance heating metal wire additive manufacturing technology is of great significance to the repair and manufacturing of space equipment. During the melting and deposition forming process of resistance heating metal wire, the plastic deformation of the metal melt affects the forming morphology of metal parts. In order to accurately explore the plastic deformation of the metal melt, the plastic change of the metal wire was observed through a high-speed camera when passing different current densities through the short-circuited metal wire. The changes of temperature and electricity signal were collected by using a thermal imager and a voltage and current acquisition system during the melting process. The electromechanical and thermal response states of metal wire plastic deformation were analyzed numerically. The results showed that the maximum deflection obtained by numerical calculation was a linear function of current density, which was consistent with the experimental results. Metal wire passing through high-density current of metal wire occurred significant plastic deformation. Under the action of a high current density current, releasing a large amount of Joule heat caused a significant increase in local temperature and a decrease in yield stress. Due to the electro-thermal-mechanical interaction, it was easy to cause plastic deformation in electronic interconnection.

-

Keywords:

- resistance additive /

- plastic deformation /

- numerical calculation

-

-

表 1 电阻加热金属丝材试验方案

Table 1 Experimental scheme of resistance heating wire

试验方案 电流值I/A 电流波形 电极距离d/mm 丝材直径w/mm 1-1 60 恒流电流 6.0 1.2 1-2 80 恒流电流 6.0 1.2 1-3 100 恒流电流 6.0 1.2 1-4 120 恒流电流 6.0 1.2 2-1 80 恒流电流 6.0 0.8 2-2 80 恒流电流 6.0 1.2 2-3 80 恒流电流 6.0 1.6 -

[1] Fateri M, Kaouk A, Cowley A, et al. Feasibility study on additive manufacturing of recyclable objects for space applications[J]. Additive Manufacturing, 2018, 24: 400 − 404.

[2] Evans W T, Neely K E, Strauss A M, et al. Weldability of an iron meteorite by friction stir spot welding: a contribution to in-space manufacturing[J]. Acta Astronautica, 2017, 140: 452 − 458. doi: 10.1016/j.actaastro.2017.09.001

[3] Ceruti A, Marzocca P, Liverani A, et al. Maintenance in aeronautics in an industry 4.0 context: the role of augmented reality and additive manufacturing[J]. Journal of Computational Design and Engineering, 2019, 6(4): 516 − 526. doi: 10.1016/j.jcde.2019.02.001

[4] Pereira T, Kennedy J V, Potgieter J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job[J]. Procedia Manufacturing, 2019, 30: 11 − 18. doi: 10.1016/j.promfg.2019.02.003

[5] Al-Meslemi Y, Anwer N, Mathieu L. Environmental performance and key characteristics in additive manufacturing: a literature review[J]. Procedia the International Academy for Production Engineering, 2018, 69: 148 − 153.

[6] Attaran M. The rise of 3-D printing: the advantages of additive manufacturing over traditional manufacturing[J]. Business Horizons, 2017, 60(5): 677 − 688. doi: 10.1016/j.bushor.2017.05.011

[7] Mawale M B, Kuthe A M, Dahake S W. Additive layered manufacturing: State-of-the-art applications in product innovation[J]. Concurrent Engineering, 2016, 24(1): 94 − 102. doi: 10.1177/1063293X15613111

[8] Williams H, Butler-Jones E. Additive manufacturing standards for space resource utilization[J]. Additive Manufacturing, 2019, 28: 676 − 681. doi: 10.1016/j.addma.2019.06.007

[9] Goulas A, Binner J G P, Harris R A, et al. Assessing extra- terrestrial regolith material simulants for in-situ resource utilisation based 3D printing[J]. Applied Materials Today, 2017, 6: 54 − 61.

[10] Pinkerton A J. Lasers in additive manufacturing[J]. Optics & Laser Technology, 2016, 78: 25 − 32.

[11] Konyashin I, Hinners H, Ries B, et al. Additive manufacturing of WC-13% Co by selective electron beam melting: achievements and challenges[J]. International Journal of Refractory Metals and Hard Materials, 2019, 84: 105028. doi: 10.1016/j.ijrmhm.2019.105028

[12] Zhang C, Gao M, Chen C, et al. Spectral diagnosis of wire arc additive manufacturing of Al alloys[J]. Additive Manufacturing, 2019, 30: 100869. doi: 10.1016/j.addma.2019.100869

[13] Li M, Lu T, Dai J, et al. Microstructure and mechanical properties of 308L stainless steel fabricated by laminar plasma additive manufacturing[J]. Materials Science and Engineering: A, 2020, 770: 138523.

[14] Chen S, Yuan C, Jiang F, et al. Study on heat generation mechanism and melting behavior of droplet transition in resistive heating metal wires[J]. Acta Metall Sin, 2018, 54(9): 1297 − 1310.

[15] Lu S, Li J, Cheng M, et al. Joule heating-a significant factor in electrocaloric effect[J]. Ceramics International, 2019, 45(14): 16992 − 16998. doi: 10.1016/j.ceramint.2019.05.248

[16] Jung H W, Kim S J, Kim Y J, et al. Finite element analysis of vertical micro-probe considering Joule-heating effect[J]. International Journal of Fatigue, 2017, 101: 96 − 105.

[17] Jamalabadi M Y A, Park J H, Rashidi M M, et al. Effects of thermal boundary conditions on the joule heating of electrolyte in a microchannel[J]. Journal of Hydrodynamics, 2016, 28(5): 850 − 862.

[18] Wei F L, Gan C L, Tan T L, et al. Electromigration-induced extrusion failures in Cu/low-k interconnects[J]. Journal of Applied Physics, 2008, 104(2): 5792 − 378.

[19] Zhang H, Wang G, Iii G S C. Local melting during electro- migration in Cu conductor lines[J]. Journal of Electronic Materials, 2007, 36(2): 117 − 122.

[20] Park Y, Monig R, Volkert C. Thermal fatigue as a possible failure mechanism in copper interconnects[J]. Thin Solid Films, 2006, 504(1): 321 − 324.

[21] Zhao G, Liu M, Yang F. The effect of an electric current on the nanoindentation behavior of tin[J]. Acta Materialia, 2012, 60(9): 3773 − 3782. doi: 10.1016/j.actamat.2012.03.049

下载:

下载: