Numerical simulation of welding residual stress and distortion in T2-Y/Q345 dissimilar materials

-

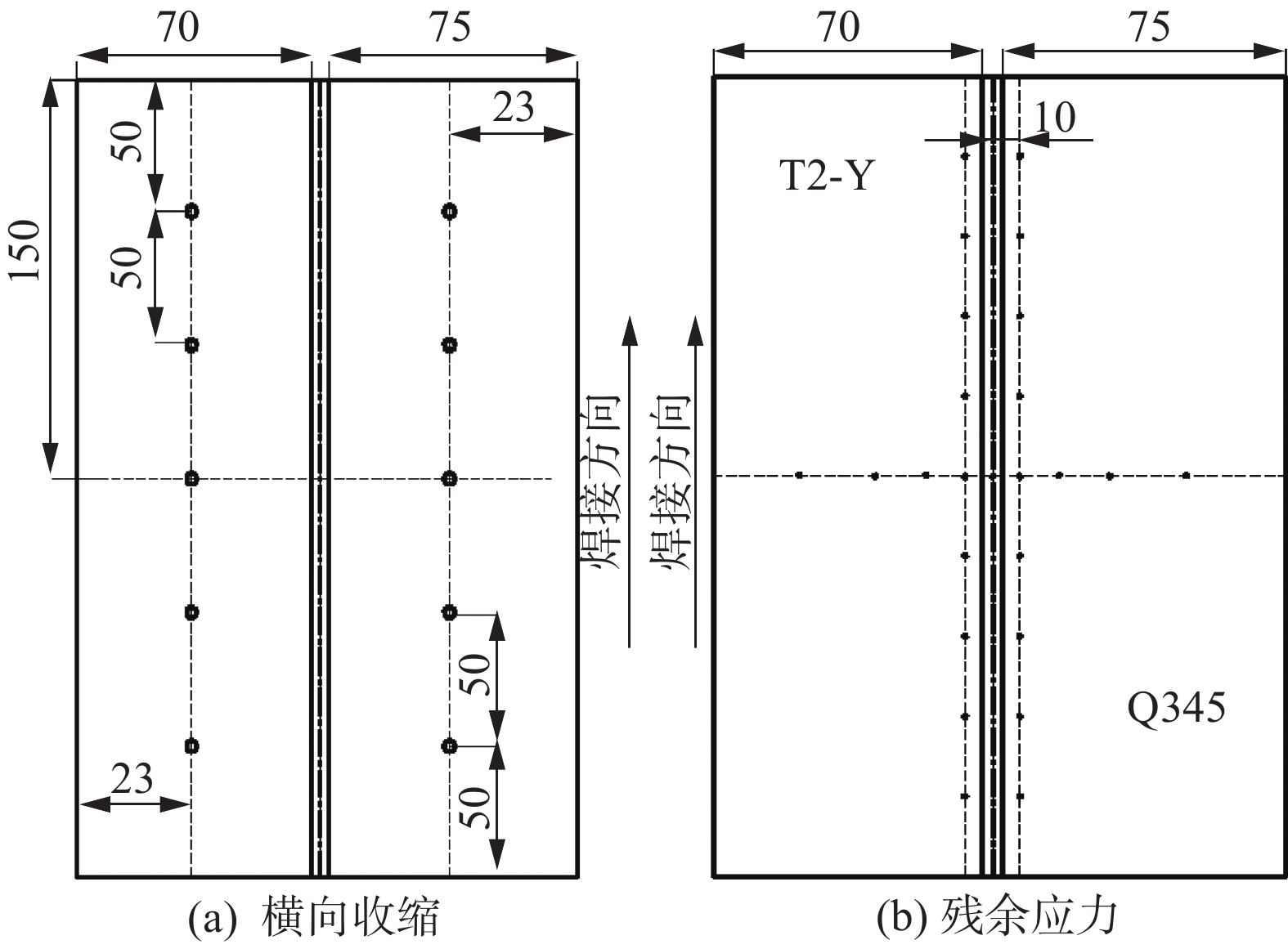

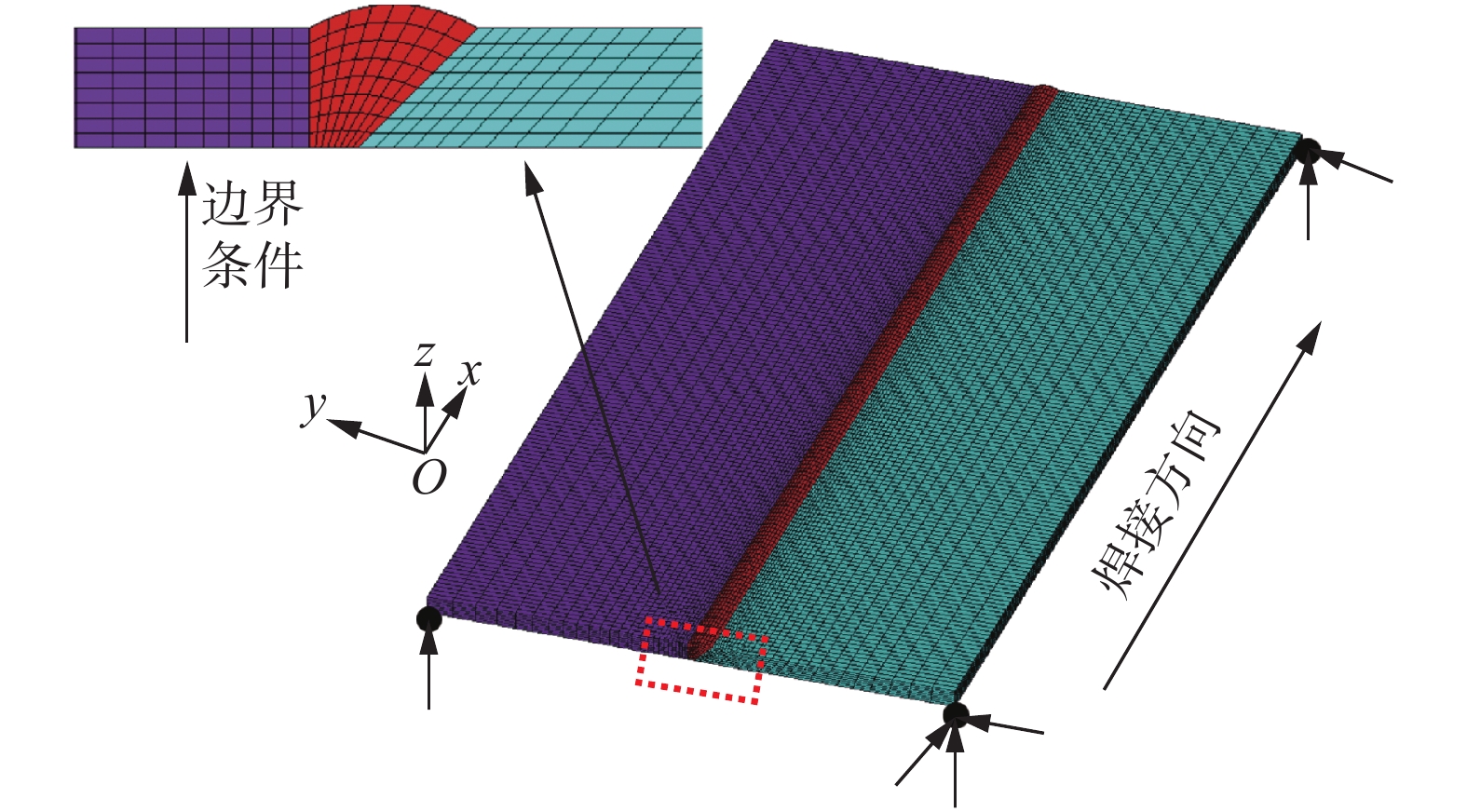

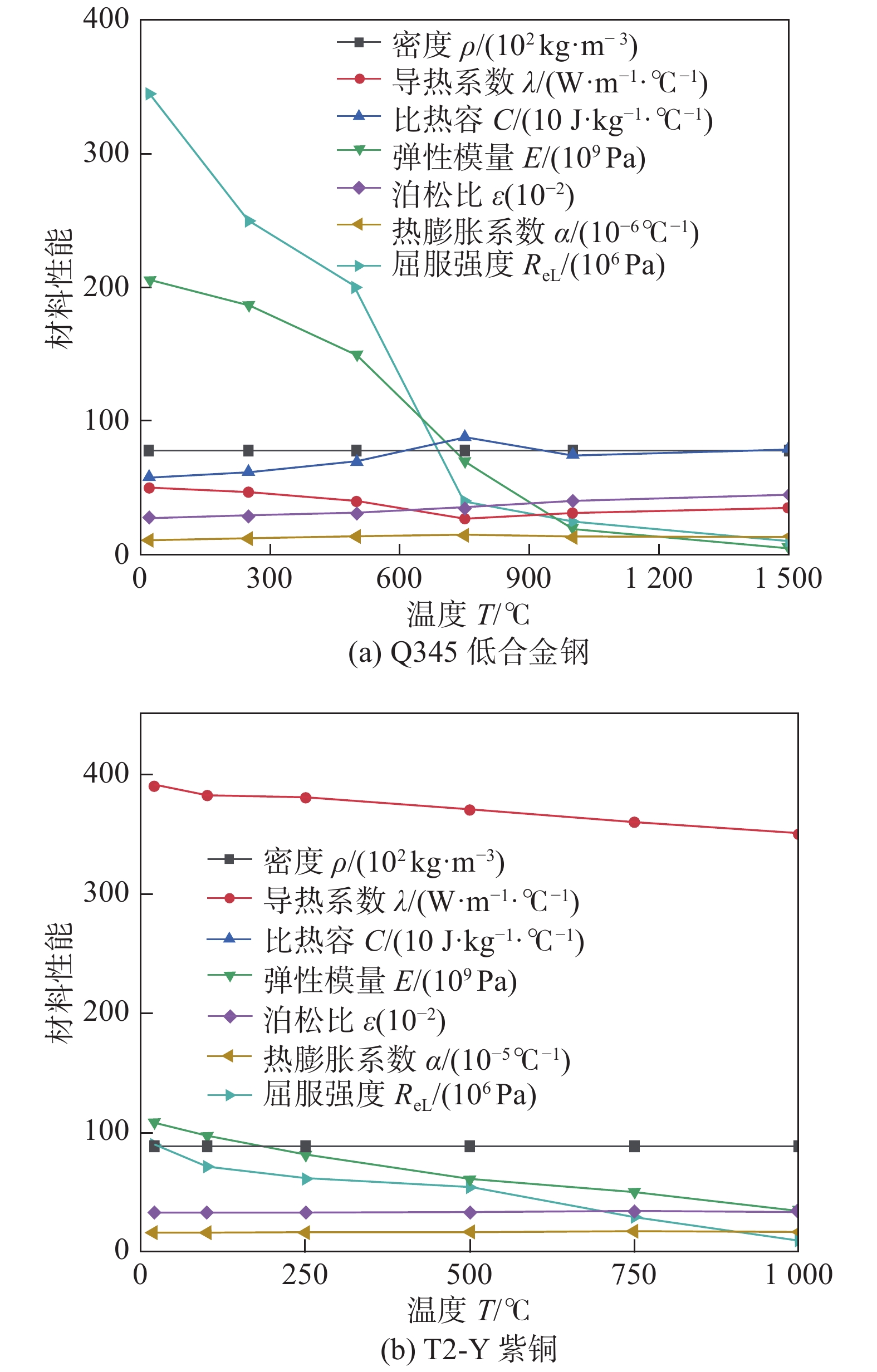

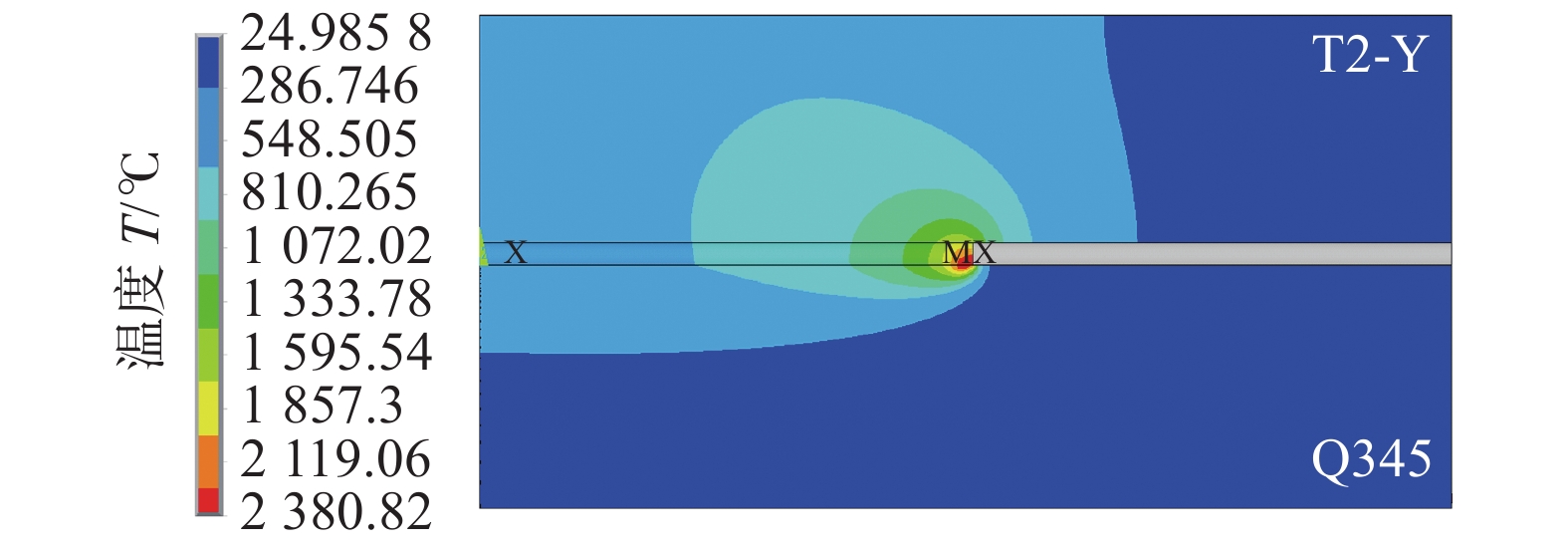

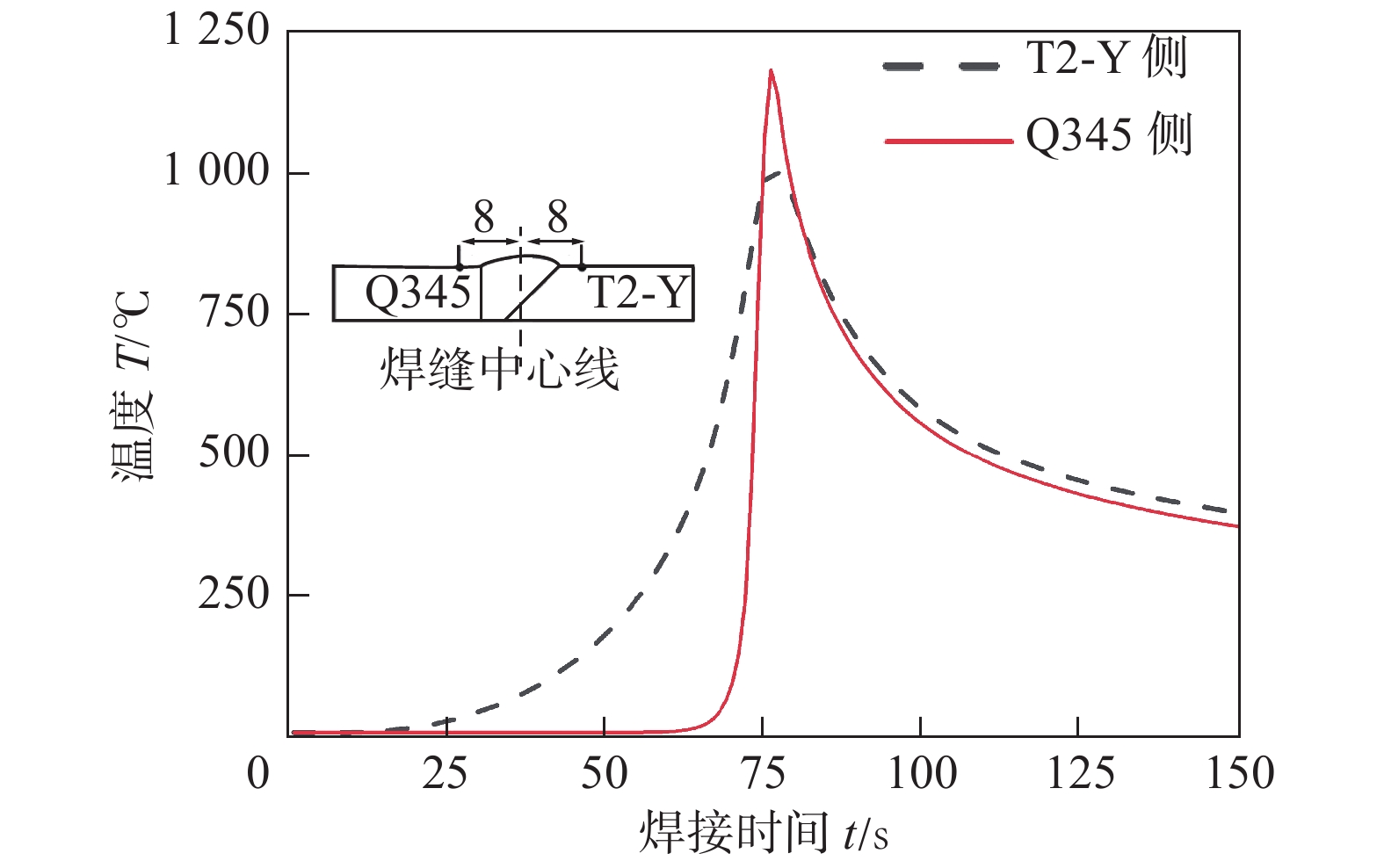

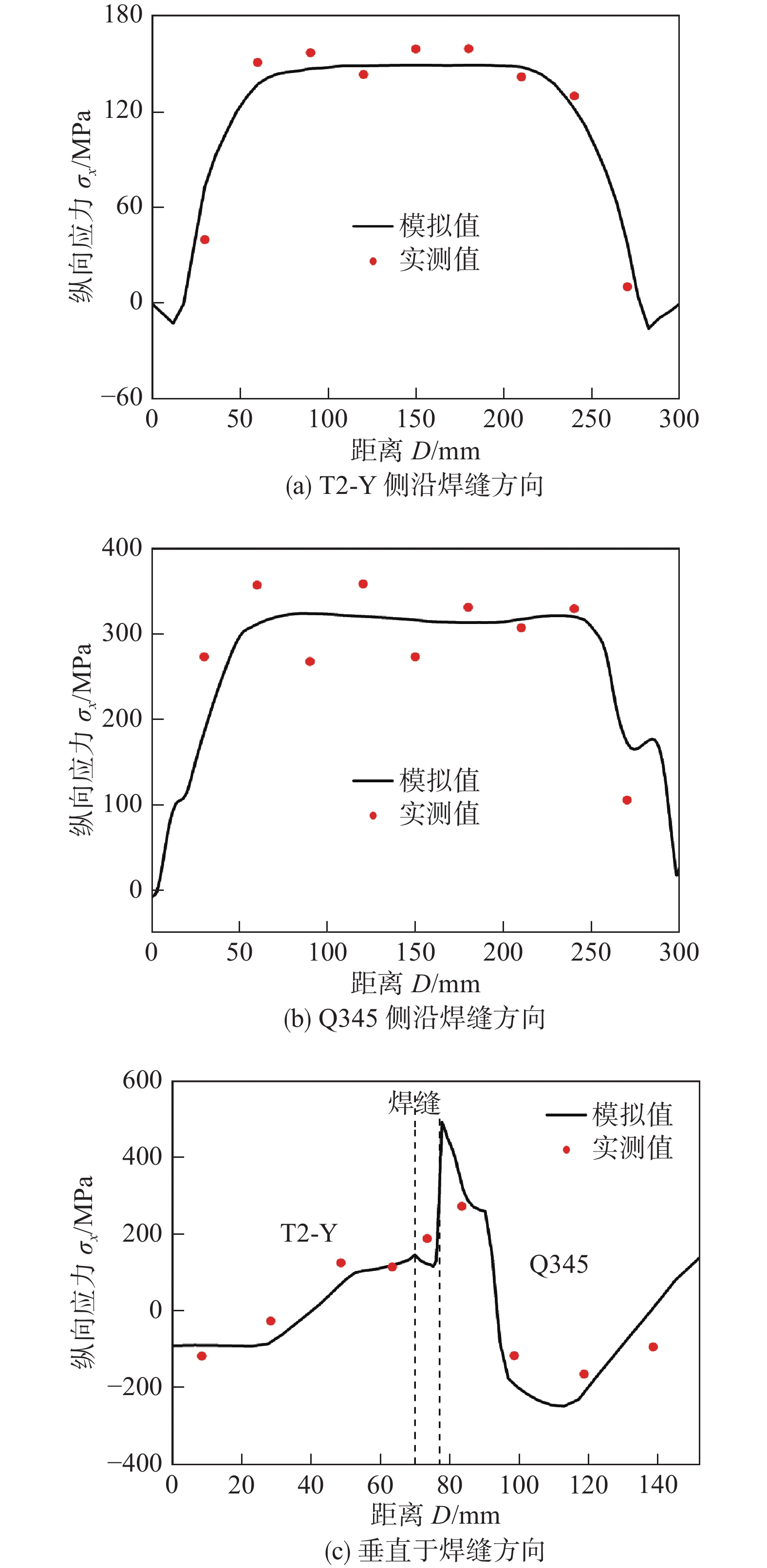

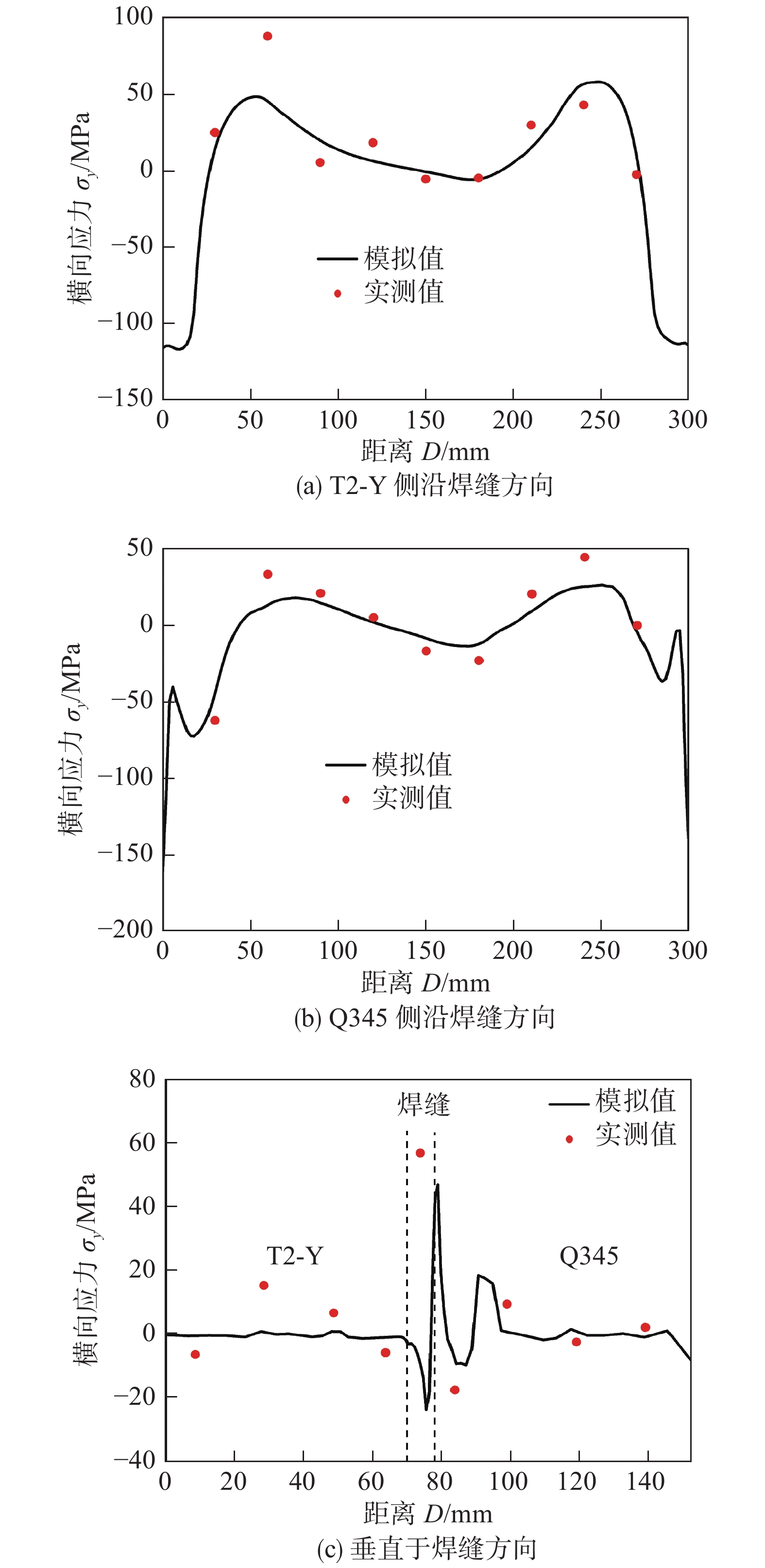

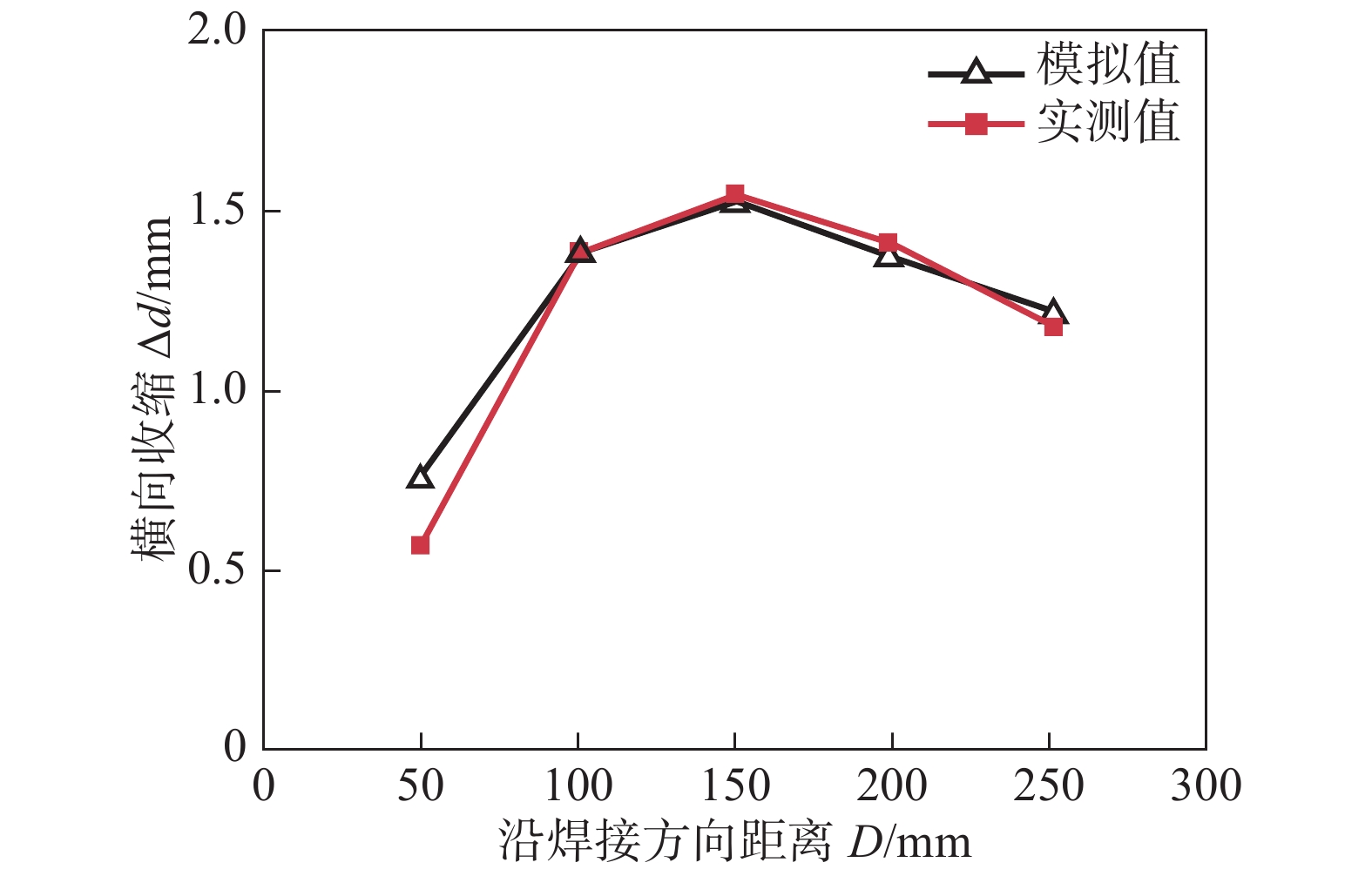

摘要: 利用ANSYS有限元软件基于APDL命令流对T2-Y/Q345异质材料平板对接接头的温度场、残余应力和横向收缩进行数值模拟计算. 同时,对焊接接头的温度、残余应力及横向收缩进行测量. 结果表明,与T2-Y侧相比,Q345侧存在较大的温度梯度. 沿焊缝方向,T2-Y与Q345侧横向应力和纵向应力分别为双驼峰状和帽状分布. 在垂直于焊缝的中央界面的上表面,纵向应力与横向应力在焊缝和热影响区的应力分布均不连续,并在Q345侧存在较大应力梯度. 此外,T2-Y/Q345横向收缩最大位置位于焊缝中间部位,且向两端逐渐减小. 数值模拟结果与试验结果相对比,两者基本吻合,验证了ANSYS有限元计算的可靠性.Abstract: Based on the APDL command flow of ANSYS finite element software to calculate the temperature field, residual stress and lateral shrinkage of the T2-Y/Q345 heterogeneous flat plate butt joint. The temperature, residual stress and lateral shrinkage of the welded joint are measured. The results show that compared with the T2-Y side, there is a larger temperature gradient on the Q345 side. Along the weld direction, the lateral stress and longitudinal stress on the T2-Y and Q345 sides are double hump-shaped and cap-shaped, respectively. On the upper surface of the central interface of the weld, the stress distribution of the longitudinal stress and the lateral stress in the weld and the heat-affected zone are discontinuous, and there is a large stress gradient on the Q345 side. In addition, the maximum lateral shrinkage of T2-Y/Q345 is at the middle part of the welding seam, which gradually decreases towards both ends. The numerical simulation results are basically agreed with the test results, which verifies the reliability of ANSYS finite element calculation.

-

0. 序言

铝/镁复合结构具有密度低、比强度高以及电磁屏蔽效应等优点,广泛应用于航空航天、轨道交通等装备制造业领域[1-3]. 铝/镁异种金属焊接时,接头易形成脆性IMCs,严重降低接头力学性能,是铝/镁异种金属连接亟待解决的难题[4-5]. FSW属于固相连接技术,可有效避免铝/镁异种金属熔化焊时出现气孔、热裂纹及热影响区(heat affected zone, HAZ)软化等问题[6-8],同时可抑制接头中脆性IMCs的形成,在铝/镁异种金属连接方面最具发展潜力[9-10].

近年来,国内外众多学者对铝/镁异种金属FSW开展大量研究,主要集中在:一是优化焊接工艺,控制转速和焊接速度改善母材塑性流动行为进而改善接头微观组织;二是引入中间层元素,对接头中IMCs种类、数量及分布进行调控,进一步提高接头强度. 研究结果表明[11-13],优化工艺参数仍无法有效避免脆性Al-Mg系IMCs的生成. 因此,近年来,引入中间层元素成为铝/镁异种金属FSW研究领域的热点. Niu 等人[14]和Gan等人[15]研究了锌中间层对铝/镁异种金属FSW接头微观组织分布特征的影响,结果表明,引入锌中间层改变了IMCs种类,接头中弥散分布的Mg-Zn IMCs代替了脆性Al-Mg系IMCs,接头抗剪强度明显提高. Zheng等人[16]研究了锡中间层对铝/镁异种金属FSW搭接接头微观组织和力学性能的影响. 结果表明,含锡接头中生成了Mg2Sn,取代了Al-Mg系IMCs,接头最大断裂载荷达3.72 kN. Liu等人[17]探讨了锌中间层厚度对铝/镁FSW接头抗拉强度的影响规律,研究发现,当中间层厚度为0.05 mm时,接头中连续分布的Al-Mg系IMCs被Mg-Zn系IMCs和Al-Mg-Zn三元系共晶组织完全取代,接头抗拉强度最高.

文献[18]表明Ni在Al和Mg中具有相当大的溶解度,在640和506 ℃时分别发生共晶反应生成Al-Ni系和Mg-Ni系IMCs. 基于此,引入0.05 mm镍中间层,采用不同FSW焊接工艺参数对铝/镁异种金属进行平板对接,对接头进行系列微观组织表征及力学性能测试,探讨工艺参数对接头中镍分布状态、IMCs种类与分布及接头强度的影响规律.

1. 试验方法

试验材料选用厚度为4 mm的AZ31镁合金和6061铝合金(供货状态T6),化学成分如表1所示. 焊件尺寸为280 mm × 150 mm × 4 mm,焊接方式为平板对焊,FSW装配示意图如图1所示. 搅拌针材质为H13钢,轴肩直径12 mm,根部直径5 mm,端部直径2 mm,针长3.7 mm. 镁合金置于前进侧,焊接工艺参数如表2所示. 金相试样用4%的硝酸酒精腐蚀镁侧10 s,用Keller试剂(6 mL HCl + 2.5 mL HNO3 + 1 mL HF)腐蚀铝侧90 s. 采用SU8010型扫描电镜(scanning electron microscope, SEM)对FSW接头微观组织进行分析,借助E1506-C2B型能谱仪(energy dispersive spectrometer, EDS)和D8 ADVANCE型X射线衍射仪(X-ray diffractometer, XRD)对接头中IMCs种类进行精确表征. 采用CMT5105型微机控制电子万能试验机对接头进行抗拉强度测试,拉伸速率为0.5 mm/min,为保证实验数据可靠性,每种焊接条件下制备了3组平行试样,测试结果取均值.

表 1 6061铝合金和AZ31镁合金的化学成分(质量分数,%)Table 1. Chemical compositions of 6061 aluminum alloys and AZ31 magnesium alloys材料 Si Fe Cu Mn Cr Zn Ti Ni Al Mg 6061 0.55 0.4 0.25 0.074 0.08 0.12 0.08 — 余量 0.8 AZ31 0.28 0.001 0.002 0.33 — 0.71 — 0.0005 2.8 余量 表 2 焊接工艺参数Table 2. Welding process parameters转速

n/(r·min−1)焊接速度

v/(mm·min−1)偏铝侧偏移量

d/mm下压量

h/mm倾角

α(°)450,550,650,

750,85020 0.3 0.2 2.5 2. 结果与讨论

2.1 引入镍中间层FSW接头微观组织

图2为不同转速下引入镍中间层铝/镁FSW接头WNZ微观组织形貌. 从图2可以看出,WNZ内母材发生明显的塑性流动而形成带状组织[19],转速不同,带状组织形貌不同.

当转速为450 r/min时,由于转速相对较低,热输入不足,致使母材塑性流动不充分,在WNZ内铝合金基体中分布着大量未完全破碎的片状镍箔颗粒,如图2a所示. 当转速增加到550 r/min时,母材塑性流动能力增强,大片状镍箔颗粒数量有所减少,且分布较为离散,如图2b所示. 转速增至850 r/min时,由于热输入过高,热塑性金属在搅拌针搅拌和轴肩挤压的双重作用下沿轴肩边缘溢出,使得WNZ内母材塑化体积减小,从而在该区域内形成了“隧道型空洞”[4].

在转速650和750 r/min时得到铝/镁异种金属FSW接头中WNZ微观组织上未观察到明显缺陷,形成了良好的机械互锁且镍元素分布较为均匀,如图2c和图2d所示. 从图2可以看出,随着转速增加,镍元素在WNZ内分布愈加均匀,但接头仍然存在片状镍箔颗粒. 相比转速650 r/min,转速为750 r/min的接头WNZ中带状组织机械互锁程度更高,而接头强度很大程度上取决于带状组织[20].

为进一步探明接头WNZ中带状组织的微观组织构成,对转速为750 r/min时接头WNZ微观组织进行SEM观察,如图3所示. 图3a为WNZ近镁侧边界处的微观组织形貌,图3b和图3c为相应的放大视图,可以看出,WNZ由呈明暗交替的黑色条带和白色IMCs所构成. 为确定IMCs种类,对接头WNZ进行XRD分析,结果如图4所示. 从图4可以看出,铝/镁异种金属FSW接头中IMCs主要为Al3Mg2,Al12Mg17及Mg2Ni,但未发现Al-Ni系IMCs. 这是由于Al-Ni系IMCs的最低生成温度约为640 ℃[21],高于铝/镁异种金属正常FSW工艺条件下的峰值温度,在焊接过程中难以形成所致.

为进一步确定接头中IMCs种类,选取图3所示5个位置,对WNZ典型IMCs进行了EDS分析,其EDS结果如表3所示. 由表3可知,白色絮状IMCs为Al12Mg17,颗粒状IMCs为Mg2Ni,灰色层状IMCs为Al3Mg2. 综上所示,镍中间层可以改变铝/镁异种金属FSW接头IMCs种类,生成颗粒状Mg2Ni抑制脆性层状Al3Mg2的形成.

表 3 WNZ内典型IMCs EDS分析结果(原子分数,%)Table 3. EDS results of typical IMCs in WNZ位置 Al Mg Ni 相 1 57.52 42.28 0.20 Al3Mg2 2 56.29 42.60 1.11 Al3Mg2 3 3.02 96.52 0.46 Mg基体 4 35.27 64.62 0.11 Al12Mg17 + Mg 5 2.16 92.47 5.37 Mg2Ni + Mg 图5为不同焊接工艺参数下铝/镁异种金属FSW接头WNZ微观组织形貌. 当转速为450 r/min时,大量镁合金条带在搅拌针的作用下沉积于WNZ底部,降低了母材的冶金结合. 当转速增加至550 r/min时,接头冶金结合效果明显改善,但大量脆性层状Al3Mg2呈长而直形态连续分布于近镁合金侧热力影响区(thermo mechanical affected zone, TMAZ)和WNZ边界处,如图5b所示. 由于Al3Mg2具有较大的室温脆性[22],在拉伸加载过程中裂纹往往于此处萌生扩展. 此外,当转速增加到650和750 r/min时,脆性层状Al3Mg2数量显著减少,且其连续分布状态得到明显改善,在WNZ内呈断续分布,如图5c和图5d所示. 由于Mg2Ni先于Al3Mg2形成[23],而Ni在WNZ内的均匀分布,促进了Mg和Ni的结合,从而抑制了脆性层状Al3Mg2的形成.

2.2 引入镍中间层FSW接头力学性能

图6为不同转速下引入镍中间层铝/镁异种金属FSW接头工程应力—应变曲线和抗拉强度. 从图6可以看出,随着转速增加,接头抗拉强度先增大后减小,当转速为750 r/min时,接头抗拉强度达到最大值121 MPa. 在较低转速下,由于材料混合不充分,致使WNZ出现“隧道型空洞”,降低了接头冶金结合效果. 在拉伸过程中,缺陷边缘处存在应力集中,严重影响接头强度. 此外,由图5b可知,在近镁合金侧TMAZ和WNZ边界处存在大量连续分布的脆性层状Al3Mg2,为裂纹的萌生和扩展提供了有利场所,加速了接头断裂失效,所以其抗拉强度较低,如图6b所示. 而在转速650 r/min下得到的FSW接头,虽无任何明显缺陷且脆性Al3Mg2数量及分布状态得到显著改善,但由于在其WNZ内存在较大体积未发生冶金反应的铝合金条带(图2c),一定程度上阻碍了母材的有效结合,机械互锁效应减弱,使得拉伸加载过程中相邻区域变形不协调,产生应力集中,加速裂纹的萌生和扩展.

当转速增加至850 r/min时,热塑性变形金属以“飞边”形式于轴肩边缘溢出,使得其在WNZ形成了“隧道型空洞”缺陷,严重降低接头强度. 而当转速为750 r/min时,接头WNZ组织均匀致密,形成了良好的机械互锁,镍的分布更加均匀,有效抑制了脆性层状Al3Mg2的生成,且断续的Al3Mg2在WNZ内呈弥散分布,显著增加了裂纹扩展阻力,因而其具有最高抗拉强度,达到镁合金的56.9%.

2.3 未引入镍中间层FSW接头组织和力学性能

图7为转速750 r/min、焊接速度20 mm/min下铝/镁异种金属FSW接头WNZ微观组织形貌. 从图7可以看出,未引入镍中间层接头WNZ存在大量呈长而直形态连续分布的脆性层状Al3Mg2,在拉伸加载过程中裂纹往往形核于此,并依附于脆性IMCs迅速扩展,严重降低接头强度,接头抗拉强度仅65 MPa,如图6b所示. 而引入镍中间层接头WNZ内Al3Mg2含量显著减少,且多为断续形态弥散分布于WNZ内,增大了裂纹扩展阻力. 此外,由于Mg-Ni系IMCs较于Al-Mg系IMCs具有较低的脆硬性[24],因而其接头强度较高.

3. 结论

(1) 与未引入中间层接头相比,引入镍改变了铝/镁异种金属FSW接头WNZ中IMCs种类及分布,WNZ存在明显的镁合金与铝合金相间的带状组织,其上分布着絮状Al12Mg17、颗粒状Mg2Ni、层状Al3Mg2及大小不一的镍箔颗粒.随着转速增加,镍箔颗粒分布愈加均匀,Al3Mg2数量相对减少,且脆性Al3Mg2由连续分布逐渐演变为断续分布.

(2) 当转速为750 r/min时,接头抗拉强度达到最大值,与未引入中间层接头相比,引入镍中间层接头抗拉强度提高了56 MPa,达到镁合金的56.9%.

-

-

[1] Shiri S G, Nazarzadeh M, Sharifitabar M, et al. Gas tungsten arc welding of CP-copper to 304 stainless steel using different filler materials[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2937 − 2942. doi: 10.1016/S1003-6326(11)61553-7

[2] 杨卫鹏, 李双吉, 朱笑睿, 等. 铜/钢异种金属CMT熔钎焊工艺研究[J]. 焊接, 2015(4): 41 − 45. doi: 10.3969/j.issn.1001-1382.2015.04.008 Yang Weipeng, Li Shuangji, Zhu Xiaorui, et al. CMT brazing-fusion welding process of dissimilar metals of Cu/steel[J]. Welding & Joining, 2015(4): 41 − 45. doi: 10.3969/j.issn.1001-1382.2015.04.008

[3] Zhang H, Ke X J, Jian L Z, et al. Microstructure and mechanical properties investigations of copper-steel composite fabricated by explosive welding[J]. Materials Science & Engineering A, 2018, 731: 278 − 287.

[4] Schasse R, Kannengiesser Th, Kromm A, et al. Residual stresses in repairwelds of high-strength low-alloy steels[J]. Welding in the World, 2015, 59(6): 757 − 765. doi: 10.1007/s40194-015-0257-9

[5] Zhang Min, Zhang Tao, Cai Junqing, et al. Effect of heat treatment on microstucture and properties of explosive welding clad plate of TA1/Q345[J]. China Welding, 2018, 27(1): 26 − 31.

[6] Bajpei T, Chelladurai H, Ansari M Z. Experimental investigation and numerical analyses of residual stresses and distortions in GMA welding of thin dissimilar AA5052-AA6061 plates[J]. Journal of Manufacturing Processes, 2017, 25: 340 − 350. doi: 10.1016/j.jmapro.2016.12.017

[7] 罗海龙, 张敏, 慕二龙, 等. Cu基药芯焊丝TIG焊TA1/Q235B接头微观组织和显微硬度[J]. 焊接学报, 2019, 40(1): 141 − 146. doi: 10.12073/j.hjxb.2019400028 Luo Hailong, Zhang Min, Mu Erlong, et al. Microstructures and microhardness of TA1/Q235B joints welded by TIG with Cu-based flux-cored wire[J]. Journal of Mechanical Engineering, 2019, 40(1): 141 − 146. doi: 10.12073/j.hjxb.2019400028

[8] 张敏, 王晓伟, 韩挺, 等. 中间Cu层对TA1/X65复合板熔焊接头性能的影响[J]. 材料研究学报, 2018, 32(2): 81 − 89. Zhang Min, Wang Xiaowei, Han Ting, et al. Effect of intermediate Cu-layer on mechanical properties of welded joints of TA1/X65 composite plate[J]. Chinese Journal of Materials Research, 2018, 32(2): 81 − 89.

[9] Ming H, Zhang Z, Wang J, et al. Microstructure of a safe-end dissimilar metal weld joint (SA508-52-316L) prepared by narrow-gap GTAW[J]. Materials Characterization, 2017, 123: 233 − 243. doi: 10.1016/j.matchar.2016.11.029

[10] Ramkumar K D, Singh A, Raghuvanshi S, et al. Metallurgical and mechanical characterization of dissimilar welds of austenitic stainless steel and super-duplex stainless steel-a comparative study[J]. Journal of Manufacturing Processes, 2015, 19: 212 − 232. doi: 10.1016/j.jmapro.2015.04.005

[11] Lee C H, Chang K H. Temperature fields and residual stress distributions in dissimilar steel butt welds between carbon and stainless steels[J]. Applied Thermal Engineering, 2012, 45: 33 − 41.

[12] 蔡建鹏, 叶延洪, 张彦杰, 等. 坡口形式对Q345/SUS304异种钢对接接头残余应力和变形的影响[J]. 机械工程学报, 2015, 51(10): 55 − 61. Cai Jianpeng, Ye Yanhong, Zhang Yanjie, et al. Study on influenceof groove type on weldingresidual stress and deformationin Q345/SUS304 dissimilar steel butt-welded joint[J]. Journal of Mechanical Engineering, 2015, 51(10): 55 − 61.

[13] 蔡建鹏, 何静, 张彦杰, 等. Q345/SUS304异种钢对接接头残余应力和变形的分析[J]. 焊接学报, 2016, 37(1): 71 − 75. Cai Jianpeng, He Jing, Zhang Yanjie, et al. Study on welding residual stress and distortion of Q345/SUS304 dissimilar steel buttweld[J]. Transactions of the China Welding Institution, 2016, 37(1): 71 − 75.

[14] 蔡建鹏, 邓德安, 蒋小华, 等. V形坡口和K形坡口Q345/SUS304异种钢对接接头残余应力和变形[J]. 焊接学报, 2016, 37(4): 69 − 72. Cai Jianpeng, Deng Dean, Jiang Xiaohua, et al. Study on weldingresidual stress and distortion in Q345/SUS304 dissimilar steel buttweld of V and K groove type[J]. Transactions of the China Welding Institution, 2016, 37(4): 69 − 72.

[15] 黄本生, 陈权, 杨江, 等. Q345/316L异种钢焊接残余应力与变形数值模拟[J]. 焊接学报, 2019, 40(2): 138 − 144. Huang Bensheng, Chen Quan, Yang Jing, et al. Numerical simulation of welding residual stress anddistortion in Q345/316L dissimilar steel[J]. Transactions of the China Welding Institution, 2019, 40(2): 138 − 144.

[16] Lee C H, Chang K H, Park J U. Three-dimensional finite element analysis of residual stresses in dissimilar steel pipe welds[J]. Nuclear Engineering and Design, 2013, 256: 160 − 168. doi: 10.1016/j.nucengdes.2012.12.016

[17] Xia J, Jin H. Numerical analysis for controlling residual stresses in welding design of dissimilar materials girth joints[J]. International Journal of Precision Engineering and Manufacturing, 2018, 19(1): 57 − 66. doi: 10.1007/s12541-018-0007-1

[18] Goldak J, Chakravarti A, Bibby M. A new finite element model for welding heat sources[J]. Metallurgical Transactions B, 1984, 15(2): 299 − 305. doi: 10.1007/BF02667333

[19] 朱春沅, 李桓, 黄超群, 等. 2219铝合金焊接残余应力分布分析[J]. 焊接学报, 2017, 38(11): 32 − 36. doi: 10.12073/j.hjxb.20160122001 Zhu Chunyuan, Li Huan, Huang Chaoqun, et al. Study on residual stress distribution of 2219 aluminum alloy[J]. Transactions of the China Welding Institution, 2017, 38(11): 32 − 36. doi: 10.12073/j.hjxb.20160122001

[20] Zhu X K, Chao Y J. Effects of temperature-dependent material properties on welding simulation[J]. Computers & Structures, 2002, 80(11): 967 − 976.

[21] Sadeghian M, Shamanian M, Shafyei A. Effect of heat input on microstructure and mechanical properties of dissimilar joints between super duplex stainless steel and high strength low alloy steel[J]. Materials & Design, 2014, 60: 678 − 684.

-

期刊类型引用(10)

1. 邵善家,李延葆,米大为. 压水堆堆内构件钴基合金堆焊组织和性能研究. 焊接技术. 2025(03): 82-86 .  百度学术

百度学术

2. 杨文选,王玥,郭玲玲,李佳乐,徐超. 进给距离对激光-电复合熔覆层组织及性能的影响. 激光与红外. 2024(02): 202-207 .  百度学术

百度学术

3. 任维泽,段绪星,裴泽宇,陈青,赵子锐. 激光熔覆钴基合金研究进展及其在核领域的应用展望. 金属热处理. 2024(04): 264-273 .  百度学术

百度学术

4. 陈乐,洪晓峰,魏光强,丁睿智,古博,宁方强. 激光熔覆Stellite 6合金涂层的耐磨耐蚀性能研究. 激光杂志. 2024(06): 210-214 .  百度学术

百度学术

5. 卞宏友,王美男,刘伟军,邢飞,王慧儒,徐效文,霍庆生. DZ125合金激光沉积CoCrW涂层的组织与性能. 热加工工艺. 2024(19): 121-127+131 .  百度学术

百度学术

6. 赵天碕,赵吉宾,何振丰,王志国,赵宇辉,陈燕. 304LN表面沉积异质合金过程多组元传输行为数值模拟. 表面技术. 2024(19): 141-152 .  百度学术

百度学术

7. 张楷,高辉,林渊浩,邵明启. 基于RSM和NSGA-Ⅱ算法的同轴送粉氩弧熔覆工艺参数分析. 焊接学报. 2024(12): 106-116 .  本站查看

本站查看

8. 田鹿岩,李新梅,路国闯. 42crmo钢表面激光熔覆Stellite6复合熔覆层组织及性能. 应用激光. 2024(12): 29-37 .  百度学术

百度学术

9. 乔园园,袁正武,刘年明,刘卓谞,梁蕊. 下承式钢结构拱桥拱肋焊接质量控制研究. 焊接技术. 2023(05): 160-164 .  百度学术

百度学术

10. 杨高林,郑权航,钱浩凯,樊文,张群莉,石岳林,姚建华. 宽高比对激光熔覆道间熔合不良的影响机制及改善策略. 焊接学报. 2023(10): 49-56+135-136 .  本站查看

本站查看

其他类型引用(10)

下载:

下载: