Effect of ultrasonic power on microstructure and properties of 2219-T351 aluminum alloy friction stir welding joint

-

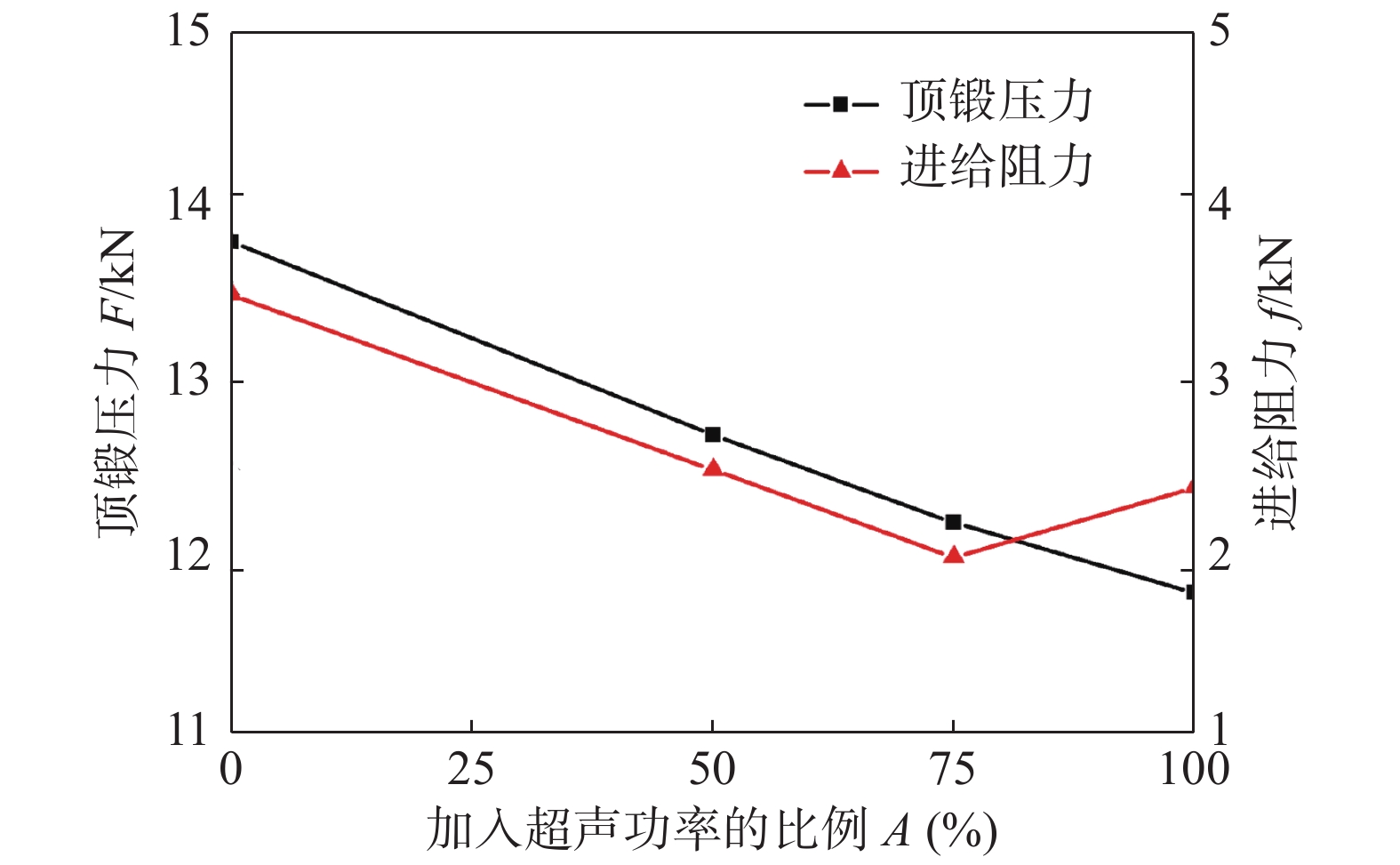

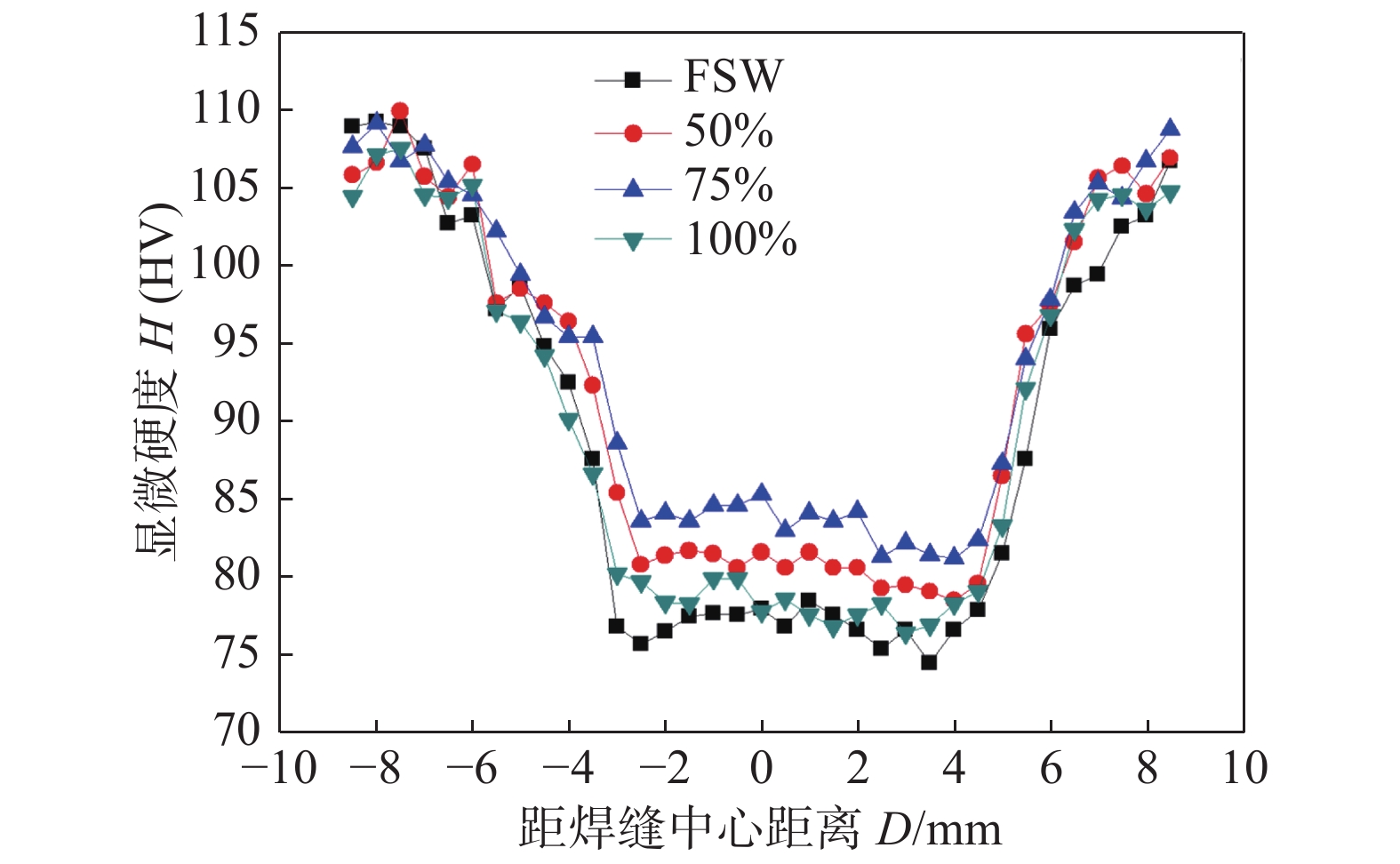

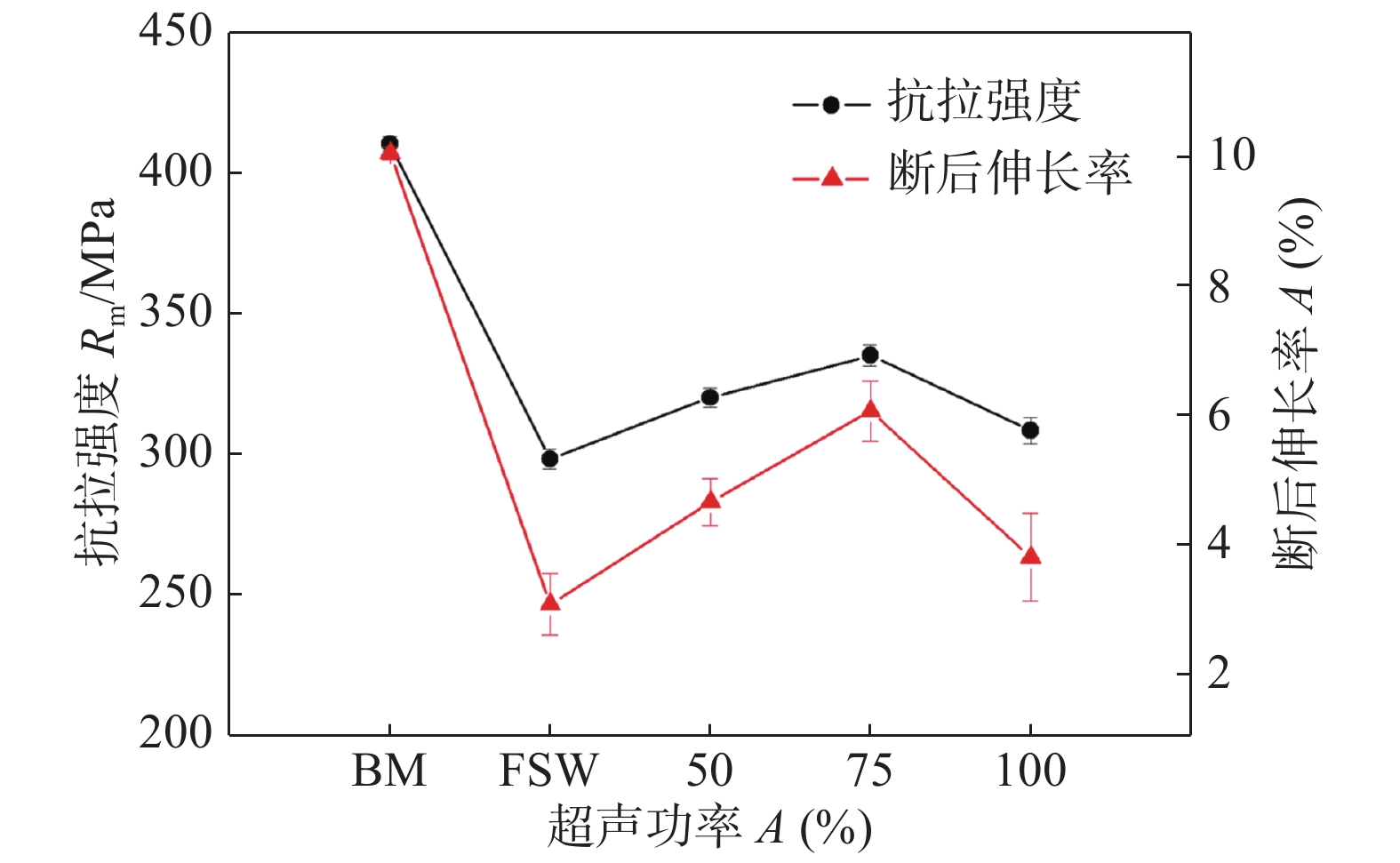

摘要: 采用搅拌摩擦焊和不同功率的超声辅助搅拌摩擦焊对2219-T351铝合金进行焊接试验,测量焊接温度和焊接压力,对焊接接头的微观组织、显微硬度和力学性能进行分析,研究了加入不同超声功率后焊缝的组织性能和材料流动性. 结果表明,超声能降低焊接温度,随着超声功率增加减小的幅度越大. 加入了超声后,焊缝微观组织更加均匀,底部材料的流动情况得到改善,焊缝区有更多的强化相残留,焊接接头的显微硬度、抗拉强度及断后伸长率在加入超声后均有提高,在加入2.25 kW的超声功率时达到最高,最高拉伸强度为331 MPa,可达到母材的80%左右.Abstract: Aluminum alloy 2219-T351plates were welded by friction stir welding and ultrasonic assisted friction stir welding with different power. The welding temperature and welding pressure were investigated. Microstructure, microhardness and mechanical properties of welds under different ultrasonic powers were analyzed. The microstructure and material fluidity of the weld with different ultrasonic power were researched. Experimental results showed that Ultrasonic energy can reduce the welding temperature and welding force. With the action of ultrasound, the microstructure of the weld is more uniform, and the fluidity of the bottom material is improved. There is more residual reinforcement phase in the weld zone. The microhardness, tensile strength and elongation of the welded joints are all improved under ultrasonic. All the magnitudes reached the highest when adding 2.25 kW ultrasonic power. The highest tensile trength is 331 MPa, which can reach about 80% of the base metal.

-

Keywords:

- friction stir welding /

- ultrasonic /

- welding temperature /

- microstructure /

- mechanical properties

-

-

-

[1] 杜波, 杨新岐, 孙转平,等. 2219-T87铝合金拉锻式摩擦塞补焊接头组织及性能[J]. 焊接学报, 2019, 40(2): 128 − 132. Du Bo, Yang Xinqi, Sun Zhuanping, et al. Microstructure and properties of 2219-T87 aluminum alloy friction pull plug welds[J]. Transactions of the China Welding Institution, 2019, 40(2): 128 − 132.

[2] 杨坤玉, 贺地求, 李东辉. 2519A铝合金超声辅助搅拌摩擦焊接试验分析[J]. 焊接学报, 2018, 39(6): 39 − 42. Yang Kunyu, He Diqiu, Li Donghui. Experimental analysis of 2519A aluminum alloy ultrasonic assisted friction stir welding[J]. Transactions of the China Welding Institution, 2018, 39(6): 39 − 42.

[3] Liu H J, Feng X L. Effect of post-processing heat treatment on microstructure and microhardness of water-submerged friction stir processed 2219-T6 aluminum alloy[J]. Materials and Design, 2013, 47(9): 101 − 105.

[4] Witthauer A T, Kim G Y, Faidley L E, et al. Effects of acoustic softening and hardening in high-frequency vibration-assisted punching of aluminum[J]. Materials and Manufacturing Processes, 2014, 29(10): 1184 − 1189. doi: 10.1080/10426914.2014.921704

[5] Hung J C, Hung C. The influence of ultrasonic-vibration on hot upsetting of aluminum alloy[J]. Ultrasonics, 2005, 43(8): 692 − 698. doi: 10.1016/j.ultras.2005.03.001

[6] Liu X C, Wu C S. Material flow in ultrasonic vibration enhanced friction stir welding[J]. Journal of Materials Processing Technology, 2015, 225: 32 − 44. doi: 10.1016/j.jmatprotec.2015.05.020

[7] 曹秒艳, 李建超, 杨卓云, 等. 超声振动对板材固体颗粒介质成形的影响[J]. 中国有色金属学报, 2016, 26(10): 2118 − 2127. Cao Miaoyan, Li Jianchao, Yang Zhuoyun, et al. Effect of ultrasonic vibration on solid granules medium forming of sheet metals[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2118 − 2127.

[8] Liu Z W, Rakita M, Han Q, et al. Microstructural evolution of reinforcements in the remelting in situ TiC/Al–12Si composites treated by ultrasonic vibration[J]. Materials Research Bulletin, 2011, 46(10): 1674 − 1678. doi: 10.1016/j.materresbull.2011.06.003

[9] 贺地求, 梁建章. 超声搅拌焊接方法及其装置: 中国, 200610004059.3[P]. 2006−01−26. [10] Li B, Shen Y. The investigation of abnormal particle-coarsening phenomena in friction stir repair weld of 2219-T6 aluminum alloy[J]. Materials and Design, 2011, 32(7): 3796 − 3802. doi: 10.1016/j.matdes.2011.03.029

[11] 姚喆赫. 超声能场在金属微/介观成形中的作用理论及试验研究[D]. 杭州: 浙江大学, 2016. [12] Chen S, Jiang X. Texture evolution and deformation mechanism in friction stir welding of 2219Al[J]. Materials Science and Engineering A, 2014, 612(9): 267 − 277.

[13] 许晓嫦, 刘志义, 党朋, 等. 研究强塑性变形过程中第二相回溶现象的现状及发展趋势[J]. 金属热处理, 2005, 30(4): 1 − 6. doi: 10.3969/j.issn.0254-6051.2005.04.001 Xu Xiaochang, Liu Zhiyi, Dang Peng, et al. Current situation and development of the research on re-dissolution of second phase during serve plastic deformation[J]. Transactions of Metal Heat Treatment, 2005, 30(4): 1 − 6. doi: 10.3969/j.issn.0254-6051.2005.04.001

[14] Ma H K, He D Q, Liu J S. Ultrasonically assisted friction stir welding of aluminium alloy 6061[J]. Science and Technology of Welding and Joining, 2015, 20(3): 216 − 221. doi: 10.1179/1362171814Y.0000000275

下载:

下载: