Multiple regression model of process for aluminum alloy self-piercing riveting based on ball-shaped die

-

摘要:

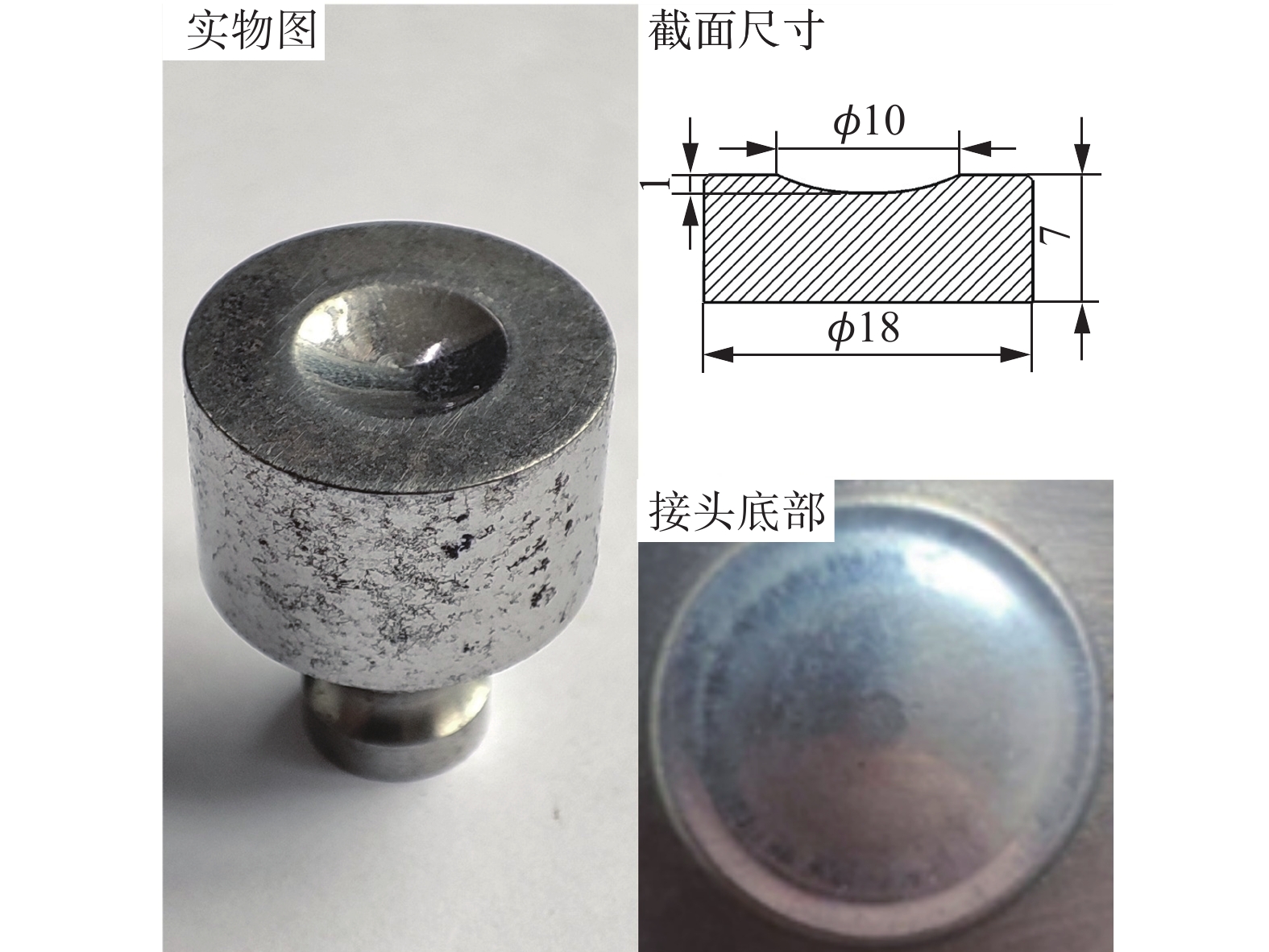

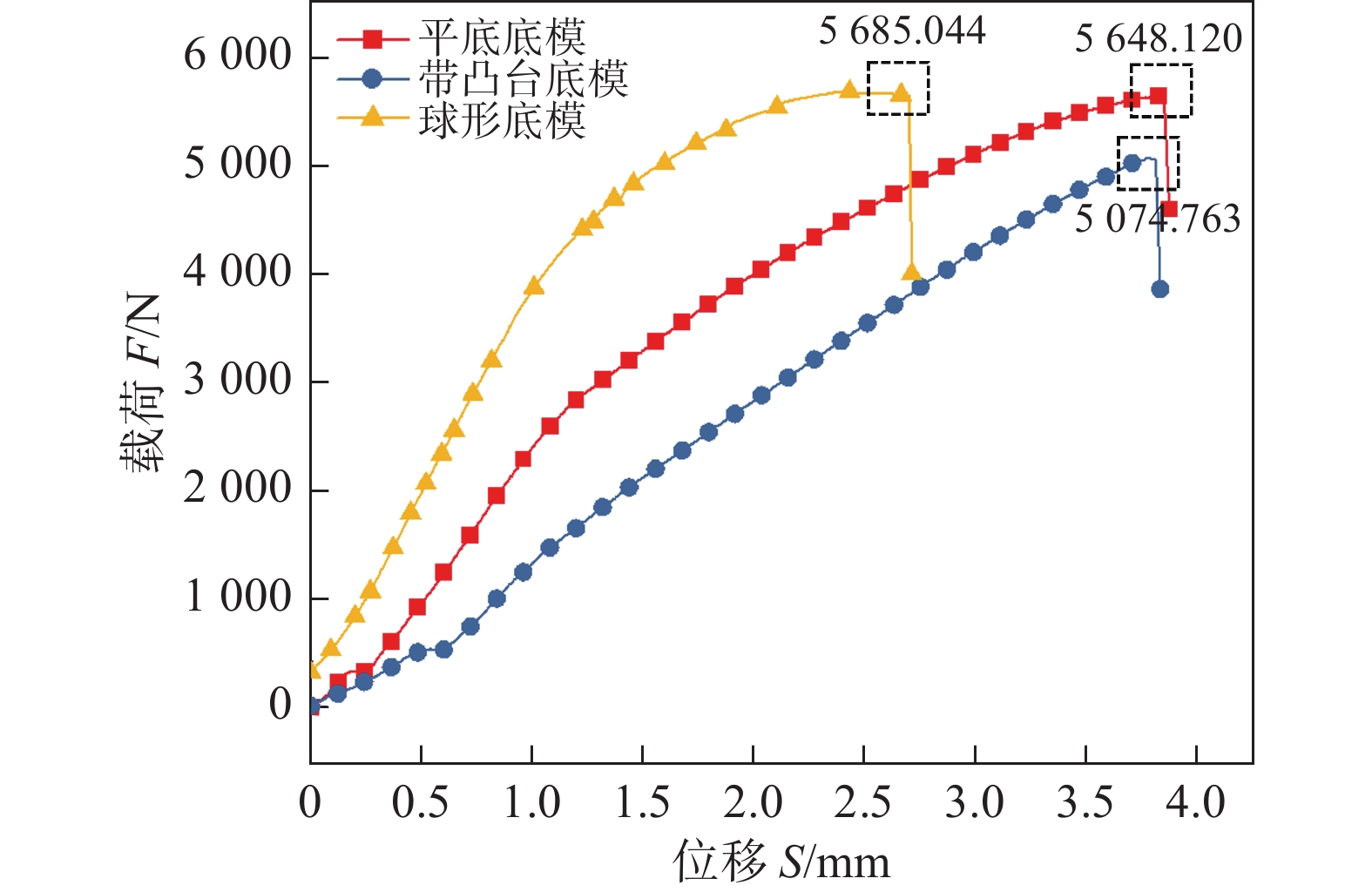

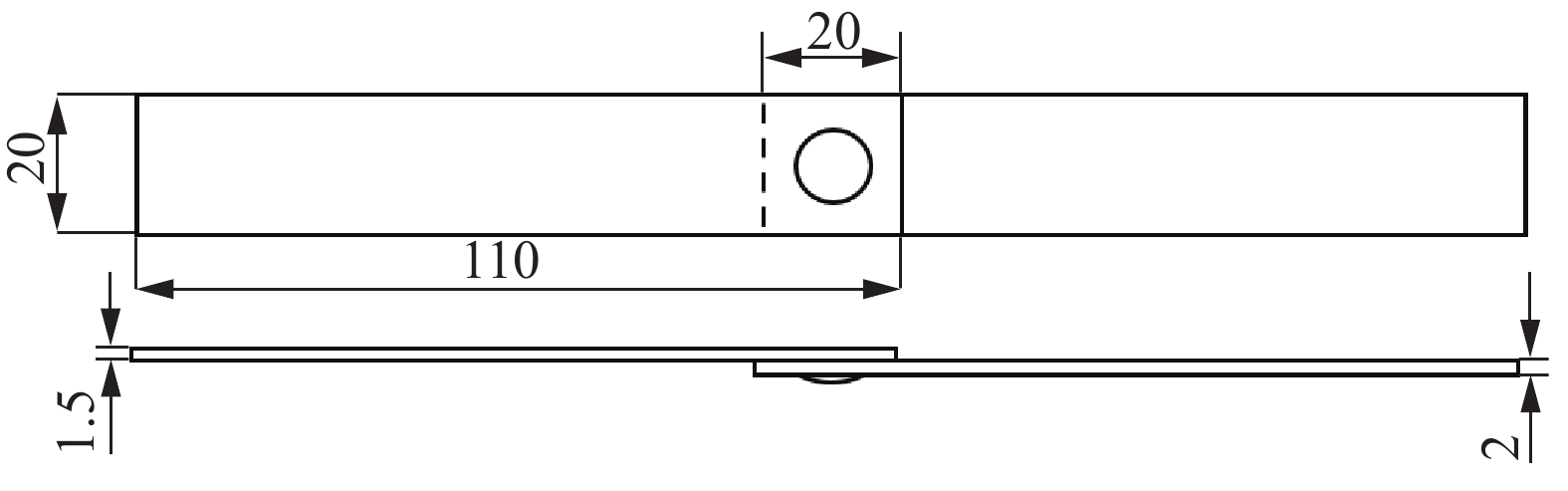

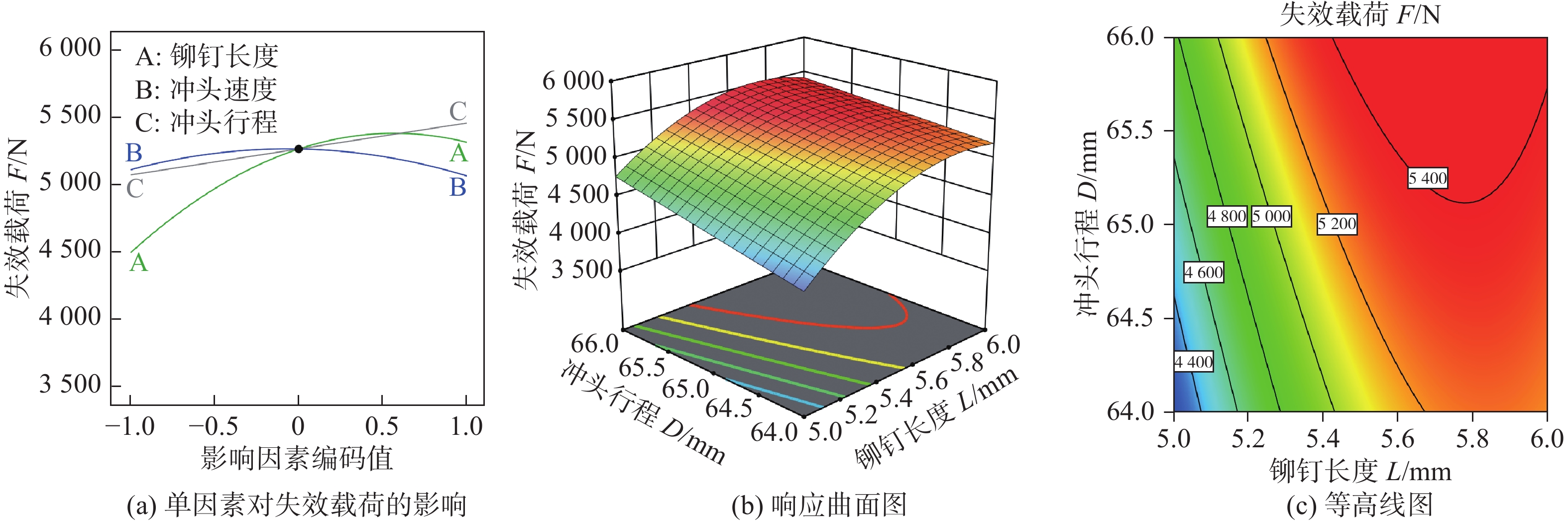

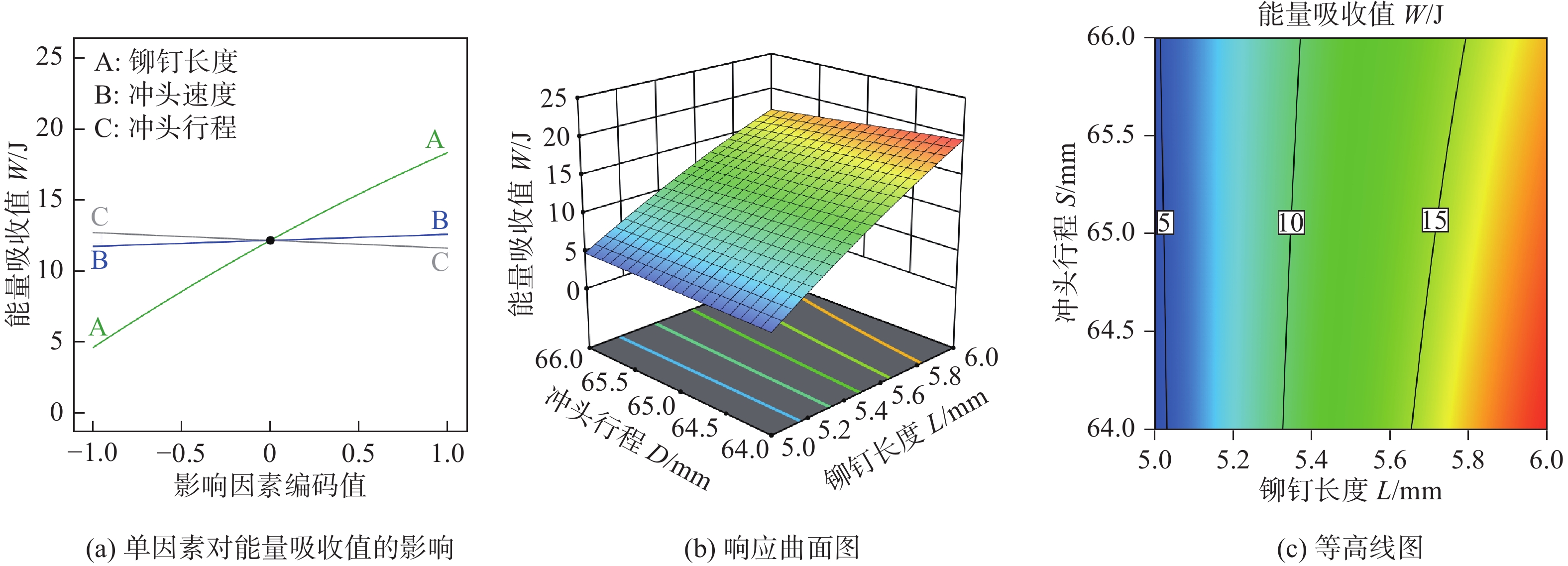

针对低延展性铝合金薄板材料自冲铆接成形过程易出现裂纹问题,提出了一种基于球形底模的自冲铆连接工艺.针对7075铝合金材料,采用Box-Behnken Design响应面试验方法,开展自冲铆接头工艺试验研究,确定最优工艺参数.以铆钉长度,冲头速度和冲头行程作为输入变量,接头的失效载荷和能量吸收值为响应值,建立基于球形底模的自冲铆接工艺多元非线性回归模型,并进行试验验证.结果表明,采用球形底模在保证接头强度下有效抑制自冲铆接头机械内锁区裂纹的产生;应用回归模型得到的理论预测值与试验值之间的相对误差较低,回归模型具有较高的可靠性;同时,单因素分析表明,铆钉长度对接头静力学性能的影响最大;交互作用分析中,铆钉长度和冲头行程的交互作用对失效载荷和能量吸收值的影响最为显著.最后通过NSGA-II遗传算法确定最优工艺参数组合.

Abstract:The self-piercing riveting (SPR) technology based on ball-shaped die is proposed to solve the problem of cracks in the SPR process of aluminum alloy sheet materials with low ductility. The Box-Behnken Design (BBD) response surface experimental method was used to study the SPR joint process for 7075 aluminum alloy material, and the optimal process parameters were determined. Taking rivet length, punch speed and punch stroke as input variables and joint failure load and energy absorption as response values, a multiple nonlinear regression model for SPR process based on ball-shaped die was established and verified by experiments. The results show that the use of ball-shaped die can effectively restrain the crack in the mechanical inner locking zone of the SPR joint under the guarantee of joint strength. The relative error between the theoretical predicted value obtained by the regression model and the experimental value is low, and the regression model has high reliability. Meanwhile, single factor analysis shows that the rivet length has the greatest influence on the static mechanical property of the joint. In the interaction analysis, the interaction of rivet length and punch stroke has the most significant influence on the failure load and energy absorption value. Finally, NSGA-II genetic algorithm was used to determine the optimal process parameter combination.

-

-

表 1 7075-T6铝合金力学性能参数

Table 1 Mechanical property parameters of 7075-T6 aluminium alloy

材料 弹性模量E/GPa 屈服强度ReL/MPa 抗拉强度Rm/MPa 断后伸长率A(%) 7075-T6 71 325 430 13 表 2 三因素三水平设计表

Table 2 Design table of three factors and levels

影响因素 因子水平 −1 0 1 铆钉长度L/mm 5 5.5 6 冲头速度V/(mm·s−1) 20 40 60 冲头行程D/mm 64 65 66 表 3 自冲铆接头拉伸试验结果

Table 3 Tensile test results of self-piercing riveting joints

组数 铆钉长度L/mm 冲头速度V/(mm·s−1) 冲头行程D/mm 失效载荷F/N 能量吸收值W/J 1 5 40 66 4667.614 4.673 2 5.5 40 65 5286.160 11.845 3 6 40 64 5259.394 19.826 4 5 20 65 4395.852 4.320 5 5.5 40 65 5386.505 11.941 6 6 40 66 5232.434 16.000 7 5 60 65 4196.894 3.955 8 5.5 20 64 4600.116 11.527 9 5.5 20 66 5381.428 10.946 10 5.5 40 65 5218.264 10.174 11 5.5 60 66 5390.007 14.960 12 5.5 60 64 4895.333 14.012 13 6 60 65 5064.895 17.496 14 5 40 64 4376.358 5.617 15 6 20 65 5353.075 20.230 表 4 方差分析表

Table 4 Analysis of variance table

响应值 项目 平方和 自由度 均方误差 F值 P值 显著性 失效载荷 模型 2.254 × 106 8 2.817 × 105 6.83 0.0154 显著 $ {x}_{1} $ 1.339 × 106 1 1.339 × 106 32.49 0.0013 $ {x}_{2} $ 4.202 × 103 1 4.202 × 103 0.10 0.7603 $ {x}_{3} $ 2.966 × 105 1 2.966 × 105 7.19 0.0364 $ {x}_{1}{x}_{2} $ 1.990 × 103 1 1.990 × 103 0.05 0.8334 $ {x}_{1}{x}_{3} $ 2.532 × 104 1 2.532 × 104 0.61 0.4630 $ {x}_{2}{x}_{3} $ 2.054 × 104 1 2.054 × 104 0.50 0.5067 $ {x}_{1}^{2} $ 4.806 × 105 1 4.806 × 105 11.66 0.0142 $ {x}_{2}^{2} $ 1.163 × 105 1 1.163 × 105 2.82 0.1440 失拟项 2.330 × 105 4 5.825 × 104 8.13 0.1125 不显著 能量吸收值 模型 387.05 6 64.51 22.09 0.0001 显著 $ {x}_{1} $ 377.95 1 377.95 129.42 <0.0001 $ {x}_{2} $ 1.44 1 1.44 0.49 0.5017 $ {x}_{3} $ 2.42 1 2.42 0.83 0.3890 $ {x}_{1}{x}_{2} $ 1.40 1 1.40 0.48 0.5078 $ {x}_{1}{x}_{3} $ 2.08 1 2.08 0.71 0.4236 $ {x}_{1}^{2} $ 1.76 1 1.76 0.60 0.4602 失拟项 21.39 6 3.56 3.61 0.2327 不显著 表 5 回归模型验证

Table 5 Regression model verification

组号 铆钉长度

L/mm冲头速度

V/(mm·s−1)冲头行程

D/mm失效载荷试验均值

Fx/N失效载荷预测值

Fy/N误差

ef (%)能量吸收值试验均值

Wx/J能量吸收值预测值

Wy/J误差

ew (%)Ⅰ 5.5 30 65 5108.727 5233.767 2.45 13.248 11.988 9.51 Ⅱ 5.5 50 64 4830.033 5054.148 4.64 14.008 12.964 7.45 -

[1] He X C, Pearson I, Young K. Self-pierce riveting for sheet materials: state of the art[J]. Journal of Materials Processing Technology, 2008, 199(1-3): 27 − 36. doi: 10.1016/j.jmatprotec.2007.10.071

[2] 曾凯, 何晓聪, 邢保英. 钉脚张开度对自冲铆构件机械内锁刚度的影响[J]. 焊接学报, 2019, 40(6): 143 − 147 + 167. doi: 10.12073/j.hjxb.2019400169 Zeng Kai, He Xiaocong, Xing Baoying. Effect of the degree of rivet opening on the rigidity of the interlock in self-piercing riveting joints[J]. Transactions of the China Welding Institution, 2019, 40(6): 143 − 147 + 167. doi: 10.12073/j.hjxb.2019400169

[3] Haque R. Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: A review[J]. Archives of Civil and Mechanical Engineering, 2018, 18(1): 83 − 93. doi: 10.1016/j.acme.2017.06.003

[4] 杨进, 邢保英, 何晓聪, 等. 腐蚀环境下自冲铆接头竞争失效机制及力学性能分析[J]. 焊接学报, 2022, 43(7): 69 − 75 + 117. doi: 10.12073/j.hjxb.20211024002 Yang Jin, Xing Baoying, He Xiaocong, et al. Analysis of competitive falure mechanisms and mechanical properties of self-piercing riveted joints in corrosive environments[J]. Transactions of the China Welding Institution, 2022, 43(7): 69 − 75 + 117. doi: 10.12073/j.hjxb.20211024002

[5] Wang J T, Chen J W, Zhang Y K, et al. Influence of ultrasonic impact treatment on stress corrosion of 7075 aluminum alloy and its welded joints[J]. Engineering Failure Analysis, 2023, 144: 106908. doi: 10.1016/j.engfailanal.2022.106908

[6] Ying L, Gao T H, Dai M H, et al. Towards joinability of thermal self-piercing riveting for AA7075-T6 aluminum alloy sheets under quasi-static loading conditions[J]. International Journal of Mechanical Sciences, 2021, 189: 105978. doi: 10.1016/j.ijmecsci.2020.105978

[7] Durandet Y, Deam R, Beer A, et al. Laser Assisted self-pierce riveting of AZ31 magnesium alloy strips[J]. Materials & Design, 2010, 31: S13 − S16.

[8] Easton M, Beer A, Barnett M, et al. Magnesium alloy applications in automotive structures[J]. Journal of the Minerals, Metals & Materials Society, 2008, 60(11): 57 − 62. doi: 10.1007/s11837-008-0150-8

[9] JäckeL M, Maul S, Kraus C, et al. Numerical simulation of thermal supported self-pierce riveting of an ultra high-strength aluminium alloy[C]//Journal of Physics: Conference Series, IOP Publishing, 2018, 1063(1): 012074.

[10] Ma Y W, Lou M, Li Y, et al. Effect of rivet and die on self-piercing rivetability of aa6061-t6 and mild steel CR4 of different gauges[J]. Journal of Materials Processing Technology, 2018, 251: 282 − 294. doi: 10.1016/j.jmatprotec.2017.08.020

[11] Drossel W G, Jäckel M. New die concept for self-pierce riveting materials with limited ductility[J]. Key Engineering Materials, 2014, 611-612: 1452 − 1459. doi: 10.4028/www.scientific.net/KEM.611-612.1452

[12] Neuser M, Kappe F, Busch M, et al. Joining suitability of cast aluminium for self-piercing riveting[J]. IOP Conference Series: Materials Science and Engineering, 2021, 1157(1): 012005.

[13] Mori K, Kato T, Abe Y, et al. Plastic joining of ultra high strength steel and aluminium alloy sheets by self piercing rivet[J]. CIRP Annals, 2006, 55(1): 283 − 286. doi: 10.1016/S0007-8506(07)60417-X

[14] Li D Z, Han L, Lu Z J, et al. Influence of die profiles and cracks on joint buttons on the joint quality and mechanical strengths of high strength aluminium alloy joint[J]. Advanced Materials Research, 2012, 548: 398 − 405. doi: 10.4028/www.scientific.net/AMR.548.398

[15] Sulaiman M S, Rohman F S S, Aziz N. Optimization process for ethylene glycol production using the pareto solution[J]. Iop Conference Series: Materials Science and Engineering, 2021, 1011(1): 012003.

下载:

下载: