Optimization of process parameters for electron beam butt welding of HR-2 hydrogen resistant steel based on response surface method

-

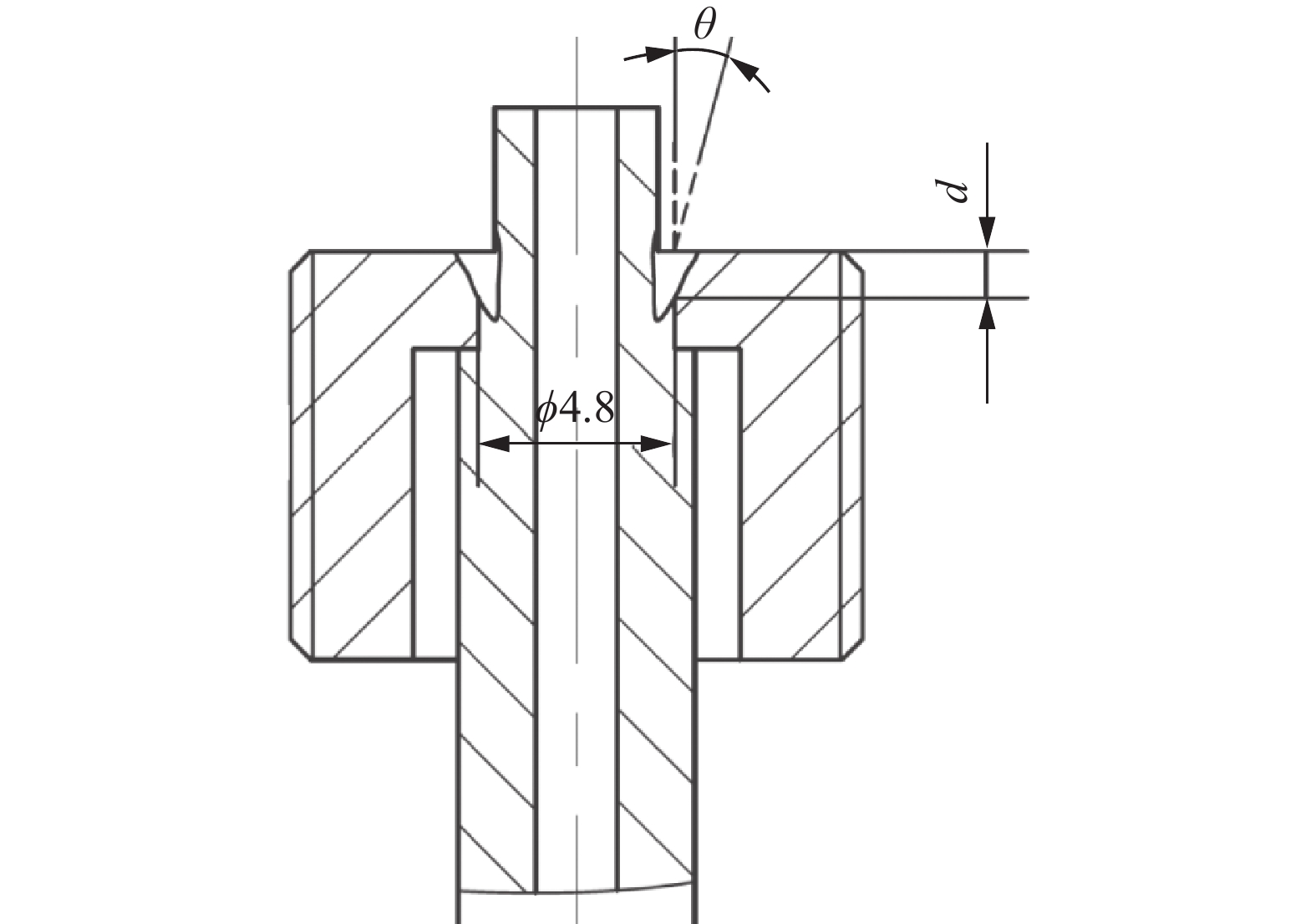

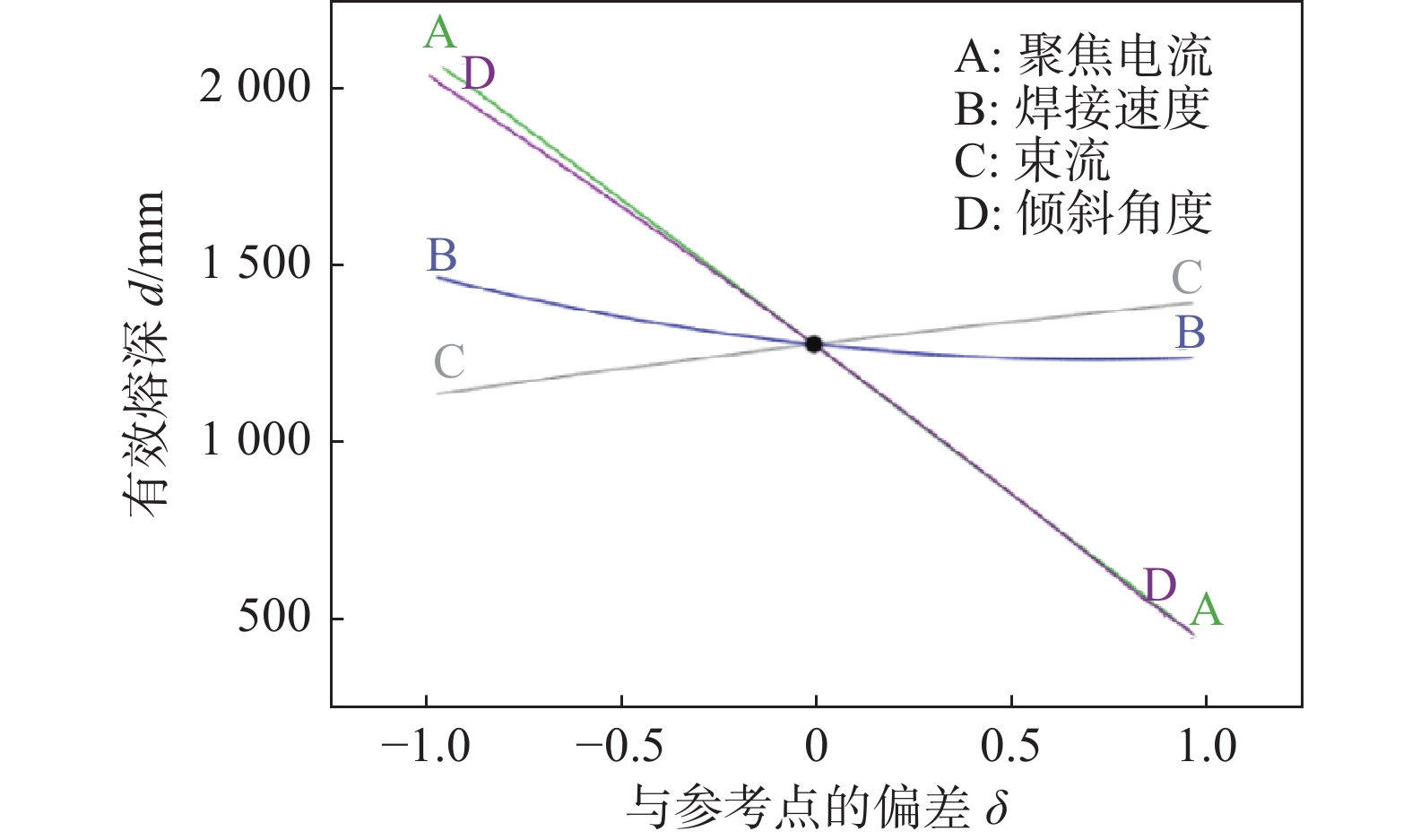

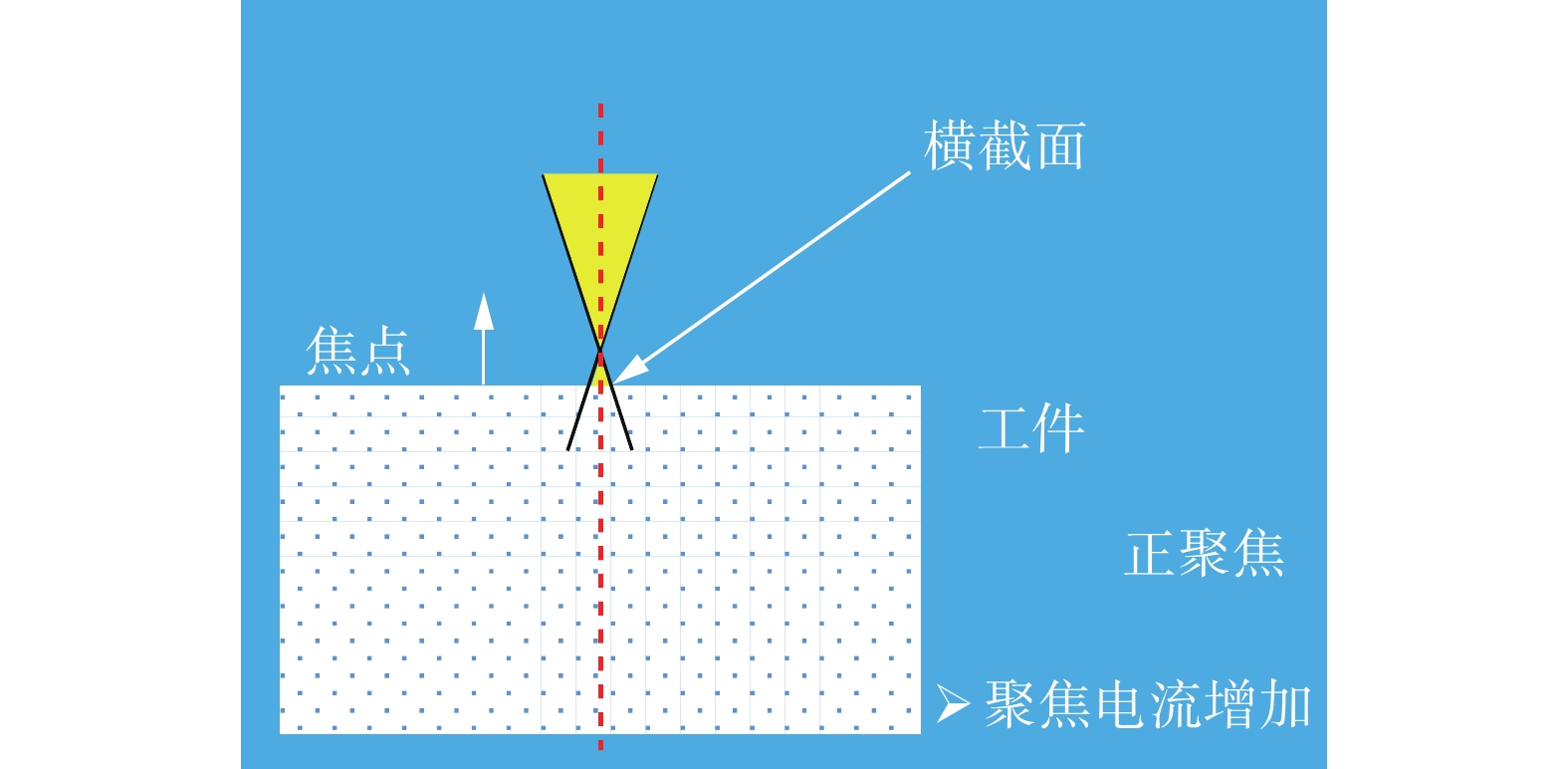

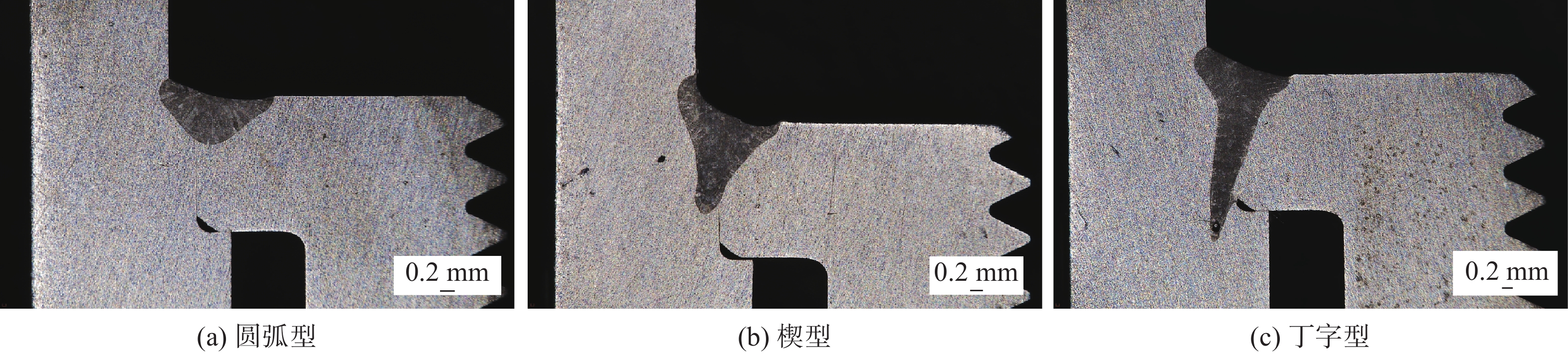

摘要: 为解决HR-2抗氢钢电子束插接焊有效熔深不足、焊缝处开裂等问题,采用BBD设计试验方案,基于响应面法建立了HR-2抗氢钢电子束插接焊焊接工艺参数(聚焦电流、焊接速度、束流、倾斜角度)与预测响应值(有效熔深、接头抗剪承载力)之间的统计模型. 根据有效熔深和接头抗剪承载力的要求优化焊接工艺参数,并通过优化电子束焊接工艺参数来预测电子束插接焊的有效熔深和接头抗剪承载力,实现焊缝截面形貌与接头强度的最佳组合. 结果表明,模型拟合度较好,有效熔深预测值比实测值高1.17%,接头抗剪承载力预测值比实测值高2.63%,得到较优的焊接参数为:聚焦电流2.46 A,焊接速度10.00 mm/s,束流8.20 mA,倾斜角度11°. 在该参数下的焊缝有效熔深1 347.82 μm,接头抗剪承载力13.525 kN.Abstract: In order to solve the problems such as insufficient effective penetration and cracking at the weld seam of HR-2 hydrogen resistant steel, a statistical model between the welding process parameters (focusing current, welding speed, beam current, tilt angle) and the predicted response values (effective penetration, joint shear load) of HR-2 hydrogen resistant steel electron beam insertion welding was established based on the response surface method using the BBD design test scheme. It can optimize the welding process parameters according to the requirements of effective penetration and joint shear load, and predict the effective penetration and joint shear load of electron beam plug welding by optimizing the electron beam welding process parameters, so as to achieve the best combination for weld section morphology and joint strength. The results show that the model fits well, the predicted value of effective penetration is 1.17% higher than that of the measured value, and the predicted value of joint shear load is 2.63% higher than the measured value. Better welding parameters are listed as follows: the focusing current is 2.46 A, the welding speed is 10.00 mm/s, the beam current is 8.20 mA, and the tilt angle is 11°. Effective penetration depth of the weld under this parameter is 1 347.82 μm, and shear load of joint is 13.525 kN.

-

-

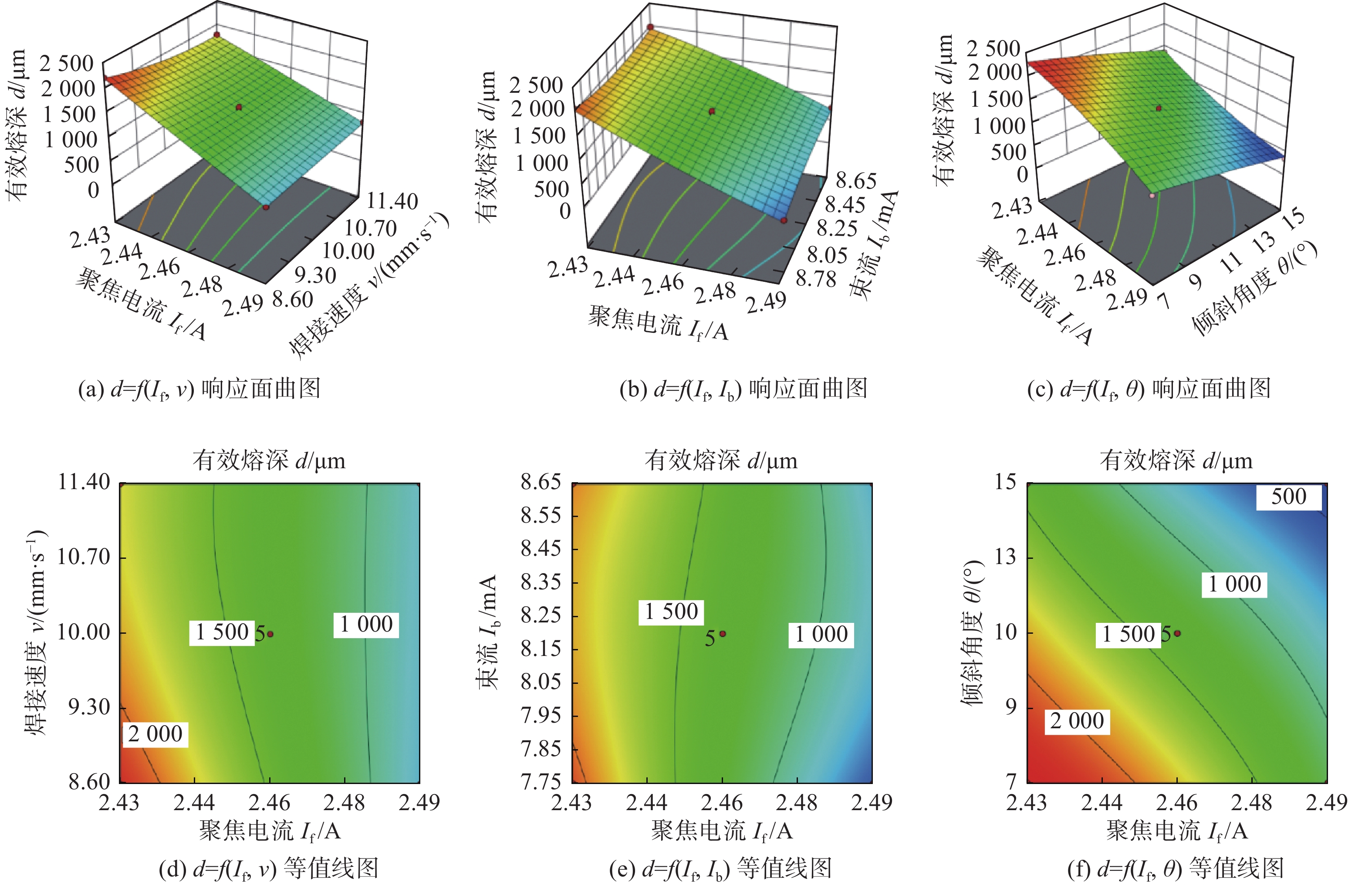

图 5 有效熔深的响应面曲图和等值线图

Figure 5. Response surface 3D graph and contour graph of effective penetration. (a) d = f ( If, v) response surface 3D graph; (b) d = f (If, Ib) response surface 3D graph; (c) d = f ( If, θ ) response surface 3D graph; (d) d = f ( If, v ) contour graph; (e) d = f ( If, Ib) contour graph; (f) d = f ( If, θ ) contour graph

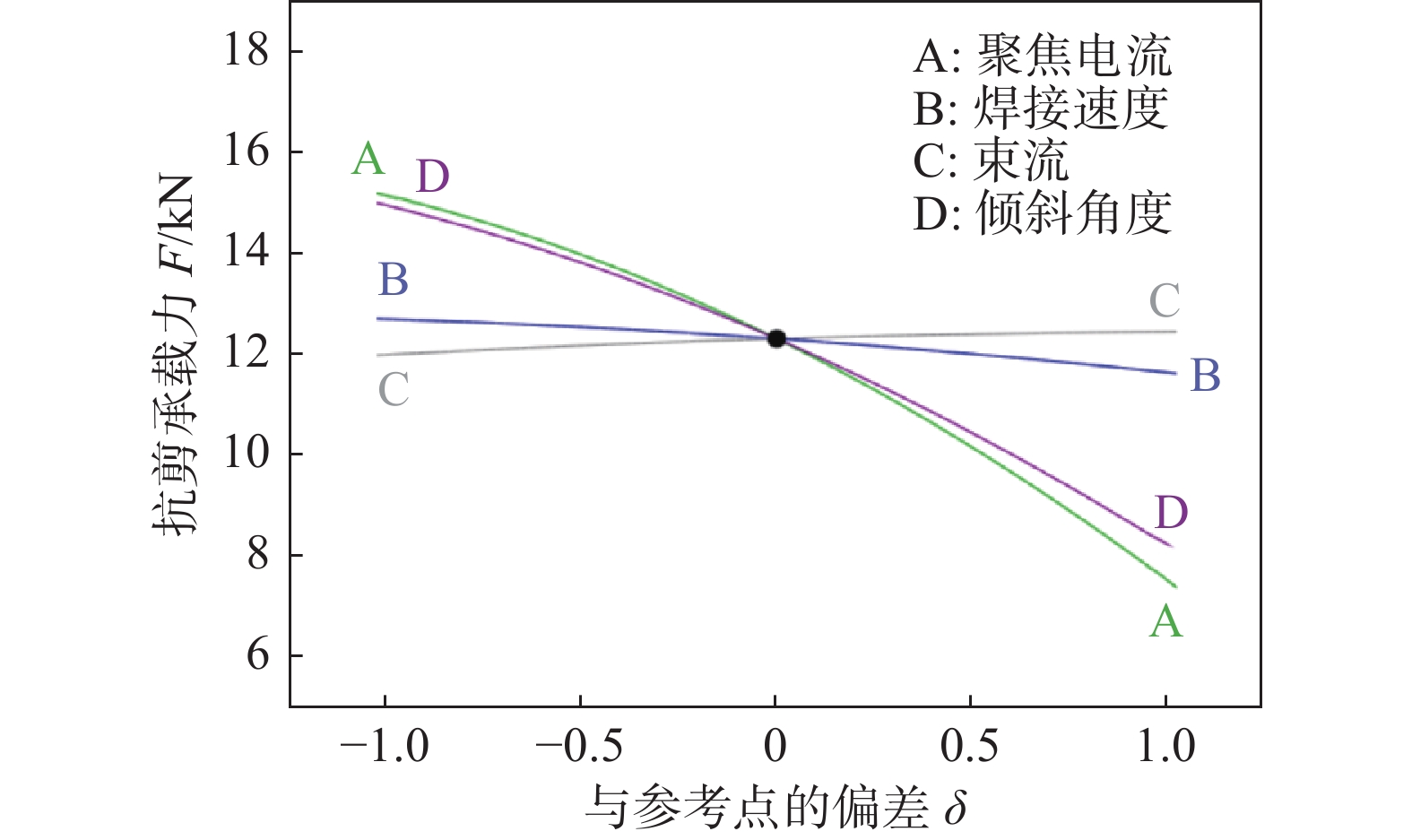

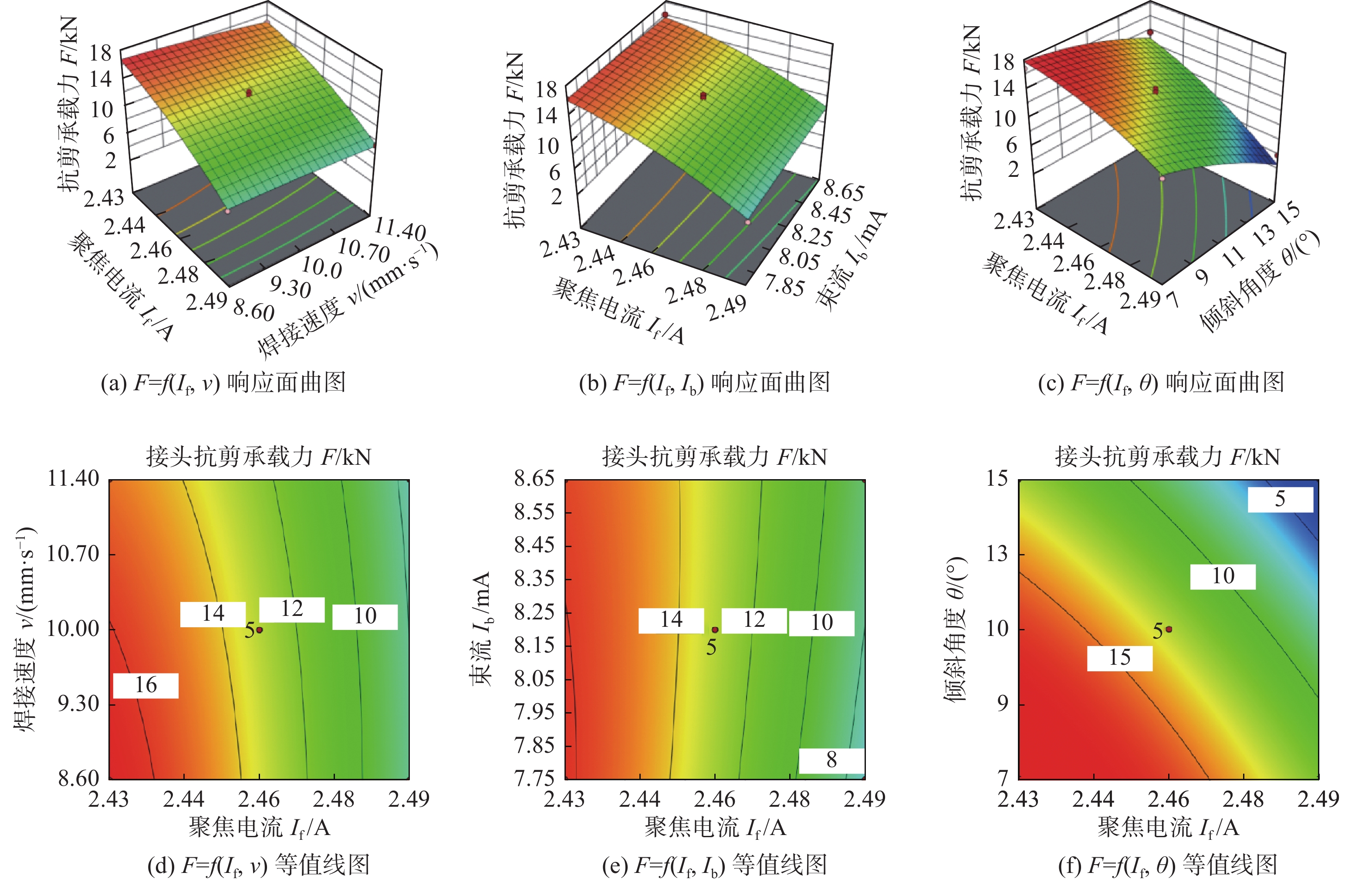

图 7 接头抗剪承载力的响应面曲图和等值线图

Figure 7. Response surface 3D graph and contour graph of of shear capacity of joint. (a) F = f (If, v) response surface 3D graph; (b) F = f (If, Ib) response surface 3D graph; (c) F = f ( If, θ ) response surface 3D graph; (d) F = f ( If, v ) contour graph; (e) F = f ( If, Ib) contour graph; (f) F = f ( If, θ) contour graphe

表 1 HR-2抗氢钢的化学成分(质量分数,%)

Table 1 Chemical compositions of HR-2 hydrogen resistant steel

C Si Mn P S Ni Cr Fe ≤0.040 ≤1.00 8.00 ~ 10.00 ≤0.025 ≤0.015 5.50 ~ 8.00 19.00 ~ 21.50 余量 表 2 工艺参数水平编码及真实值表

Table 2 Process parameter level coding and true value table

水平 聚焦电流

If /A焊接速度

v/(mm·s−1)束流

Ib /mA倾斜角度

θ/(°)1 2.49 11.40 8.65 15 0 2.46 10.00 8.20 11 −1 2.43 8.60 7.75 7 表 3 试验方案及相对应的响应值

Table 3 Test scheme and corresponding response value

试验序号 聚焦电流If /A 焊接速度v/(mm∙s−1) 束流Ib/mA 倾斜角度θ/(°) 有效熔深d/μm 抗剪承载力F/kN 1 2.49 10.00 8.20 15 360.07 3.856 2 2.43 10.00 8.65 11 1 997.30 16 137 3 2.46 10.00 8.20 11 1 397.18 13.037 4 2.43 10.00 7.75 11 2 117.32 16.352 5 2.43 10.00 8.20 7 2 252.73 16.779 6 2.46 10.00 8.65 15 830.92 8.938 7 2.46 10.00 8.20 11 1 275.58 12.330 8 2.46 11.40 8.20 7 1 840.34 15.907 9 2.46 10.00 7.75 7 1 717.24 16. 096 10 2.46 10.00 8.20 11 1 357.18 13.725 11 2.46 8.60 8.65 11 1 175.61 13.681 12 2.46 11.40 8.20 15 815.54 8.120 13 2.46 10.00 8.65 7 1 975.75 15.935 14 2.49 10.00 8.65 11 787.84 8.388 15 2.49 10.00 7.75 11 575.49 6.710 16 2.49 8.60 8.20 11 775.53 7.844 17 2.43 10.00 8.20 15 1 369.49 13.696 18 2.46 10.00 8.20 11 1 375.64 13.265 19 2.43 11.40 8.20 11 1 796.56 14.908 20 2.46 10.00 8.20 11 1 320.56 13.018 21 2.46 8.60 7.75 11 1 427.96 14.690 22 2.43 8.60 8.20 11 2 203.49 16.368 23 2.49 11.40 8.20 11 827.85 7.564 24 2.46 8.60 8.20 7 2 172.71 16.383 25 2.46 8.60 8.20 15 787.84 8.046 26 2.46 10.00 7.75 15 744.76 7.013 27 2.46 11.40 8.65 11 1 461.81 12.204 28 2.49 10.00 8.20 7 1 089.44 11.404 29 2.46 11.40 7.75 11 1 311.02 11.557 表 4 有效熔深模型方差分析

Table 4 ANOVA for effective weld penetration reduced cubic model

项目 平方和SS/105 自由度f 均放值MS /105 F值 Prob>F值 模型 80.22 22 3.646 60.48 < 0.000 1 If 11.80 1 11.80 195.74 < 0.000 1 θ 11.21 1 11.21 185.88 < 0.000 1 vIf 0.527 276 4 1 0.527 276 4 8.75 0.025 4 vIb 0.406 304 6 1 0.406 304 6 6.74 0.040 9 IfIb2 0.418 443 5 1 0.418 443 5 6.94 0.038 8 残差 0.361 760 2 6 0.060 293 4 失拟项 0.269 499 2 2 0.134 749 6 5.84 0.065 0 绝对误差 0.092 261 0 4 0.023 065 3 总离差 80.58 28 表 5 接头抗剪承载力模型方差分析

Table 5 ANOVA for the shear capacity of welded joins reduced quadratic model

项目 平方和SS /107 自由度f 均方值MS /106 F值 Prob > F值 模型 37.13 14 26.52 36.23 < 0.000 1 If 19.58 1 195.8 267.50 < 0.000 1 v 0.379 9 1 3.799 5.19 0.038 9 θ 15.29 1 152.9 208.88 < 0.000 1 θIf 0.498 4 1 4.984 6.81 0.020 6 If2 0.729 9 1 7.299 9.97 0.007 0 θ2 0.404 7 1 4.047 5.53 0.033 9 残差 1.025 14 0.732 0 失拟项 0.923 0 10 0.923 0 3.63 0.113 0 绝对误差 0.101 8 4 0.254 6 总离差 38.15 28 表 6 响应面法分析优化验证结果

Table 6 Optimization and verification results of response surface analysis method

类别 聚焦电流If /A 焊接速度v/(mm∙s−1) 束流Ib /mA 倾斜角度θ/(°) 有效熔深d/μm 接头抗剪承载力F/kN 试验值 2.46 10.00 8.20 11 1 347.82 13.525 预测值 2.463 10.21 8.12 11.26 1 363.63 13.881 相对误差e(%) 0.12 2.1 −0.98 2.36 1.17 2.63 -

[1] 丁亚茹, 陈芙蓉, 杨帆, 等. 响应面法分析7075铝合金激光焊接参数对焊接质量的影响规律[J]. 材料导报, 2021, 35(2): 2103 − 2108. Ding Yaru, Chen Furong, Yang Fan, et al. Analyzing the influence of laser welding parameters on the welding quality of 7075 aluminum alloy by response surface methodology[J]. Materials Reports, 2021, 35(2): 2103 − 2108.

[2] Mohammadpour M, Yazdian N, Wang H P, et al. Effect of filler wire composition on performance of Al/Galvanized steel joints by twin spot laser welding-brazing method[J]. Journal of Manufacturing Processes, 2018, 31: 20 − 34.

[3] Kumar C, Das M, Paul C P, et al. Experimental investigation and metallographic characterization of fiber laser beam welding of Ti-6Al-4V alloy using response surface method[J]. Optics and Lasers in Engineering, 2017, 95: 52 − 68. doi: 10.1016/j.optlaseng.2017.03.013

[4] 王洪潇, 史春元, 王春生, 等. 基于响应面法的不锈钢车体激光焊接工艺参数优化[J]. 焊接学报, 2010, 31(10): 69 − 72. Wang Hongxiao, Shi Chunyuan, Wang Chunsheng, et al. Optimization of laser welding parameters of stainless steel vehicle body based on response surface methodology[J]. Transactions of the China Welding Institution, 2010, 31(10): 69 − 72.

[5] Zhang W W, Cong S. Process optimization and performance evaluation on laser beam welding of austenitic/martensitic dissimilar materials[J]. International Journal of Advanced Manufacturing Technology, 2017, 92: 4161 − 4168.

[6] 孔谅, 周洋, 王敏, 等. TA2薄板电弧辅助激光高速焊接的焊缝成形稳定性[J]. 机械工程学报, 2021, 57(10): 137 − 147. Kong Liang, Zhou Yang, Wang Min, et al. Robustness of weld appearance on high-speed arc-assisted laser welding process on titanium sheet[J]. Journal of Mechanical Engineering, 2021, 57(10): 137 − 147.

[7] 范文学, 陈芙蓉. 基于响应面法7A52高强铝合金FSW接头抗拉强度预测及优化[J]. 焊接学报, 2021, 42(9): 55 − 60. Fan Wenxue, Chen Furong. Prediction and optimization of tensile strength of 7A52 aluminum alloy friction stir welding joints based on response surface methodology[J]. Transactions of the China Welding Institution, 2021, 42(9): 55 − 60.

[8] Acherjee B, Misra D, Bose D, et al. Prediction of weld strength and seam width for laser transmission welding of thermoplastic using response surface methodology[J]. Optics & Laser Technology, 2009, 41(8): 956 − 967.

[9] 张明敏, 胡玥, 吴家云, 等. 电子束焊接参数对高温合金小熔深焊缝形貌的影响[J]. 热加工工艺, 2017, 46(1): 233 − 235. Zhang Mingmin, Hu Yue, Wu Jiayun, et al. Effect of electron beam welding parameters on little penetration depth weld shape of high temperature alloys[J]. Hot Working Technology, 2017, 46(1): 233 − 235.

[10] 孙家豪, 张超勇, 吴剑钊, 等. 基于神经网络的316L不锈钢激光焊焊缝形貌预测[J]. 焊接学报, 2021, 42(12): 40 − 47. Sun Jiahao, Zhang Chaoyong, Wu Jianzhao, et al. Prediction of weld profile of 316L stainless steel based on generalized regression neural network[J]. Transactions of the China Welding Institution, 2021, 42(12): 40 − 47.

下载:

下载: