Structure optimization design of BGA solder joints based on surface response method

-

摘要:

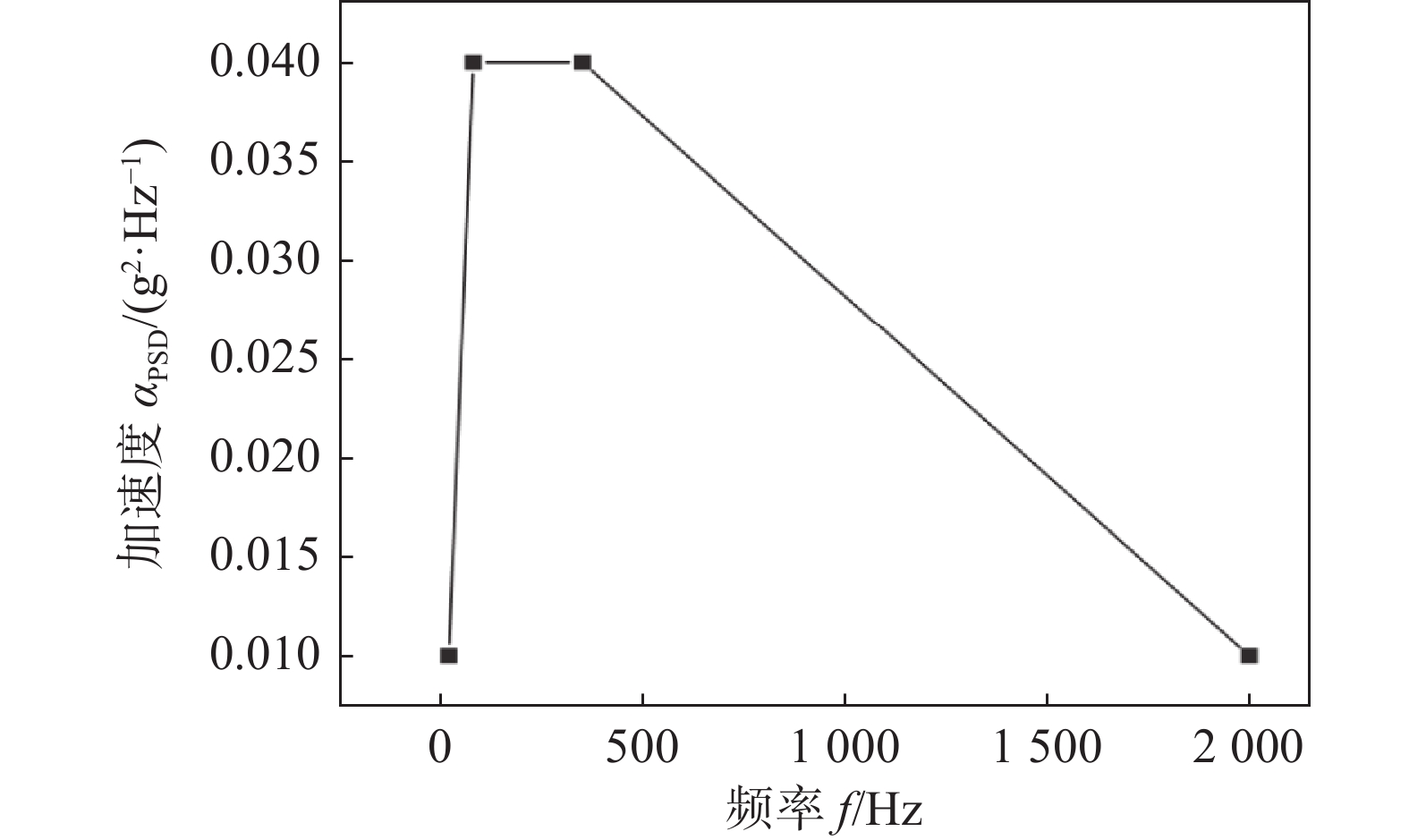

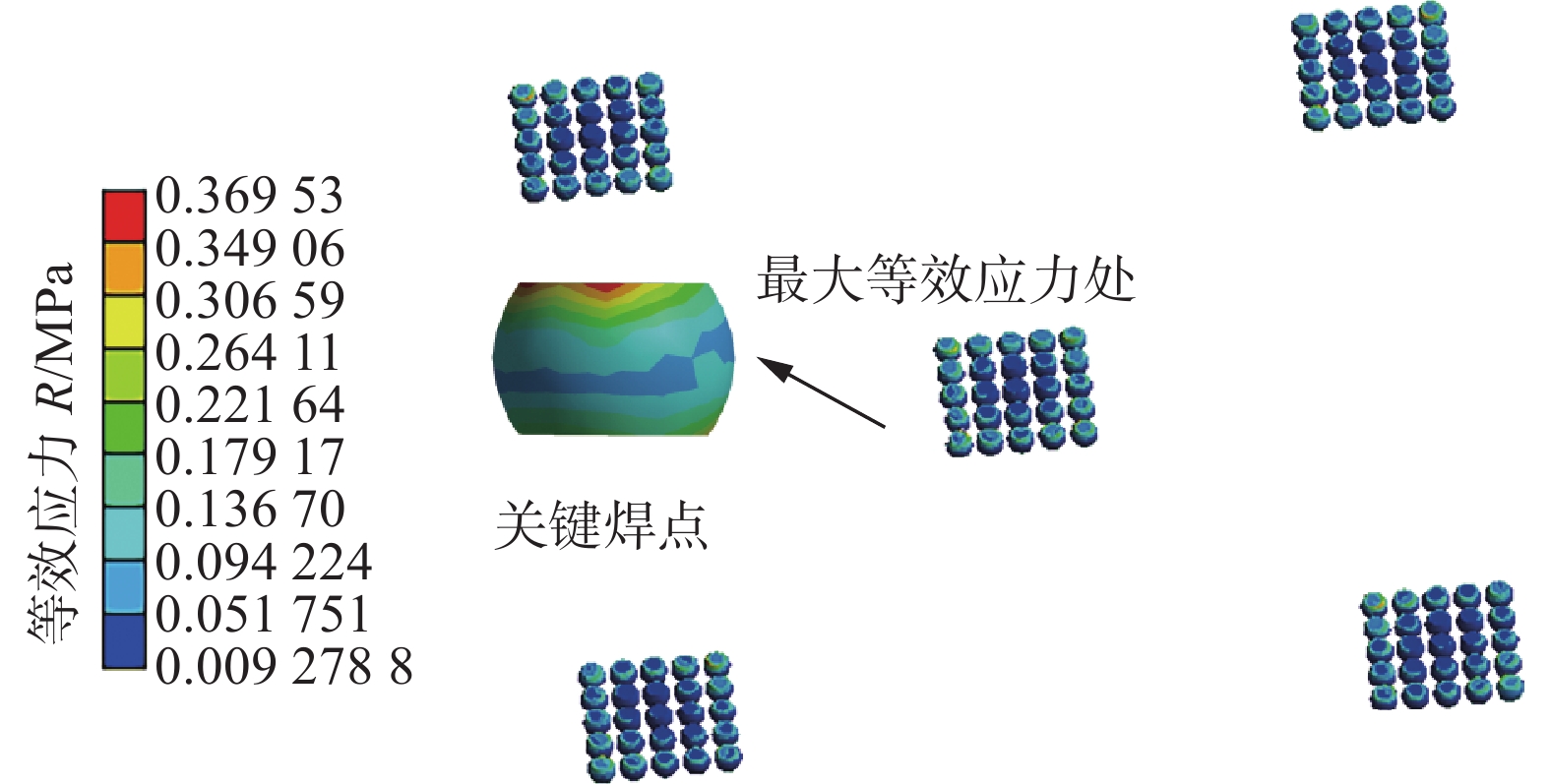

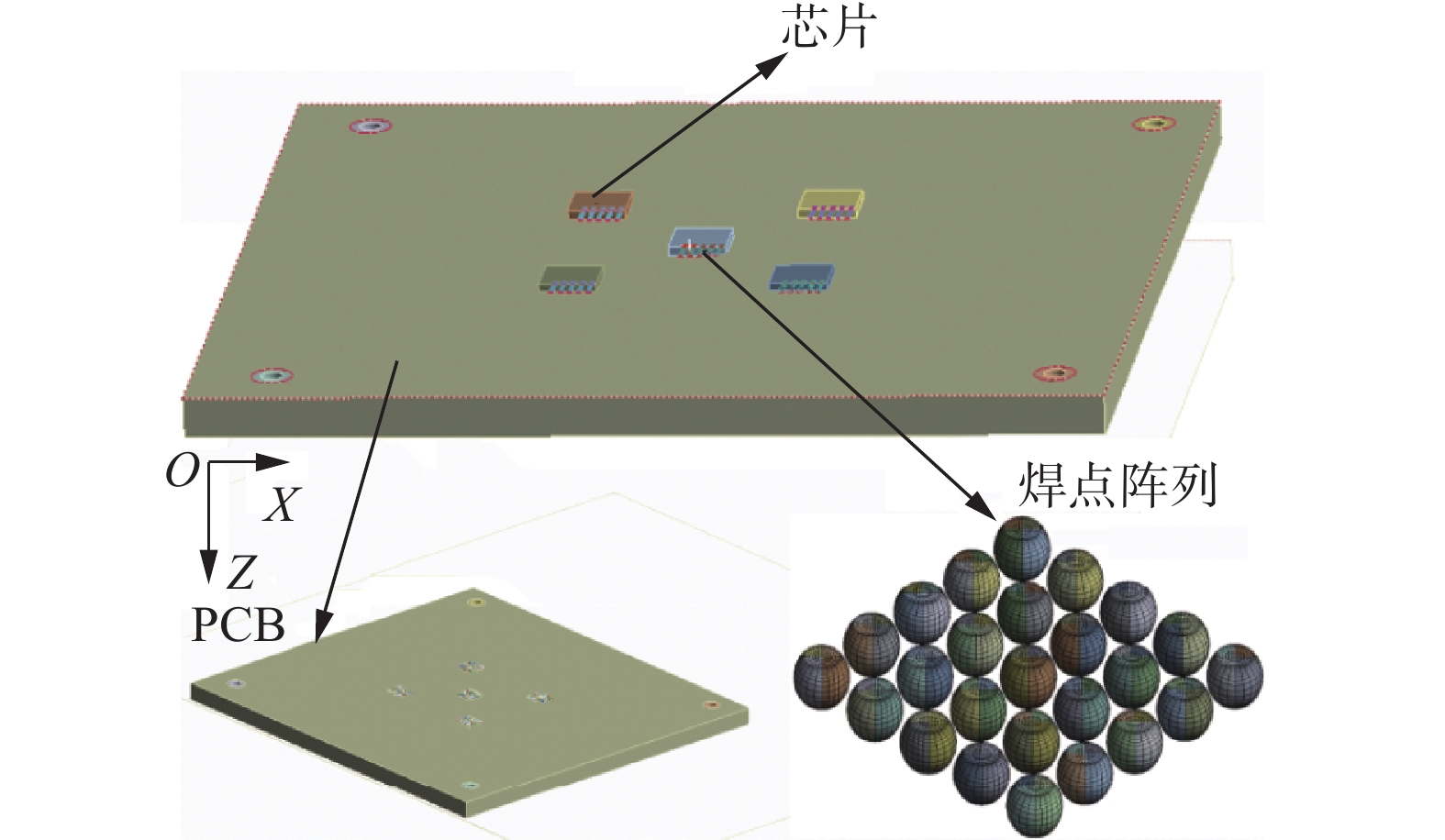

球栅阵列(ball grid array package,BGA)封装因其成本低、电气性能好而被广泛应用于集成电路产业中. 文中建立了BGA三维模型,将等效应力作为响应目标,选取焊点直径、焊点高度、焊点间距、芯片厚度作为设计因子,采用响应曲面法设计了25组不同水平组合的焊点结构参数进行仿真计算,并基于遗传算法分析对焊点结构热振可靠性进行了优化. 结果表明,焊点间距对BGA结构热振可靠性有重要影响;优化方案组合为焊点直径0.28 mm,焊点高度0.20 mm,焊点间距0.40 mm.经过优化验证分析,该优化方案较原始设计方案等效应力降低了11.92%,实现了BGA器件焊点参数优化目的.

Abstract:Due to low cost and good electrical performance, BGA packaging is widely used in integrate circuit (IC) industry. Finite element method (FEM) analysis was carried out for evaluation of stress distribution in the Ball Grid Array (BGA) solder joints, and the radial scale, the height, the spacing of the solder joints, the height of chip were selected as design factors. Response surface methodology (RSM) was used to generate 25 designs and finite element modeling was employed to simulate the response of the assemblies to reliability influencing simulation calculations. The equation regression was associated with genetic algorithm (GA) to search for an optimal combination of parameters that meet the thermal vibration quality characteristics. The confirmation results showed that the space played a role in the reliability, and the radical scale 0.28 mm, the height 0.20 mm, the spacing 0.4mm settings of produce optimal assembly which demonstrated potential of reducing equivalent stress of the best design by 11.92%, respectively. The aim of optimizing BGA solder joints parameters was succeeded.

-

Keywords:

- BGA solder joints /

- RSM /

- the analysis of regression /

- FEM

-

-

表 1 SAC305焊料的Anand模型粘塑性材料参数

Table 1 Visco-plastic parameters of Anand model for SAC305 solder joints

激活能

Q/(J∙mol−1)气体常数

R/( J∙K−1∙mol−1)常数

A/s−1应力乘子

ξ敏感系数

m系数

$ \hat{\boldsymbol{S}} $/MPa指数

n硬化常数

h0/MPa应变指数

α形变阻抗

S0/MPa62022.4 8.314 5.8E6 2.0 0.0942 58.3 0.015 9350 1.50 45.9 表 2 材料性能参数

Table 2 Property parameters of materials

材料

名称弹性模量E/GPa 泊松比μ 线膨胀系数α/(10−6K−1) 密度ρ/(kg∙m−3) Si芯片 131 0.30 2.8 2 320 SAC305 38 0.35 25 7 300 PCB板 18.2 0.25 15.0 1 200 表 3 控制因素及水平因子

Table 3 Control factors and levels

水平 芯片高度h1/mm 焊点直径

d1/mm焊点高度h2/mm 焊点间距

d2/mm1 0.39 0.28 0.19 0.36 2 0.40 0.3 0.2 0.38 3 0.41 0.32 0.21 0.40 表 4 BBD试验方案及等效应力结果

Table 4 BBD test scheme and equivalent stress results

试验 芯片高度h1/mm 焊点直径

d1/mm焊点高度h2/mm 焊点间距

d2/mm等效应力R/MPa 1 2 2 2 2 0.479 6 2 1 1 2 2 0.527 9 2 3 1 2 2 0.534 6 4 1 3 2 2 0.444 1 5 3 3 2 2 0.456 2 6 2 2 1 1 0.436 7 7 2 2 3 1 0.448 4 8 2 2 1 3 0.588 1 9 2 2 3 3 0.564 8 10 1 2 2 1 0.423 7 11 3 2 2 1 0.434 6 12 1 2 2 3 0.581 7 12 3 2 2 3 0.542 3 14 2 1 1 2 0.582 1 15 2 3 1 2 0.524 9 16 2 1 3 2 0.542 1 17 2 3 3 2 0.446 7 18 1 2 1 2 0.523 3 19 3 2 1 2 0.539 1 20 1 2 3 2 0.470 9 21 3 2 3 2 0.487 2 22 2 1 2 1 0.484 5 22 2 3 2 1 0.419 5 24 2 1 2 3 0.618 8 25 2 3 2 3 0.551 6 表 5 筛选前方差显著性验证

Table 5 Analysis of variance significance before screening

来源 自由度 调整平方和 SSAdj F值 P值 模型 4 0.083 5 27.32 0.001 4 芯片高度 1 0.003 4 0.47 0.586 2 焊点直径 1 0.016 7 75.26 0.000 3 焊点高度 1 0.004 6 19.31 0.000 5 焊点间距 1 0.053 3 237.26 0.000 2 表 6 筛选前回归方程分析

Table 6 Analysis of regression equation before screening

系数R2(%) 调整系数 RAdj2(%) 预测系数 RPre2(%) 拟合情况 92.14 90.26 81.76 成功 表 7 筛选后方差显著性验证

Table 7 Analysis of variance significance after screening

来源 自由度 校正平方和 SSAdj F值 P值 模型 3 0.079 2 61.47 0.000 6 焊点直径 1 0.016 7 77.49 0.000 2 焊点高度 1 0.004 6 21.25 0.000 3 焊点间距 1 0.053 3 248.14 0.000 1 表 8 筛选后回归方程分析

Table 8 Analysis of regression equation after screening

系数R2(%) 调整系数 RAdj2(%) 预测系数 RPre2(%) 拟合情况 94.86 93.31 89.93 成功 -

[1] 王建培, 黄春跃, 梁颖, 等 基于回归分析和遗传算法的BGA焊点功率载荷热应力分析与优化[J]. 电子学报, 2019, 47 (3): 734-740. Wang Jianpei, Huang Chunyue, Liang Ying, et al. Thermal stress analysis and optimization of BGA solder joint power load based on regression analysis and genetic algorithm [J]. Chinese Journal of Electronics, 2019, 47 (3): 734-740.

[2] Mršnik Matjaž, Slavič Janko, Boltežar Miha. Multiaxial vibration fatigue—A theoretical and experimental comparison[J]. Mechanical Systems and Signal Processing, 2016, 76: 409 − 423.

[3] Xia Jiang, Yang Lin, Liu Qunxing, et al. Comparison of fatigue life prediction methods for solder joints under random vibration loading[J]. Microelectronics Reliability, 2019, 95: 58 − 64. doi: 10.1016/j.microrel.2019.02.008

[4] Xia Jiang, Li Guoyuan, Li Bin, et al. Optimal design for vibration reliability of package-on-package assembly using FEA and taguchi method[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2016, 6(10): 1482 − 1487. doi: 10.1109/TCPMT.2016.2611622

[5] 韩立帅, 黄春跃, 梁颖, 等. 3D封装微尺度CSP焊点随机振动应力应变分析[J]. 焊接学报, 2019, 40(6): 64 − 70. doi: 10.12073/j.hjxb.2019400156 Han Lishuai, Huang Chunyue, Liang Ying, et al. Random vibration stress-strain analysis of 3D packaging microscale CSP solder joints[J]. Transactions of the China Welding Institution, 2019, 40(6): 64 − 70. doi: 10.12073/j.hjxb.2019400156

[6] 黄春跃, 赵胜军, 梁颖, 等. CSP焊点焊后残余应力分析与预测[J]. 电子科技大学学报, 2021, 50(1): 148 − 154. Huang Chunyue, Zhao Shengjun, Liang Ying, et al. Analysis and prediction of post-welding residual stress in CSP solder joints[J]. Journal of University of Electronic Science and Technology of China, 2021, 50(1): 148 − 154.

[7] Cho Minjin, Kim Sujin, Joun Man Soo. Optimal process design of an optimal, single-stage, symmetrical L-bending process employing taguchi method with finite element method, and experimental verification thereof[J]. International Journal of Precision Engineering and Manufacturing, 2022, 23(4): 395 − 404. doi: 10.1007/s12541-022-00631-4

[8] Zhang Z-H, Wang X-S, Ren H-H, et al. Simulation study on thermo-fatigue failure behavior of solder joints in PoP structure[J]. Microelectronics Reliability, 2017, 75: 127 − 134. doi: 10.1016/j.microrel.2017.06.033

[9] Liang Z, Xue S, Gao L, et al. Thermal Fatigue Behavior of SnAgCu Soldered Joints in Fine Pitch Devices[J]. Rare Metal Materials and Engineering, 2010, 39(3): 382 − 387. doi: 10.1016/S1875-5372(10)60084-7

-

期刊类型引用(3)

1. 马振,闫玉东,史畅,牟立婷,王龙权,邸可新,张二林. 医用钛合金激光表面改性抗菌涂层的研究进展. 焊接. 2025(01): 71-81 .  百度学术

百度学术

2. 王伟志,马国政,韩珩,李洋,周雳,赵海朝,许建峰,郭伟玲,王海斗. 激光熔覆陶瓷涂层研究现状与展望. 机械工程学报. 2023(07): 92-109 .  百度学术

百度学术

3. 周其龙,窦丽霞. 蚁群算法的激光熔覆工艺多目标优化研究. 激光杂志. 2022(09): 213-217 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: