High temperature creep behavior of friction stir welding joints for CLAM steel

-

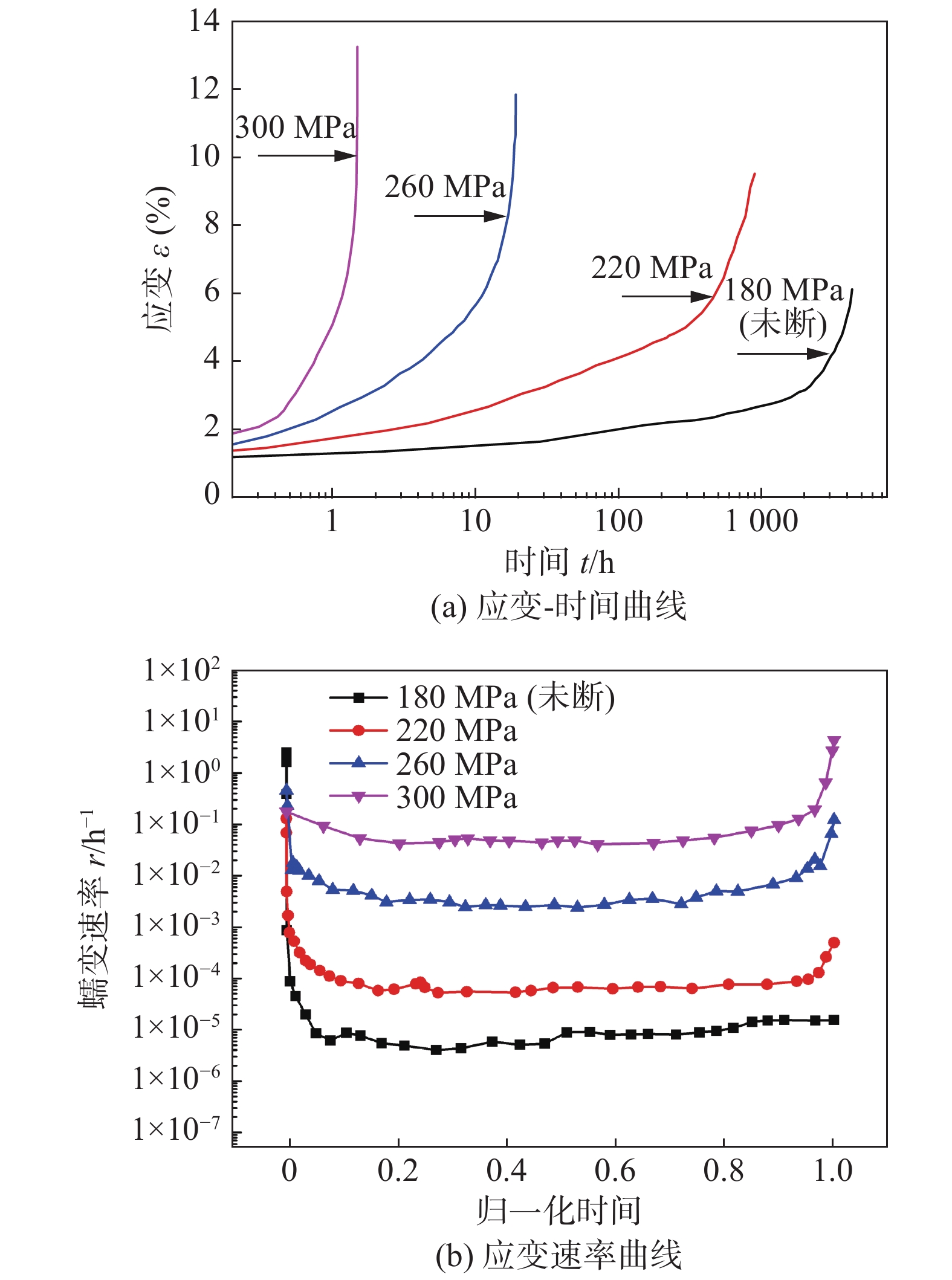

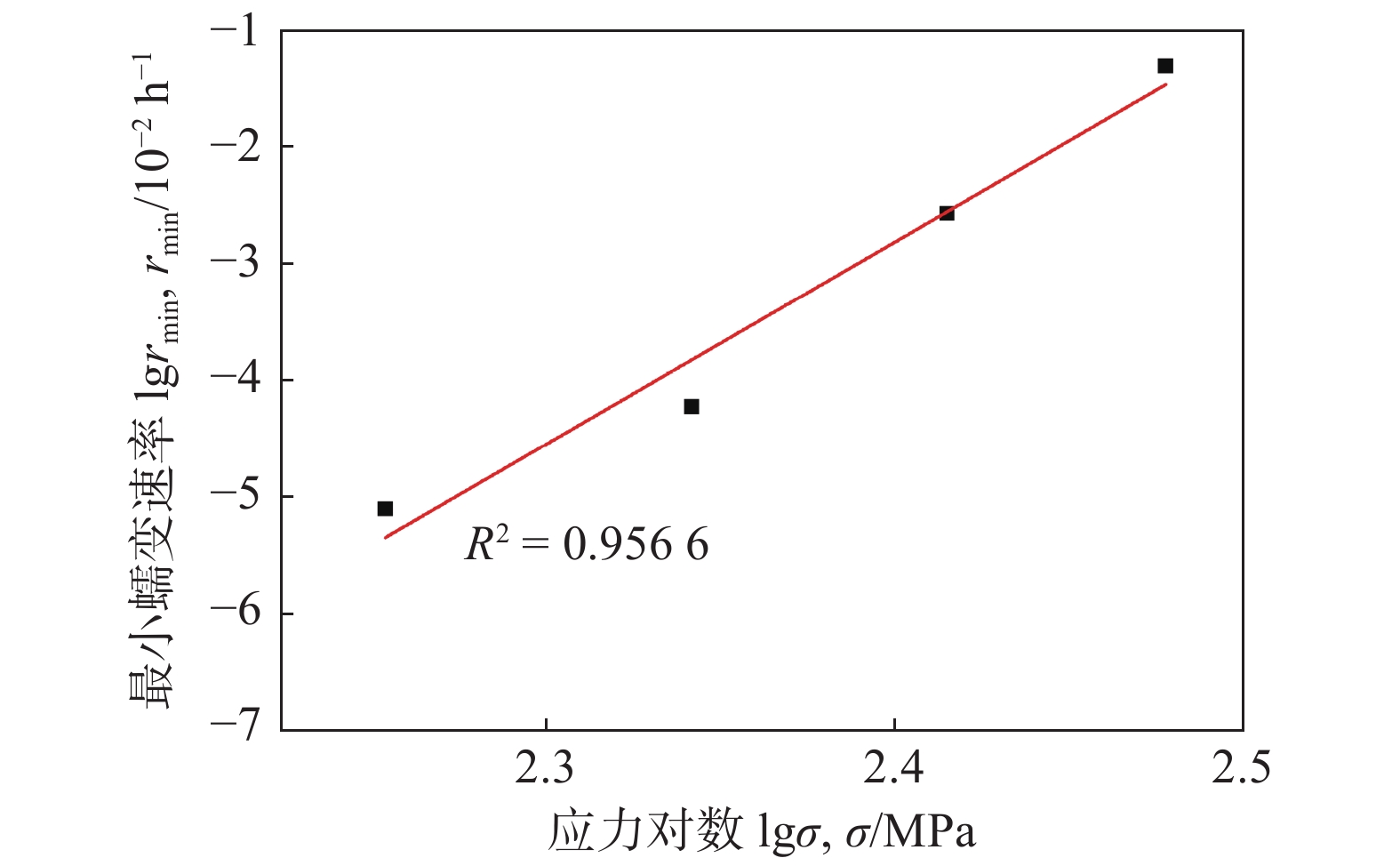

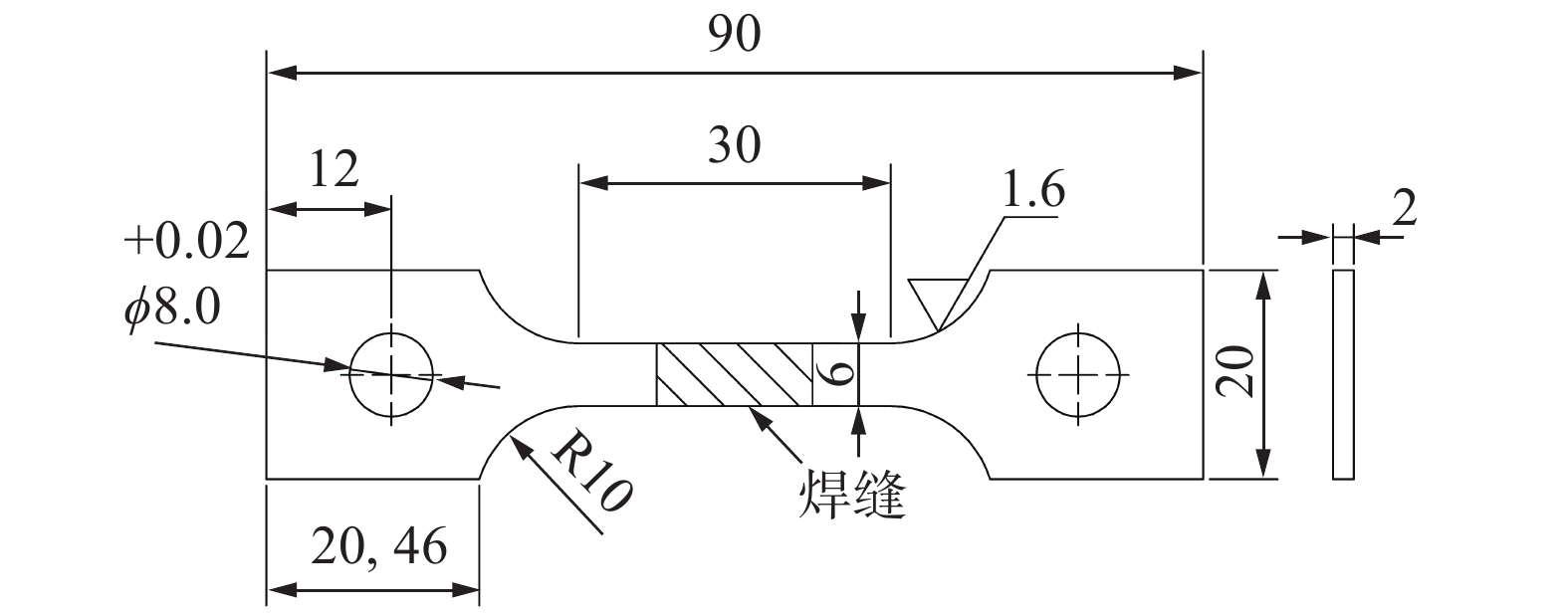

摘要: 针对核聚变堆用CLAM钢,对焊后热处理的搅拌摩擦焊接头在823 K条件和180~300 MPa应力水平下的单轴拉伸蠕变性能、断口形貌、显微组织进行了研究. 结果表明,当蠕变应力由300,260及220 MPa降低到180 MPa时,CLAM钢搅拌摩擦焊接头的蠕变寿命分别由1.5,19.2及883 h增加到6769 h以上. 临界热影响区是接头蠕变断裂的最薄弱区域,主要呈现位错控制的蠕变变形机制和穿晶韧性断裂模式. 在蠕变过程中临界热影响区组织发生回复并形成亚晶,导致位错强化作用降低;M23C6碳化物发生不同程度的粗化或周围生成Laves相,导致析出和固溶强化作用减弱;这些因素是CLAM钢FSW接头蠕变性能恶化的主要原因. 采用Monkman-Grant方程预测FSW接头在1×105 h蠕变寿命下的蠕变断裂强度估计为156 MPa,达到母材强度的88%.Abstract: The uniaxial creep tensile strength, fracture features and microstructures of friction stir welded joint with postweld heat treatment for CLAM steel have been investigated in the range of the creep applied stress from 180 MPa to 300 MPa at 823 K condition. It is found that the creep life of the FSW joints of CLAM steel increase from 1.5 h, 19.2 h and 883 h to above 6769 h respectively, when the creep stresses decrease from 300 MPa, 260 MPa and 220 MPa to 180 MPa. The inter critical heat affected zone is the weakest zone of creep rupture resistance for the FSW joint of CLAM steel, the joints mainly exhibit dislocation-controlled creep deformation mechanism and the transgranular ductile fracture mode. The microstructures of inter critical heat affected zone produce recovery and subgrain boundaries are formed in here during creep process, which result in the decrease of dislocation strengthening action; the coarser M23C6 carbides is produced or the coarser Laves phase around the M23C6 carbides is formed, which result in the reduction of precipitation and solution strengthening action, these issues are the main reasons for the deterioration of the creep performance of FSW joints. The creep fracture strength of FSW joint is estimated to be 156 MPa in the condition of 1 × 105 h creep life according to the Monkman-Grant equation, which reaches 88 % of the strength of base metal.

-

Keywords:

- low activation steel /

- friction stir welding /

- creep performance /

- microstructure /

- life prediction

-

-

表 1 CLAM钢的化学成分(质量分数,%)

Table 1 Chemical composition of CLAM steel

C Cr Mn V W Ta Si N Fe 0.098 8.7 0.56 0.19 1.4 < 0.002 0.11 0.005 3 余量 表 2 焊接接头最小蠕变速率和断裂时间

Table 2 Minimum creep rate and fracture time of welded joints

应力水平σ/MPa 最小蠕变速率rmin/h−1 断裂时间t/h 180 8.09×10−6 6 769 (未断) 220 6.02×10−5 883 260 2.68×10−3 19.2 300 4.89×10−2 1.5 -

[1] 黄群英, 李春京, 刘少军, 等. 中国实验包层模块材料研发进展[J]. 核科学与工程, 2009, 29(3): 260 − 265. doi: 10.3321/j.issn:0258-0918.2009.03.011 Huang Qunying, Li Chunjing, Liu Shaojun, et al. R & D status of materials for test blanket modules in China[J]. Nuclear Science and Engineering, 2009, 29(3): 260 − 265. doi: 10.3321/j.issn:0258-0918.2009.03.011

[2] Tan L, Katoh Y, Tavassoli A A F, et al. Recent status and improvement of reduced-activation ferritic-martensitic steels for high-temperature service[J]. Journal of Nuclear Materials, 2016, 479: 515 − 523. doi: 10.1016/j.jnucmat.2016.07.054

[3] Sklenicka V, Kucharova K, Svoboda M, et al. Long-term creep behavior of 9%-12% Cr power plant steels[J]. Master Character, 2003, 51: 35 − 37. doi: 10.1016/j.matchar.2003.09.012

[4] 姜志忠, 黄继华, 胡杰, 等. 聚变堆用CLAM钢激光焊接接头显微组织及性能[J]. 焊接学报, 2012, 33(2): 5 − 8. Jiang Zhizhong, Huang Jihua, Hu Jie, et al. Microstructure and mechanical properties of laser welded joints of CLAM steel used for fusion reactor[J]. Transactions of the China Welding Institution, 2012, 33(2): 5 − 8.

[5] Aubert P, Tavassoli F, Rieth M, et al. Review of candidate welding processes of RAFM steels for ITER test blanket modules and DEMO[J]. Journal of Nuclear Materials, 2011, 417(1−3): 43 − 50. doi: 10.1016/j.jnucmat.2010.12.248

[6] Das C R, Albert S K, Sam S, et al. Mechanical properties of 9Cr–1W reduced activation ferritic martensitic steel weldment prepared by electron beam welding process[J]. Fusion Engineering & Design, 2014, 89(11): 2672 − 2678.

[7] 许乐, 温建锋, 涂善东. P92钢焊接接头蠕变损伤与裂纹扩展数值模拟[J]. 焊接学报, 2019, 40(8): 80 − 88. Xu Le, Wen Jianfeng, Tu Shandong. Numerical simulations of creep damage and crack growth in P92 steel welded joints[J]. Transactions of the China Welding Institution, 2019, 40(8): 80 − 88.

[8] Albert S K, Tabuchi M, Hongo H, et al. Effect of welding process and groove angle on type IV cracking behavior of weld joints of a ferritic steel[J]. Science & Technology of Welding & Joining, 2013, 10(2): 149 − 157.

[9] Wang J, Lu S, Dong W, et al. Microstructural evolution and mechanical properties of heat affected zones for 9Cr2WVTa steels with different carbon contents[J]. Materials & Design, 2014, 64(12): 550 − 558.

[10] Noh S, Ando M, Tanigawa H, et al. Friction stir welding of F82H steel for fusion applications[J]. Journal of Nuclear Materials, 2016, 478: 1 − 6. doi: 10.1016/j.jnucmat.2016.05.028

[11] Manugula V L, Rajulapati K V, Reddy G M, et al. A critical assessment of the microstructure and mechanical properties of friction stir welded reduced activation ferritic–martensitic steel[J]. Materials & Design, 2016, 92: 200 − 212.

[12] Zhang C, Cui L, Wang D, et al. The heterogeneous microstructure of heat affect zone and its effect on creep resistance for friction stir joints on 9Cr–1.5 W heat resistant steel[J]. Scripta Materialia, 2019, 158: 6 − 10. doi: 10.1016/j.scriptamat.2018.08.028

[13] 雷玉成, 张鑫, 陈玲, 等. 中国低活化马氏体钢TIG焊焊接接头的高温蠕变性能分析[J]. 焊接学报, 2016, 37(3): 5 − 8. Lei Yucheng, Zhang Xin, Chen Ling, et al. Analysis on creep properties of TIG welding joints of China low activation martensitic steel[J]. Transactions of the China Welding Institution, 2016, 37(3): 5 − 8.

[14] Norton F H. The creep of steel at high temperatures[M]. McGraw-Hill Book Company, Incorporated, 1929.

[15] Betten J. Creep mechanics[M]. Springer Science & Business Media, 2008.

[16] Deng K K, Li J C, Xu F J, et al. Hot deformation behavior and processing maps of fine-grained SiCp/AZ91 composite[J]. Materials & Design, 2015, 67(2): 72 − 81.

[17] Lee J S, Armaki H G, Maruyama K, et al. Causes of breakdown of creep strength in 9Cr-1.8W-0.5Mo-VNb steel[J]. Materials Science and Engineering: A, 2006, 428(1/2): 270-275.

[18] 叶有俊, 王一宁, 姜勇, 等. 基于碳化物相分析法的 P92 钢寿命无损评价[J]. 压力容器, 2020, 37(8): 1 − 5, 23. Ye Youjun, Wang Yining, Jiang Yong, et al. Nondestructive life assessment based on carbide phase analysis of P92 steel[J]. Pressure Vessel Technology, 2020, 37(8): 1 − 5, 23.

[19] Zhang X, Lei Y, Chen L, et al. Study on creep properties for TIG welded joints of CLAM steel[J]. Journal of Fusion Energy, 2016, 35(2): 299 − 304. doi: 10.1007/s10894-015-0024-3

下载:

下载: