Diffusion bonding of 316L stainless steel

-

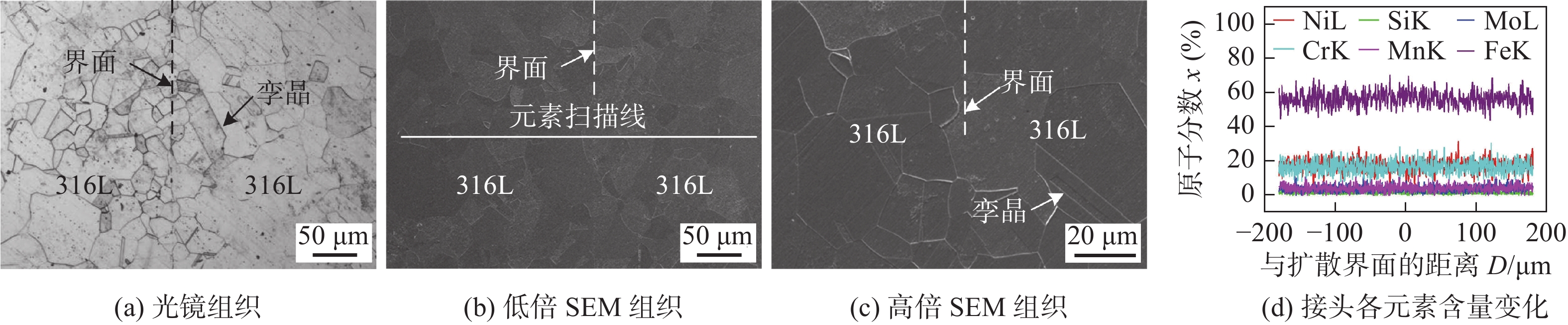

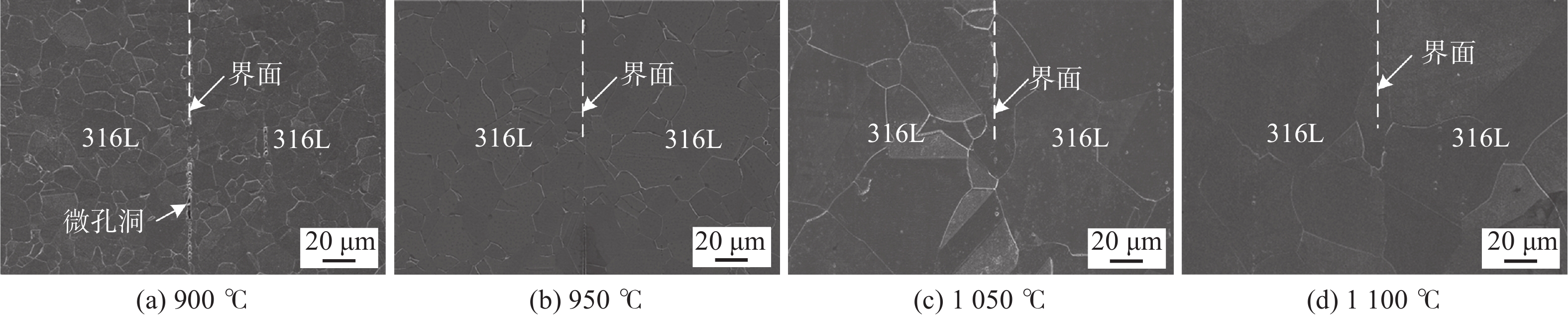

摘要: 印刷电路板式换热器具有多层薄壁、微通道的结构,如何实现其高质量连接的问题亟待解决. 316L不锈钢因其优异的力学性能、焊接性能与耐腐蚀性能,常用于印刷电路板式换热器的制造. 文中采用真空扩散连接的方法实现了316L奥氏体不锈钢的连接,并探究了最优工艺参数,建立了工艺参数—界面组织—力学性能之间的关系. 结果表明,随焊接温度升高和保温时间的延长,接头焊合率、变形率上升,晶粒尺寸增长,硬度下降,抗拉伸剪切强度先升高后降低. 1 000 ℃–60 min–10 MPa为最优参数,此时接头抗剪强度最高,为626 MPa. 该参数下的断裂方式为塑性断裂,断口呈典型的韧窝花样.Abstract: The printed circuit heat exchanger (PCHE) has a multilayer, thin-walled, micro-channel structure. Solving the problem of achieving its high-quality connection is urgently needed. 316L stainless steel is commonly used to manufacture PCHE due to its excellent mechanical properties, weldability, and corrosion resistance. In this study, vacuum diffusion bonding was used to connect 316L stainless steel. The optimal process parameters of the diffusion bonding process were explored, and the relationship between the process parameters, interface structure, and mechanical properties was established. With increasing bonding temperature and holding time, the bonding rate, grain size, and deformation rate of the joints continue to increase, while the hardness continues to decrease. The tensile shear strength initially increases and then decreases. A temperature of 1000 ℃, time of 60 min, and pressure of 10 MPa are the optimal parameters, giving a maximum joint strength of 626 MPa. The fracture morphology of the bonded joint was a dimple pattern with features of ductile fracture.

-

-

表 1 各温度参数下接头晶粒尺寸与焊合率统计

Table 1 Statistical table of joint grain size and bonding rate at various temperature

焊接温度T/℃ 晶粒尺寸d/μm 焊合率ε(%) 900 23.04 55.99 950 38.74 86.21 1 000 70.81 93.86 1 050 125.43 94.81 1 100 197.51 99.22 表 2 各时间参数下接头晶粒尺寸与焊合率统计

Table 2 Statistical table of joint grain size and bonding rate at various time

保温时间t/min 晶粒尺寸d/μm 焊合率ε(%) 30 57.31 74.15 60 70.81 93.86 90 75.10 94.15 120 132.59 98.61 -

[1] 胡建伟, 张 骁, 蒋佳良, 等. 316L不锈钢电热管弯曲断裂的研究[J]. 全面腐蚀控制, 2019, 33(5): 64 − 67. Hu Jianwei, Zhang Xiao, Jiang Jialiang, et al. Bending fracture of 316L stainless steel electric heating tube[J]. Total Corrosion Control, 2019, 33(5): 64 − 67.

[2] Mueggenburg H H, Hidahl J W, Kessler E L, et al. Platelet actively cooled thermal management devices, AIAA 92-3127[R]. Nashville: American Institute of Aeronautics and Astronautics, 1992.

[3] Xu Tao, Wang Zishun, Shi Yonghua. Investigation of C276 alloy and 316L SS TIG welded joints with ERNiCrMo-4 and ER304 welding wires[J]. China Welding, 2021, 30(4): 9 − 16.

[4] Torkamany M J, Sabbaghzadeh J, Hamedi M J. Effect of laser welding mode on the microstructure and mechanical performance of dissimilar laser spot welds between low carbon and austenitic stainless steels[J]. Materials & Design, 2012, 34: 666 − 672.

[5] 程小华, 李小宇. 核电用不锈钢双钨极氩弧焊接头组织与性能[J]. 焊接学报, 2022, 43(7): 108 − 112. doi: 10.12073/j.hjxb.20220617001 Cheng Xiaohua, Li Xiaoyu. Structure and properties of the double tungsten argon arc hybrid welding joint of stainless steel used in nuclear power plant[J]. Transactions of the China Welding Institution, 2022, 43(7): 108 − 112. doi: 10.12073/j.hjxb.20220617001

[6] 王晓光, 刘奋成, 方 平, 等. CMT电弧增材制造316L不锈钢成形精度与组织性能分析[J]. 焊接学报, 2019, 40(5): 100 − 106. doi: 10.12073/j.hjxb.2019400135 Wang Xiaoguang, Liu Fencheng, Fang Ping, et al. CMT arc additive manufacturing 316L stainless steel forming accuracy and tissue properties analysis[J]. Transactions of the China Welding Institution, 2019, 40(5): 100 − 106. doi: 10.12073/j.hjxb.2019400135

[7] 杨明轩, 齐铂金, 从保强, 等. 不锈钢超高频直流脉冲GTAW焊缝成形行为[J]. 焊接学报, 2012, 33(11): 31 − 34. Yang Mingxuan, Qi Bojin, Cong Baoqiang, et al. Stainless steel UHF DC pulse GTAW weld seam forming behavior[J]. Transactions of the China Welding Institution, 2012, 33(11): 31 − 34.

[8] Meysam H, Saman M. Microstructure and mechanical properties of friction stir processed AISI 316 stainless steel: Evaluation of the effect of cooling media and multi-step processing on microstructure and mechanical properties of friction stir processed AISI 316 stainless steel[J]. Metallography, Microstructure, and Analysis, 2022, 11: 72 − 87. doi: 10.1007/s13632-021-00815-w

[9] Hamed J A, Altino L. Effect of inverse differential friction stir welding on properties of AA7075 and AISI304 welds[J]. Chinese Journal of Nonferrous Metals (English Edition), 2019, 29(5): 964 − 975.

[10] Lu Y, Xu X, Zhang B, et al. Microstructural analysis and mechanical behavior of TC4 Titanium alloy and 304 stainless steel by friction stir lap welding[J]. Weld World, 2021, 65: 1915 − 1930. doi: 10.1007/s40194-021-01133-z

[11] He P, Feng J C, Zhang B G, et al. Microstructure and strength of diffusion-bonded joints of TiAl base alloy to steel[J]. Materials Characterization, 2002, 48(5): 401 − 406. doi: 10.1016/S1044-5803(02)00319-4

[12] He P, Zhang J H, Feng J C, et al. Diffusion bonding of TiAl to Ti and TC4 alloy[J]. Acta Metallurgica Sinica (English Letters), 2000, 13(1): 162 − 167.

[13] David S. Diffusion bonding in compact heat exchangers[J]. Transactions of the American Nuclear Society, 2009, 100: 265 − 267.

[14] 杨晓雅. 核电用316LN奥氏体不锈钢热变形组织演变与断裂行为[D]. 北京: 北京科技大学, 2016. Yang Xiaoya. Heat deformation tissue evolution and fracture behavior of 316LN austenitic stainless steel for nuclear power[D]. Beijing: University of Science and Technology Beijing, 2016.

[15] 王敏, Michel G, Jullien J F. 316L奥氏体不锈钢焊接热影响区性能[J]. 上海交通大学学报, 2001, 35(3): 424 − 426. Wang Min, Michel G, Jullien J F. Thermal simulation on the welding heat affected zone of 316L Steel[J]. Journal of Shanghai Jiao Tong University, 2001, 35(3): 424 − 426.

下载:

下载: