Study on phase and texture of TC17(α + β)/TC17(β) linear friction welding joint

-

摘要: 利用电子背散射衍射技术对TC17(α + β)/TC17(β)钛合金线性摩擦焊接头测试并分析,对接头各区域进行相鉴定和织构分析. 结果表明,与母材相比,焊态接头两侧热力影响区α相减少,β相增多. 由于焊缝区冷却迅速快,焊态焊缝处发生动态再结晶,生成了大量的亚稳定β相晶粒. TC17(β)侧母材及热力影响区的织构分布密度比TC17(α + β)侧强,且焊态焊缝区产生(5 4 6)[1

$\bar 3 \; \bar 3$ ]织构,轧面与(1 1 1)近似平行. 经过610 ℃热处理后,焊缝区亚稳定β相发生分解,形成细小的次生α相和β相. 与焊态焊缝相比,热处理后焊缝区晶体稍有转动,焊缝区织构强度较焊态有较大增强,形成(5 5 7)[$\overline {11}\; \overline {17}$ 20]织构. 热处理前后的焊缝区晶体取向都存在着ND方向与[1 1 1]靠近,轧面与(111)接近平行的择优取向.Abstract: The linear friction welded joints of TC17(α + β)/TC17(β) titanium alloy were tested and analyzed by electron backscatter diffraction technique. Phase identification and texture analysis were carried out on each part of the joint. The results show that compared with the parent metal, the α phase of thermo-mechanically affected zone decreases, and the β phase of the joint increases as weld. Due to the rapid cooling of the weld zone, dynamic recrystallization occurs at the weld joint, and a large number of metastable β phase grains are formed. The texture distribution density of TC17(β) side base metal and thermo-mechanically affected zone is stronger than TC17(α + β) side. The joint displayed texture (5 4 6)[1$\bar 3$ $\bar 3$ ] in the as-welded weld zone. The rolling plane is approximately parallel to (1 1 1). After heat treatment at 610 °C, the metastable β phase of the weld zone decomposes to form a fine secondary α phase and β phase. Compared with the as-welded weld, the crystal of the weld zone is slightly rotated after postweld heat treatment, and the texture strength development, exhibited (5 5 7)[$\overline {11}\; \overline {17}$ 20] texture. The crystal orientation of the weld zone has a preferred orientation in which the normal direction is close to [1 1 1] and the rolling plane is close to (1 1 1).-

Keywords:

- linear friction welding /

- titanium alloy /

- electron backscatter diffraction /

- texture

-

0. 序言

线性摩擦焊(linear friction welding,LFW)是一种集摩擦学、塑性加工等学科和技术为一体的先进固相焊接技术[1-2]. 线性摩擦焊能够实现非轴对称、复杂截面、同质及异质材料的固相焊接. 能有效防止熔焊中易出现的偏析、裂纹、气孔等问题,成为当前国内外公认的理想航空发动机整体叶盘制造与维修的关键技术.

TC17是一种富β稳定元素的α-β型两相钛合金,名义成分为Ti-5Al-2Sn-2Zr-4Mo-4Cr. TC17钛合金既适用于在两相区进行常规锻造和近β锻造,得到高周疲劳性能好的双态或者等轴组织;又适用于在单相区进行β锻造,获得具有抗裂纹扩展能力好的网篮组织[3].

线性摩擦焊焊接过程的特殊性,焊接时接头温度达到钛合金相变温度,接头处发生剧烈地塑性变形,接头产生较强织构. 目前国内外对于线性摩擦焊同种材料异种组织的钛合金接头织构分析还鲜有报道,利用电子背散射衍射(EBSD)技术研究钛合金线性摩擦焊接头织构与相分布,进而分析线性摩擦焊接头织构及组织对力学性能的影响,对于提高接头质量,发展中国高推重比航空发动机具有重要意义[4].

1. 试验方法

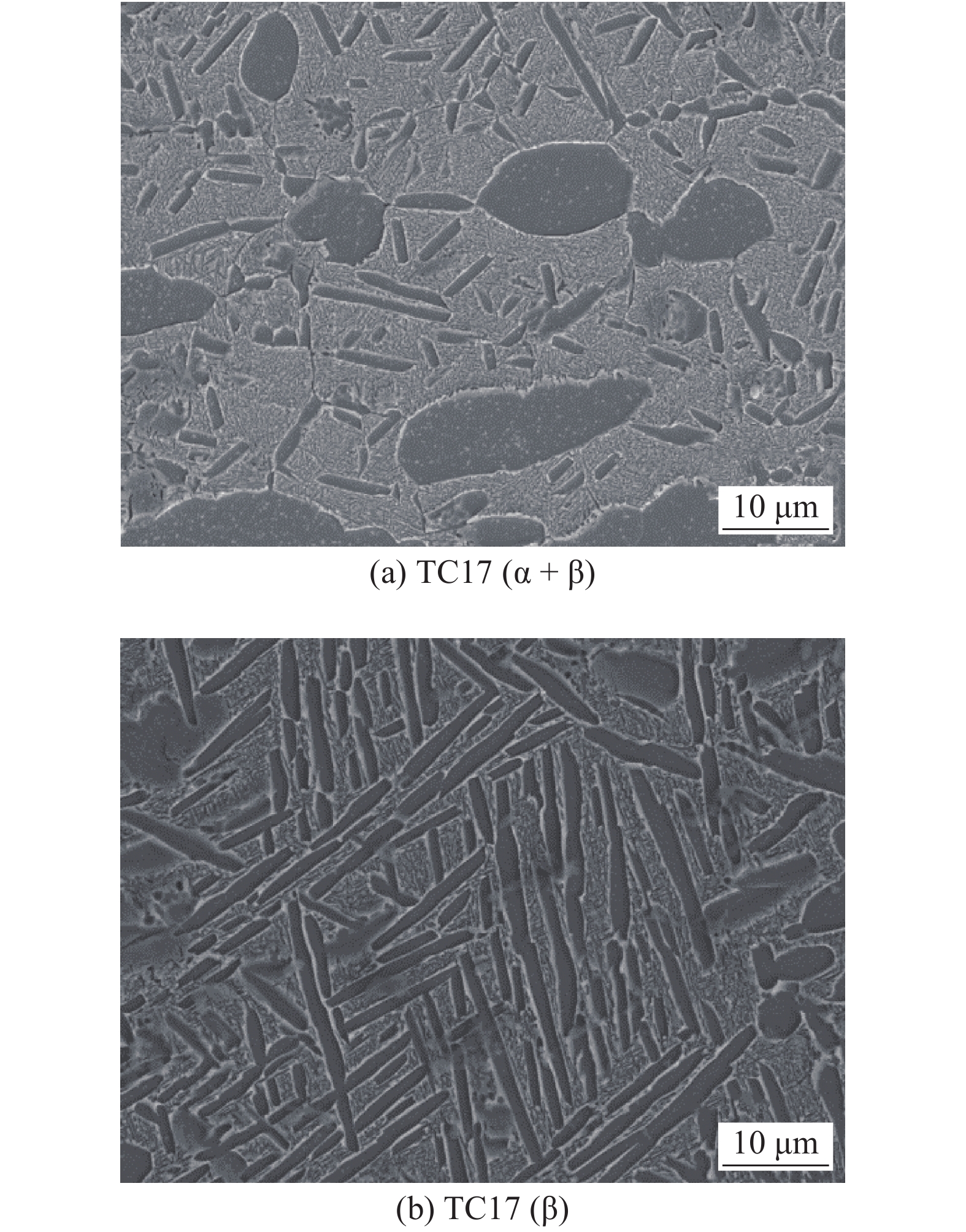

试验采用两种锻造工艺的TC17钛合金. 两种材料的化学成分如表1所示.一种为常规锻造下的TC17钛合金,它具有双态组织;另一种是β区锻造的TC17钛合金,该母材具有网篮组织,组织形貌如图1所示.

表 1 TC17钛合金的化学成分(质量分数,%)Table 1. Chemical compositions of TC17 titanium材料 Al Sn Zr Mo Cr Fe Ti TC17(α + β) 5.07 2.06 2.05 3.80 3.99 0.15 余量 TC17(β) 5.10 2.0 1.90 4.10 3.9 0.04 余量 采用中国航空制造技术研究院自行研制的LFW-60T型线性摩擦焊机进行焊接试验. EBSD试验采用JSM 7001F扫描电子显微镜配备EDAX-TSL系统,获取到清晰的菊池花样后,使用EBSD数据处理软件EDAX-TSL进行数据处理. EBSD试验中,试样测试面与水平方向倾斜,如图2所示. 试验选取锻造方向(RD)为垂直焊接界面方向,横向(TD)与法线方向(ND)组成的平面平行于焊接界面. 文中EBSD扫描时使用β相进行标定,试样采用610 ℃温度下,保温时间3 h,随炉冷却的焊后热处理工艺(PWHT).

2. 试验结果及分析

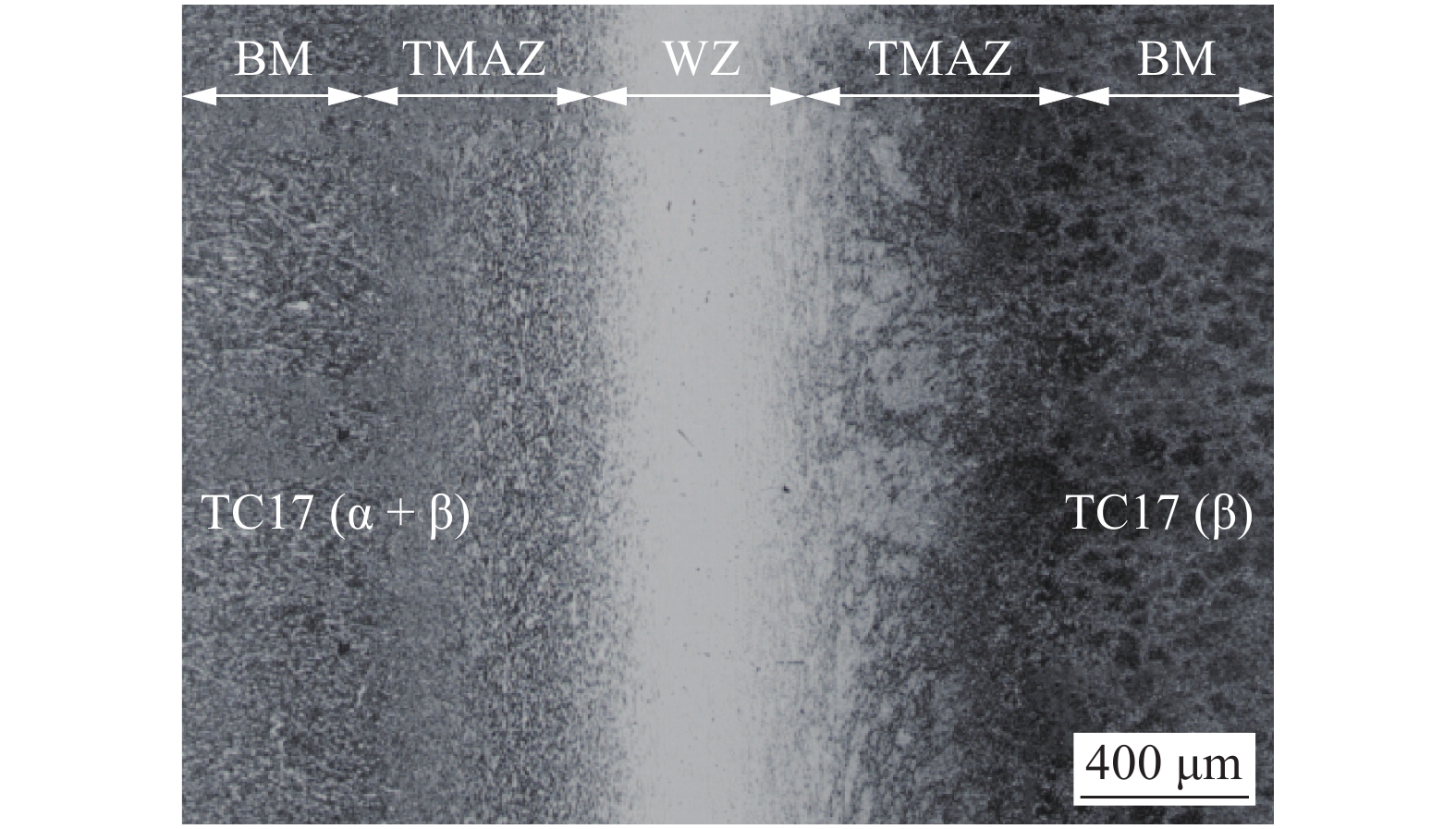

TC17(α + β)/TC17(β)钛合金线性摩擦焊接头从组织特点上可分为5个区域[5]:TC17(α + β)母材区(BM)、TC17(α + β)热力影响区(TMAZ)、焊缝区(WZ)、TC17(β)热力影响区、TC17(β)母材区,如图3所示.

2.1 相鉴定

2.1.1 焊态接头各区域相鉴定

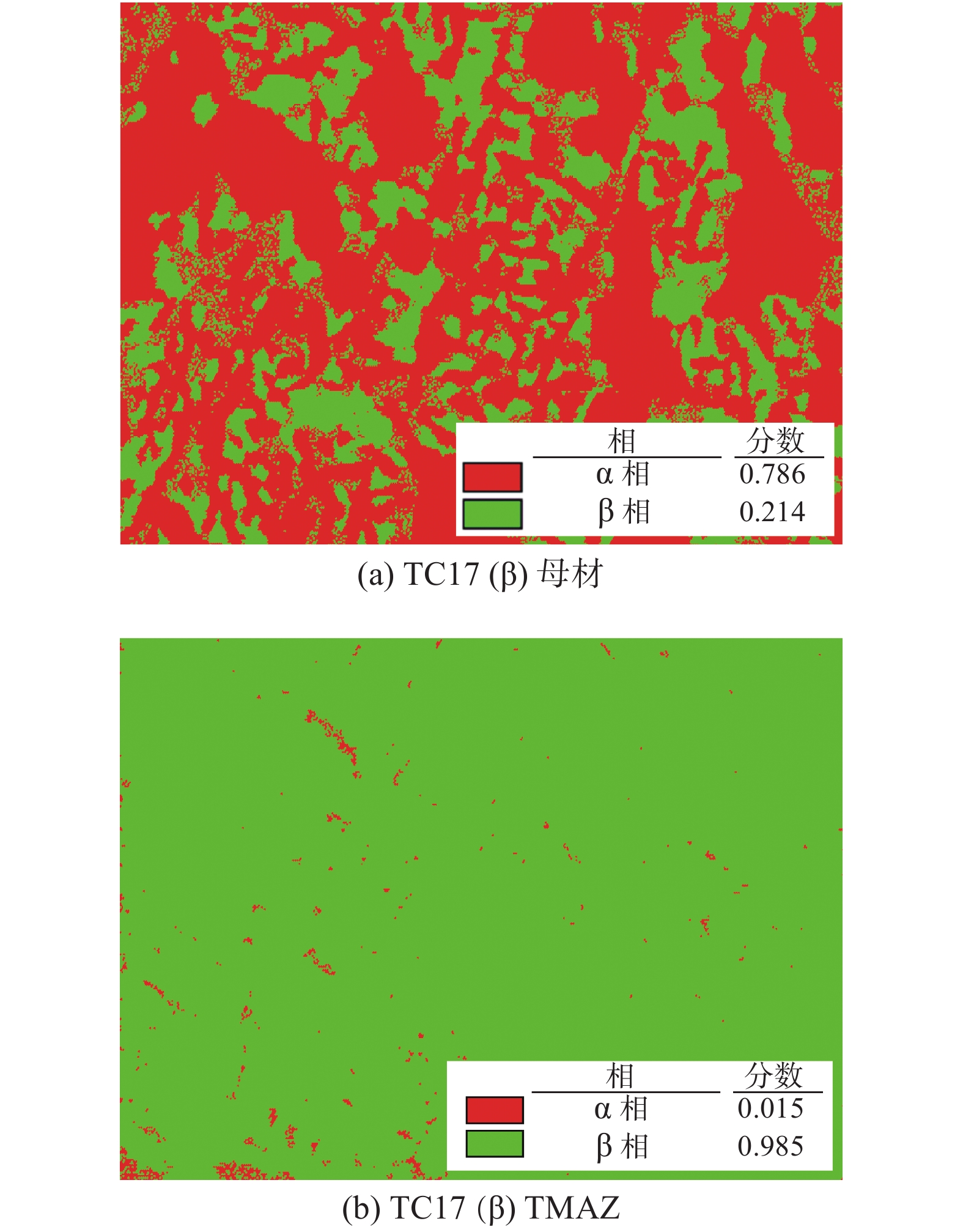

EBSD技术可以区分相的结晶学关系,可对7大晶系任意对称的物质标定[6]. 接头各区域相分布及各相面积百分比如图4 ~ 图6所示,TC17钛合金由α和β两相组成,深色为α相,浅色为β相. 如图4a所示,TC17(α + β)母材中α相含量占71.3%,而β相含量占28.7%. 母材金属经过热和力的共同作用后,TMAZ在α + β相区温度内变形,初生α相分解生成β相. α相含量下降,β相含量上升,如图4b所示. TC17(β)母材和热力影响区相鉴定如图5所示,因为母材是在β相区锻造,该区域的网篮组织由大量的α相构成,β相只占21.4%. 焊接过程中,TC17(β)热力影响区在α + β相区温度范围内发生严重变形,该区域发生动态再结晶,网篮状α相片层组织发生相变,片层状α转变为β相,导致β相增多.

图6为焊态焊缝中心相鉴定图. 焊态下的焊缝区域β相占99.8%,表明线性摩擦焊焊缝区域已经达到了β转变温度,在焊后快速冷却的过程中,由于焊缝冷却速度快,焊缝处保留了大量的亚稳定β相晶粒,但仍有微小的α相晶粒在焊缝处依附杂质点优先形核.

2.1.2 热处理后接头各区域相鉴定

接头经过热处理后,TC17(α + β)侧接头组织发生了明显变化,如图7所示. TC17(α + β)母材中β转变基体的次生α相片层细化,初生α相等轴化,β相含量增加. TC17(α + β)侧热力影响区中β相中弥散析出α相,β相含量降低. 热处理后TC17(β)侧接头相鉴定,TC17(β)母材相鉴定如图8a所示,网篮状的α相层片厚度减小,母材α相含量提高. 经过热处理后TC17(α + β)TMAZ中的β相分解析出层片状的α相,β相含量大幅度降低,α相含量提高到60.3%,如图8b所示.

图9所示为热处理后的焊缝中心相分布图. 焊后热处理使得焊缝区动态再结晶生成的亚稳定β相分解,再结晶晶粒内部为细小的次生α相和β相. 其中β相含量较低,α相含量高达72.1%. 这是由于β相为高温相,焊缝区金属经过610 ℃热处理后,焊缝区两相组元平衡所致.

2.2 TC17(α + β)/TC17(β)接头各区域织构

2.2.1 焊态接头各区域织构

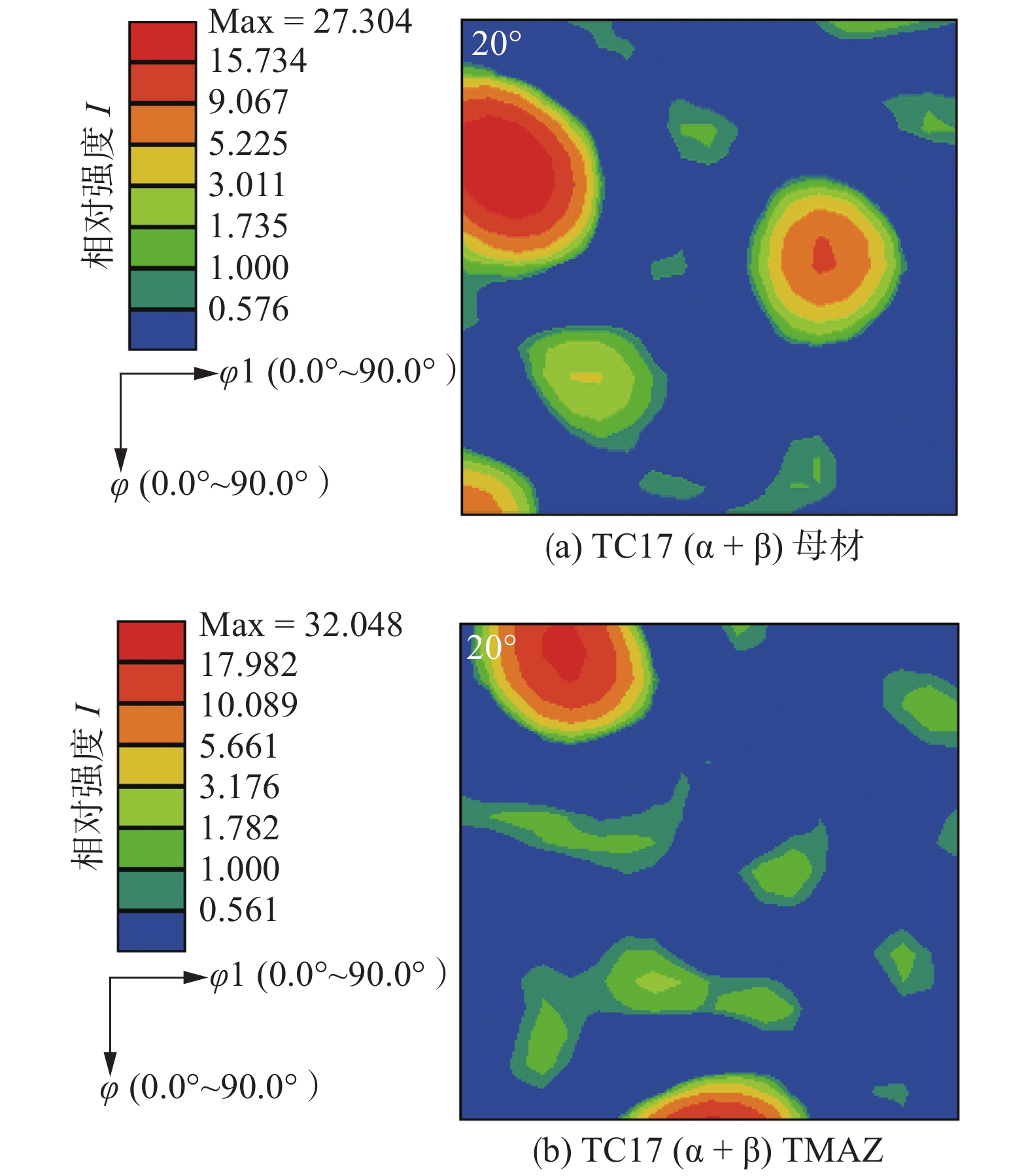

图10为焊态接头TC17(α + β)侧的取向分布函数(ODF)图. 图10a为TC17(α + β)母材区域φ2 = 75°的ODF截面图,从中可知该母材中主要织构为(15 4 5)[1

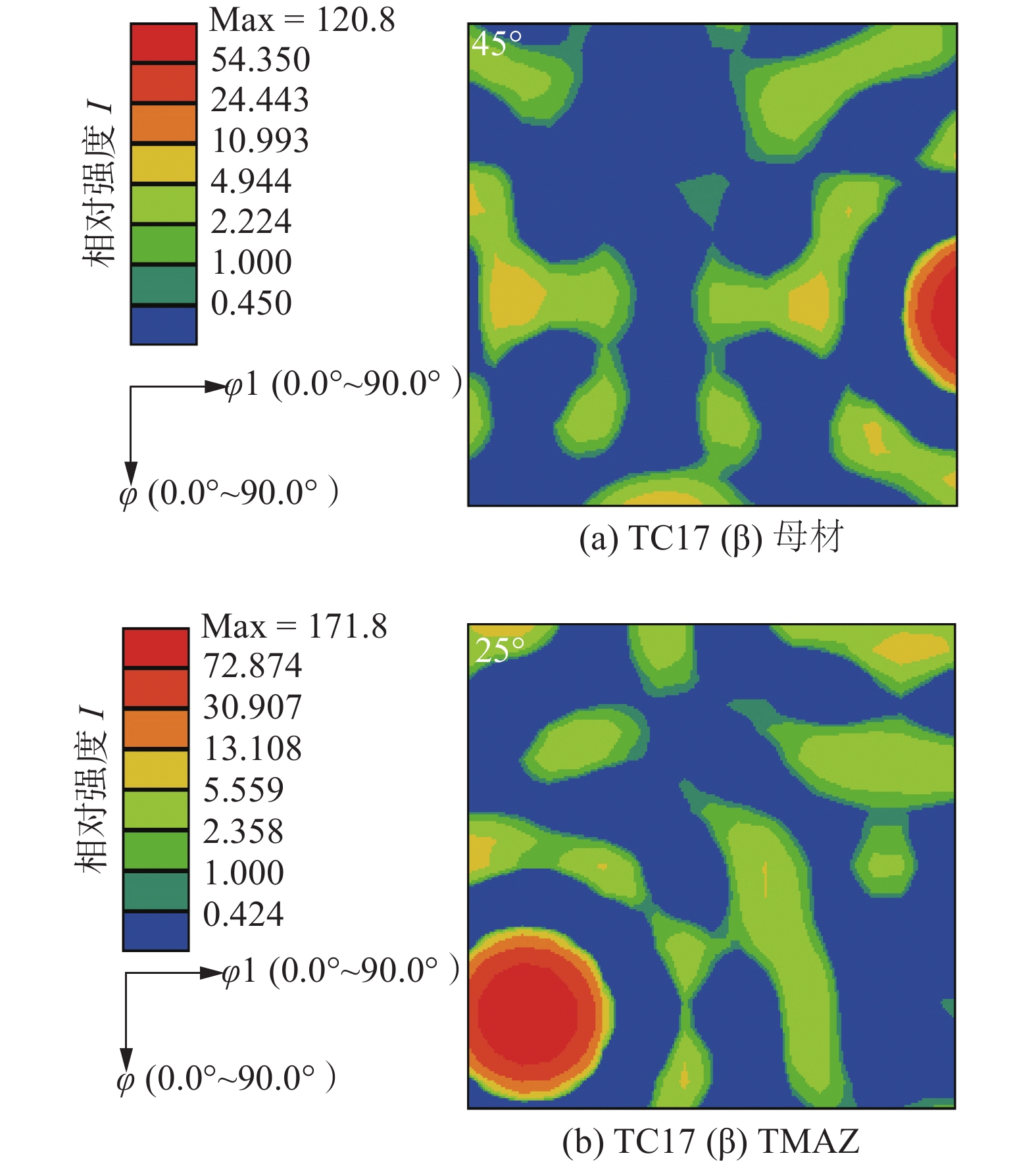

$\overline {10}$ 5],这是母材在锻造过程中产生的织构. 而图10b为TC17(α + β)热力影响区φ2 = 70°的ODF恒φ2截面图,对比图10a可知,TMAZ中(9 3 22)[1$\overline {3}$ 0]织构是由于焊接时,母材受到热和力的共同作用,晶体滑移、转动,引起了该晶体的取向变化,产生了热加工织构. 焊态接头TC17(β)侧区域取向分布函数图,图11a所示为TC17(β)母材φ2 = 45°的ODF截面图. 该母材中存在(1 1 1)[$\overline {1}$ $\overline {1}$ 2]的基面织构. 因热力影响区发生动态再结晶,(1 1 1)[$\overline {1}$ $\overline {1}$ 2]的基面织构组分消失,产生了(16 35 10)[35$\overline {18}$ 7]织构,一定程度上反映出再结晶晶粒在焊接过程中吞噬(1 1 1)[$\overline {1}$ $\overline {1}$ 2]取向变形晶粒的现象,如图11b所示. 由于具有网篮组织的TC17(β)母材有α相集束,所以接头TC17(β)侧织构分布密度比TC17(α + β)侧强.焊态焊缝处的取向分布函数截面图如图12所示. 焊接时,在摩擦热的作用下,焊缝区金属加热到粘塑性状态. 在随后的摩擦剪切力和顶锻力的共同作用下,塑性金属被挤出焊接界面,形成飞边,焊缝区发生动态再结晶,产生(5 4 6)[1

$\overline {3}$ $\overline {3}$ ]织构,轧面与(1 1 1)平面近似平行. 由于塑性变形过程导致金属内生成变形织构,动态再结晶过程会造成再结晶织构,但因两过程同时或交替进行,使两类织构均不能得到充分发展,所以经过热变形后形成的焊缝区织构强度很弱.2.2.2 热处理后接头各区域织构

线性摩擦焊在经过热处理后,接头残余应力降低,晶粒长大[7];同时焊缝区的亚稳定β相组织在热处理后,发生相变,生成α相,使得接头两侧热处理前后织构类型发生不同程度的改变,如图13 ~ 图14所示. 图13a和图13b分别为TC17(α + β)母材和热力影响区φ2 = 20°ODF截面图,经过热处理后母材中主要织构为(3 10 19)[7

$\overline {4}$ 1],织构强度较焊态有所降低,而TC17(α + β)热力影响区中主要是(1 3 23)[16$\overline {13}$ 1]织构. 这是因为线性摩擦焊焊接过程中,热力影响区金属发生严重变形[8-10],晶格发生畸变,变形组织结构中存在着以位错为主的晶体缺陷. 这使得热力影响区内保留了一定的储存能,并成为再结晶的驱动力. 再结晶通常包含再结晶晶核的形成,并涉及大角度晶界迁移的晶核生成过程. 热处理后畸变能释放,高缺陷密度的变形基体被新晶粒取代. TC17(α + β)热力影响区中发生再结晶,大量α相晶粒形核且长大(图13b),生成再结晶织构. 图14a所示为TC17(β)母材φ2 = 80°的ODF截面图,该热处理后母材中存在(6 1 1)[$\overline {2}$ $\overline {9}$ 21]的织构. TC17(β)热力影响区在热处理后晶体取向稍有转动,存在(6 18 1)[11$\overline {4}$ 6]织构,如图14b所示.热处理后焊缝处的取向分布函数截面图如图15所示. 与焊态焊缝相比,热处理后焊缝区晶体稍有转动,焊缝区织构强度较焊态有较大增强,形成(5 5 7)[

$\overline {11}$ $\overline {17}$ 20]织构. 热处理前后的焊缝区晶体取向都存在着ND方向与[1 1 1]靠近,轧面与(111)接近平行的择优取向.3. 结论

(1) 利用电子背散射衍射技术,对TC17(α + β)/TC17(β)钛合金线性摩擦焊接头进行了相鉴定. 接头两侧热力影响区α相减少,β相增多. 由于焊缝冷却速度快,焊态焊缝处保留了大量的亚稳定β相晶粒. 热处理后,焊缝区动态再结晶生成的亚稳定β相发生分解,形成细小的次生α相和β相.

(2) 网篮组织的TC17(β)母材具有α相集束,TC17(β)侧母材织构分布密度比TC17(α + β)侧母材强. 焊态焊缝区产生(5 4 6)[1

$\overline {3}$ $\overline {3}$ ]织构,轧面与(1 1 1)近似平行.(3) 与焊态焊缝相比,热处理后焊缝区晶体稍有转动,焊缝区织构强度较焊态有较大增强,形成(5 5 7)[

$\overline {11}$ $\overline {17}$ 20]织构. 热处理前后的焊缝区晶体取向都存在着ND方向与[1 1 1]靠近,轧面与(111)接近平行的择优取向. -

表 1 TC17钛合金的化学成分(质量分数,%)

Table 1 Chemical compositions of TC17 titanium

材料 Al Sn Zr Mo Cr Fe Ti TC17(α + β) 5.07 2.06 2.05 3.80 3.99 0.15 余量 TC17(β) 5.10 2.0 1.90 4.10 3.9 0.04 余量 -

[1] Vairis A, Frost M. On the extrusion stage of linear friction welding of Ti6Al4V[J]. Materials Science and Engineering, 1999, 271: 477 − 484. doi: 10.1016/S0921-5093(99)00449-9

[2] 常川川, 张田仓, 李菊. Ti-22Al-27Nb合金线性摩擦焊接头组织与显微硬度分析[J]. 焊接学报, 2019, 40(3): 146 − 150. Chang Chuanchuan, Zhang Tiancang, Li Ju. Study on microstructure and microhardness of linear friction welded joints of Ti-22Al-27Nb alloy,[J]. Transactions of the China Welding Institution, 2019, 40(3): 146 − 150.

[3] 田伟, 伏宇, 钟燕, 等. 锻造工艺对TC17钛合金的显微组织和力学性能的影响[J]. 材料热处理学报, 2016, 37(9): 57 − 61. Tian Wei, Fu Yu, Zhong Yan, et al. Effects of forging process on microstructure and properties of TC17 titanium alloy[J]. Transactions of Materials and Heat Trearment, 2016, 37(9): 57 − 61.

[4] 李菊, 张田仓, 郭德伦, 等. TC17(α + β)/TC17(β)钛合金线性摩擦焊接头组织与力学性能[J]. 航空制造技术, 2015, 472(3): 68 − 70. Li Ju, Zhang Tianchang, Guo Delun, et al. Structure and mechanical property of TC17(α + β) and TC17(β) linear friction welding joint[J]. Aeronautical Manufacturing Technology, 2015, 472(3): 68 − 70.

[5] Anthony R McAndrew, Paul A Colegrove, Clement Bühr, et al. A literature review of Ti-6Al-4V linear friction welding[J]. Progress in Materials Science, 2018, 92: 225 − 257. doi: 10.1016/j.pmatsci.2017.10.003

[6] Ma T J, Zhong B, Li W Y, et al. On microstructure and mechanical properties of linear friction welded dissimilar Ti-6Al-4V and Ti-6.5Al-3.5Mo-1.5Zr-0.3Si joint[J]. Science and Technology of Welding & Joining, 2012, 17(1): 9 − 12.

[7] Yang X, Li W, Li J, et al. Finite element modeling of the linear friction welding of GH4169 superalloy[J]. Materials & Design, 2015, 87: 215 − 230.

[8] 张传臣, 张田仓, 刘颖. TA15线性摩擦焊接头高周疲劳性能分析[J]. 焊接学报, 2018, 39(5): 105 − 108. Zhang Chuanchen, Zhang Tiancang, Liu Ying. Cycle fatigue properties of TA15 titanium alloy linear friction welded joint[J]. Transactions of the China Welding Institution, 2018, 39(5): 105 − 108.

[9] 季亚娟, 张田仓, 张连锋, 等. TC17钛合金线性摩擦焊接头组织及性能[J]. 焊接学报, 2019, 40(9): 156 − 160. Ji Yajuan, Zhang Tiancang, Zhang Lianfeng, et al. Structure and mechanical property of TC17 linear friction welding joint[J]. Transactions of the China Welding Institution, 2019, 40(9): 156 − 160.

[10] 张传臣, 黄继华, 张田仓, 等. 异质钛合金线性摩擦焊接头显微组织与显微硬度分析[J]. 焊接学报, 2012, 33(4): 97 − 100. Zhang Chuanchen, Huang Jihua, Zhang Tiancang, et al. Investigation on microstructure and microhardness of linear firction welded joints of dissimilar titanium alloys[J]. Transactions of the China Welding Institution, 2012, 33(4): 97 − 100.

-

期刊类型引用(4)

1. 张群兵,东拓,谭猛猛,门浩翔,张建勋. TC17钛合金激光焊接接头微观组织和力学性能. 机械制造文摘(焊接分册). 2024(02): 1-5 .  百度学术

百度学术

2. 张春波,袁明强,周军,全威,孙佳佳,乌彦全,王志永. 42CrMo/GH4169异种金属惯性摩擦焊工艺. 焊接. 2023(08): 6-13 .  百度学术

百度学术

3. 何光进,李川,吴厦,李昊瑜,陈大军,付扬帆,刘正涛,代野,莫非,江波. 铝合金线性摩擦焊研究现状. 精密成形工程. 2022(06): 131-140 .  百度学术

百度学术

4. 李睿,周军,张春波,乌彦全,梁武,秦丰. TC4/Ti17异质钛合金线性摩擦焊接头组织及力学性能. 机械制造文摘(焊接分册). 2021(02): 11-17 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: