Arc spraying Ag-based coating on aluminum alloy surface and its low-temperature soldering behavior

-

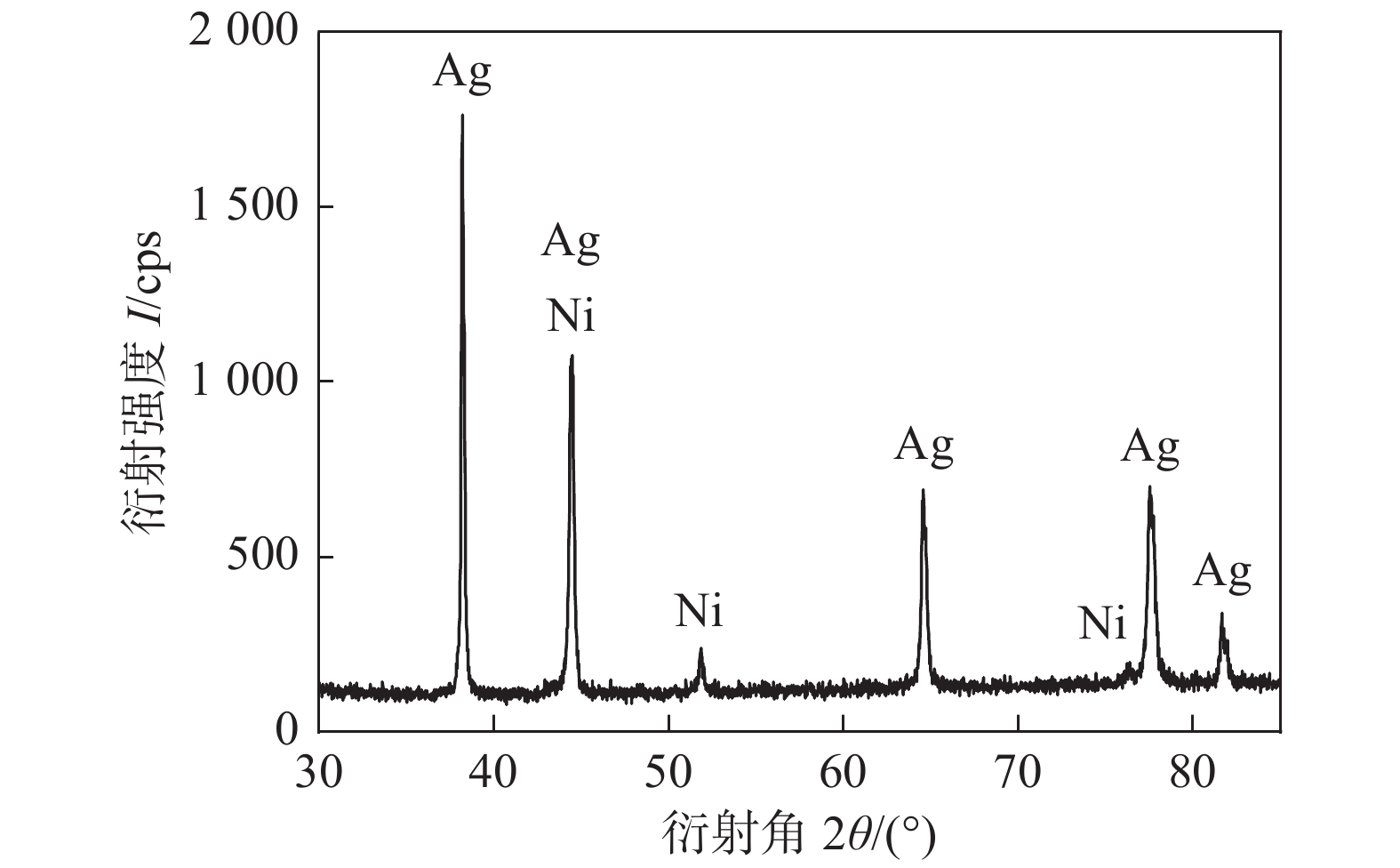

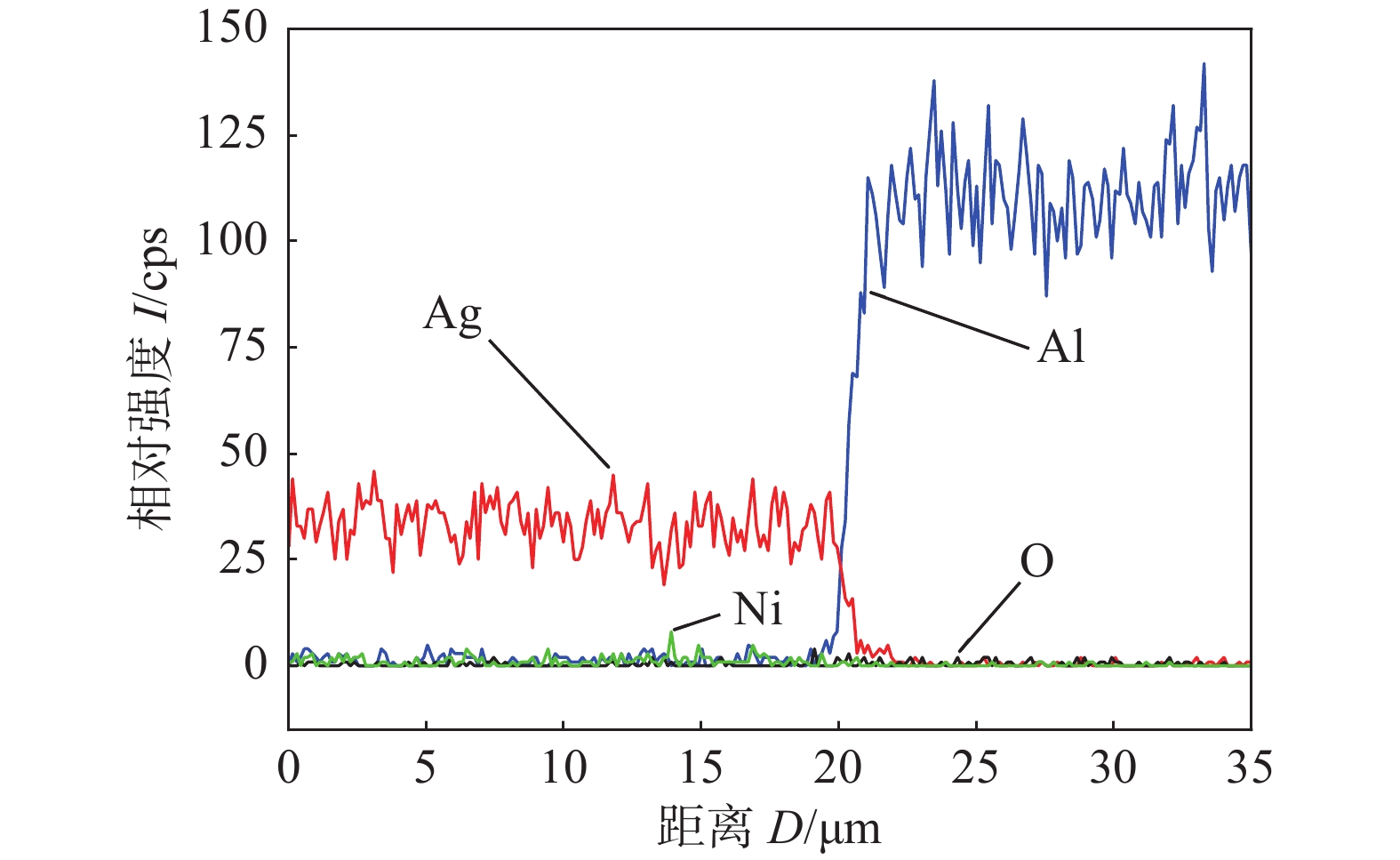

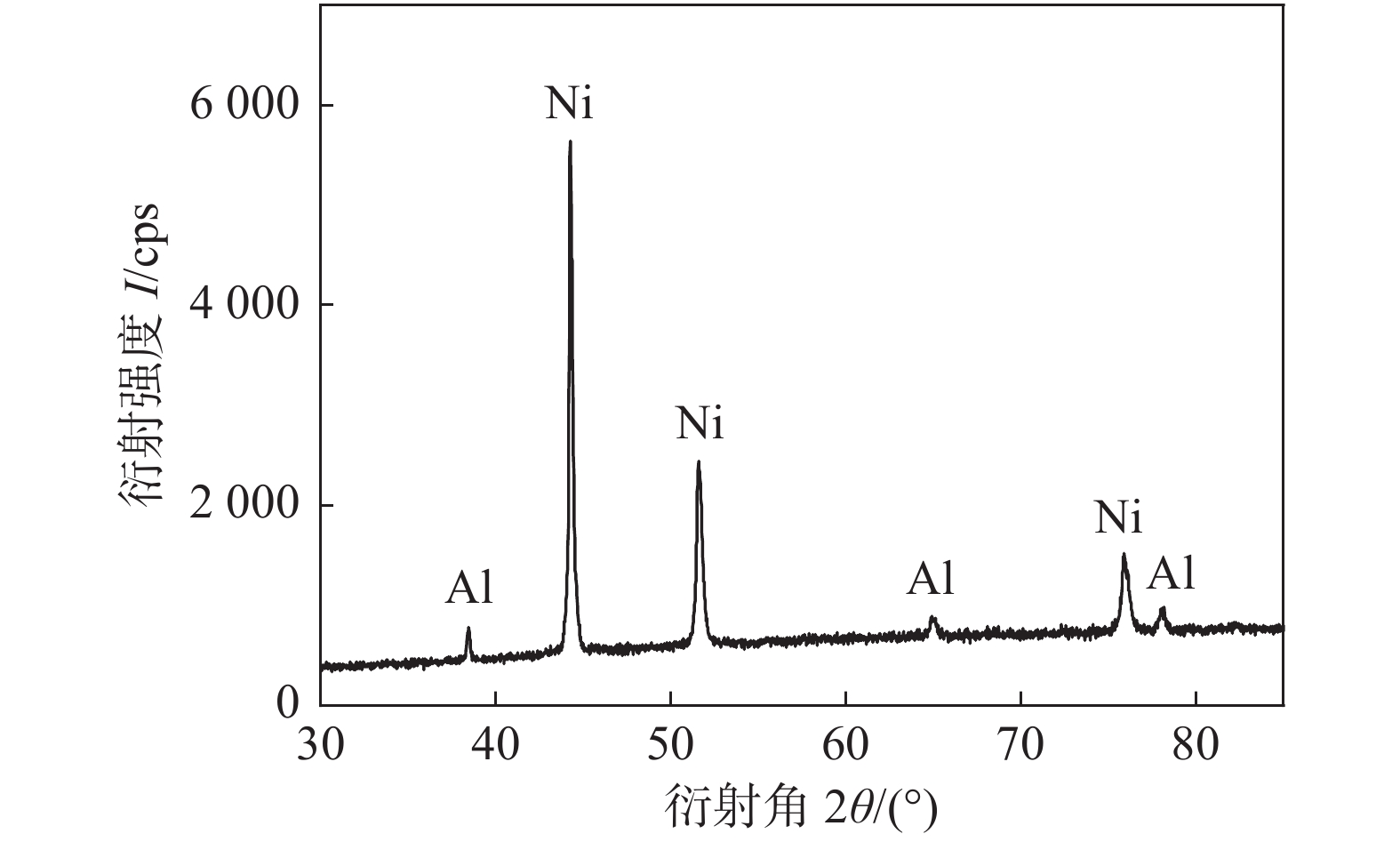

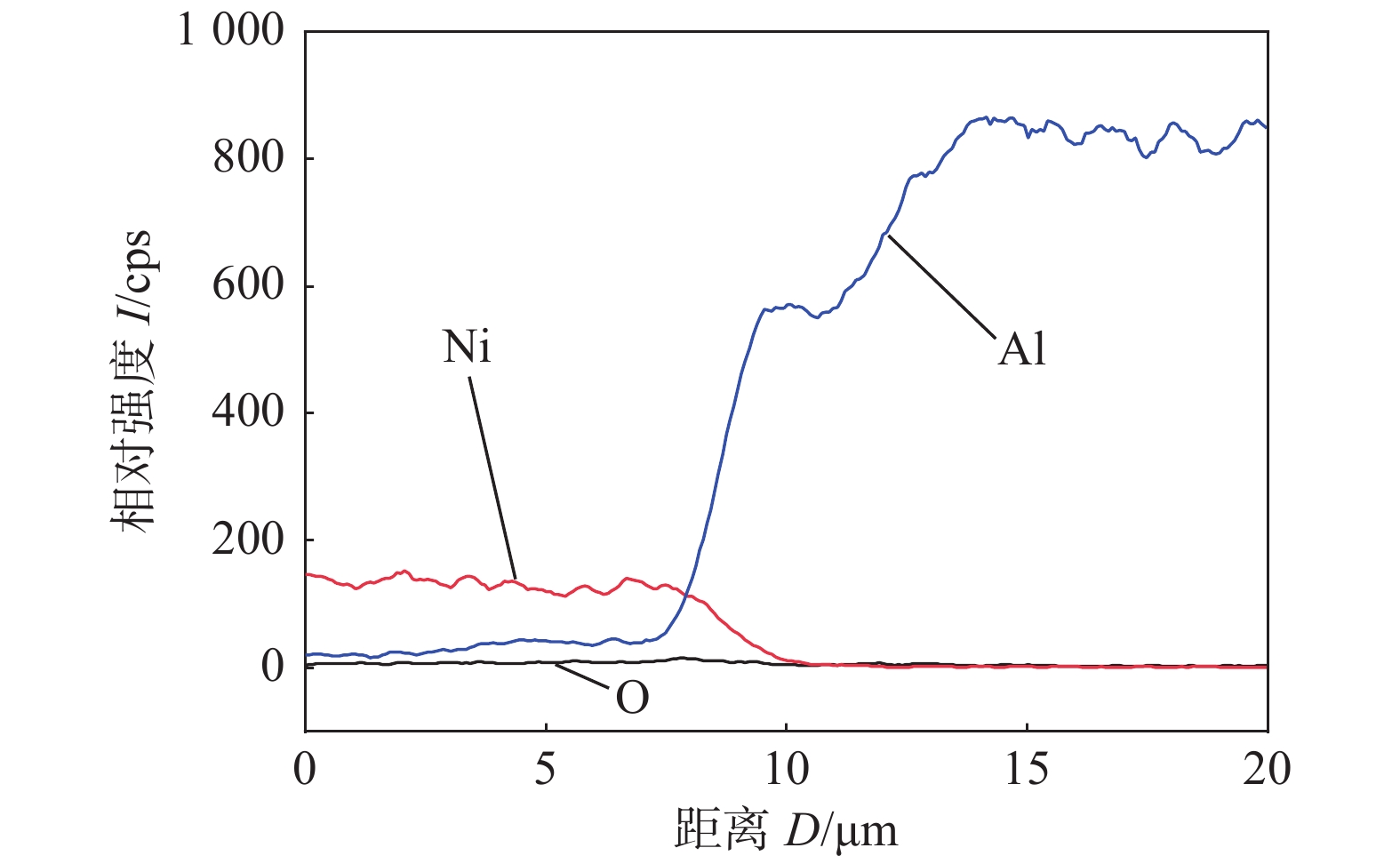

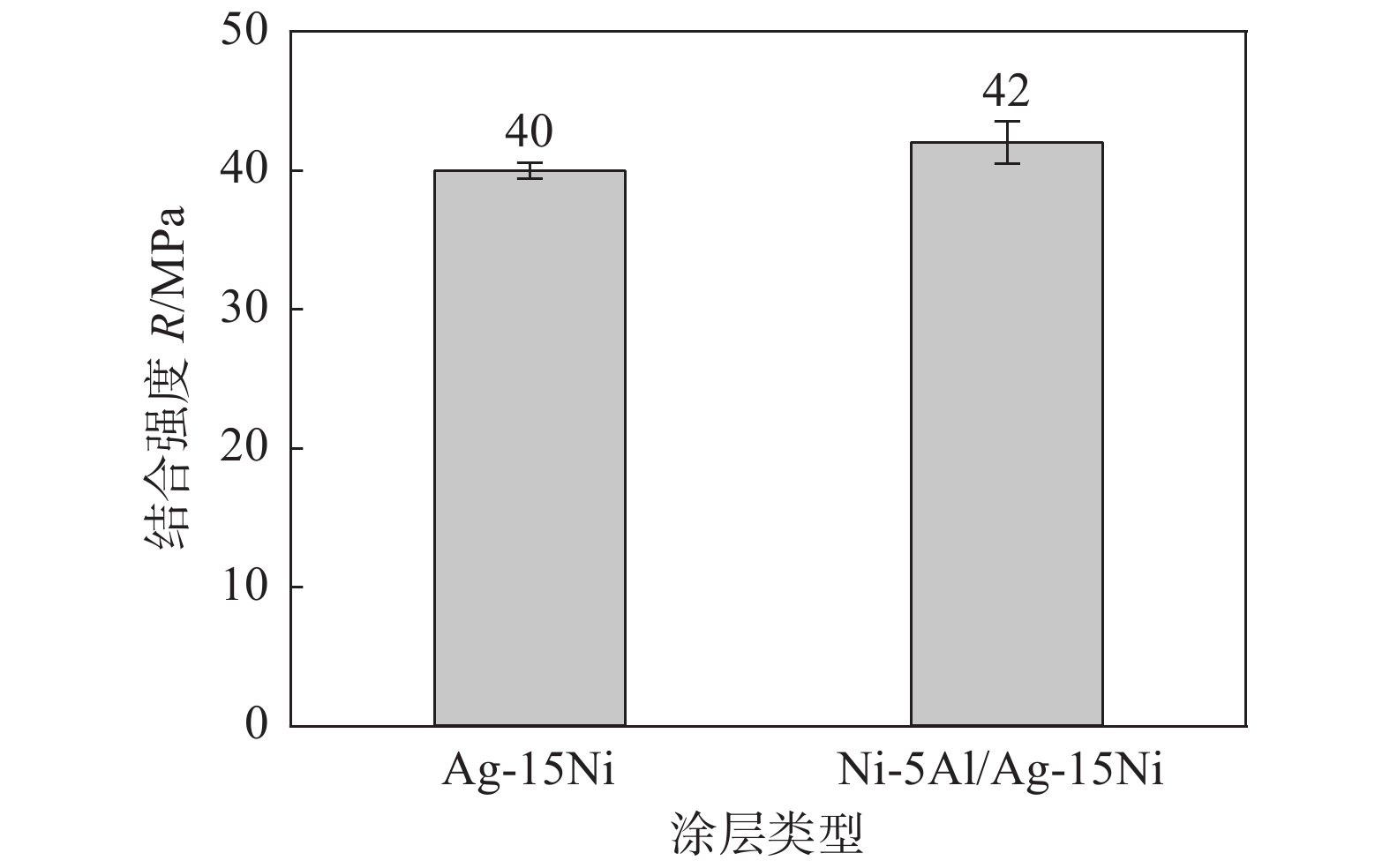

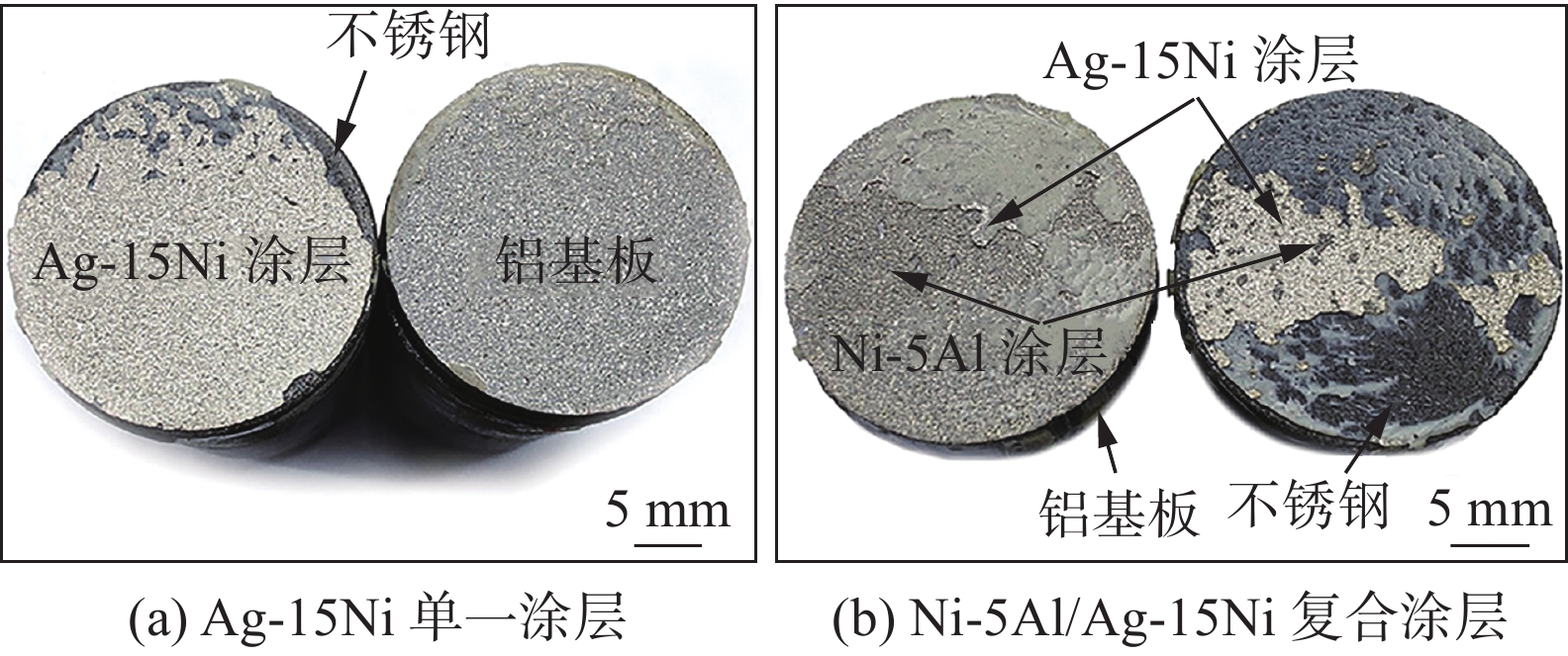

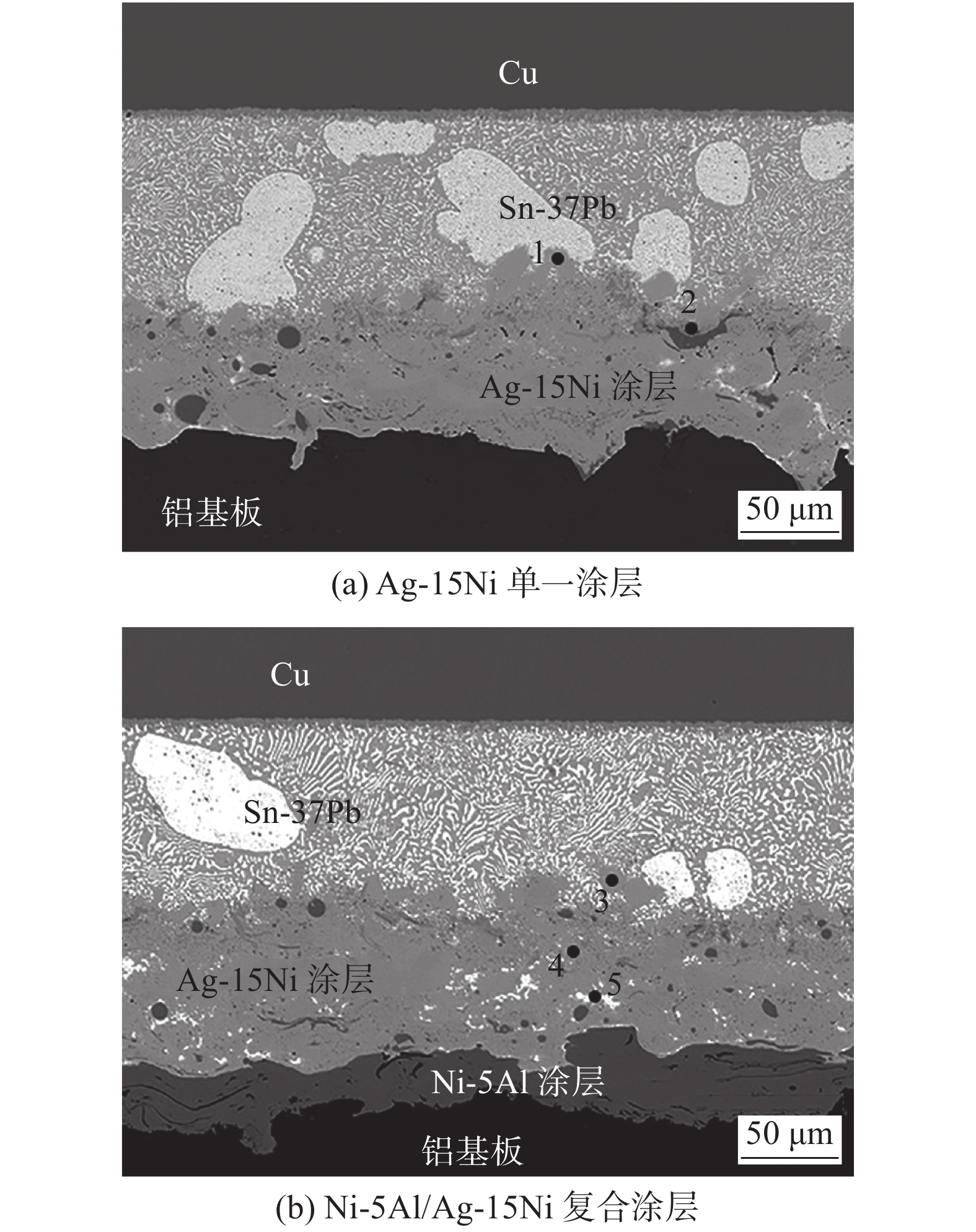

摘要: 在波导器件中,铝合金壳体较差的润湿性制约了其与微带电路板之间大面积、可靠低温钎焊连接. 通过电弧喷涂技术在5A06铝合金表面制备了厚度约为80 μm的Ag-15%Ni(质量分数)单一涂层和Ni-5%Al/Ag-15%Ni(质量分数)复合涂层,以提升Sn-Pb钎料在其表面的润湿性. 对比研究了两种涂层的显微结构、涂层界面结合性能、低温钎焊行为及钎焊接头剪切失效机制. 结果表明,涂层与铝合金基板间形成了良好的界面结合,并且两种涂层均具有较好的低温焊接性. 其中,Ag-15%Ni单一涂层与铝合金基板的结合强度为40 MPa,喷涂后铝合金基板与T2紫铜形成的钎焊接头抗剪强度为26 MPa. 相较而言,Ni-5%Al /Ag-15%Ni复合涂层展现出更佳的涂层结合强度(42 MPa)和钎焊接头抗剪强度(31 MPa).Abstract: In waveguide devices, large-area and reliable low-temperature soldering bonding between the aluminum alloy shell and the microstrip circuit board were difficult because of the poor wettability of the Al alloy. In this study, Ag-15%Ni coating layer and Ni-5%Al/Ag-15%Ni composite coating layers with a thickness approximately of 80 μm were prepared on the surface of 5A06 Al alloy by arc spraying technology to improve the wettability of Sn-Pb alloy solder on the Al alloy surface. Comparable studies were performed on the microstructure, interfacial bonding behavior, low-temperature soldering behavior of the two kinds of coating layers, and the shearing failure mechanism of joints were investigated. Results showed that sound interfacial bonding was realized between the coating layer and the Al alloy substrate. Moreover, the two kinds of coating layers both exhibited good solderability at low-temperature. The bonding strength between the Ag-15%Ni coating layer and the Al alloy substrate was 40 MPa, and the shear strength of the soldering joint formed by the sprayed aluminum alloy substrate and T2 copper was 26 MPa. While, the Ni-5%Al/Ag-15%Ni composite coatings exhibited better bonding strength with the Al alloy substrate (42 MPa) and higher shear strength of the soldering joint (31 MPa) than the Ag-15%Ni single coating layer.

-

-

表 1 涂层的制备参数

Table 1 Preparation parameters of the coatings

涂层类型 电弧喷涂

丝材喷涂电压

U/V喷涂电流

I/A喷枪移动速度

v/(m·min−1)喷枪口到工件

距离S/cm气体压力

P/MPa气源

类型Ag-15Ni单一涂层 Ag-15Ni 34 280 10 15 0.6 纯N2 Ni-5Al/Ag-15Ni

复合涂层Ni-5Al 34 150 10 18 0.6 纯N2 Ag-15Ni 34 280 12 15 0.6 纯N2 表 2 Ag-15Ni涂层内局部位置的元素含量(原子分数, %)

Table 2 Elemental compositions in local positions inside the Ag-15Ni coating layer

测试点 Ni Al Ag O 1 97.36 — 2.64 — 2 7.27 ― 92.73 ― 表 3 Ni-5Al涂层内部局部位置的元素含量(原子分数, %)

Table 3 Elemental compositions in local positions inside the Ni-5Al coating layer

测试点 Ni Al Ag O 1 13.59 56.28 ― 30.13 2 88.31 11.69 ― ― 表 4 Ni-5Al/Ag-15Ni复合涂层内部局部位置的元素含量 (原子分数, %)

Table 4 Elemental compositions in local positions inside the Ni-5Al/Ag-15Ni composite coating layer

测试点 Ni Al Ag O 1 21.85 ― 78.15 ― 2 8.80 ― 91.20 ― 表 5 不同涂层钎焊接头中局部位置的元素含量(原子分数,%)

Table 5 Elemental compositions in local positions inside the soldered joints with different coating layer

测试点 Ni Cu Ag Sn Pb 主要物相 1 ― ― 66.02 31.57 2.41 Ag3Sn 2 6.99 41.66 ― 44.74 6.61 (Cu,Ni)6Sn5 3 ― ― 76.16 23.84 ― Ag3Sn 4 ― ― 73.55 26.45 ― Ag3Sn 5 ― ― ― 37.57 62.43 Sn-Pb过共晶 -

[1] 苑博. 微带天线大面积钎焊技术研究[J]. 焊接技术, 2019, 48(4): 39 − 41,47. doi: 10.13846/j.cnki.cn12-1070/tg.2019.04.011 Yuan Bo. Research on large-area brazing technology of microstrip antenna[J]. Welding Technology, 2019, 48(4): 39 − 41,47. doi: 10.13846/j.cnki.cn12-1070/tg.2019.04.011

[2] Zbigniew M, Ireneusz C, Tomasz W. Soldering of 7075 aluminum alloy using Ni-P and Cu-Cr electrodeposited interlayers[J]. Materials, 2020, 13(18): 4100. doi: 10.3390/ma13184100

[3] 杨波, 田修波, 巩春志. 铝合金表面磁控溅射Cu膜的镀制及其低温钎焊性能研究[J]. 真空科学与技术学报, 2014, 34(2): 153 − 157. doi: 10.3969/j.issn.1672-7126.2014.02.11 Yang Bo, Tian Xiubo, Gong Chunzhi. Low temperature soldering of Al alloy modified with sputtered and ion implanted Cu coatings[J]. Chinese Journal of Vacuum Sciense and Technology, 2014, 34(2): 153 − 157. doi: 10.3969/j.issn.1672-7126.2014.02.11

[4] Guo K, Liu Y, Gou G, et al. Electroplating and brazing joining of 5083 aluminum alloy to CFRP[J]. International Journal of Modern Physics B, 2019, 33(1-3): 1940044.

[5] 皇倩. 铝合金表面高性能涂层的制备与性能研究[D]. 北京: 北京大学, 2019. Huang Qian. Preparation and properties of high-performance coating on aluminum alloy[D]. Beijing: Peking University, 2019.

[6] 李文亚, 曹聪聪, 杨夏炜, 等. 冷喷涂复合加工制造技术及其应用[J]. 材料工程, 2019, 47(11): 53 − 63. doi: 10.11868/j.issn.1001-4381.2019.000262 Li Wenya, Cao Congcong, Yang Xiawei, et al. Cold spraying hybrid processing technology and its application[J]. Journal of Materials Engineering, 2019, 47(11): 53 − 63. doi: 10.11868/j.issn.1001-4381.2019.000262

[7] 聂海杰, 李红, 龙伟民, 等. 采用冷喷涂铜涂层做中间层的镁合金与钢共晶接触反应钎焊工艺及接头性能[J]. 焊接学报, 2016, 37(7): 83 − 87. Nie Haijie, Li Hong, Long Weimin, et al. Brazing process and jointproperties of eutectic contact reaction between magnesium alloyand steel using cold sprayed copper coating as the intermediatelayer[J]. Transactions of the China Welding Institution, 2016, 37(7): 83 − 87.

[8] Tomasz W, Paweł S, Leszek Ł, et al. Application of plasma sprayed Cu intermediate layers in the soldering process of graphite composite to 6060 aluminum alloy[J]. Materials, 2020, 13(22): 5114. doi: 10.3390/ma13225114

[9] 刘正卫. 电弧喷涂锌铝涂层工艺参数优化及性能研究[D]. 广州: 广东工业大学, 2019. Liu Zhengwei. Study on process parameters and optimization andpropertis of arc spraying zinc-aluminium coating[D]. Guangzhou: Guangdong University of Technology, 2019.

[10] 李长久. 热喷涂技术应用及研究进展与挑战[J]. 热喷涂技术, 2018, 10(4): 1 − 22. doi: 10.3969/j.issn.1674-7127.2018.04.001 Li Changjiu. Applications, research progresses and future challenges of thermal spray technology[J]. Thermal Spray Technology, 2018, 10(4): 1 − 22. doi: 10.3969/j.issn.1674-7127.2018.04.001

[11] Li Q, Song P, Ji Q, et al. Microstructure and wear performance of arc-sprayed Al/316L stainless-steel composite coating[J]. Surface & Coatings Technology, 2019, 374: 189 − 200.

[12] Kim J-K, Xavier F-A, Kim D-E. Tribological properties of twin wire arc spray coated aluminum cylinder liner[J]. Materials & Design, 2015, 84: 231 − 237.

[13] Naimi A, Yousfi H, Trari M. Microstructure and corrosion resistance of molybdenum and aluminum coatings thermally sprayed on 7075-T6 aluminum alloy[J]. Protection of Metals and Physical Chemistry of Surfaces, 2012, 48(5): 557 − 562. doi: 10.1134/S2070205112050061

[14] 陈永雄, 梁秀兵, 程江波, 等. 异质双丝电弧喷涂制备复合涂层的工艺优化[J]. 焊接学报, 2019, 40(2): 38 − 41. Chen Yongxiong, Liang Xiubing, Cheng Jiangbo, et al. Process optimization of a hybrid twin-wire arc sprayed composite coating[J]. Transactions of the China Welding Institution, 2019, 40(2): 38 − 41.

[15] 吴铭方, 司乃潮, 陈健. 铝/镀银层/钢的扩散钎焊及界面化合物的生长行为[J]. 中国有色金属学报, 2010, 20(6): 1209 − 1213. doi: 10.19476/j.ysxb.1004.0609.2010.06.027 Wu Mingfang, Si Naichao, Chen Jian. Diffusion brazing of Al/Ag plating layer/steel and growth behavior of interface compound[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1209 − 1213. doi: 10.19476/j.ysxb.1004.0609.2010.06.027

[16] Luo X, Smith G M, Sampath S. On the interplay between adhesion strength and tensile properties of thermal spray coated laminates—Part I: high velocity thermal spray coatings[J]. Journal of Thermal Spray Technology, 2018, 27(3): 296 − 307. doi: 10.1007/s11666-018-0695-1

[17] Wang J X, Wang G X, Liu J S, et al. Microstructure of Ni–Al powder and Ni–Al composite coatings prepared by twin-wire arc spraying[J]. International Journal of Minerals Metallurgy and Materials, 2016, 23(7): 810 − 818. doi: 10.1007/s12613-016-1295-z

[18] Wang J X, Liu J S, Zhang L Y, et al. Microstructure and mechanical properties of twin-wire arc sprayed Ni-Al composite coatings on 6061-T6 aluminum alloy sheet[J]. International Journal of Minerals Metallurgy and Materials, 2014, 21(5): 469 − 478. doi: 10.1007/s12613-014-0931-8

[19] Li J F, Agyakwa P A, Johnson C M. Kinetics of Ag3Sn growth in Ag-Sn-Ag system during transient liquid phase soldering process[J]. Acta Materialia, 2010, 58(9): 3429 − 3443. doi: 10.1016/j.actamat.2010.02.018

-

期刊类型引用(4)

1. 朱清清,张津超,王恒,曹宇鹏,苏波泳,花国然. 开放环境下钛合金激光熔覆的表面色差模型研究. 表面技术. 2024(07): 156-163+199 .  百度学术

百度学术

2. 宣鹏举,张淑婷,唐卫岗,欧阳佩旋,张涛,唐紫苑. 铜磷钎料热加工过程表观变色机理研究. 有色金属工程. 2022(03): 24-31 .  百度学术

百度学术

3. 刘晓芳,张冠星,常云峰,王蒙,钟素娟. 干燥过滤器焊后泄露原因. 焊接. 2021(10): 34-37+62-63 .  百度学术

百度学术

4. 刘亦贤,陈永,李书珍,蔡国磊,赵晨,李国鹏,戴谷川. 铜磷钎料对钎焊性能影响的研究进展. 热加工工艺. 2020(23): 1-7 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: