Effect of banded structure on mechanical properties of aluminum/magnesium dissimilar metal friction stir welding joint

-

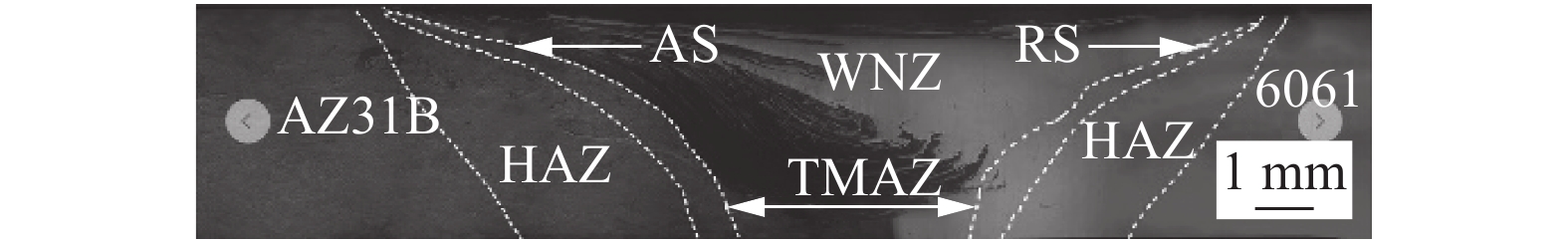

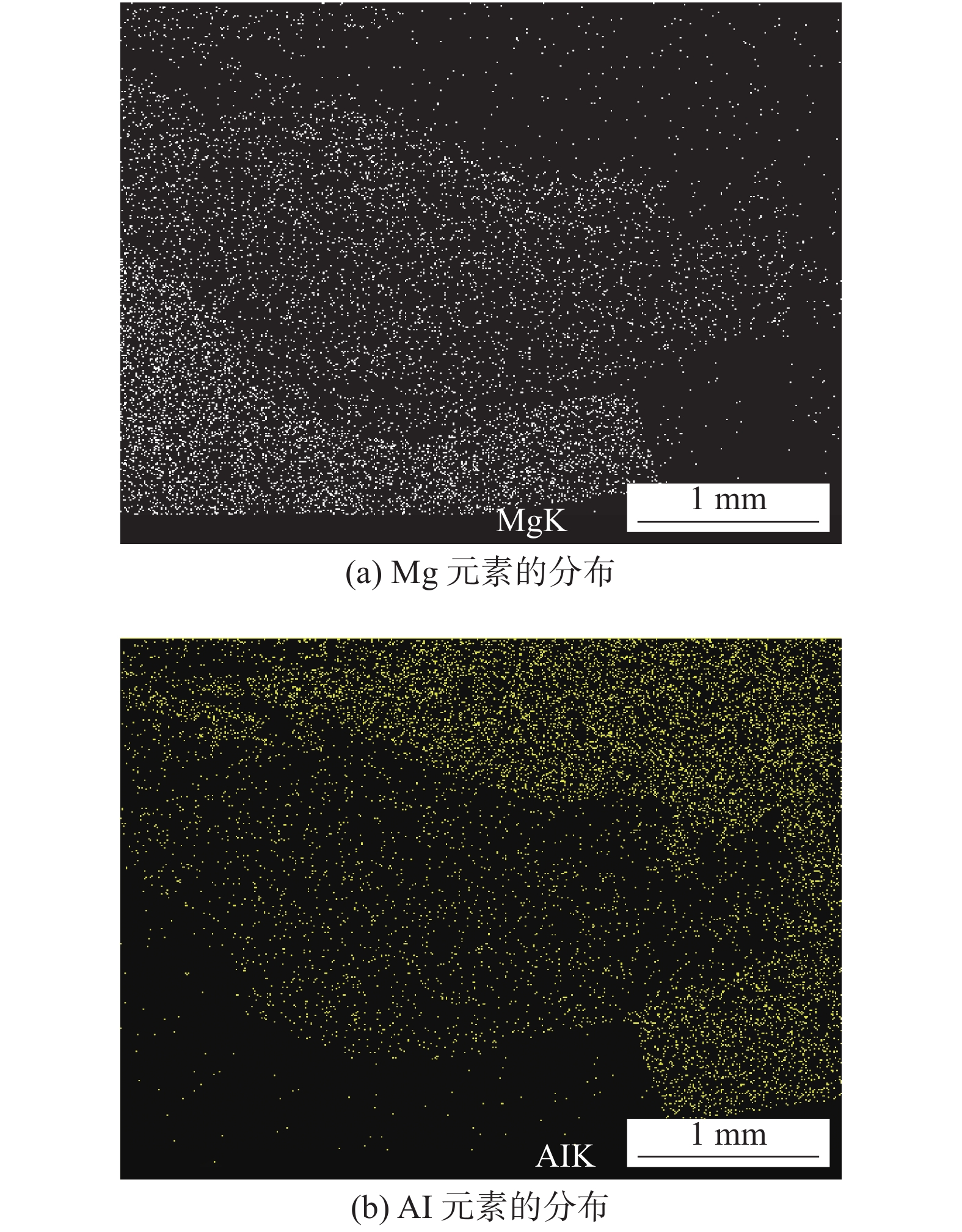

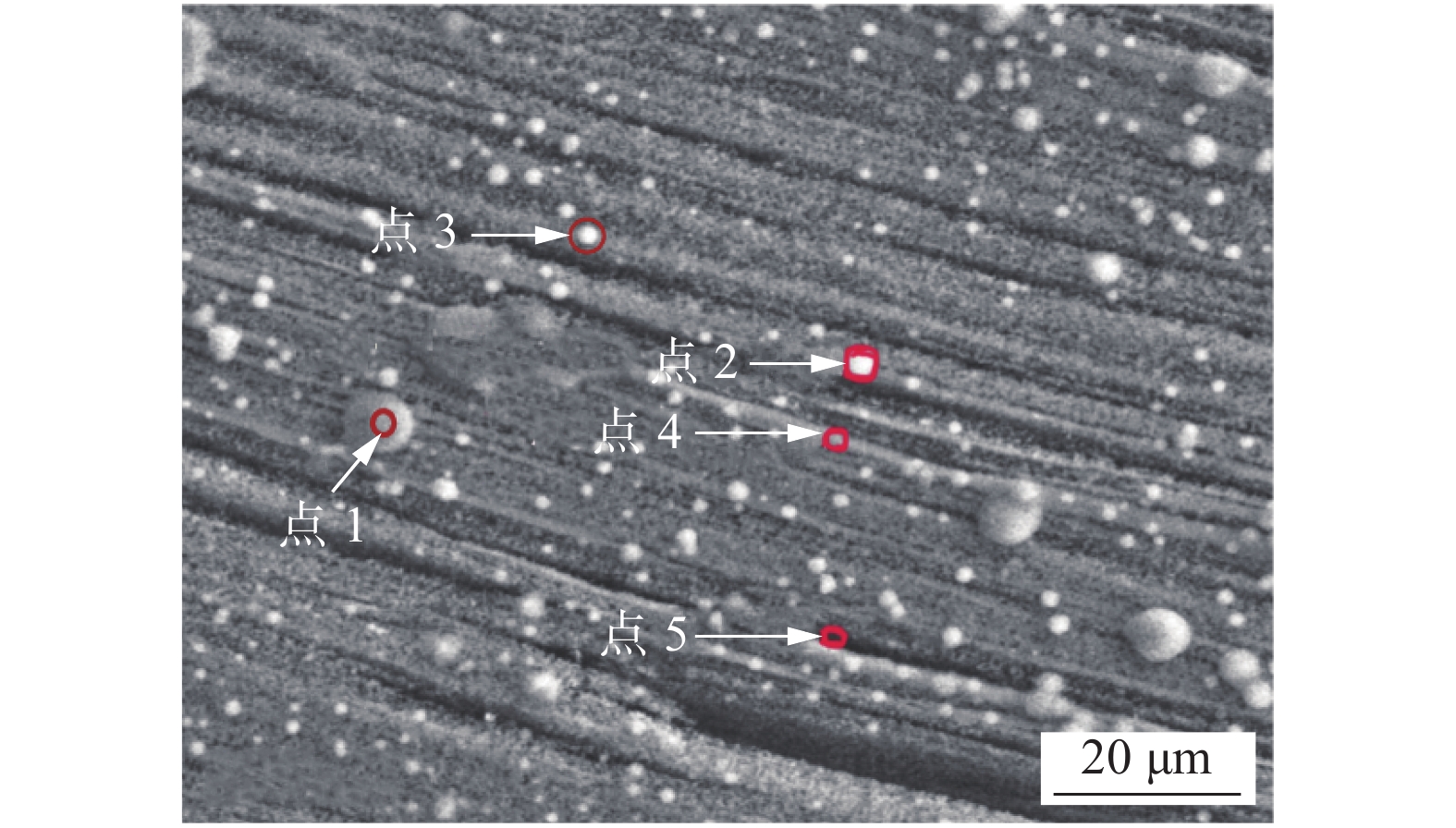

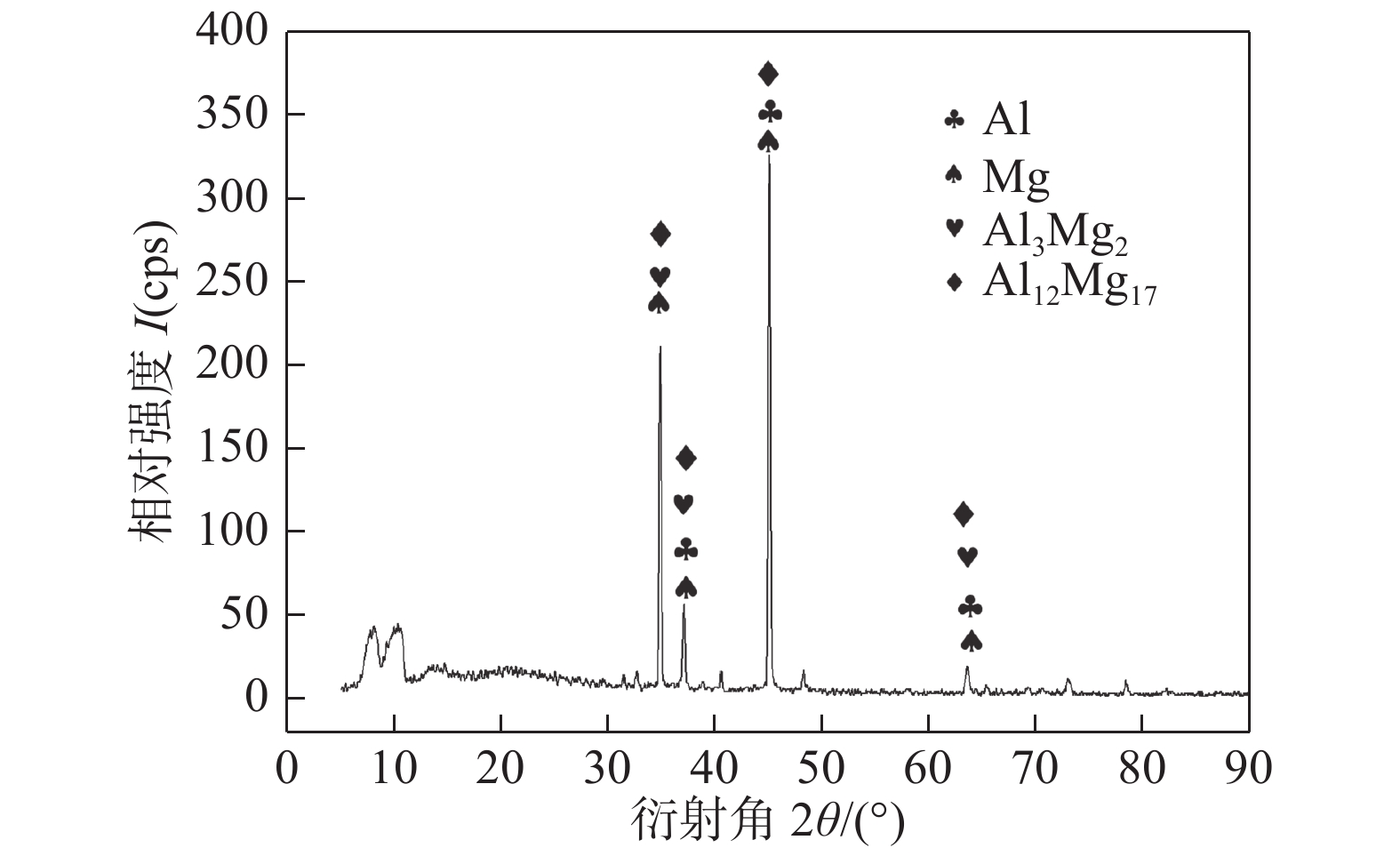

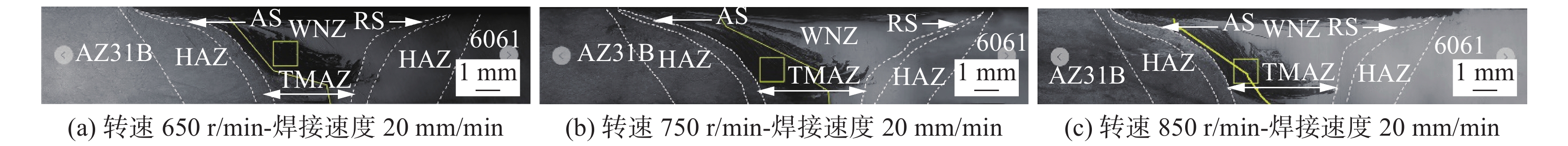

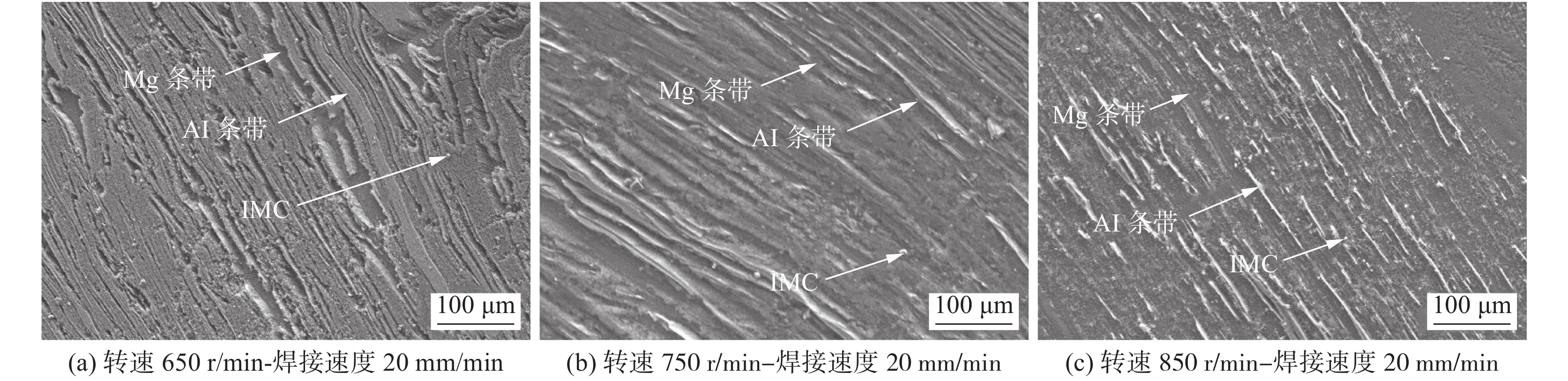

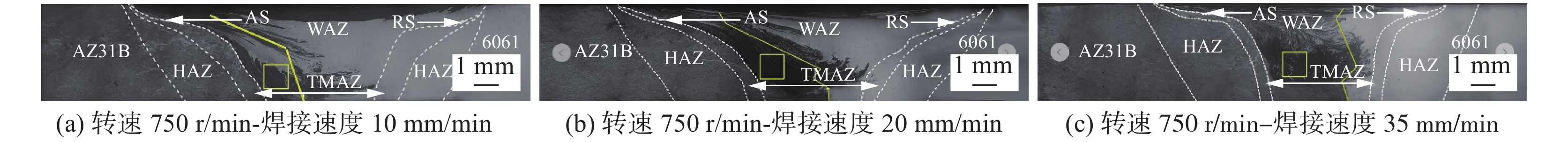

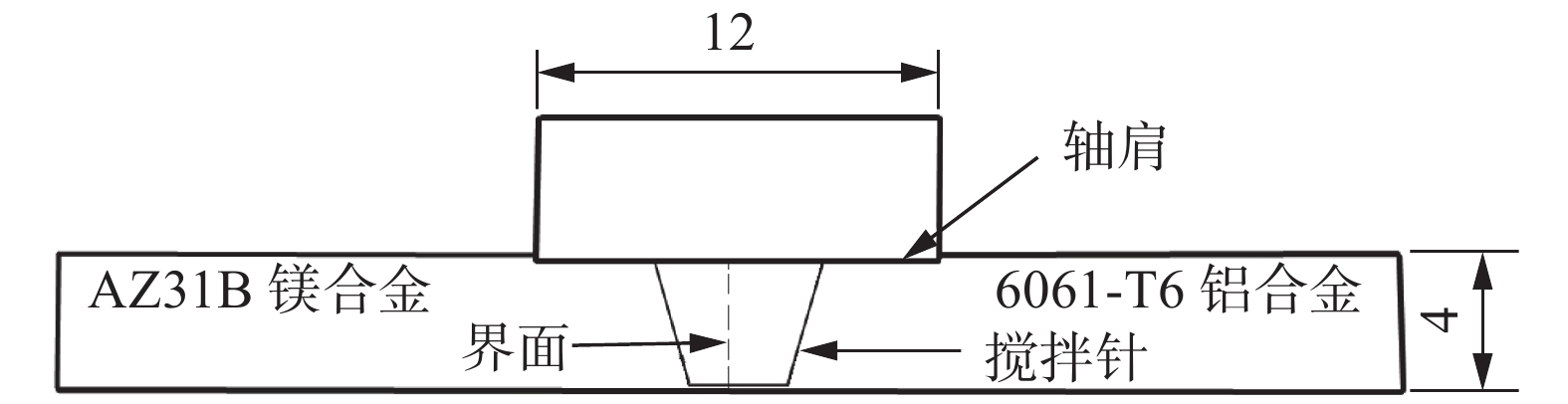

摘要: 采用搅拌摩擦焊(FSW)对厚度为4 mm的6061铝合金与AZ31B镁合金进行不同工艺的平板对接试验. 采用光学显微镜(OM)、扫描电镜(SEM)、X射线衍射仪(XRD)及能谱仪(EDS)对接头进行微观组织观察,采用电子万能试验机对接头力学性能进行测试. 结果表明,在接头焊核区(WNZ)中存在着明显的带状组织,带状组织是由插入镁基体中的铝合金条以及弥散分布在条带上的金属间化合物(IMCs)组成;IMCs主要为Al12Mg17和Al3Mg2;铝/镁异种金属FSW接头裂纹形核和扩展均发生在带状组织内;焊接工艺影响带状组织形态和IMCs尺寸及数量;随着转速(n)的增加或焊接速度(v)的降低,带状组织呈弯曲状,长度相对较短且呈不连续分布;当转速(n)过高或焊接速度(v)过低时,带状组织变细,但IMCs数量增多且尺寸变大;铝/镁异种金属FSW接头强度主要取决于带状组织形态和IMCs尺寸及数量.Abstract: The flat butt welding tests of different processes for 6061 aluminum alloy and AZ31B magnesium alloy with thickness of 4 mm were carried out by friction stir welding (FSW). Microstructure of the joints was observed and analyzed by optical microscopy (OM), scanning electron microscopy (SEM), X-ray diffraction (XRD) and energy dispersive spectrometer (EDS), mechanical properties of the joints were tested by electronic universal testing machine. The results show that, there are obvious banded structures in the weld nugget zone (WNZ), which are composed of aluminum slices inserted in the magnesium matrix and IMCs dispersed on the band. The types of IMCs are Al12Mg17 and Al3Mg2. Crack nucleation and propagation of aluminum/magnesium dissimilar metal FSW joints occur among the banded structure. Welding technology affects the morphology of banded structure and size and quantity of IMCs. With the increasing of rotational speed (n) or the decreasing of welding speed (v), the banded structure in the joint WNZ are curved, relatively short in length and discontinuously distributed. The banded structure becomes thinner, but the quantity of IMCs increase and the size becomes larger when the rotation speed (n) is too high or the welding speed (v) is too low. The ultimate strength of aluminum/magnesium dissimilar metal FSW joint mainly depends on the morphology of the banded structure and the size and quantity of IMCs.

-

-

表 1 带状组织EDS分析

Table 1 EDS analysis of banded structure

点 Al元素原子分数a(%) Mg元素原子分数a(%) 相 1 59.31 34.056 Al3Mg2 2 29.31 42.43 Al12Mg17 3 31.406 45.124 Al12Mg17 4 34.35 52.8 Al12Mg17 + Al 5 10.53 70.32 Mg -

[1] 李达, 孙明辉, 崔占全, 等. 工艺参数对铝镁搅拌摩擦焊焊缝成形质量的影响[J]. 焊接学报, 2011, 32(8): 97 − 100. Li Da, Sun Minghui, Cui Zhanquan, et al. Effect of parameters on friction stir welding joint of 7075 Al and AZ31B Mg[J]. Transactions of the China Welding Institution, 2011, 32(8): 97 − 100.

[2] 许志武, 李政玮, 冯艳, 等. 静轴肩辅助铝镁搅拌摩搭接接头的组织与性能[J]. 焊接学报, 2017, 38(4): 1 − 6. doi: 10.12073/j.hjxb.20170401 Xu Zhiwu, Li Zhengwei, Feng Yan, et al. Microstructure and mechanical properties of Mg/Al friction stir lap welding joint assisted by stationary shoulder[J]. Transactions of the China Welding Institution, 2017, 38(4): 1 − 6. doi: 10.12073/j.hjxb.20170401

[3] 刘震磊, 崔祜涛, 姬书得, 等. 温度峰值影响6061铝/AZ31B镁异种材料FSW接头成形的规律[J]. 焊接学报, 2016, 37(6): 23 − 26. Liu Zhenlei, Cui Hutao, Ji Shude, et al. Effect of peak temperature on formation of 6061Al / AZ31BMg dissimilar FSW joint[J]. Transactions of the China Welding Institution, 2016, 37(6): 23 − 26.

[4] Rhodnev C G, Mahonev M V, Bingel W H, et al. Effect of friction stir welding on microstructure of 7075 aluminum alloy[J]. Scripta Materialia, 2002, 37(1): 69 − 75.

[5] Liu Liming, Tan Jinhong, Liu Xujing, et al. Reactive brazing of Al alloy to Mg alloy using zinc-based brazing alloy[J]. Materials Letters, 2007, 61(11): 2373 − 2377.

[6] 张华, 林三宝, 吴林, 等. 搅拌摩擦焊研究进展及前景展望[J]. 焊接学报, 2003, 24(3): 91 − 96. doi: 10.3321/j.issn:0253-360X.2003.03.025 Zhang Hua, Lin Sanbao, Wu Lin, et al. Current progress and prospect of friction stir welding[J]. Transactions of the China Welding Institution, 2003, 24(3): 91 − 96. doi: 10.3321/j.issn:0253-360X.2003.03.025

[7] Firouzdor Vahid, Kou Sindo. Formation of liquid and intermetallics in Al-to-Mg friction stir welding[J]. Metallurgical and Materials Transactions A, 2010, 41(12): 3238 − 3251. doi: 10.1007/s11661-010-0366-4

[8] 李丰, 党鹏飞, 刘雪松, 等. 基于不旋转轴肩的铝镁异种材料搅拌摩擦焊[J]. 焊接学报, 2018, 39(5): 55 − 58. Li Feng, Dang Pengfei, Liu Xuesong, et al. Dissimilar friction stir welding of Al/Mg alloys based on[J]. Transactions of the China Welding Institution, 2018, 39(5): 55 − 58.

[9] 陈影, 付宁宁, 沈长斌, 等. 镁铝异种金属搅拌摩擦焊搭接接头组织与性能分析[J]. 焊接学报, 2012, 33(7): 93 − 96. Chen Ying, Fu Ningning, Shen Changbin, et al. Microstructure and properties of dissimilar materials Mg/Al laped joint by friction stir welding[J]. Transactions of the China Welding Institution, 2012, 33(7): 93 − 96.

[10] 王东, 刘杰, 肖伯律, 等. 铝合金/镁合金搅拌摩擦焊接界面处Mg/Al反应及接头力学性能[J]. 金属学报, 2010, 46(5): 589 − 594. Wang Dong, Liu Jie, Xiao Bolü, et al. Mg/Al reaction and mechanical properties of Al alloy/Mg alloy friction stir welding joints[J]. Metals Journal, 2010, 46(5): 589 − 594.

[11] 刘奋军, 傅莉, 陈海燕, 等. 铝合金薄板高转速搅拌摩擦焊接头组织与力学性能[J]. 金属学报, 2017, 53(12): 1651 − 1658. doi: 10.11900/0412.1961.2017.00025 Liu Fenjun, Fu Li, Chen Haiyan, et al. Microstructures and mechanical properties of thin plate aluminum alloy joint prepared by high rotational speed friction stir welding[J]. Acta Metallurgica Sinica, 2017, 53(12): 1651 − 1658. doi: 10.11900/0412.1961.2017.00025

[12] Milagre M X, Mogili N V, Donatus U, et al. On the microstructure characterization of the AA2098-T351 alloy welded by FSW[J]. Materials Characterization, 2018, 140: 233 − 246. doi: 10.1016/j.matchar.2018.04.015

[13] Chang Woong-Seong, Rajesh S R, Chun Chang-Keun, et al. Microstructure and mechanical properties of hybrid laser-frictionstir welding between AA6061-T6 Al alloy and AZ31 Mg alloy[J]. Journal Materials Science Technology, 2011, 27(3): 199 − 204. doi: 10.1016/S1005-0302(11)60049-2

[14] 金玉花, 吴永武, 王希靖, 等. Zn粉辅助Al/Mg异种合金搅拌摩擦搭接连接[J]. 兰州理工大学学报, 2018, 44(4): 26 − 30. doi: 10.3969/j.issn.1673-5196.2018.04.006 Jin Yuhua, Wu Yongwu, Wang Xijing, et al. Zn poder-assisted friction stir lap welding of Al/Mg heterogeneous alloying plates[J]. Journal of Lanzhou University of Technology, 2018, 44(4): 26 − 30. doi: 10.3969/j.issn.1673-5196.2018.04.006

[15] Wang Peng, Hu Shengsun, Shen Junqi, et al. Effects of electrode positive/negative ratio on microstructure and mechanical properties of Mg/Al dissimilar variable polarity cold metal transfer welded joints[J]. Materials Science and Engineering: A, 2016, 652: 127 − 135. doi: 10.1016/j.msea.2015.11.080

[16] 崔少朋, 朱浩, 郭柱, 等. 7075铝合金搅拌摩擦焊接头变形及失效行为[J]. 焊接学报, 2016, 37(6): 27 − 30. Cui Shaopeng, Zhu Hao, Guo Zhu, et al. Deformation and failure behavior of friction stir weld joint of 7075 aluminum alloy[J]. Transactions of the China Welding Institution, 2016, 37(6): 27 − 30.

[17] 赵熠朋, 朱浩, 姜月, 等. 7075铝合金搅拌摩擦焊接头断裂机理[J]. 焊接学报, 2017, 38(11): 77 − 81. doi: 10.12073/j.hjxb.20160105005 Zhao Yipeng, Zhu Hao, Jiang Yue, et al. Fracture mechanism on friction stir welding joint of 7075 aluminum alloy[J]. Transactions of the China Welding Institution, 2017, 38(11): 77 − 81. doi: 10.12073/j.hjxb.20160105005

[18] Tan Ming, Quan Gaofeng, Liu Zhaoming, et al. Extrusion process and property of AZ31 magnesium alloy[J]. China Welding, 2019, 28(2): 10 − 14.

下载:

下载: