Effect of V content and tempering treatment on microstructure and mechanical properties of the high strength steel TIG weld metal

-

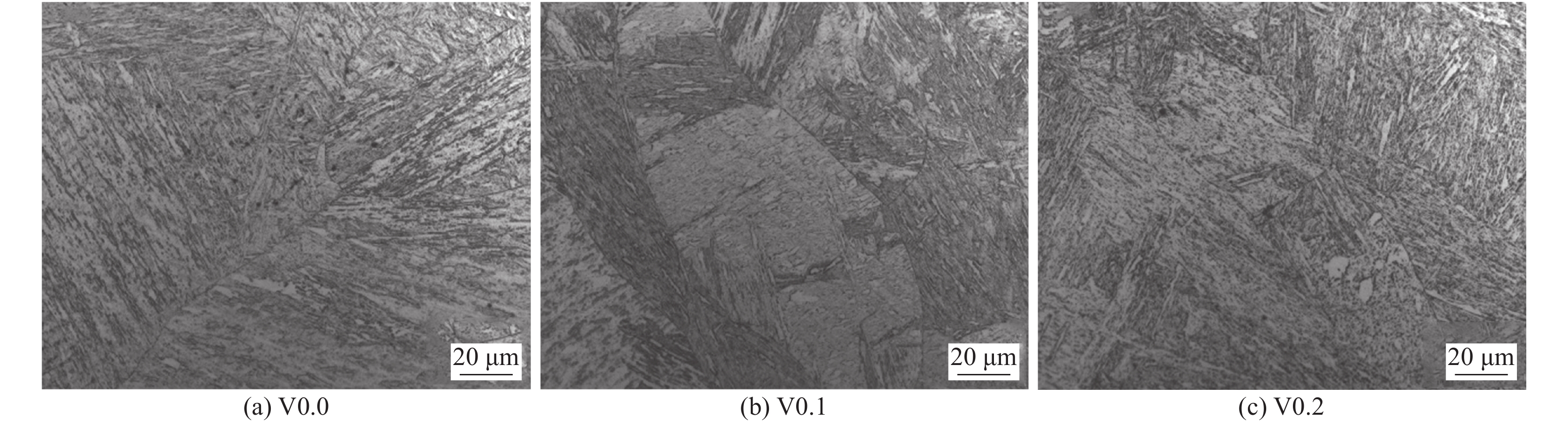

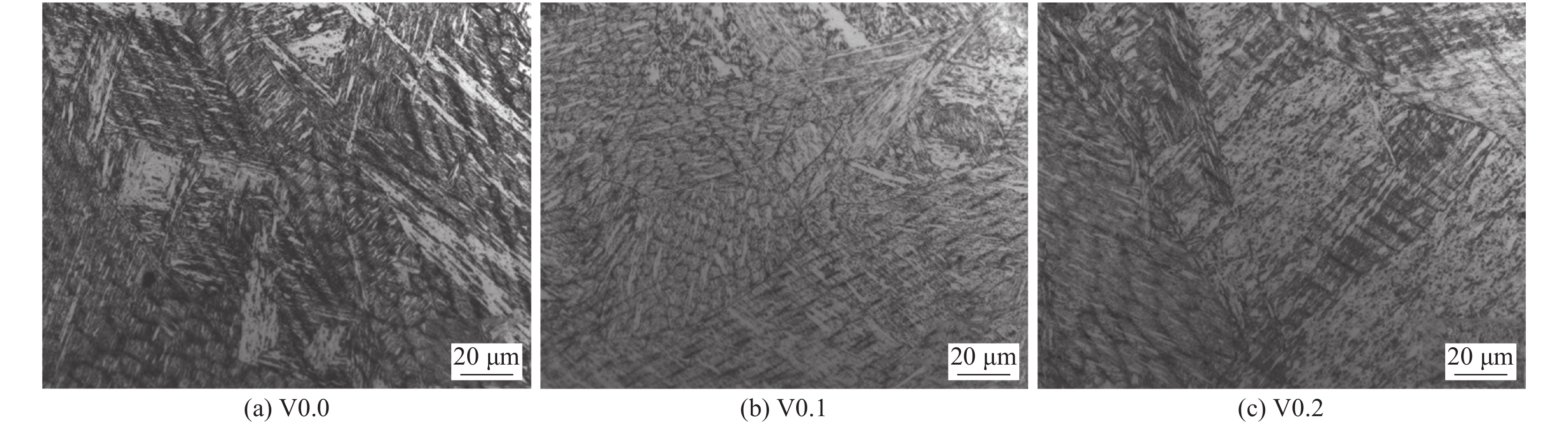

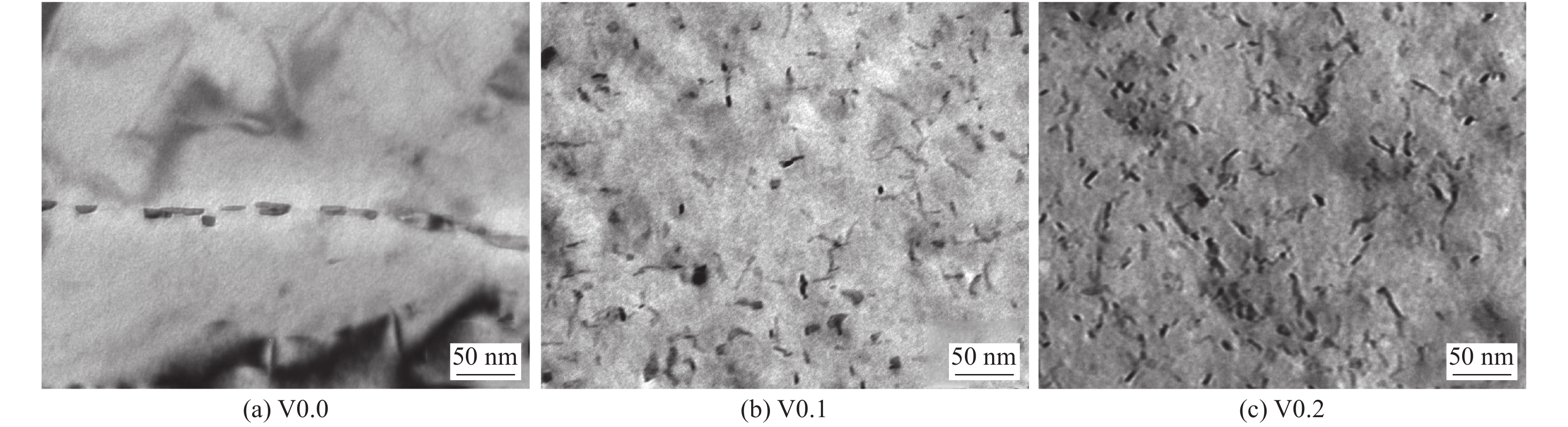

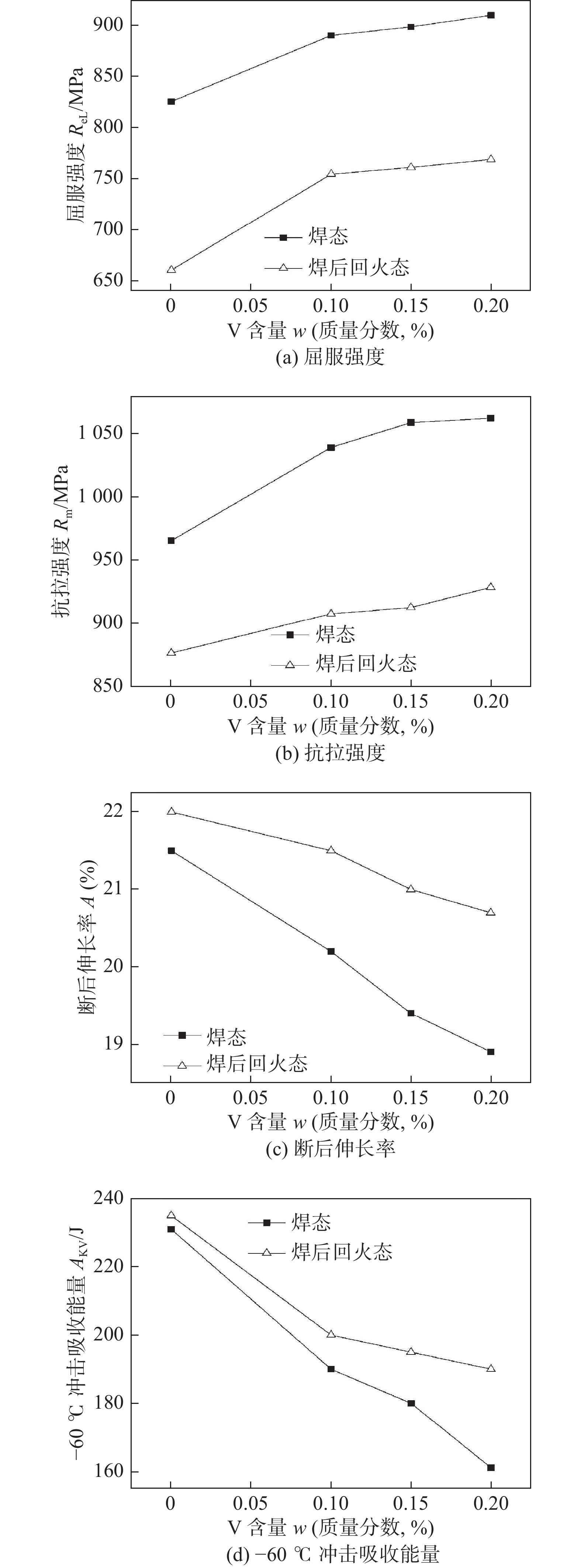

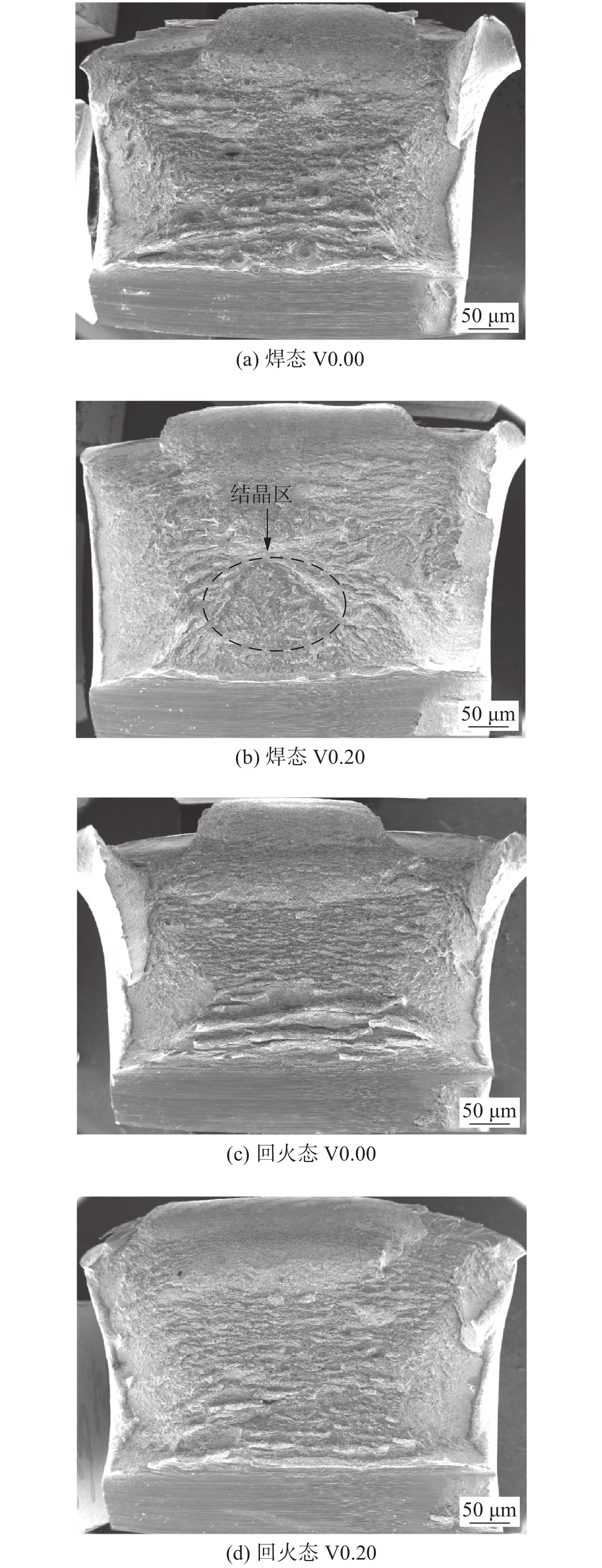

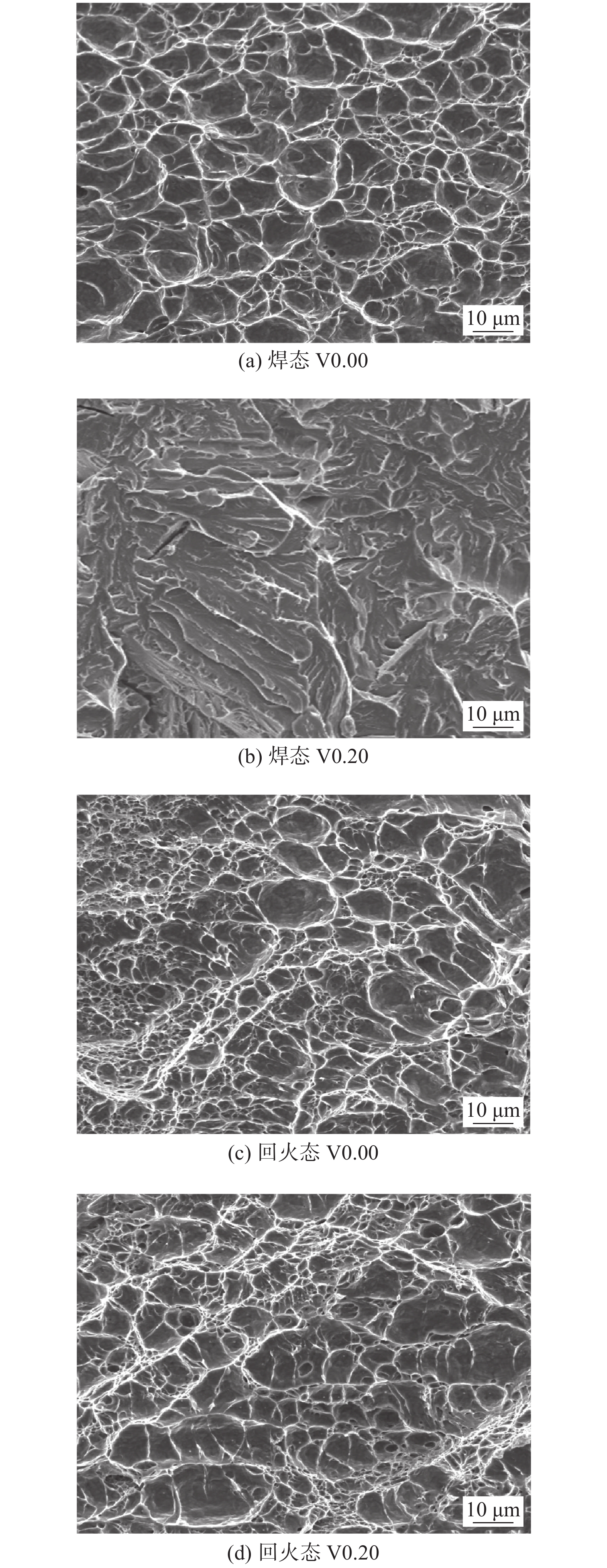

摘要: 采用四种不同V含量焊丝对高强钢板进行钨极氩弧焊试验,焊后对熔敷金属进行640 ℃保温2 h的回火处理. 研究了V含量和回火处理对熔敷金属微观组织及力学性能的影响. 结果表明,焊态及焊后回火态条件下,随着V含量的增加,熔敷金属强度升高,延伸率和冲击功降低,经回火处理后,不含V熔敷金属内晶界处析出M2C碳化物,而含V熔敷金属内析出弥散分布的VC析出相,焊后回火过程中位错回复引起基体软化的作用高于M2C及VC的析出强化作用,导致回火后强度降低,断后伸长率冲击吸收能量升高. 细小VC具有阻碍位错运动的作用,导致回火后含V熔敷金属仍保留较高的位错密度. 实际应用中应根据熔敷金属性能要求合理选择V含量及焊后回火工艺.Abstract: Four kinds of welding wires with different V contents were used to weld the high strength steel plates by tungsten inert gas welding method. After welding, the weld metals of different welding wires were tempered at 640 ℃ for 2 h. The effects of V content and tempering treatment on microstructure and mechanical properties of weld metal were studied. The results show that for the as-welded and as-tempered weld metals, with the increase of V content, the strength increases and the elongation and impact energy decrease. Furthermore, after tempering treatment, M2C carbide precipitated at the grain boundary of the V-free weld metal, while VC precipitated in V-bearing weld metals. During the post weld tempering process, the effect of dislocation recovery on matrix softening is stronger than precipitation strengthening of M2C and VC. Therefore, under the combined effects of the two factors, the tempering treatment decreases the strength and improves the elongation and impact energy. The dispersed VC precipitates have the effect of hindering dislocation movement, which causes that the V-bearing weld metal retains high dislocation density after tempering. In practical application, V content and post weld tempering process should be selected reasonably according to the performance requirements of weld metal.

-

Keywords:

- high strength steel /

- weld metal /

- post weld heat treatment /

- microstructure /

- mechanical property

-

-

表 1 母材及焊材化学成分(质量分数,%)

Table 1 Chemical compositions of base metal and welding wires

材料 C Si Mn Ni Cr Mo V 母材 0.15 0.30 1.40 4.20 0.80 0.60 <0.01 焊丝V0.00 0.03 0.40 1.20 5.50 1.00 0.70 <0.01 焊丝V0.10 0.03 0.40 1.20 5.50 1.00 0.70 0.10 焊丝V0.15 0.03 0.40 1.20 5.50 1.00 0.70 0.15 焊丝V0.20 0.03 0.40 1.20 5.50 1.00 0.70 0.20 表 2 微应变及位错密度

Table 2 Microstrain and austenite volume fraction

熔敷金属 微应变e 位错密度ρ/nm−2 焊态V0.00 0.24 13.30 焊态V0.20 0.30 20.80 回火态V0.00 0.17 7.10 回火态V0.20 0.24 12.90 -

[1] 文明月, 董文超, 庞辉勇, 等. 一种Fe-Cr-Ni-Mo高强钢焊接热影响区的显微组织与冲击韧性研究[J]. 金属学报, 2018, 54(4): 501 − 511. Wen Mingyue, Dong Wenchao, Pang Huiyong, et al. Microstructure and Impact toughness of welding heat-affected zones of a Fe-Cr-Ni-Mo high strength steel[J]. Acta Metallurgica Sinica, 2018, 54(4): 501 − 511.

[2] 王长军, 梁剑雄, 刘振宝, 等. 亚稳奥氏体对低温海工用钢力学性能的影响与机理[J]. 金属学报, 2016, 52(4): 385 − 393. doi: 10.11900/0412.1961.2015.00312 Wang Changjun, Liang Jianxiong, Liu Zhenbao, et al. Effect of metastable austenite on mechanical property and mechanism in cryogenic steel applied in oceaneering[J]. Acta Metallurgica Sinica, 2016, 52(4): 385 − 393. doi: 10.11900/0412.1961.2015.00312

[3] Zhou Yanlei, Jia Tao, Zhang Xiangjun, et al. Microstructure and toughness of the CGHAZ of an offshore platform steel[J]. Journal of Materials Processing Technology, 2015, 219: 314 − 320. doi: 10.1016/j.jmatprotec.2014.12.017

[4] 张熹, 张楠, 刘宏, 等. 母材熔合作用对EQ51海工钢焊缝组织及韧性的影响[J]. 焊接学报, 2016, 37(12): 125 − 128. Zhang Xi, Zhang Nan, Liu Hong, et al. Fusion effect on weld joint microstructure and toughness of EQ51 ocean engineering steel[J]. Transactions of the China Welding Institution, 2016, 37(12): 125 − 128.

[5] Li Hongliang, Liu Duo, Tang Dongyan, et al. Microstructure and mechanical properties of E36 steel joint welded by underwater wet welding[J]. China Welding, 2016, 25(1): 30 − 35.

[6] Haslberger P, Holly S, Ernst W, et al. Microstructure and mechanical properties of high-strength steel welding consumables with a minimum yield strength of 1100 MPa[J]. Journal of Materials Science, 2018, 53(9): 6968 − 6979. doi: 10.1007/s10853-018-2042-9

[7] Holly S, Haslberger P, Zügner D, et al. Development of high-strength welding consumables using calculations and microstructural characterisation[J]. Welding in the World, 2018, 62(3): 451 − 458. doi: 10.1007/s40194-018-0562-1

[8] Ju Yulin, Goodall Aimee, Strangwood Martin, et al. Characterisation of precipitation and carbide coarsening in low carbon low alloy Q & T steels during the early stages of tempering[J]. Materials Science and Engineering: A, 2018, 738: 174 − 189. doi: 10.1016/j.msea.2018.09.044

[9] Williamson G K, Smallman R E. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum[J]. Philosophical Magazine, 1956, 1(1): 34 − 46. doi: 10.1080/14786435608238074

[10] Yan Jiacheng, Xu Hongwei, Zuo Xiaowei, et al. Strategies for strengthening-ductility and hierarchical co-precipitation in multicomponent nano-precipitated steels by Cu partitioning[J]. Materials Science and Engineering: A, 2019, 739: 225 − 234. doi: 10.1016/j.msea.2018.10.036

[11] Xu S S, Zhao Y, Chen D, et al. Nanoscale precipitation and its influence on strengthening mechanisms in an ultra-high strength low-carbon steel[J]. International Journal of Plasticity, 2019, 113: 99 − 110. doi: 10.1016/j.ijplas.2018.09.009

-

期刊类型引用(3)

1. 张明军,李晨希,邹江林,程波,张健,仝永刚,胡永乐,陈根余. AZ31B镁合金功率调制环形光斑光纤激光焊接试验研究. 机械工程学报. 2025(02): 151-161 .  百度学术

百度学术

2. 刘坤,李洁,王浩,简思捷. 镁合金焊接凝固裂纹敏感性评价及晶间液相回填规律分析. 焊接学报. 2023(09): 9-15+129 .  本站查看

本站查看

3. 焦婧,黄金鑫,张志凯. 论带复杂油路类镁合金铸件的清理方法. 世界有色金属. 2022(23): 175-177 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: