Microstructure analysis of additive manufacturing produced RAFM steel laser welding joint

-

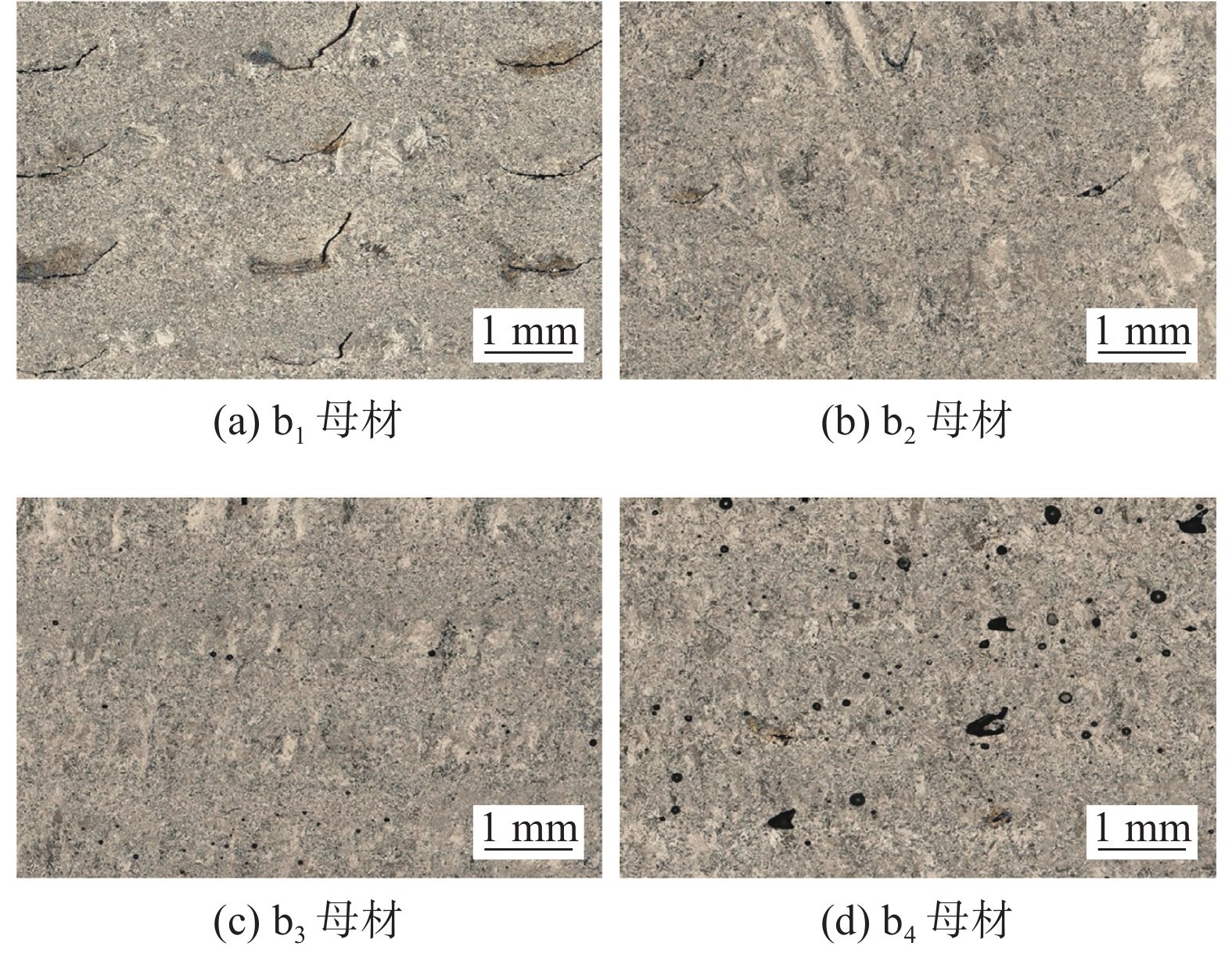

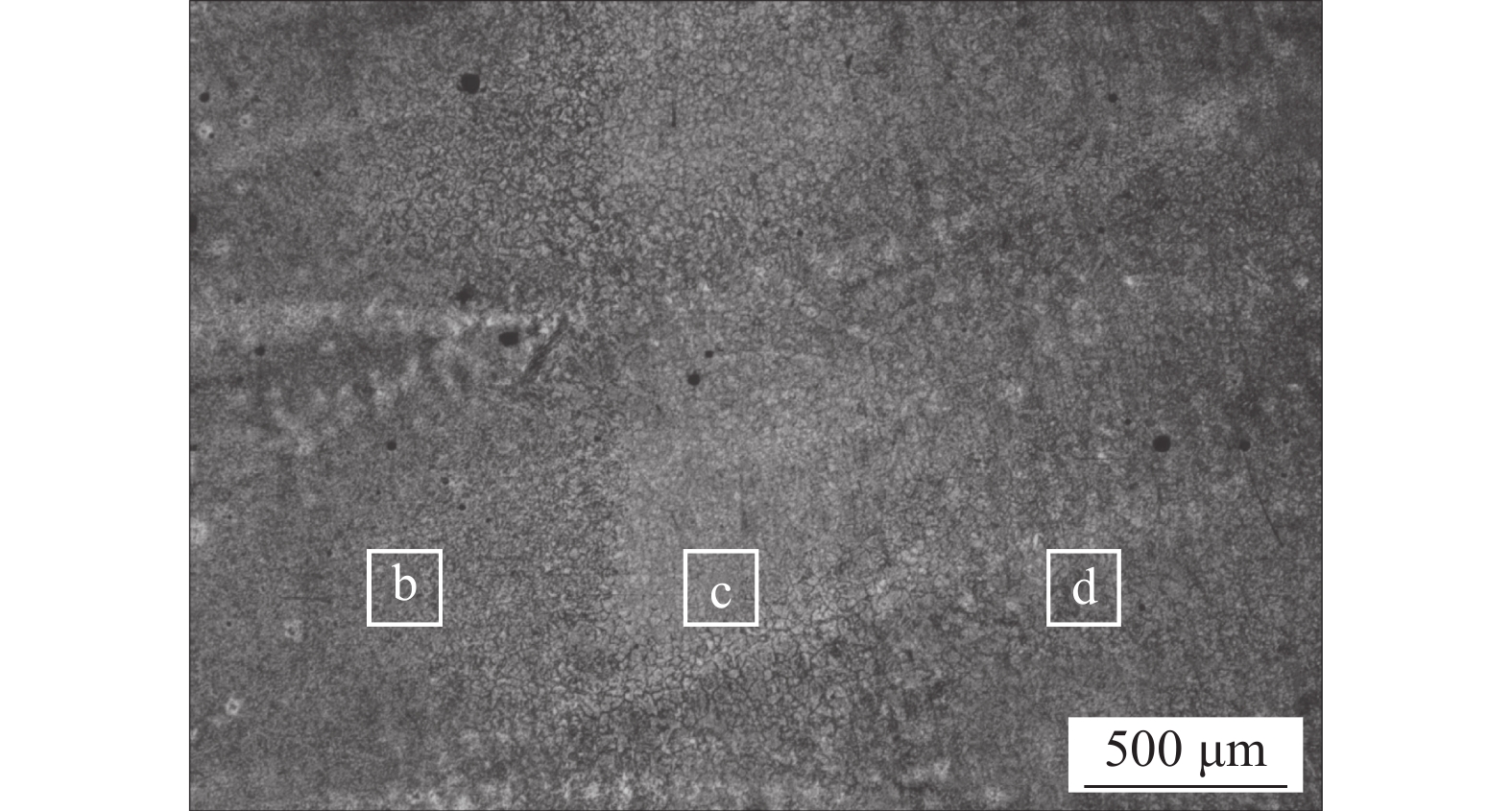

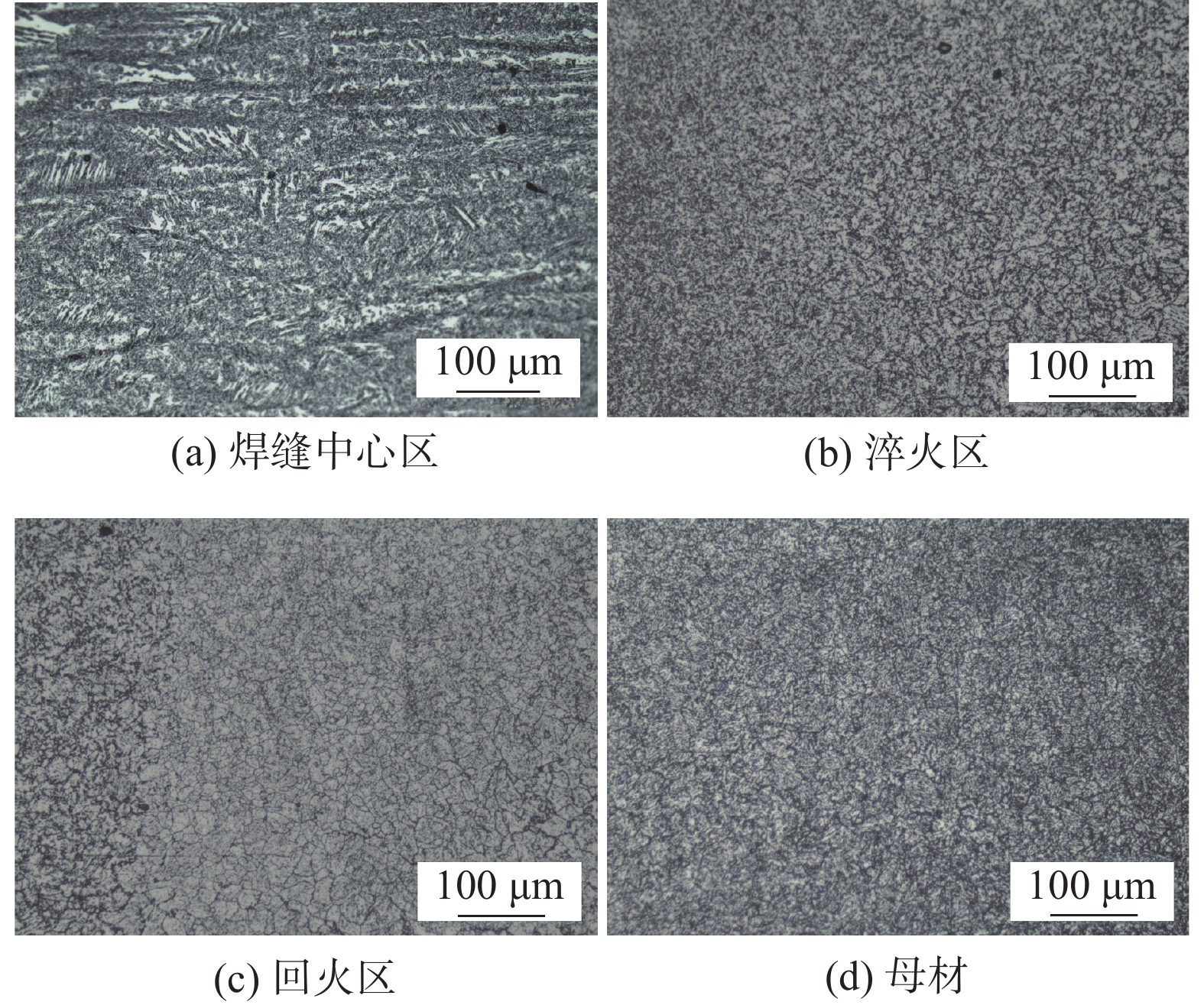

摘要: 局部工件采用增材制造技术成型再焊接完成装配是未来精密加工较为可行的方案之一. 采用激光焊对4种不同粒径粉末增材制造得到的低活化铁素体/马氏体钢板(reduced activation ferritic/martensitic steel,RAFM钢)进行焊接,分析激光焊接头显微组织演变特征.结果表明,粉末粒径小于25 µm的增材RAFM钢的道间未熔合缺陷在焊缝区得到修复,而热影响区与母材未熔合缺陷无法改善;粉末粒径为15 ~ 53,45 ~ 105 µm以及大于100 µm的增材RAFM钢的气孔缺陷在焊接过程中无法消除,焊缝区与母材皆有分布,后者的气孔数量和大小明显大于前两者;4种接头焊缝区微观组织皆为粗大的板条状马氏体,柱状晶生长至中心线相交,无等轴晶出现. 由增材制造工艺特点导致热影响区与母材区出现偏析带.近焊缝淬火区峰值温度较高,为细小的马氏体组织;远焊缝回火区产生二次回火的珠光体组织,且伴随部分晶粒长大.Abstract: It’s one of the more feasible solutions for precision machining in the future that a mount of the workpieces produced by the additive manufacturing technology are connected by welding. Reduced activation ferrite/martensitic (RAFM) steel plates produced with four different particle sizes powder (0 ~ 25, 15 ~ 53, 45 ~ 105, > 100 μm) additive manufacturing are connected by laser welding technology. The microscopic microstructure evolution characteristics of laser welding joints were characterized. The results show that the unfused defects of additive manufacturing RAFM steel with powder particle size less than 25 μm are repaired in the weld area, while the unfused defects of the heat-affected zone and the base metal area cannot be improved. The defects in the welding of other steel plates are mainly pores, which are both distributed in the weld area and the base material area. And the number of steel welding pores with powder particle size exceeds 100 μm is much greater than other two welds. The microscopic structure of the weld area of the four joints is a coarse slatted martensite, and the columnar crystals grow from the edge of the pool to intersect the centerline. The characteristics of the additive manufacturing process lead to precipitation zone in heat affected area and base metal zone. The peak temperature of the quenched zone near the weld is higher, which is fine martensite structure. The tempering area far away from the weld is composed of secondary tempered pearlite structure, and therein grains partially get coarsened.

-

Keywords:

- laser additive manufacturing /

- RAFM steel /

- laser welding /

- lack of fusion

-

-

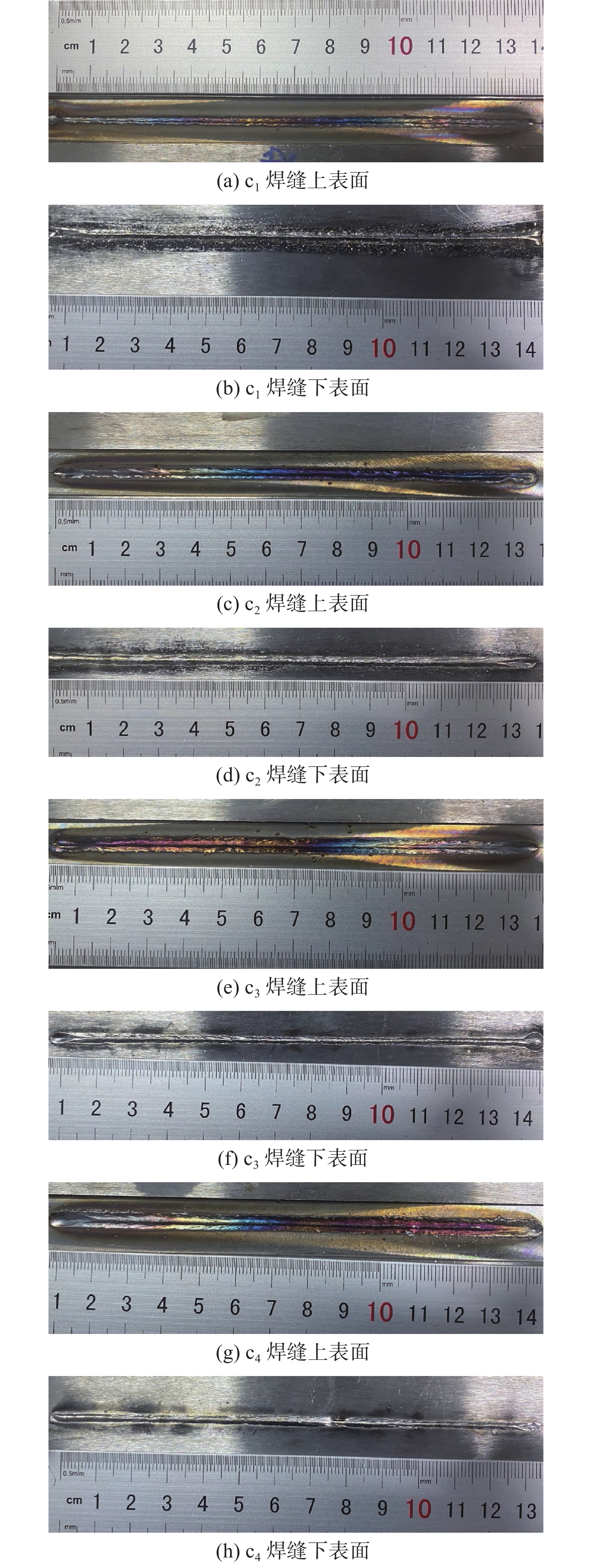

图 2 不同粒径粉末增材制造RAFM钢激光焊后表面形貌

Figure 2. Surface morphology of RAFM steel with different particle size powder by additive manufacturing after laser welding. (a) c1 weld upper surface; (b) c1 weld bottom surface; (c) c2 weld upper surface; (d) c2 weld bottom surface; (e) c3 weld upper surface; (f) c3 weld bottom surface; (g) c4 weld upper surface; (h) c4 weld bottom surface

表 1 RAFM钢化学成分(质量分数,%)

Table 1 Chemical compositions of RAFM steel

材料 C Cr Ta V W Si Mn Fe RAFM粉末 0.092 8.9 0.14 0.20 1.5 0.05 0.49 余量 增材RAFM钢 3.3 8.9 — 0.3 1.3 — — 余量 表 2 激光焊工艺参数

Table 2 Parameters of laser welding

激光功率

P/kW焊接速度

v/(m·min−1)离焦量

f/mm气体流量

Q/(L·min−1)6.1 1.3 + 10 1.5 -

[1] Li Y, Huang Q, Wu Y, et al. Mechanical properties and microstructures of China low activation martensitic steel compared with JLF-1[J]. Journal of Nuclear Materials, 2007, 367: 117 − 121.

[2] 姜志忠, 黄继华, 胡杰, 等. 聚变堆用CLAM 钢激光焊接接头显微组织及性能[J]. 焊接学报, 2012, 33(2): 5 − 8. Jiang Zhizhong, Huang Jihua, Hu Jie, et al. Microstructure and mechanical properties of laser welded joints of CLAM steel used for fusion reactor[J]. Transactions of the China Welding Institution, 2012, 33(2): 5 − 8.

[3] 胡杰, 姜志忠, 黄继华, 等. 热处理工艺对CLAM 钢电子束焊缝显微组织与冲击韧性的影响[J]. 焊接学报, 2012, 33(11): 67 − 71. Hu Jie, Jiang Zhizhong, Huang Jihua, et al. Effects of heat treatment processes on microstructure and impact toughness of weld metal of vacuum electron beam welding on CLAM steel[J]. Transactions of the China Welding Institution, 2012, 33(11): 67 − 71.

[4] 耿志杰, 王善林, 陈玉华, 等. 激光增材制造GH3625高温合金激光焊接头组织及力学性能[J]. 稀有金属材料与工程, 2020, 49(7): 2480 − 2487. Geng Zhijie, Wang Shanlin, Chen Yuhua, et al. Microstructure and mechanical properties of superalloy laser welded joints for GH3625 fabricated by laser additive[J]. Rare Metal Materials and Engineering, 2020, 49(7): 2480 − 2487.

[5] Yi Yan, Zhang Yuan, Dong Kaiji, et al. The development of 3D printing technology and the current situation of controlling defects in SLM technology[J]. China Welding, 2020, 29(3): 9 − 19.

[6] 吴世凯, 张建超, 廖洪彬, 等. 聚变堆低活化铁素体/马氏体(RAFM)钢焊接研究进展[J]. 机械工程学报, 2019, 55(2): 195 − 203. doi: 10.3901/JME.2019.02.195 Wu Shikai, Zhang Jianchao, Liao Hongbin, et al. Research progress of reduced activation ferrite/martensitic (RAFM) steel welding for fusion reactors[J]. Journal of Mechanical Engineering, 2019, 55(2): 195 − 203. doi: 10.3901/JME.2019.02.195

[7] 顾康家. CLAM 钢 TIG 焊组织与性能的研究[D]. 镇江: 江苏大学, 2009. Gu Kangjia. Microstructures and mechanical properties of CLAM steel in TIG weld[D]. Zhenjiang: Jiangsu University, 2009.

[8] Von der weth A, Kempe H, Aktaa J, et al. Optimization of the EUROFER uniaxial diffusion weld[J]. Journal of Nuclear Materials, 2007, 367: 1203 − 1207.

[9] Widodo Widjaja Basuki, Jarir Aktaa. Process optimization for diffusion bonding of tungsten with EUROFER97 using a vanadium interlayer[J]. Journal of Nuclear Materials, 2015, 459: 217 − 224. doi: 10.1016/j.jnucmat.2015.01.033

[10] Hu Zhiqiang, Zhao Fengchao, Wang Xiaoyu, et al. Mechanical and microstructural characterization for HIPed joints of CLF-1 steel with different surface roughness[J]. China Welding, 2020, 29(2): 53 − 59.

[11] 陈路, 王泽明, 陶海燕, 等. CLF-1低活化铁素体/马氏体钢真空电子束焊接研究[J]. 焊接技术, 2014, 43(5): 26 − 29,30. doi: 10.13846/j.cnki.cn12-1070/tg.2014.05.009 Chen Lu, Wang Zeming, Tao Haiyan, et al. Research on electron beam welding for CLF-1 reduced activation ferritic/martensitic steel[J]. Welding Technique, 2014, 43(5): 26 − 29,30. doi: 10.13846/j.cnki.cn12-1070/tg.2014.05.009

[12] Zou J L, Zhang G W, Xiao R S, et al. Ultra-narrow-groove laser welding for heavy sections in ITER[J]. Welding Journal, 2016, 95(8): 300s − 308s.

[13] Sanghoon Noh, Masami Ando, Hiroyasu Tanigawa, et al. Friction stir welding of F82H steel for fusion applications[J]. Journal of Nuclear Materials, 2016, 478: 1 − 6. doi: 10.1016/j.jnucmat.2016.05.028

[14] Cardella A, Rigal E, Bedel L, et al. The manufacturing technologies of the European breeding blankets[J]. Journal of Nuclear Materials, 2004, 329: 133 − 140.

[15] Hisashi Serizawa, Daiki Mori, Yuma Shirai, et al. Weldability of dissimilar joint between F82H and SUS316L under fiber laser welding[J]. Fusion Engineering and Design, 2013, 88: 2466 − 2470. doi: 10.1016/j.fusengdes.2013.03.041

[16] Hisashi Serizawa, Daiki Mori, Hiroyuki Ogiwara, et al. Effect of laser beam position on mechanical properties of F82H/SUS316L butt-joint welded by fiber laser[J]. Fusion Engineering and Design, 2014, 89: 1764 − 1768. doi: 10.1016/j.fusengdes.2013.12.003

[17] 张建超, 乔俊楠, 吴世凯, 等. 低活化铁素体/马氏体钢厚板光纤激光焊接接头组织及力学性能分析[J]. 焊接学报, 2018, 39(4): 124 − 128,134. doi: 10.12073/j.hjxb.2018390109 Zhang Jianchao, Qiao Junnan, Wu Shikai, et al. Microstructure and mechanical properties of fiber laser welded joints of reduced activation ferritic/martensitic CLF-1 steel heavy plate[J]. Transactions of the China Welding Institution, 2018, 39(4): 124 − 128,134. doi: 10.12073/j.hjxb.2018390109

[18] Wu Wenyong, Yang Zhi, Yue Shuangcheng. The comparison between laser screw welding and resistant spot welding of lap joint with large thickness ratio[J]. China Welding, 2021, 30(2): 58 − 66.

下载:

下载: