Microstructure and mechanical properties of joints of a new Al-Mg-Mn-Er alloy by TIG welding

-

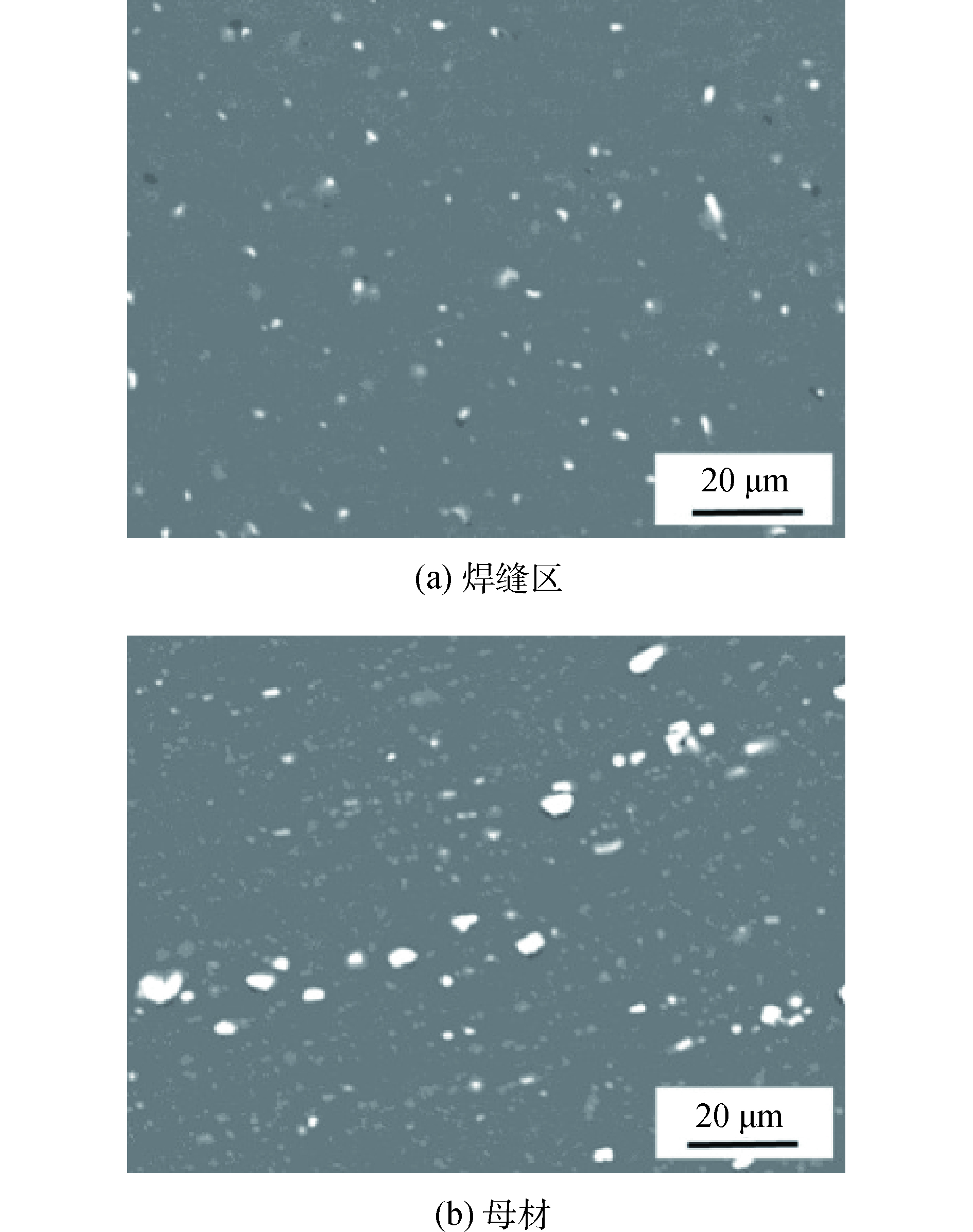

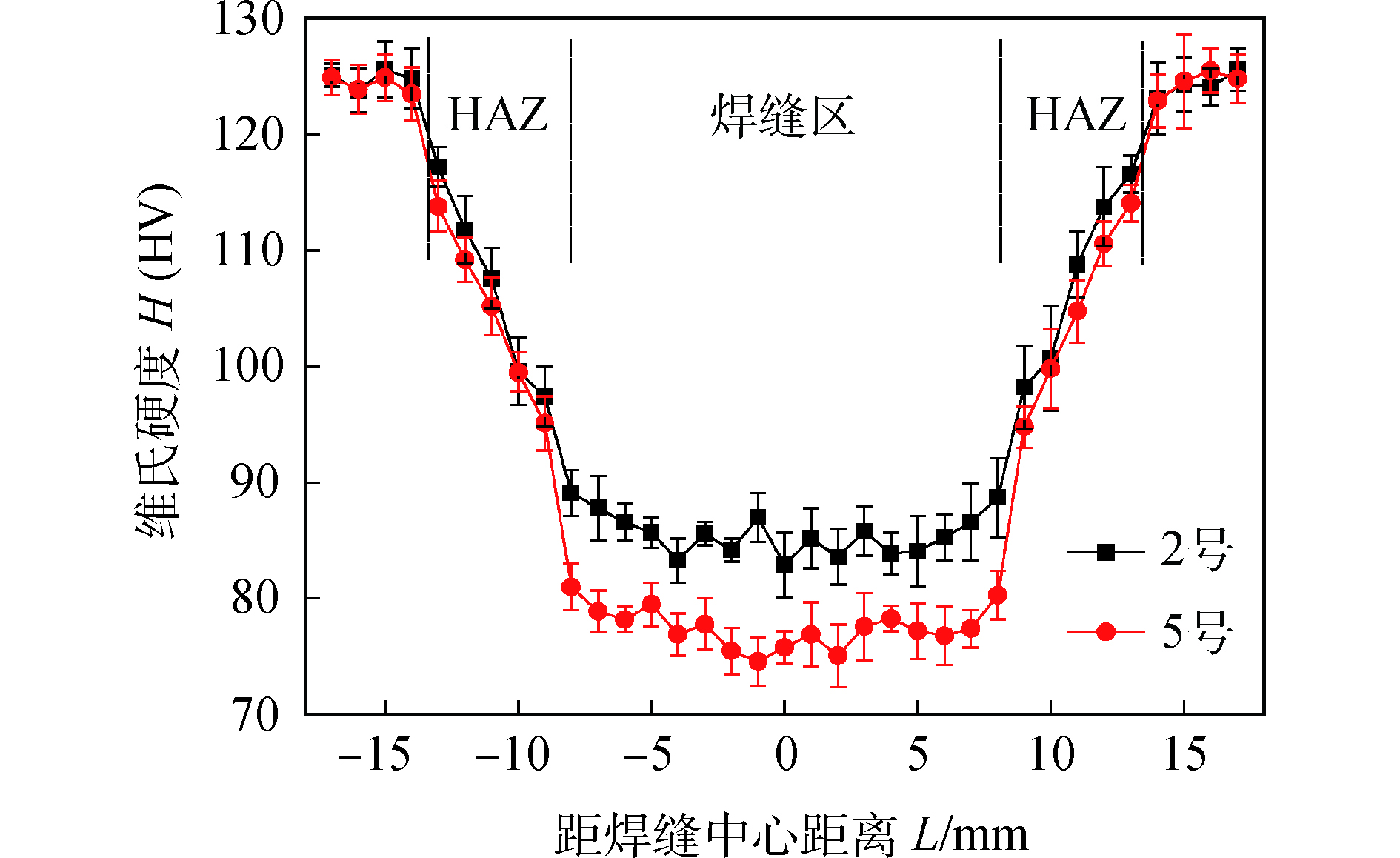

摘要: 对一种Al-Mg-Mn-Er合金薄板进行TIG填丝焊接,并研究接头的微观组织以及力学性能. 结果表明,焊缝中心为等轴树枝晶,熔合线附近未出现典型的联生结晶形貌,而是存在着一个宽度约为100 μm的细晶带,热影响区出现再结晶组织. 焊缝中的析出相主要以初生Al3Er的形式存在,与母材相比,焊缝中初生Al3Er的尺寸更加细小,分布更加均匀,焊缝中次生Al3Er的数量相对较少,而且这些次生Al3Er是焊接时母材中未熔化而保留下来的. 焊接区和热影响区的硬度均低于母材,其中焊缝区的硬度最低. 随着焊接热输入的增加,接头的抗拉强度先增加后减小,当焊接热输入为218 J/mm时,接头的抗拉强度最高,达到母材的71.4%,试样的断裂位置均位于焊缝区,断口形貌呈现韧性断裂特征.

-

关键词:

- Al-Mg-Mn-Er合金 /

- TIG焊 /

- 微观组织 /

- 力学性能

Abstract: New Al-Mg-Mn-Er alloy sheets were welded by TIG welding with filler wires. The microstructure and mechanical properties of the joints were studied. The results show that the center of the weld seam is mainly composed of equiaxed crystals. There is no typical epitaxial solidification appeared, but a fine-grained zone with width of 100 μm is formed near the fusion line. The recrystallized structure is appeared in the heat affected zone. The precipitates in the weld zone mainly exist in the form of primary Al3Er. Compared with the base metal, the size of primary Al3Er in the weld seam is smaller and its distribution is more uniform. The number of secondary Al3Er in the weld seam is relatively small and the secondary Al3Er is from the base metal. The microhardness of the weld zone and the heat affected zone are lower than that of base metal, and the microhardness of the weld zone is the lowest. With the increase of the welding heat input, the tensile strength of the joints increases first and then decreases. When the welding heat input is 218 J/mm, the tensile strength of the joint is the highest which is 71.4% of that of the base metal. The fracture of all tensile samples is located at the weld zone, and the fracture morphology shows the typical ductile fracture characteristics.-

Keywords:

- Al-Mg-Mn-Er alloy /

- TIG welding /

- microstructure /

- mechanical properties

-

-

表 1 TIG焊工艺参数

Table 1 TIG welding parameters

编号 焊接电流

I/A焊接电压

U/V焊接速度

v/(mm·s−1)热输入

E/(J·mm−1)1 75 16.5 5 198 2 80 17.0 5 218 3 85 17.6 5 239 4 90 18.2 5 262 5 100 19.1 5 306 表 2 XRF检测结果(质量分数,%)

Table 2 XRF testing results

区域 Al Mg Mn Er 母材 94.41 4.58 0.65 0.36 焊缝区 96.10 2.98 0.59 0.33 表 3 拉伸试验结果

Table 3 Tensile test average results

序号 热输入E/(J·mm−1) 抗拉强度Rm/MPa 接头系数φ(%) 断裂位置 1 198 297 70.7 焊缝 2 218 300 71.4 焊缝 3 239 292 69.5 焊缝 4 262 288 68.6 焊缝 5 306 285 67.9 焊缝 母材 — 420 — — -

[1] 周民, 甘培原, 邓鸿华, 等. 含钪微合金化铝合金研究现状及发展趋势[J]. 中国材料进展, 2018, 37(2): 154 − 160. Zhou Min, Gan Peiyuan, Deng Honghua, et al. Research status and prospect of Sc microalloying aluminum alloys[J]. Materials China, 2018, 37(2): 154 − 160.

[2] Liu T H, Wen S P, Wu X L, et al. Effect of trace element Hf on the precipitation process and recrystallization resistance of Al-Er-Zr alloys[J]. Materials Science Forum, 2017, 898: 3 − 8. doi: 10.4028/www.scientific.net/MSF.898.3

[3] Moreira P M G P, Figueiredo M A V D, Castro P M S T D. Fatigue behaviour of FSW and MIG weldments for two aluminium alloys[J]. Theoretical and Applied Fracture Mechanics, 2007, 48(2): 169 − 177. doi: 10.1016/j.tafmec.2007.06.001

[4] Zhou Li, Zhang Mingjun, Jin Xiangzhong, et al. Study on the burning loss of magnesium in fiber laser welding of an Al-Mg alloy by optical emission spectroscopy[J]. International Journal of Advanced Manufacturing Technology, 2017, 88(5-8): 1373 − 1381. doi: 10.1007/s00170-016-8867-y

[5] Jiang Xunyan, Cheng Donghai, Chen Yiping, et al. The superplastic deformation of electron beam welded aluminum lithium alloy[J]. China Welding, 2018, 27(1): 41 − 45.

[6] Li Yonggang, Wei Yinghui, Hou Lifeng, et al. Effect of erbium on microstructures and properties of Mg-Al intermetallic[J]. Journal of Rare Earths, 2014, 32(11): 1064 − 1072. doi: 10.1016/S1002-0721(14)60184-8

[7] Yang Junjun, Nie Zuoren, Jin Tounan, et al. Effect of trace rare earth element Er on high pure Al[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(5): 1035 − 1039.

[8] Kostrivas A, Lippold J C. Fusion boundary microstructure evolution in aluminium alloys[J]. Welding in the World, 2006, 50(11-12): 24 − 34. doi: 10.1007/BF03263458

[9] 王祝堂, 田荣璋.铝合金及其加工手册[M]. 长沙: 中南大学出版社, 1989. [10] Wen S P, Gao K Y, Li Y, et al. Synergetic effect of Er and Zr on the precipitation hardening of Al-Er-Zr alloy[J]. Scripta Materialia, 2011, 65(7): 592 − 595. doi: 10.1016/j.scriptamat.2011.06.033

[11] Mondolfo L F. 铝合金的组织与性能[M]. 王祝堂等译. 北京: 冶金工业出版社, 1988. [12] Mark C C. Improvements to the strength and corrosion resistance of Al-Mg-Mn alloys of near-AA5083 chemistry[D]. Columbus: The Ohio State University, 2001.

[13] Wen S P, Xing Z B, Huang H, et al. The effect of erbium on the microstructure and mechanical properties of Al-Mg-Mn-Zr alloy[J]. Materials Science and Engineering A, 2009, 516(1): 42 − 49.

[14] 温林秀, 赵运强, 董春林, 等. 1561铝合金搅拌摩擦焊接过程压力特征及接头组织性能分析[J]. 焊接学报, 2019, 40(12): 91 − 96. Wen Linxiu, Zhao Yunqiang, Dong Chunlin, et al. Analysis on characteristics of welding pressure,microstructures and mechanical properties of friction stir welded 1561 aluminum alloy[J]. Transactions of the China Welding Institution, 2019, 40(12): 91 − 96.

[15] 陈澄, 薛松柏, 孙乎浩, 等. 5083铝合金TIG焊接头组织与性能分析[J]. 焊接学报, 2016, 44(6): 92 − 97. Chen Cheng, Xue Songbai, Sun Huhao, et al. Microstructure and mechanical properties of 5083 aluminum alloy joint by TIG welding[J]. Transactions of the China Welding Institution, 2016, 44(6): 92 − 97.

[16] 闫德俊, 李海洋, 刘晓莉, 等. 船用5083铝合金变极性等离子焊接头组织和性能[J]. 稀有金属材料与工程, 2018, 47(10): 3161 − 3166. Yan Dejun, Li Haiyang, Liu Xiaoli, et al. Microstructure and mechanical properties of variable polarity plasma arc welded joints of 5083 aluminum alloy for shipbuilding[J]. Rare Metal Material and Engineering, 2018, 47(10): 3161 − 3166.

[17] 聂祚仁, 文胜平, 黄晖, 等. 铒微合金化铝合金的研究进展[J]. 中国有色金属学报, 2011, 21(10): 2361 − 2370. Nie Zuoren, Wen Shengping, Huang Hui, et al. Research progress of Er-containing aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2361 − 2370.

-

期刊类型引用(2)

1. 艾孝文,龚建勋,李再华. Cr对Fe-Cr-C-Nb-V系堆焊合金组织及耐磨性的影响. 兵器材料科学与工程. 2024(03): 42-48 .  百度学术

百度学术

2. 关帅,曲洺剑,闫屾,申玉龙,那晓晨,李泰华. 高硬度过共晶高铬铸铁的合金化与热处理工艺研究. 阀门. 2023(04): 432-435 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: