Analysis of reheat embrittlement and softening of coarse-grained zone of Q960E welding joint

-

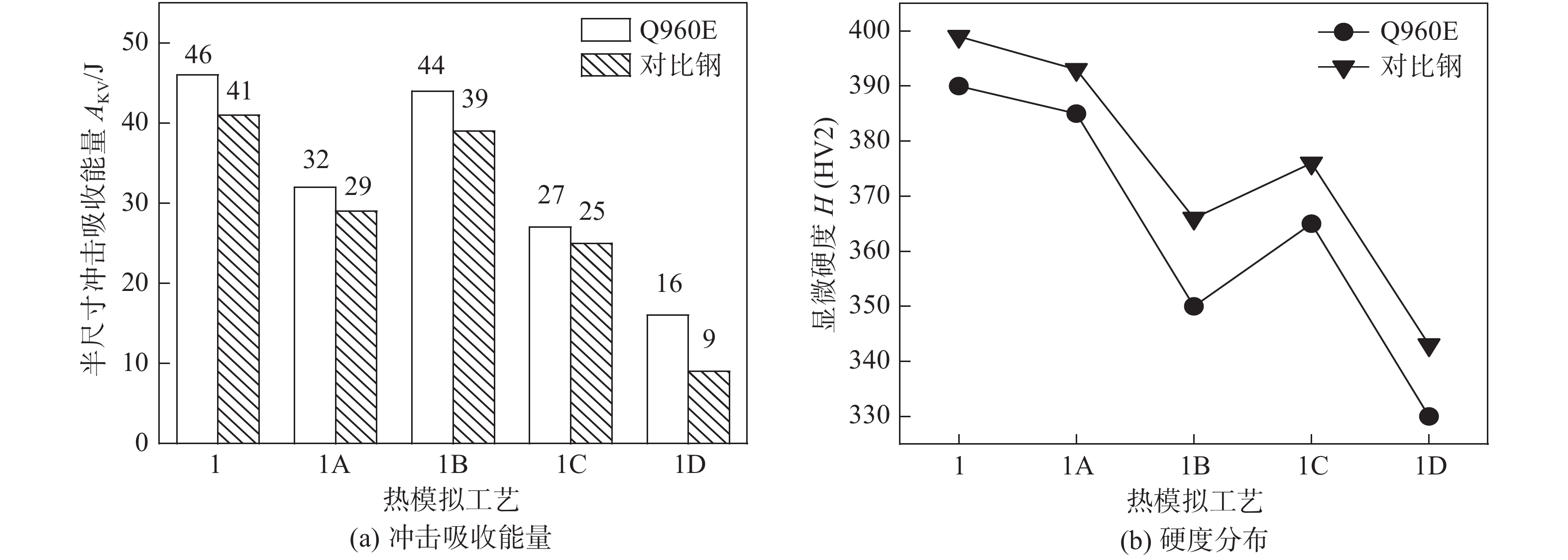

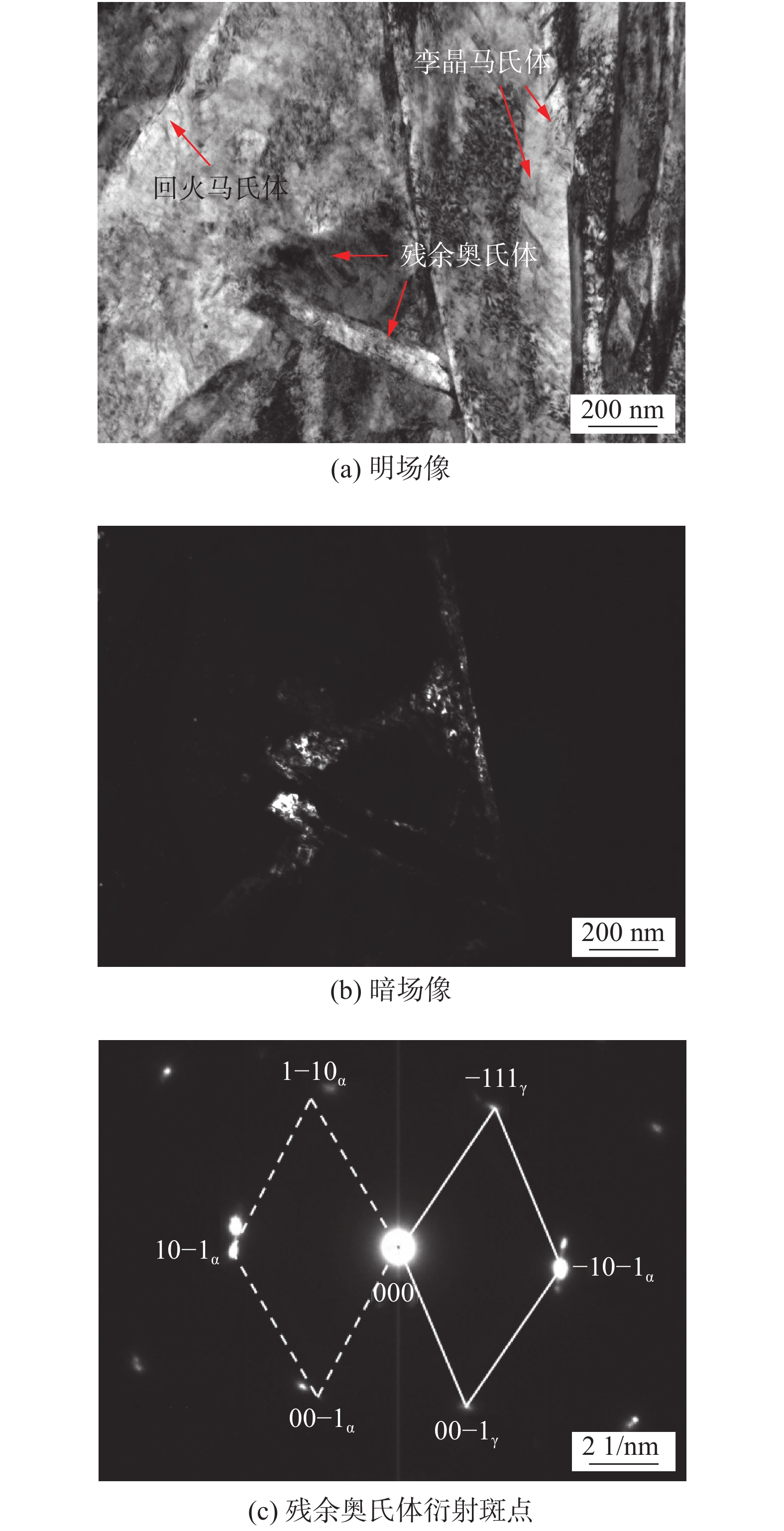

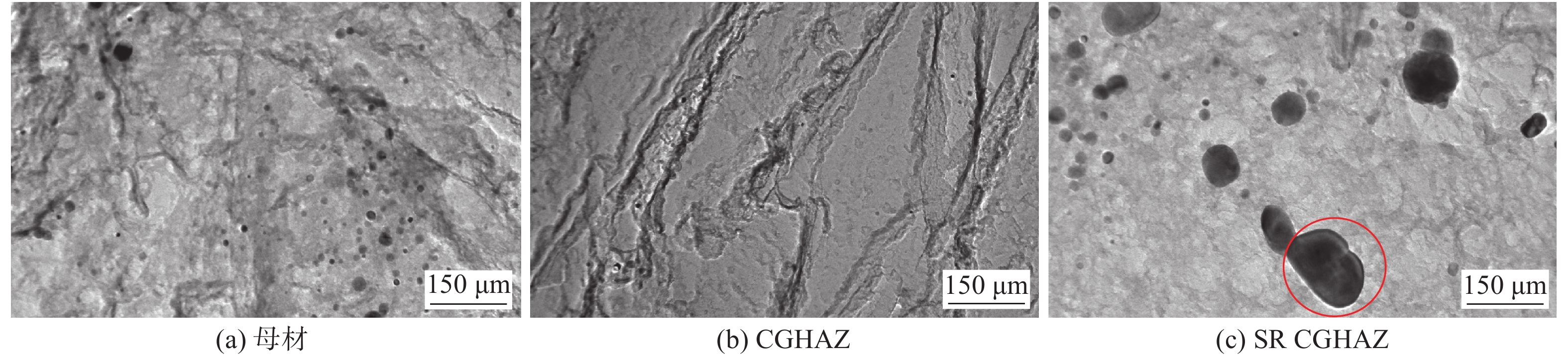

摘要: 为了精确获得不同温度梯度条件下焊接热影响区的组织和性能,采用焊接热模拟的方式对一种低碳当量Q960E及其对比钢进行了两次模拟热循环试验,并获得了一次热模拟后的CGHAZ,以及二次热模拟后的未变粗晶热影响区(UA CGHAZ)、过临界粗晶热影响区(SCR CGHAZ)、临界粗晶热影响区(ICR CGHAZ)和亚临界粗晶热影响区(SR CGHAZ)的显微组织,开展了组织分析、冲击韧性测试和硬度表征.结果表明,低碳当量Q960E和高碳当量对比钢的ICR CGHAZ和SR CGHAZ均有再热脆化敏感性,在−40 ℃下对比钢的SR CGHAZ的冲击韧性低至9 J,其晶界点状和条状碳化物分布是再热脆化的主要原因;低碳当量Q960E的SR CGHAZ软化最为严重,其原因是细晶强化、位错强化和析出强化联合丧失造成的.Abstract: In order to accurately obtain the microstructure and properties of the welding heat affected zone under different temperature gradient conditions, two simulated thermal cycle tests were carried out on a low carbon equivalent Q960E and its comparative steel by using the welding thermal simulation method. And the microstructures of CGHAZ after the first thermal simulation, and UA CGHAZ, SCR CGHAZ, ICR CGHAZ and SR CGHAZ after the second thermal simulation were obtained. Microstructures were analyzed, impact toughness test and hardness characterization were carried out in this paper. Results showed that both ICR CGHAZ and SR CGHAZ of Q960E and comparative steel had reheat embrittlement sensitivity. The impact toughness of SR CGHAZ of comparative steel was as low as 9 J at −40 ℃. And the distribution of point-type and strip-type carbides formed at the grain boundary was the main reason for reheating embrittlement. The softening of SR CGHAZ with low carbon equivalent Q960E is the most serious, which is caused by the combined loss of fine-grain strengthening, dislocation strengthening and precipitation strengthening.

-

Keywords:

- CGHAZ /

- reheat embrittlement /

- softening /

- thermal simulation

-

-

图 1 不同tp2温度下再热CGHAZ的SEM像

Figure 1. SEM images of reheated CGHAZ under different tp2 temperatures. (a) UA CGHAZ of Q960E; (b) UA CGHAZ of comparative steel; (c) SCR CGHAZ of Q960E; (d) SCR CGHAZ of comparative steel; (e) ICR CGHAZ of Q960E; (f) ICR CGHAZ of comparative steel; (g) SR CGHAZ of Q960E; (h) SR CGHAZ of comparative steel

表 1 Q960E和对比钢的化学成分(质量分数,%)

Table 1 Chemical composition of Q960E and its comparative steel

材料 C Si Mn P S Cu Ni Cr Mo B V Ceq Q960E 0.12 0.23 1.30 ≤0.02 ≤0.002 — — 0.50 0.50 0.001 2 0.1 0.395 对比钢 0.14 0.40 1.0 ≤0.02 ≤0.002 0.1 2.2 0.50 0.50 0.001 1 — 0.546 注:Ceq= C + ( Mn + Si )/6 + ( Ni + Cu )/15 + ( Cr + Mo + V )/50 表 2 Q960E和对比钢的典型力学性能

Table 2 Typical mechanical properties of Q960E and its comparative steel

材料 屈服强度ReL/MPa 抗拉强度Rm/MPa 断后伸长率A50(%) −40 ℃冲击吸收能量AKV(%) Q960E 990 1 020 13.5 43, 40, 49 对比钢 1 000 1 080 13.0 45, 47, 43 表 3 CGHAZ热模拟工艺

Table 3 Thermal simulation process of CGHAZ

工艺

编号一次热循环 二次热循环 预热温度

T0/℃升温速率

v /(℃·s−1)峰值温度

Tc/℃保温时间

ts/s热循环时间

t8/5/ s升温速率

v /(℃·s−1)峰值温度

Tc/℃保温时间

ts/s热循环时间

t8/5/s1 25 150 1 250 2 7 — — — — 1A 25 150 1 250 2 7 150 1 250 2 7 1B 25 150 1 250 2 7 150 950 2 10 1C 25 150 1 250 2 7 150 750 2 12 1D 25 150 1 250 2 7 150 600 2 15 -

[1] Joseph C, Benedyk. Light metal in automotive applications[J]. Light Metal Age, 2000, 58(10): 34 − 35.

[2] 张楠, 田志凌, 董现春, 等. Q960E热影响粗晶区疲劳寿命与ΔKth值的关系分析[J]. 焊接学报, 2018, 39(7): 106 − 110. Zhang Nan, Tian Zhiling, Dong Xianchun, et al. Research on relationship between ΔKth and fatigue life of heat-affected coarse grain zone in Q960E[J]. Transactions of the China Welding Institution, 2018, 39(7): 106 − 110.

[3] Zhou Y L, Jia T, Zhang X J, et al. Microstructure and toughness of the CGHAZ of an offshore platform steel[J]. Journal of Materials Processing Technology, 2015, 219: 314 − 320.

[4] Lambert A, Drillet J, Gourgues A F, et al. Microstructure of mattensite-austensite constituents in heat affected zones of high strength low alloy steel welds in relation to toughness properties[J]. Science and Technology of Welding and Joining, 2000, 5(3): 168 − 173.

[5] Davis C L, King J E. Cleavage initiation in the intercritically reheated coarse-grained heat-affected zone: Part I. fractographiv evidence[J]. Metallurgical and Materials Transactions A, 1994, 25(3): 563 − 573.

[6] Wang C M, Wu X F, Liu J, et al. Transmission electron microscopy of martensite/austensite islands in pipeline steel X70[J]. Materials Science and Engineering A, 2006, 438(25): 257 − 271.

[7] 张楠, 田志凌, 张书彦, 等. 700MPa微合金高强钢焊接软化机理及解决方案[J]. 钢铁研究学报, 2019, 31(3): 318 − 326. Zhang Nan, Tian Zhiling, Zhang Shuyan, et al. Mechanism and solution of welding softening for 700MPa microalloyed high strength steel[J]. Journal of Iron and Steel Research, 2019, 31(3): 318 − 326.

[8] 董现春, 潘辉, 赵阳, 等. 仿弹钢板激光焊接接头的组织和性能[J]. 材料热处理学报, 2019, 40(9): 163 − 168. Dong Xianchun, Pan Hui, Zhao Yang, et al. Microstructure and properties of laser welded joint of bulletproof steel plant[J]. Transactions of Materials and Heat Treatment, 2019, 40(9): 163 − 168.

[9] 王学, 常建伟, 黄关政, 等. WB36钢临界再热粗晶区组织和性能[J]. 焊接学报, 2008, 29(10): 29 − 32. Wang Xue, Chang Jianwei, Huang Guanzheng, et al. Study on microstructure and properties of IRCGHAZ in WB36 steel[J]. Transactions of the China Welding Institution, 2008, 29(10): 29 − 32.

[10] 姚钦. HQ-80钢再热裂纹机理[J]. 焊接学报, 2004, 25(6): 77 − 81. Yao Qin. Mechanism of HQ-80 steel reheat crack[J]. Transactions of the China Welding Institution, 2004, 25(6): 77 − 81.

[11] Hu J, Du L X, Wang J J, et al. High toughness in the intercritically reheated coarse-grained (ICRCG) heat-affected zone (HAZ) of low carbon microalloyed steel[J]. Materials Science and Engineering A, 2014, 590: 323 − 328.

[12] 张楠, 董现春, 张熹, 等. 钛微合金化SQ700MCD高强钢粗晶热影响区软化的原因[J]. 机械工程材料, 2012, 36(4): 88 − 92. Zhang Nan, Dong Xianchun, Zhang Xi, et al. The softening analysis of CGHAZ in Ti microalloyed SQ700MCD steel[J]. Materials for Mechanical Engineering, 2012, 36(4): 88 − 92.

[13] 张楠, 董现春, 徐晓宁, 等. Ti-Nb微合金化高强钢的焊接接头组织和性能[J]. 材料热处理学报, 2014, 35(6): 115 − 120. Zhang Nan, Dong Xianchun, Xu Xiaoning, et al. Microstructure and property of welding joint with Ti-Nb microalloyed high-strength steel[J]. Transactions of Materials and Heat Treatment, 2014, 35(6): 115 − 120.

[14] 张楠, 董现春, 潘辉, 等. 高Ti-Nb系高强钢焊接接头回火前后的力学行为[J]. 焊接学报, 2015, 36(5): 93 − 98. Zhang Nan, Dong Xianchun, Pan Hui, et al. Mechanical behavior of welded joint of a high Ti-Nb content microalloyed high-strength steel before and after drawing temper treatment[J]. Transactions of the China Welding Institution, 2015, 36(5): 93 − 98.

[15] 张楠, 田志凌, 张书彦, 等. 感应回火对含钒900MPa级高强钢组织与性能的影响[J/OL]. 热加工工艺: 1-5[2020-11-11]. https://doi.org/10.14158/j.cnki.1001-3814.20193019. Zhang Nan, Tian Zhiling, Zhang Shuyan, et al. Effects of induction tempering on microstructure and properties of 900 MPa grade high strength steel containing vanadium[J/OL]. Hot Working Technology: 1-5 [2020-11-11]. https://doi.org/10.14158/j.cnki.1001-3814.20193019.

[16] 李晓林, 崔阳, 肖宝亮, 等. V-N微合金钢在线快速感应回火工艺中V(C, N)析出强化机制[J]. 金属学报, 2018, 54(10): 1368 − 1376. doi: 10.11900/0412.1961.2018.00119 Li Xiaolin, Cui Yang, Xiao Baoliang, et al. Effect of on-line rapid induction tempering on precipitation strengthening mechanism of V(C, N) in V-N microalloyed steel[J]. ACTA Metallurgica Sinica, 2018, 54(10): 1368 − 1376. doi: 10.11900/0412.1961.2018.00119

[17] Mohseni P, Solberg J K, Karlsen M, et al. Investigation of mechanism of cleavage fracture initiation in intercritically coarse grained heat affected zone of HSLA steel[J]. Materials Science and Technology, 2012, 28(11): 1261 − 1268.

[18] Moeinifar S, Kokabi A H, Hosseini H R M. Influence of peak temperature during simulation and real thermal cycles on microstructure and fracture properties of the reheated zones[J]. Materials and Design, 2010, 31(6): 2948 − 2955.

[19] 李永亮. 700 MPa级高强度汽车大梁钢成分设计与组织控制研究[D]. 北京: 北京科技大学, 2017. Li Yongliang. Study on composition design and microstrucyure control about 700 MPa grade high strength beam steel for vehicles [D].Beijing: University of Science and Technology Beijing, 2017.

[20] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006. Yong Qilong. Secondary phases in steels [M]. Beijing: Metallurgical Industry Press, 2006.

下载:

下载: